Say, I do believe I see a string-and-weight antiskating device on this arm. With the way the AS weight string is attached to the bearing yoke, it will correctly apply compensation force outward away from the spindle at the outer grooves, zero compensation in the middle, and compensation force inward toward the spindle at the inner grooves.

You always have the eagle-eyed observations, Ray!

But in their two videos and few pictures, they have one arm with no anti-skating compensation at all. And another one using leaning weight on the left side of the arm. So I'm not sure which one is the final production.

Here are couple more close-up pictures. Looks like the pulley is adjustable. Not sure what the bottom string is for...

Hi Directdriver,Not sure what the bottom string is for...

We were talking about Rude Goldberg toys, isn't it?

I think that bottom string is nothing more than the tonearm lift.

Turning the pivot CCW will stretch the string and the tonearm will lift off 😉

Last edited:

Having a closer look at https://www.phileweb.com/news/photo/audio/205/20570/IMG_6287.jpg we can see the TA playing late Eva Cassidy's record and the pivot is slightly turned CW to allow the TA land on the record.

Hi Carlo,Hi Consty - I can't make the two last simulations work

Here is the promised 74Labs Linkage simulation movie.

Yours,

Consty

Attachments

Could be also a mechanism to facilitate inner movement (or outer, it depends how the pulley is wound). A small "trick" somehow like the rail slanting on some linear trackers since the inextensible string has to exert relevant pressure on bearings, to work properly.

But in the detail the pulley seems unwound, so it could be just a friction dampening, adjusted by the nylon pulley position. (that weight seems too heavy for antiskating or to aid the movement)

carlo

goin 'to update my Linkage2 program - thanks Consty

But in the detail the pulley seems unwound, so it could be just a friction dampening, adjusted by the nylon pulley position. (that weight seems too heavy for antiskating or to aid the movement)

carlo

goin 'to update my Linkage2 program - thanks Consty

Last edited:

goin 'to update my Linkage2 program - thanks Consty

You're welcome Carlo,

Take care since Linkage is pretty buggy when zero length segments are involved. Probably some "division by zero" error is not properly handled inside the code.

If your problem persists, try moving some measurement connectors some 0.001 mm. It won't significantly disturb the measurements but will unblock the simulation. It really helped me many times 🙂

Going, maybe, a bit further: one side of the string is fixed on the left, the other one attached to the weight via the nylon pulley. If the string is wound clockwise around the pulley it could only lift the weight (antiskating), but the position of the nylon pulley has no role, and why not to fix it directly on the pulley?. Wounding the pulley anti-clockwise can only stop the arm movement. (my movement aid idea was wrong)

So the dampening hypothesis seems truer. In effect with such a pulley and bearing at the shaft's end there is a great horizontal mass to control on eccentricities

carlo

linkage 3 installed - now your simulations run freely, thanks Consty

So the dampening hypothesis seems truer. In effect with such a pulley and bearing at the shaft's end there is a great horizontal mass to control on eccentricities

carlo

linkage 3 installed - now your simulations run freely, thanks Consty

Last edited:

mass vs weight

You guys are clearly the ones to present this question to; Would two arms with equivalent weight but differing mass change the compliance requirement of the cart? For all intents and purposes, are they not the same thing? TIA

You guys are clearly the ones to present this question to; Would two arms with equivalent weight but differing mass change the compliance requirement of the cart? For all intents and purposes, are they not the same thing? TIA

Hi Discopete,You guys are clearly the ones to present this question to; Would two arms with equivalent weight but differing mass change the compliance requirement of the cart? For all intents and purposes, are they not the same thing? TIA

Form a strictly scientific point of view, mass is a fundamental property of a body measuring its inertia. Weight is the vertical force exerted by that mass due to the gravitational attraction. If we are discussing about the same body, at the same place, on the same planet, yes, in a broader way, we can say they are equivalent.

This being said, how two different bodies can have equivalent weight but different mass?

