@Astal: welcome to the crazy world of Akai CD players! I am currently having another break from mine as it was becoming too time consuming with little or no progress for the time and effort invested. It is still very frustrating that I haven't been able to resolve the problem.

I have also inadvertently fried the motor control chip before during my tests. Thankfully it is cheap and still available as a replacement part, so you should be able to pick up a replacement quite easily. I also changed the 8R2 resistor that smokes just to be safe.

The CD73 differs slightly from the 93 as it has 4 leaf switches and no optical sensors but the tray problem appears to be the same and can be got around by cycling the main power switch a few times until the tray eventually closes and the disc clamps down. If the laser is good, it will then spin the disc and work fine until you press the eject button.

@Mooly: I'm pretty sure I previously looked closely at the logic level from the micro for this kind of problem. I had something similar on a product at work where a logic output wasn't switching fully to 0V when it got hot and the subsequent push-pull stage it was driving would crowbar the supply and blow up.

I have also inadvertently fried the motor control chip before during my tests. Thankfully it is cheap and still available as a replacement part, so you should be able to pick up a replacement quite easily. I also changed the 8R2 resistor that smokes just to be safe.

The CD73 differs slightly from the 93 as it has 4 leaf switches and no optical sensors but the tray problem appears to be the same and can be got around by cycling the main power switch a few times until the tray eventually closes and the disc clamps down. If the laser is good, it will then spin the disc and work fine until you press the eject button.

@Mooly: I'm pretty sure I previously looked closely at the logic level from the micro for this kind of problem. I had something similar on a product at work where a logic output wasn't switching fully to 0V when it got hot and the subsequent push-pull stage it was driving would crowbar the supply and blow up.

@Andy, @Mooly thanks. The replacement motor driver chip (well, two of them, got one spare) has arrived today. Hopefully I will have some time over the weekend to install it and be ... back at square one 🙂

I had a thought that theoretically, CD93 with an optical sensor could have a signal to start slowing down loading motor or even reversing just before tray reaches the stop switch. However, that would mean have a slightly different programming of the chip or at least a different subroutine when that pin 57 (93/73) reads "93" (don't remember if that is high or low). This would also mean that with somewhat different loading control both 73 and 93 have the same loading issue. Not impossible but then optical sensor probably doesn't make a difference.

I had a thought that theoretically, CD93 with an optical sensor could have a signal to start slowing down loading motor or even reversing just before tray reaches the stop switch. However, that would mean have a slightly different programming of the chip or at least a different subroutine when that pin 57 (93/73) reads "93" (don't remember if that is high or low). This would also mean that with somewhat different loading control both 73 and 93 have the same loading issue. Not impossible but then optical sensor probably doesn't make a difference.

Whatever is causing the tray/clamp oscillation, I'm confident it isn't due to any problem with the leaf switches, having cleaned, tested and rewired mine to ensure good signals.

I even went to the trouble of fitting schmitt trigger buffers to make sure the inputs to the micro were clean. For this reason and the fact the 93 has the same problem, I don't think the optical sensor will be the cause with yours.

I did wonder why they fitted the optical sensor to the 93 if the 73 worked fine with 4 x leaf switches... perhaps it was because it didn't?!

My You Tube post from last year Akai CD73 defect - YouTube has received a reply from another owner with the same problem... I have invited them to join the discussion.

I even went to the trouble of fitting schmitt trigger buffers to make sure the inputs to the micro were clean. For this reason and the fact the 93 has the same problem, I don't think the optical sensor will be the cause with yours.

I did wonder why they fitted the optical sensor to the 93 if the 73 worked fine with 4 x leaf switches... perhaps it was because it didn't?!

My You Tube post from last year Akai CD73 defect - YouTube has received a reply from another owner with the same problem... I have invited them to join the discussion.

Last edited:

Hello,

I am French from Paris and I use an automatic translator and therefore not necessarily well translated

I am the person who replied on Youtube, I am the new owner of the broken CD-73 player with the same symptoms.

Bought on Ebay UK for only 50 €, I would love to be able to bring it back to life to accompany the set that I already own

An Akai AM-95 GX-95 and AT-93

I (have read some of the various comments and that does not reassure me, it seems that this running fault is impossible to solve?

