On another forum, I was asked about the wiring and the influence on the mechanism.

The wiring cannot interfere with the movement because they are part of ensuring the movement.

The wiring cannot interfere with the movement because they are part of ensuring the movement.

Hello 2wice,

Your new tone arm is ingenious. I can imagine the hard work involved with not only coming up with that idea, but making it work.

I hope that we get to see how it performs on an actual turntable.

Sincerely,

Ralf

Your new tone arm is ingenious. I can imagine the hard work involved with not only coming up with that idea, but making it work.

I hope that we get to see how it performs on an actual turntable.

Sincerely,

Ralf

Hello 2wice,

Your new tone arm is ingenious. I can imagine the hard work involved with not only coming up with that idea, but making it work.

I hope that we get to see how it performs on an actual turntable.

Sincerely,

Ralf

Thank you very much Ralf, the hardest part was shutting up about it till the IP was in place, even though it grated some people. 2 more parts and if all goes to plan it goes on a TT early next week.

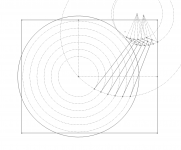

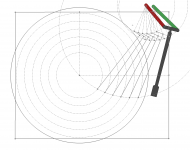

While waiting for 2wice to get his remarkable arm mounted on a TT, I messed around with a couple of drawings.

The one based on the Birch/Thales patent is an attempt to picture one of the forces which might cause skating. The blue lines represent an inverse conventional pivot "J" arm with the "J" at the pivot end instead of the normal headshell end. Sort of like Frank's "Alto," I think. The resulting offset at the outer groove is only about 12 degrees - about 2/3 of a 12" Baerwald alignment arm - and it gets smaller from there. In other words, if this is accurate, a small and shrinking force. I believe the straight line from point B through the stylus mitigates the skating forces, but have no idea how to represent that or how to calculate it, but Carlo did with a vector analysis of his Rabbit twin arm.

I noticed something peculiar about the Thiele arm, again. In the drawing, all the movements seemed smaller than I'm used to seeing so I tried measuring them. The angles the Thiele pivot and control arm swing through - 39 and 42 degrees respectively - are much smaller than the equivalent angles in my original drawing - 60 and 50 degrees respectively - and the stylus moves a shorter distance relative to the spindle - 48 and 68 mm respectively. I think there's a possibility the extra arm on the Thiele allows for a more compressed movement and that this design has added a possibly valuable wrinkle to PLT design, but at the cost of higher mass, more complexity, and more bearings.

The one based on the Birch/Thales patent is an attempt to picture one of the forces which might cause skating. The blue lines represent an inverse conventional pivot "J" arm with the "J" at the pivot end instead of the normal headshell end. Sort of like Frank's "Alto," I think. The resulting offset at the outer groove is only about 12 degrees - about 2/3 of a 12" Baerwald alignment arm - and it gets smaller from there. In other words, if this is accurate, a small and shrinking force. I believe the straight line from point B through the stylus mitigates the skating forces, but have no idea how to represent that or how to calculate it, but Carlo did with a vector analysis of his Rabbit twin arm.

I noticed something peculiar about the Thiele arm, again. In the drawing, all the movements seemed smaller than I'm used to seeing so I tried measuring them. The angles the Thiele pivot and control arm swing through - 39 and 42 degrees respectively - are much smaller than the equivalent angles in my original drawing - 60 and 50 degrees respectively - and the stylus moves a shorter distance relative to the spindle - 48 and 68 mm respectively. I think there's a possibility the extra arm on the Thiele allows for a more compressed movement and that this design has added a possibly valuable wrinkle to PLT design, but at the cost of higher mass, more complexity, and more bearings.

Attachments

The skating force on a regular pivot arm decreases at the beginning of the groove and increases towards the end of the groove. The rate of decrease and increase is not linear. For my 6B PT arm, I believe that the skating force decreases from the beginning of the groove. Its rate is linear since the arm is constantly tangent to the groove. And, the skating force should be much lower than a regular pivot arm.