Except for that joke: What would you prefer to fall on your head? 1kg of iron or 1kg of wool? 🙂

What most probably interests you is the EFFECTIVE mass of a tonearm. But this is a different (and more complex) topic. I'm sure the attached Excel file will help you figure it out 🙂

Yours,

Consty

Attachments

Hi Consty. Thank you for that. My question refers to post #1 where the op mentions limitations due to "enormous" horizontal mass of air bearing tone arm wands. So I'm wondering how a pivoted arm with equal weight would cause such contrary circumstance. His concern clearly suggests an inherent flaw in design of such arms since pivoted arms also dictate cart requirement/compliance due to over all mass.Hi Discopete,

Form a strictly scientific point of view, mass is a fundamental property of a body measuring its inertia. Weight is the vertical force exerted by that mass due to the gravitational attraction. If we are discussing about the same body, at the same place, on the same planet, yes, in a broader way, we can say they are equivalent.

This being said, how two different bodies can have equivalent weight but different mass?

Except for that joke: What would you prefer to fall on your head? 1kg of iron or 1kg of wool? 🙂

What most probably interests you is the EFFECTIVE mass of a tonearm. But this is a different (and more complex) topic. I'm sure the attached Excel file will help you figure it out 🙂

Yours,

Consty

Hi Discopete,Hi Consty. Thank you for that. My question refers to post #1 where the op mentions limitations due to "enormous" horizontal mass of air bearing tone arm wands. So I'm wondering how a pivoted arm with equal weight would cause such contrary circumstance. His concern clearly suggests an inherent flaw in design of such arms since pivoted arms also dictate cart requirement/compliance due to over all mass.

I see what you mean. Especially since I've also built myself an air bearing tonearm about two years ago. What Directdriver means in his #1 post (and confused you) is in fact just half a statement. Yes, gliding or air bearing tonearms have an enormous HORIZONTAL EFFECTIVE mass compared to their VERTICAL EFFECTIVE mass. While the vertical effective mass is mostly important in case of warped records, horizontal effective mass is also important in case of an off-centered record. Also, since we are listening to stereo records, where the groove modulation involves both horizontal and vertical minute movement of the stylus, it is very important that the two perpendicular effective masses to be equal (or as close to each other as possible).

I hope this explanation helped you.

Yours,

Consty

So if there is such large difference in vertical/horizontal mass with air bearing arms, what is the solution? Does such an arm exist with equal perpendicular masses, air bearing or not? Is this spec given by manufacturers?Hi Discopete,

I see what you mean. Especially since I've also built myself an air bearing tonearm about two years ago. What Directdriver means in his #1 post (and confused you) is in fact just half a statement. Yes, gliding or air bearing tonearms have an enormous HORIZONTAL EFFECTIVE mass compared to their VERTICAL EFFECTIVE mass. While the vertical effective mass is mostly important in case of warped records, horizontal effective mass is also important in case of an off-centered record. Also, since we are listening to stereo records, where the groove modulation involves both horizontal and vertical minute movement of the stylus, it is very important that the two perpendicular effective masses to be equal (or as close to each other as possible).

I hope this explanation helped you.

Yours,

Consty

Yes, it exists: the unipivot 😉So if there is such large difference in vertical/horizontal mass with air bearing arms, what is the solution? Does such an arm exist with equal perpendicular masses, air bearing or not? Is this spec given by manufacturers?

Hmm.. I always wondered what the trick is with those.Yes, it exists: the unipivot 😉

Dual unipivot zero tracker?😀

Hmm.. I always wondered what the trick is with those.

Dual unipivot zero tracker?😀

Have you seen the Italian Reed 5T?

I don't know if it's unipivot or not but it's definitely a zero tracker (electronically controlled) and they claim it has identical horizontal and vertical effective mass.

Once you step into the arena of servo driven arms you are essentially dealing with a 'conventional' tonearm that has no offset angle and has a feedback controlled motor drive to move the pivot to maintain tangency. The arm design can be anything you want, and can have any type of bearing that you want. Typically such arms have similar vertical and horizontal mass.

An arm's vertical and horizontal effective mass doesn't have to be equal. In general, the arm needs to be more nimble in the vertical direction to negotiate rapid movement caused by pinch warps without excessive vertical cantilever deflection. In the horizontal direction the groove moves the cartridge/arm much more slowly and gradually, so the cartridge can tolerate greater horizontal mass without excessive horizontal cantilever deflection as compared to vertical. Of course there are limits to everything, and I have actually seen a record with a horizontal warp. The record apparently had been stored in the 'proper' upright position but was exposed to high heat so that the bottom perimeter was deformed inward toward the spindle hole. That record would be a challenge for high horizontal mass arms.

