Thanks for the update, and for all your work and time. Sometimes I forget to "read between the lines" and remember that the original TSE was optimized for the 45.I still haven't solved the R5 puzzle.

I will say that when mine "poofed", I was absolutely ecstatic to find a 5 W resistor of a similar value lurking in my parts bin. It was a PITA to install, but the additional margin was worth it; the amp has worked flawlessly since. Barring any further discoveries, I "ain't" removing it anytime soon.

Just got my TSE-II board today! I am very excited to build my first tube amp.

Is this Digikey part number (from what I take to be the original SE parts list on tubelab.com) good for R5 or is it one of the bad ones?

Digikey P270W-2BK-ND (Panasonic ERG-2SJ271)

Digikey has ~5000 in stock but they are listed as "Not for New Designs"

Is this Digikey part number (from what I take to be the original SE parts list on tubelab.com) good for R5 or is it one of the bad ones?

Digikey P270W-2BK-ND (Panasonic ERG-2SJ271)

Digikey has ~5000 in stock but they are listed as "Not for New Designs"

That is if you want control over the life cycle of your product. So essentially if you are an amplifier manufacturer and you would like to be able to use parts for which you want notifications from the manufacturer of the part about the life cycle of that particular part.Digikey has ~5000 in stock but they are listed as "Not for New Designs"

In short. There is nothing wrong with the part itself.

Good luck! I think you have chosen an awesome first project!Just got my TSE-II board today! I am very excited to build my first tube amp.

Last edited:

That does look a bit close, but I'd just run it and see at this point. Probably not a huge problem with 45s as the combined heat from the filaments and plate dissipation is maybe at 15 W for each tube (someone chime in if I'm wrong). I'd be much more concerned if you were running 2A3s or 300Bs.

Here is an early picture of the very first TSE ever made. At this time (2003) it still had the prototype PC board in it. Shortly after this picture was taken I rotated the power transformer 90 degrees to kill some hum created by magnetic coupling.

I swapped out the PC board once the first production batch was made, and added a heat sink to the regulator so that I could run 300B tubes......the 300B's nearly touch each other and the output transformers.

In 2006 our house was trashed by a hurricane and this amp got rather wet. It had been placed on a shelf and the case had filled about halfway with nasty water. I cleaned it up and it played on just fine without any new parts, but the power transformer would fail several months later. It looked fine on the outside, but as quite rusty and green on the inside. I swapped it out, and all was well.

In 2008 I took the amp to visit some very expensive Lowther based horn speakers with 106 dB sensitivity. Here some hum was evident, so I added a choke and supplemental cap to the power supply. They can be seen in the hand held picture, the white cap can be seen behind the output tubes, and the choke is under the right OPT.

Clearly this amp is a perfect example of too much stuff crammed into too small of a cabinet, yet it just works...very well.

It is now 2019 and the old amp still works just fine. It has run some 90 year old NX-483 tubes for the last 10 years. They are like a 45 with a 5 volt heater....seen in the last picture.

If your amp works well, and the OPT's do not get too hot to touch after hours of playing, I would not worry about it.

I swapped out the PC board once the first production batch was made, and added a heat sink to the regulator so that I could run 300B tubes......the 300B's nearly touch each other and the output transformers.

In 2006 our house was trashed by a hurricane and this amp got rather wet. It had been placed on a shelf and the case had filled about halfway with nasty water. I cleaned it up and it played on just fine without any new parts, but the power transformer would fail several months later. It looked fine on the outside, but as quite rusty and green on the inside. I swapped it out, and all was well.

In 2008 I took the amp to visit some very expensive Lowther based horn speakers with 106 dB sensitivity. Here some hum was evident, so I added a choke and supplemental cap to the power supply. They can be seen in the hand held picture, the white cap can be seen behind the output tubes, and the choke is under the right OPT.

Clearly this amp is a perfect example of too much stuff crammed into too small of a cabinet, yet it just works...very well.

It is now 2019 and the old amp still works just fine. It has run some 90 year old NX-483 tubes for the last 10 years. They are like a 45 with a 5 volt heater....seen in the last picture.

If your amp works well, and the OPT's do not get too hot to touch after hours of playing, I would not worry about it.

Attachments

To all -

What are your recommendations for brands of 5842? I plan to build a TSEII around 45s and I want to make sure I'm buying smartly.

Thanks

What are your recommendations for brands of 5842? I plan to build a TSEII around 45s and I want to make sure I'm buying smartly.

Thanks

I would not worry too much about a specific R5.

My solution was 2 x 570 Ohm 2W metal oxides in parallel.

Maybe not as elegant looking as a single resistor but works.

Use what resistors you have to make R5. It just needs to be close.

My solution was 2 x 570 Ohm 2W metal oxides in parallel.

Maybe not as elegant looking as a single resistor but works.

Use what resistors you have to make R5. It just needs to be close.

Any success in finding a replacement for R5?

The problem I'm having is that I can't seem to blow one, even the tiny little 1 watt resistor that blew for two other users holds up in my two boards. I have even removed the output tubes and wired up huge power transformer that results in a B+ of over 500 volts on my 450 volt caps. I can flip that power switch dozens of times, one at a time letting the caps bleed down to zero between each hit, or even feed the board 500 volts of DC through a switch with the same abuse......I have tried all 10 of the small Vishay parts that I have and haven't been able to blow one.

I have 5 to 10 each of just about any 270 ohm 2 watt resistor that Digikey stocked for less than $2 each......can't blow any of them either.

I remember some issues with the solid state diodes blowing in early SSE's and it was very power transformer specific, so I'm going to dig out a bunch of different transformers and a variac for more testing.

I have to leave town for an unknown period of time early Wednesday morning, so I may not have an answer right away.

It would seem that any of the larger metal oxide or wirewound resistors would do fine, but I haven't been able to duplicate the failure mode yet. It's big and ugly but those 5 watt white ceramic and cement resistors are nearly bullet proof.

As stated, the value isn't very important. 270 ohm was chosen at a time when the TSE was intended to be a 45 amp, and I never saw any reason to change it. The resistor specified for the original TSE was a metal oxide part which has been discontinued. They never failed.

i should add I never had an issue with R5 blowing and was using the recommended 1W part but changed it because of the anecdotal evidence, striving for maximum reliability.

If it helps, my amp was a completely "stock" build (built entirely with the then-current BOM) when R5 blew. It used the following power supply iron:I remember some issues with the solid state diodes blowing in early SSE's and it was very power transformer specific, so I'm going to dig out a bunch of different transformers and a variac for more testing.

- PT: Hammond 270HX

- Choke: Hammond 159S (4H, 225 mA, 65 Ohm DCR)

[And yes, I hot-switched it, which all but guaranteed a huge inrush of currentQUOTE]

that will do it 😉

Try a CL90 I.C.L. inthe PT centre tap.

I installed one from the beginning.

One more thing (Columbo style)

I have played with the usul DHT suspects 300b, 2a3, 6b4g in both SE and PP and gave up with them ~ 15 years ago, they really had fantastic mids (coloured but nice) but I found the frequency extremes lacking.

This TSE II from George is unreal.

Unlike any other I built which included a 5842 I.T. 300b SE which was the best of my tries.

I am so impressed that I just purchased a pair of JJ300b's although I have 2 pairs of Valve art 300B's (they are around 15 years old as well but with little use as above).

Also have 4 pairs of 307A's which may be used at some stage but probably in a second TSE PCB.

I would tell George he has a truly fantastic product but I'm pretty sure he alredy knows that.

If your amp works well, and the OPT's do not get too hot to touch after hours of playing, I would not worry about it.

That does look a bit close, but I'd just run it and see at this point. Probably not a huge problem with 45s as the combined heat from the filaments and plate dissipation is maybe at 15 W for each tube (someone chime in if I'm wrong). I'd be much more concerned if you were running 2A3s or 300Bs.

Thanks both as always. The OPT's did not get too hot but nonetheless I re-did the top plate. I moved the OPT's a bit back and the PCB forward and gained another 0.5in there.

My amp is finally almost complete, I only need to wire the headphone out.

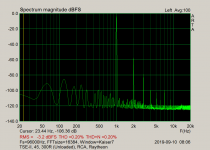

With tomchr's HV Maida regulator and the ISO power transformer, this amp is now dead silent and sounds amazing.

Headphones are temporarily connected to a terminal strip while I run a measurements with and without load resistors for matching 300R headphones.

The current results are actually that unloaded had the best distortion without much (if any) loss in FR. I wrote a more detailed response in a dedicated thread I started regarding that.

I also ran the same FFT with Raytheon (Windmill Getter) 5842 and WE417A.

The WE measured with marginally better distortion, but I have found are more microphonic.

Attachments

Beautiful job on the top plate. How did you get the vent hole around the tubes so evenly spaced?

Hah, you give me too much credit !! I purchased the chassis from Landfall Systems, including the top panel. I must say that this has probably been the BEST experience I have ever had with a vendor and can highly recommend using them.

Their prices are pretty good too.

Initially, I only wanted to order a custom sized aluminum base from them, and then a top plate from Front Panel Express or get a blank plate and drill on my own.

They charged only $25 extra (to the cost of the top plate) for CNC it, all I had to provide was the .FPD file and they did the rest.

One other reason I didnt really want to drill my own was because of the square holes for the Power transformer and power inlet

Their prices are pretty good too.

Initially, I only wanted to order a custom sized aluminum base from them, and then a top plate from Front Panel Express or get a blank plate and drill on my own.

They charged only $25 extra (to the cost of the top plate) for CNC it, all I had to provide was the .FPD file and they did the rest.

One other reason I didnt really want to drill my own was because of the square holes for the Power transformer and power inlet

Last edited:

That's good to know, I plan on building the SE2 this winter and $25 for the CNC work is a steal. I've built the other TL amps and drilling the holes (neatly) was the most tedous part of the whole thing.

- Home

- More Vendors...

- Tubelab

- After a 14 year run, the TSE must DIE!