Question, is that when the drawer shakes (bounces) the display flashes?

If so, it might be good to check the power supply

Disconnect the drawer and see on the display remains stable

Thank you for welcoming me among the happy owners of this magnificent Reference Master series

I am French from Paris and I use an automatic translator and therefore not necessarily well translated

I am the person who replied on Youtube, I am the new owner of the broken CD-73 player with the same symptoms.

Bought on Ebay UK for only 50 €, I would love to be able to bring it back to life to accompany the set that I already own

An Akai AM-95 GX-95 and AT-93

I (have read some of the various comments and that does not reassure me, it seems that this running fault is impossible to solve?

Question, is that when the drawer shakes (bounces) the display flashes?

If so, it might be good to check the power supply

Disconnect the drawer and see on the display remains stable

Thank you for welcoming me among the happy owners of this magnificent Reference Master series

Welcome, 1822stephane

I think andyb1712 has checked pretty much everything already, changed the large 3300 uF capacitors in power supply. Mine tested ok, both for capacitance and ESR so I decided to keep them.

@andyb1712 @Mooly I have installed the replacement BA6247 and am back to where I was before I lubricated the motors and fried the motor driver. BA6247 is a bit more powerful than BA6247N and has metal heat sink built-in. I may have to bend or cut some of it off as it might be touching analog board metal shield when I get it installed. Not sure yes if that contact may present a problem. But again, will cross that bridge if we ever get there.

I think andyb1712 has checked pretty much everything already, changed the large 3300 uF capacitors in power supply. Mine tested ok, both for capacitance and ESR so I decided to keep them.

@andyb1712 @Mooly I have installed the replacement BA6247 and am back to where I was before I lubricated the motors and fried the motor driver. BA6247 is a bit more powerful than BA6247N and has metal heat sink built-in. I may have to bend or cut some of it off as it might be touching analog board metal shield when I get it installed. Not sure yes if that contact may present a problem. But again, will cross that bridge if we ever get there.

I have become a spectator on this too as I am out of ideas what else to test.

I haven't given up hope of resolving this problem but the more minds involved the better the chance there is of a fix.

It's just a shame there is no chance of getting hold of a replacement or known good micro just so it can be eliminated as the problem.

I haven't given up hope of resolving this problem but the more minds involved the better the chance there is of a fix.

It's just a shame there is no chance of getting hold of a replacement or known good micro just so it can be eliminated as the problem.

I think that point has been reached as well, a known good uP to prove or disprove. I know its never the big chip but just once in while... it is. Everything else seems to have been so exhaustively checked that it just has to be tried at this point.

Has anyone tried using freeze mist on the original MCU to see whether that temporarily “fixes” the tray oscillation fault?

Note: Hold a spray can of modern “air duster” upside-down to get liquid to come out. This works perfectly as “freeze spray.”

I have recently ID’d several bad IC chips this way. Evidently there are internal broken connections between the silicon die and the external pins. A few cycles of “freeze” appears to cause enough thermal contraction/extension to temporarily “fix” these faulty internal connections.

If this test confirms a bad MCU, then (of course) the next question is “where can one get a replacement IC?”

-EB

Note: Hold a spray can of modern “air duster” upside-down to get liquid to come out. This works perfectly as “freeze spray.”

I have recently ID’d several bad IC chips this way. Evidently there are internal broken connections between the silicon die and the external pins. A few cycles of “freeze” appears to cause enough thermal contraction/extension to temporarily “fix” these faulty internal connections.

If this test confirms a bad MCU, then (of course) the next question is “where can one get a replacement IC?”

-EB

I have some freezer spray at work which I will try. I have a feeling I tried this before at some point but will give it a go to be sure. At least I will when I return to work as I am stuck at home isolating as a contact of a work colleague that tested positive for Covid last week.

This remains one of the strangest faults I have heard about.

Out of all the CD players in existence this fault seems to occur only in these two Akai models. Additionally it appears to have a very high incidence rate.

It would be great to see one of these machines which is still working correctly for comparison. Unfortunately every reference I can find to these two models reports the tray oscillation fault.

Odd. Very odd!

-EB

Out of all the CD players in existence this fault seems to occur only in these two Akai models. Additionally it appears to have a very high incidence rate.

It would be great to see one of these machines which is still working correctly for comparison. Unfortunately every reference I can find to these two models reports the tray oscillation fault.

Odd. Very odd!

-EB

Freezer spray didn't work on mine either.

I think the only way left to fix this now is to modify it. I think the tray and clamper control needs to be taken away from the old micro and given to a separate logic circuit or something like a pic micro.

Unfortunately designing this is a bit above my 'pay grade' as they say but I'm sure it could be done.

I think the only way left to fix this now is to modify it. I think the tray and clamper control needs to be taken away from the old micro and given to a separate logic circuit or something like a pic micro.

Unfortunately designing this is a bit above my 'pay grade' as they say but I'm sure it could be done.

I had a notification from You Tube yesterday of a comment posted on my video of the tray oscillation... another owner with two units, a 73 and a 93, both exhibiting the same fault. Clearly this isn't just a few isolated units that have failed and is an inherent problem with the product.

How to resolve it remains the problem as so far no one else has cured it... or has yet to come forward.

How to resolve it remains the problem as so far no one else has cured it... or has yet to come forward.

very interesting failure mode. looking at the BA6247 rohm driver datasheet, it is clear that the two motors share a common signal pin between the chip's two output stages. should the OUT1 connection (or the wire harnesses, pcb traces, etc) become intermittent, then attempting to drive one of the motors will cause the other one to run as well. Try double checking the wiring harnesses, pcb traces etc.

Hello Andy,

I came across your u-tube video and responded to it a couple days ago, in a stupid way, without the knowledge that you and fellow members have gone through such a spectacular journey trying to tackle this stubborn problem.

Although I have the (almost) exact same player, except a Japanese domestic model A&D DP-7000 that I hand carried to Canada, I never dug too much into its inner works, as I have never had any issues with it, until coming across your video.

The strange behavior of the MCU hammering the CD tray by alternating the motor drive direction at limit switch status changes, on both loading and clamping cycles, appears increasingly more intentional, by design, the more I watch your videos, than a mere MCU defect or something by accident. Probably the machine is issuing some warnings about troubles with other systems by doing that.

On a hunch, that means I could be very wrong, there is this signal coming from IC10, and goes into #59 of the MCU (L.M.I.), which has to do with the laser pickup carriage linear motor, or its feedback coil to be exact. Usually people don't like having linear motors work open-loop, so 1/2 of IC10 is to detect a faulty feedback coil (at Sensor-H and Sensor-G). And my guess is when there is a defective feedback coil, or the detection circuit itself malfunctions, MCU would see a logic L at #59, it would then refuse to load or clamp the CD tray or the CD, even being forced to do.

Again, a wild guess, but perhaps worth a look. And there could be more of this kind of self-protection or warning mechanisms in working with this MCU.

By the way, Andy, if you are to try forcing TR3 off, it is better to disconnect the linear motor drive beforehand, in order to prevent possible damage if the linear motor does operate open-loop.

I came across your u-tube video and responded to it a couple days ago, in a stupid way, without the knowledge that you and fellow members have gone through such a spectacular journey trying to tackle this stubborn problem.

Although I have the (almost) exact same player, except a Japanese domestic model A&D DP-7000 that I hand carried to Canada, I never dug too much into its inner works, as I have never had any issues with it, until coming across your video.

The strange behavior of the MCU hammering the CD tray by alternating the motor drive direction at limit switch status changes, on both loading and clamping cycles, appears increasingly more intentional, by design, the more I watch your videos, than a mere MCU defect or something by accident. Probably the machine is issuing some warnings about troubles with other systems by doing that.

On a hunch, that means I could be very wrong, there is this signal coming from IC10, and goes into #59 of the MCU (L.M.I.), which has to do with the laser pickup carriage linear motor, or its feedback coil to be exact. Usually people don't like having linear motors work open-loop, so 1/2 of IC10 is to detect a faulty feedback coil (at Sensor-H and Sensor-G). And my guess is when there is a defective feedback coil, or the detection circuit itself malfunctions, MCU would see a logic L at #59, it would then refuse to load or clamp the CD tray or the CD, even being forced to do.

Again, a wild guess, but perhaps worth a look. And there could be more of this kind of self-protection or warning mechanisms in working with this MCU.

By the way, Andy, if you are to try forcing TR3 off, it is better to disconnect the linear motor drive beforehand, in order to prevent possible damage if the linear motor does operate open-loop.

Last edited:

Welcome to the Akai CD-73/93 discusssion and thank you for your replies here and on You Tube. I hadn't considered the RF amp PCB and the sensor coil as being part of the loading procedure problem but having exhausted all other avenues of investigation I decided to have a closer look at this.Hello Andy,

I came across your u-tube video and responded to it a couple days ago, in a stupid way, without the knowledge that you and fellow members have gone through such a spectacular journey trying to tackle this stubborn problem.

Although I have the (almost) exact same player, except a Japanese domestic model A&D DP-7000 that I hand carried to Canada, I never dug too much into its inner works, as I have never had any issues with it, until coming across your video.

The strange behavior of the MCU hammering the CD tray by alternating the motor drive direction at limit switch status changes, on both loading and clamping cycles, appears increasingly more intentional, by design, the more I watch your videos, than a mere MCU defect or something by accident. Probably the machine is issuing some warnings about troubles with other systems by doing that.

On a hunch, that means I could be very wrong, there is this signal coming from IC10, and goes into #59 of the MCU (L.M.I.), which has to do with the laser pickup carriage linear motor, or its feedback coil to be exact. Usually people don't like having linear motors work open-loop, so 1/2 of IC10 is to detect a faulty feedback coil (at Sensor-H and Sensor-G). And my guess is when there is a defective feedback coil, or the detection circuit itself malfunctions, MCU would see a logic L at #59, it would then refuse to load or clamp the CD tray or the CD, even being forced to do.

Again, a wild guess, but perhaps worth a look. And there could be more of this kind of self-protection or warning mechanisms in working with this MCU.

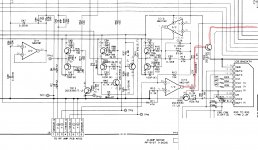

View attachment 1068916

By the way, Andy, if you are to try forcing TR3 off, it is better to disconnect the linear motor drive beforehand, in order to prevent possible damage if the linear motor does operate open-loop.

I have removed the RF amp PCB to reflow the 30 year old solder joints and check any electrolytic caps as I think this is always a starting point with old electronics of any kind. That completed I pulled the laser ribon and cleaned the contacts as this hasn't been removed in 30 years either.

I put it back together and measured the two coils mentioned on You Tube. The motor coil, pins 4 and 5, measures 36ohms and the sense coil, pins 1 and 8, measures 44Kohms on mine so very different to the figures you quoted on You Tube. The rework on the PCB made no difference to the problem so I will have to get the scope out and have a look at the circuit around IC10 and TR3 to see what this is doing when the tray is operated.

That sounds like we had a suspect....... and the sense coil, pins 1 and 8, measures 44Kohms .......

I measured the drive coil resistance again and got 35-ohm, matching yours. the sense coil is confirmed at 3.16Kohm.

I also measured the coils at both the connector on digital PCB and on their terminals on the pickup sled to make sure they match.

To get at the coil terminals on the sled, first turn off the power while the tray is out, then manually move the sled to its out most position, or tilt up the front of the machine and let the gravity do it, then secure the sled with the sled lock. --------- duh, this part is most likely unnecessary, you spent much more hours than I did around it...

OK, so the drive coil is fine but the sense coil is way higher than yours. I already moved the sled fully back to check this directly and eliminate the connectors and ribbon as a problem. It definitely reads 44k. I checked with two different meters to be sure.That sounds like we had a suspect.

I measured the drive coil resistance again and got 35-ohm, matching yours. the sense coil is confirmed at 3.16Kohm.

I also measured the coils at both the connector on digital PCB and on their terminals on the pickup sled to make sure they match.

To get at the coil terminals on the sled, first turn off the power while the tray is out, then manually move the sled to its out most position, or tilt up the front of the machine and let the gravity do it, then secure the sled with the sled lock. --------- duh, this part is most likely unnecessary, you spent much more hours than I did around it...

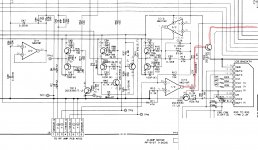

View attachment 1070041

I suppose the next thing is what to do about it? I'm assuming this is part of the pickup assembly and is unlikely to be available as a replacement part now. The strange thing is the player works fine once you can persuade it to load a disc, so maybe this circuit can be modified to eliminate the problem?

I guess the coil has become open circuit, and the 44Kohm is probably resistance of the rest of the circuit being probed at.

Neither coil seems to be part of the pickup. They are rather part of the deck mechanism, probably making even more difficult than the pickup to come by. I haven't seen any of the online pictures of the pickup has a coil on it.

I don't know about repairing the sense coil being practical or not. That coil is a mystery to me to begin with. At a DC resistance at about 3.4Kohm, it would take 370 meters of #44 AWG wire, probably the thinnest magnet wire you can get and be able to handle, before questioning being able to fit it all in such a small package. I wonder what the sense coil was wounded with.

The coil drive amplifier (U10-2) has a very different response with and without the sense coil. From my reading of the schematic, with the sense coil in circuit, the amp has a gain of 39 at DC, rolling off 6db/Oct at 50Hz, until flattening out to gain of 4 at much higher frequencies. This is before counting in the feedback from the sense coil as a secondary input but I think we can leave that part out for now. With the sense coil open circuit, on the other hand, the amp is at straight unity gain.

The good news is, despite the much altered amplifier characteristic, once the disc is somehow successfully loaded the tracking/sled-servo works, well perhaps not as perfectly, but certainly much better than non-worky at all.

So let's hope we could trick the MCU and defeat the supposed coil-detection process.

We probably don't want to put a resistor, 3.3Kohm, in place of the sense coil. Although doing that may trick the MCU into thinking there is a coil, and subsequently completes loading a disc, the resistor would also restore the amplifiers frequency response. This could be dangerous. as without a functioning sense coil feeding back the sled traversing velocity there may be chances the amplifier puts the entire rail voltage (12V) onto the motor coil and instantly speeds the sled up to a very high speed, and possibly crashes them into the end stop. We would rather have a sluggish sled than one out of control. However if you lock the sled up with that sled lock, it's safe to try it quickly, just remember take the resistor out immediately after.

If it's more convenient to access, instead of a resistor, we could short the base of TR3 to ground. This would defeat the supposed coil sensing process at MCU, without worrying about the sled speeding.

Neither coil seems to be part of the pickup. They are rather part of the deck mechanism, probably making even more difficult than the pickup to come by. I haven't seen any of the online pictures of the pickup has a coil on it.

I don't know about repairing the sense coil being practical or not. That coil is a mystery to me to begin with. At a DC resistance at about 3.4Kohm, it would take 370 meters of #44 AWG wire, probably the thinnest magnet wire you can get and be able to handle, before questioning being able to fit it all in such a small package. I wonder what the sense coil was wounded with.

The coil drive amplifier (U10-2) has a very different response with and without the sense coil. From my reading of the schematic, with the sense coil in circuit, the amp has a gain of 39 at DC, rolling off 6db/Oct at 50Hz, until flattening out to gain of 4 at much higher frequencies. This is before counting in the feedback from the sense coil as a secondary input but I think we can leave that part out for now. With the sense coil open circuit, on the other hand, the amp is at straight unity gain.

The good news is, despite the much altered amplifier characteristic, once the disc is somehow successfully loaded the tracking/sled-servo works, well perhaps not as perfectly, but certainly much better than non-worky at all.

So let's hope we could trick the MCU and defeat the supposed coil-detection process.

We probably don't want to put a resistor, 3.3Kohm, in place of the sense coil. Although doing that may trick the MCU into thinking there is a coil, and subsequently completes loading a disc, the resistor would also restore the amplifiers frequency response. This could be dangerous. as without a functioning sense coil feeding back the sled traversing velocity there may be chances the amplifier puts the entire rail voltage (12V) onto the motor coil and instantly speeds the sled up to a very high speed, and possibly crashes them into the end stop. We would rather have a sluggish sled than one out of control. However if you lock the sled up with that sled lock, it's safe to try it quickly, just remember take the resistor out immediately after.

If it's more convenient to access, instead of a resistor, we could short the base of TR3 to ground. This would defeat the supposed coil sensing process at MCU, without worrying about the sled speeding.

- Home

- Source & Line

- Digital Source

- Akai CD-93