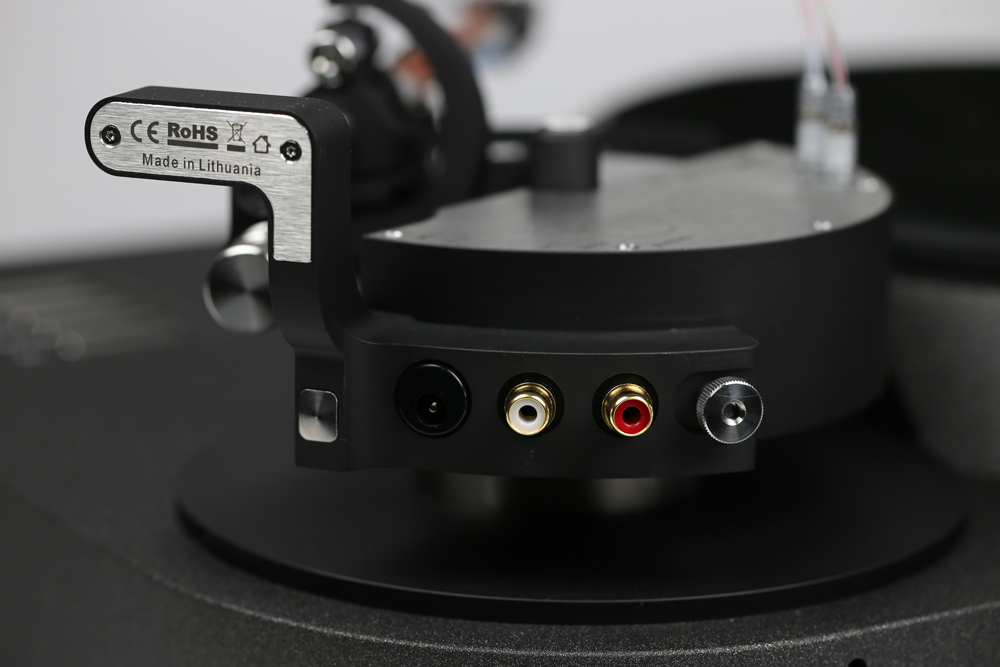

The Reed 5T is a mystery as far as what kind of bearing(s) it has. I found no information on the internet, and reviews only resate the manufacturer's literature. I did find two closeup photos which show what appears to be some type of adjustable points on each side of the housing. Also, the 5T appears to be made in Lithuania, not Italy

Ray K

An arm's vertical and horizontal effective mass doesn't have to be equal. In general, the arm needs to be more nimble in the vertical direction to negotiate rapid movement caused by pinch warps without excessive vertical cantilever deflection. In the horizontal direction the groove moves the cartridge/arm much more slowly and gradually, so the cartridge can tolerate greater horizontal mass without excessive horizontal cantilever deflection as compared to vertical. Of course there are limits to everything, and I have actually seen a record with a horizontal warp. The record apparently had been stored in the 'proper' upright position but was exposed to high heat so that the bottom perimeter was deformed inward toward the spindle hole. That record would be a challenge for high horizontal mass arms.

The Reed 5T is a mystery as far as what kind of bearing(s) it has. I found no information on the internet, and reviews only resate the manufacturer's literature. I did find two closeup photos which show what appears to be some type of adjustable points on each side of the housing. Also, the 5T appears to be made in Lithuania, not Italy

Ray K

Attachments

Correct 🙂

My old eyes, as Carlo used to say, missed the .lt for .it in their website address 🙂

And I also didn't find that label closeup picture.

Thanks Ray for correcting me.

My old eyes, as Carlo used to say, missed the .lt for .it in their website address 🙂

And I also didn't find that label closeup picture.

Thanks Ray for correcting me.

Once you step into the arena of servo driven arms you are essentially dealing with a 'conventional' tonearm that has no offset angle and has a feedback controlled motor drive to move the pivot to maintain tangency.

I just need to add one more thing. Many conventional pivot tonearms have an offset angle at the vertical bearing matching the offset angle of the headshell. In a servo arm, we need to remove any antiskating device and delete the offset angles at the headshell AND bearing so the stylus to the cantilever to the pivot point can form a straight line. (Before the string test principal can rap our knuckles! 😀)

(Reed 5T) Servo linear tonearm with no offset angle at headshell and bearing.

(Reed 2G) Conventional pivot tonearm with bearing offset.

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms