I'll just throw something real quick out there and then I've got to get to my chores:

There's a warmth to this unit none of my other SS amps have and I have quite a few.

There's a warmth to this unit none of my other SS amps have and I have quite a few.

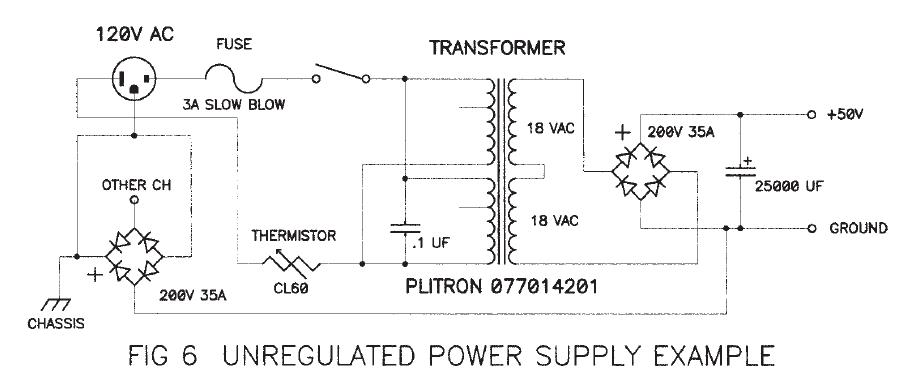

Put the two you have in the primary circuit.

Use a bridge for ground lift duty, as shown on the following -

Use a bridge for ground lift duty, as shown on the following -

Last edited:

I have 2 black units and 1 blue one.

Nice amp fellas. A bit more bass forward than what I'm use to. Very nice, fluid, deep and fast and warm. Were liken it.

Nice amp fellas. A bit more bass forward than what I'm use to. Very nice, fluid, deep and fast and warm. Were liken it.

A common rule of thumb (or finger) is keep the heat sink temperature at 55C or lower for longevity of the output Mosfets. The Papa Pass method of temperature determination is that you can touch the heat sink for about 2 seconds at 55C.

Your heat sink placement does not provide maximum cooling efficiency. Vertical placement of the heat sinks with the fins aligned vertically, and with free space below, above, and around the heat sink is the best. An enclosed space, if you keep the closet door closed, is also not good.

If the heat sinks get too hot, a small fan blowing air across the heat sinks would make a big difference.

The less desirable fix is to lower the bias.

Your heat sink placement does not provide maximum cooling efficiency. Vertical placement of the heat sinks with the fins aligned vertically, and with free space below, above, and around the heat sink is the best. An enclosed space, if you keep the closet door closed, is also not good.

If the heat sinks get too hot, a small fan blowing air across the heat sinks would make a big difference.

The less desirable fix is to lower the bias.

Amps been for 4 lp's now. Front part of heat sink is 50.1° C. The PS is just underneath. Rear portion is right at 40° C. I'll check this throughout the evening.

The temperatures are not too bad then.

You have a vent slot between the heat sinks but do you have holes or vents in the bottom of your case? Having air flow through the inside of the case would aid in lowering heat sink temperatures, as the Mosfets and heat sinks as well as the power transformer also radiate heat inward. Also raising the case a few inches above the floor would allow better air flow into the case.

You have a vent slot between the heat sinks but do you have holes or vents in the bottom of your case? Having air flow through the inside of the case would aid in lowering heat sink temperatures, as the Mosfets and heat sinks as well as the power transformer also radiate heat inward. Also raising the case a few inches above the floor would allow better air flow into the case.

Last edited:

I drilled 15 1/2" holes in the bottom and there's room for more. I have the amp sitting on some 3/4" tall footers. I'll double them us and take a measurement.

I'm using 2 different types of thermal interface products in this build. The grey colored one almost feels like vinyl seat covering and is used on the PS.. The orange looking stuff is used on the amp boards. My question is would the while aluminum oxide pads be a better choice?

So far heat is not an issue.

So far heat is not an issue.

I'm using 2 different types of thermal interface products in this build. The grey colored one almost feels like vinyl seat covering and is used on the PS.. The orange looking stuff is used on the amp boards. My question is would the while aluminum oxide pads be a better choice?

So far heat is not an issue.

Temperature management is rather complicated. AFAIK the silver-mica has better temperature-resistance but because it needs some „grease“ to make thermal connections, you have to add 2 more joints into the equation.

The red stuff is keratherm from DIYAUDIOstore? This is good enough, but of course you’re interested in having the best possible...

How about using a fat pure copperplate (or silver while we‘re at it), and panasonic carbon between it and heatsink? It MAY give you a tiny slight advantage...

Here’s a great redux about all this: Taming the LM3886 Chip Amplifier: Thermal Design – Neurochrome

But, but, but, you don't have an overheating problem.

After all that trouble to get the amplifier working, don't risk messing it up by removing output devices in order to change the thermal interfaces.🙂

After all that trouble to get the amplifier working, don't risk messing it up by removing output devices in order to change the thermal interfaces.🙂

That's my train of thought Ben Mah. Yesterday was another one of those days. I dissembled the amp to tidy up the wiring.

When it was done it appeared more presentable to the eye but I had another problem. No power to the right and offset was -26VDC.

You know what, after 4 hours fiddling I found the issue. V+ was hooked to a blank spot in the terminal block. Back where i started, a birds nest and I'm out of wire, again.

When it was done it appeared more presentable to the eye but I had another problem. No power to the right and offset was -26VDC.

You know what, after 4 hours fiddling I found the issue. V+ was hooked to a blank spot in the terminal block. Back where i started, a birds nest and I'm out of wire, again.

I second what Ben said.

If your mosfet temperatures are reasonable then you should leave as is.

If your orange pads are the Karatherms from the store then they are excellent. Their

only downside is they are fragile and can be damaged from mounting/dismounting the mosfets.

Al oxide insulators require the use of thermal grease. They are thick enough that

you need to account for that when you mount your parts.

If your mosfet temperatures are reasonable then you should leave as is.

If your orange pads are the Karatherms from the store then they are excellent. Their

only downside is they are fragile and can be damaged from mounting/dismounting the mosfets.

Al oxide insulators require the use of thermal grease. They are thick enough that

you need to account for that when you mount your parts.

Thanks for the feedback Temps 45° C this morning. I'll give it a few hours and check bias,,,,,,,again.

Sounds wonderful BTW. Excels with unamplified acoustic ( Windahm Hill ) & classical and not bad with vocals either.

F6 next?

Sounds wonderful BTW. Excels with unamplified acoustic ( Windahm Hill ) & classical and not bad with vocals either.

F6 next?

But, but, but, you don't have an overheating problem.

After all that trouble to get the amplifier working, don't risk messing it up by removing output devices in order to change the thermal interfaces.🙂

Yes. Don't worry about the thermal interfaces if you're running at 45°C and the amp is working properly now.

- Home

- Amplifiers

- Pass Labs

- Aleph J build guide for noobs