For a double Birch arm, if the links are more than two, it is not necessary, in my opinion, unless there is a particular reason to do that. I don't see any reasons to add extra links for Thiele arm so far. Further study may be needed. Compressed movements may not be good since they will increase tracking errors.

For a double Birch arm, if the links are more than two, it is not necessary, in my opinion, unless there is a particular reason to do that. I don't see any reasons to add extra links for Thiele arm so far. Further study may be needed. Compressed movements may not be good since they will increase tracking errors.

Ever heard of African time?

I ordered some materials from the US, it got to Sandton where I live in 4 days, and then took another 13 days to get to Johannesburg where I don't live.

At least the all metal build is starting to come together. Needs some clean-up.

I have been invited to a photoshoot with Fast Company ZA for their December magazine on Friday. It will be the polymer build, though.

I ordered some materials from the US, it got to Sandton where I live in 4 days, and then took another 13 days to get to Johannesburg where I don't live.

At least the all metal build is starting to come together. Needs some clean-up.

I have been invited to a photoshoot with Fast Company ZA for their December magazine on Friday. It will be the polymer build, though.

Attachments

Great, 2wice: where can be bought? Here in Italy it would be really useful, since we are in the same time zone (even if with a 6-month difference)

carlo

carlo

Thanks, very interesting link (expensive, I guess - do they even make just a few pieces?).

But, above all, I was interested in that cute clock: here too we have a very similar conception of time ...

c

what's "EiSH" meaning?

But, above all, I was interested in that cute clock: here too we have a very similar conception of time ...

c

what's "EiSH" meaning?

They were very reasonable, $120 for the 3 parts.

Eish is can be many emotions, but mostly resignation, or giving up.

Eish is can be many emotions, but mostly resignation, or giving up.

It seems a really fair price for that parts, and the possibility of having complex parts in sintered aluminum or other materials is very attractive for us builders.

But, as I was wondering at the time of my printable 3DToy, is it still DIY (do it your self), or simply DIY (design it yourself)?

carlo

But, as I was wondering at the time of my printable 3DToy, is it still DIY (do it your self), or simply DIY (design it yourself)?

carlo

Carlo,

“Is it still DIY.” Nope, you could only claim a percentage - 60% do IY and 40% design IY for instance - and you’d have to have that certified by DD.

Good to see you back.

“Is it still DIY.” Nope, you could only claim a percentage - 60% do IY and 40% design IY for instance - and you’d have to have that certified by DD.

Good to see you back.

It really doesn't matter too much. The digital age opens all kinds of possibilities from designs(software) to prototyping(hardware) for DIYer's. DIY should have its new meaning now. I recently ordered a 3D printed box to house 5 pin phono connector. It is about $30. I can make it myself, but for $30, I rather have it printed by someone else.

Just Do It!

Any percentage of do-it-yourself or design-it-yourself is better than zero percent from some armchair experts like me! Glad to see the gang. Welcome back, Carlo!

and you’d have to have that certified by DD.

Any percentage of do-it-yourself or design-it-yourself is better than zero percent from some armchair experts like me! Glad to see the gang. Welcome back, Carlo!

I hope there are yet signs of life in this splendid thread.

I played around with the Linkage simulation software, of which Carlo is a master.

First a Klaudio-like quasi linear tonearm. If we only had good linear bearings...

Video

But we don't. So I replaced it with a pivoted arm, with slightly less precision.

Video

I played around with the Linkage simulation software, of which Carlo is a master.

First a Klaudio-like quasi linear tonearm. If we only had good linear bearings...

Video

But we don't. So I replaced it with a pivoted arm, with slightly less precision.

Video

I am probably missing the point here.

But what is wrong with the approach I suggest here.

(I don’t see what’s wrong, but it is so simple there must be something wrong with it.

View attachment 1031797

There is a movie with some lines :

and some drawings:View attachment 1031781View attachment 1031780

This one is the same as one of the two options I didn't use. I will update yet another version of my PT arm later.

https://www.diyaudio.com/community/...king-pivot-tonearm.373984/page-3#post-6762099

Last edited:

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms