Thanks. 🙂

However, the current developments in the Ath thread show that the effort to integrate a midrange driver is basically no longer necessary. Either I or my printer are too slow to keep up. 😉

However, the current developments in the Ath thread show that the effort to integrate a midrange driver is basically no longer necessary. Either I or my printer are too slow to keep up. 😉

Hi all,

Amazing to see all the great projects people are sharing. Besides just getting inspiration from all people contributing to this forum, here's our two cents from Addit Audio.

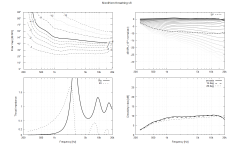

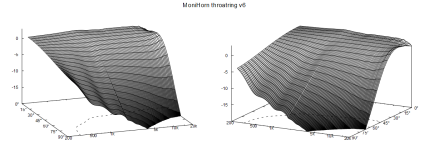

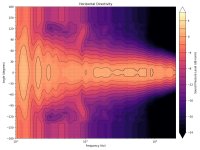

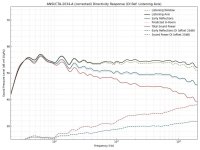

This is our take on a high output monitor speaker. We call her “The Monihorn”. The speaker features a 440mm ATH horn as basis with midrange ports for 3 4" mids. A 12" driver with a passive radiator takes care of the lowend. It's a 3 way design with DSP and amplification onboard.

The cabinet itself has been 3D printed in one piece with a large scale industrial printer. Print time around 10 hours. Material used was PETG (post industrial recycled PET with 30% glassfiber) . The woofer and amp holes were cnc milled after the printing. Horn and woofer mounts are all 3D printed with a MJF printer. Foam was used to fill the hollow print for added stiffness and dampening. Essentially creating a composite sandwich.

Here are some measurements and photos from the process!

Amazing to see all the great projects people are sharing. Besides just getting inspiration from all people contributing to this forum, here's our two cents from Addit Audio.

This is our take on a high output monitor speaker. We call her “The Monihorn”. The speaker features a 440mm ATH horn as basis with midrange ports for 3 4" mids. A 12" driver with a passive radiator takes care of the lowend. It's a 3 way design with DSP and amplification onboard.

The cabinet itself has been 3D printed in one piece with a large scale industrial printer. Print time around 10 hours. Material used was PETG (post industrial recycled PET with 30% glassfiber) . The woofer and amp holes were cnc milled after the printing. Horn and woofer mounts are all 3D printed with a MJF printer. Foam was used to fill the hollow print for added stiffness and dampening. Essentially creating a composite sandwich.

Here are some measurements and photos from the process!

Attachments

-

Afbeelding van WhatsApp op 2023-11-25 om 20.41.24_db844148.jpg220.4 KB · Views: 537

Afbeelding van WhatsApp op 2023-11-25 om 20.41.24_db844148.jpg220.4 KB · Views: 537 -

Afbeelding van WhatsApp op 2023-11-25 om 20.41.23_f5b68de0.jpg215.4 KB · Views: 529

Afbeelding van WhatsApp op 2023-11-25 om 20.41.23_f5b68de0.jpg215.4 KB · Views: 529 -

Afbeelding van WhatsApp op 2023-11-25 om 20.41.22_bfee0215.jpg180.6 KB · Views: 610

Afbeelding van WhatsApp op 2023-11-25 om 20.41.22_bfee0215.jpg180.6 KB · Views: 610 -

b99fdfae-4650-4181-9e81-05e2db1db642.jpg470.1 KB · Views: 575

b99fdfae-4650-4181-9e81-05e2db1db642.jpg470.1 KB · Views: 575 -

Afbeelding van WhatsApp op 2023-11-25 om 20.34.37_1ed05c4a.jpg107.4 KB · Views: 584

Afbeelding van WhatsApp op 2023-11-25 om 20.34.37_1ed05c4a.jpg107.4 KB · Views: 584 -

Afbeelding van WhatsApp op 2023-11-25 om 20.34.44_dbd3a1a7.jpg99 KB · Views: 589

Afbeelding van WhatsApp op 2023-11-25 om 20.34.44_dbd3a1a7.jpg99 KB · Views: 589 -

IMG_8499.jpeg694.6 KB · Views: 596

IMG_8499.jpeg694.6 KB · Views: 596 -

IMG_8494.jpeg695.5 KB · Views: 572

IMG_8494.jpeg695.5 KB · Views: 572 -

IMG_8517.jpeg618.2 KB · Views: 557

IMG_8517.jpeg618.2 KB · Views: 557 -

IMG_8373.jpeg981.4 KB · Views: 550

IMG_8373.jpeg981.4 KB · Views: 550 -

BC8DC3D0-4F6D-474A-BCED-7D00E572D615.jpg389.3 KB · Views: 538

BC8DC3D0-4F6D-474A-BCED-7D00E572D615.jpg389.3 KB · Views: 538 -

Afbeelding van WhatsApp op 2023-11-24 om 21.13.10_3dc643aa.jpg69.5 KB · Views: 549

Afbeelding van WhatsApp op 2023-11-24 om 21.13.10_3dc643aa.jpg69.5 KB · Views: 549

The speaker's a creative design, and the measurements look great.

But never mind the speaker. That is one hell of a CNC!

But never mind the speaker. That is one hell of a CNC!

Aha! Now as you share the design in the "Make" thread, would you care to present also the other driver make and type? 🙂

//

//

Drivers:

CD - B&C DE250

Mid - B&C 4NDF34

Low active - B&C 12BG100

Low passive - Dayton Audio RSS315

MEH simulation and ATH params I need to dig up somewhere

CD - B&C DE250

Mid - B&C 4NDF34

Low active - B&C 12BG100

Low passive - Dayton Audio RSS315

MEH simulation and ATH params I need to dig up somewhere

The design goals were (pretty standard):and tell us about the Horn MEH simulation/ ATH script?

- consistent DI (throat adapter to prevent beaming)

- wide coverage

- directivity control at least down to ~1000hz

Here's the ATH script for this version:

Code:

; ATH 4.9 20230530

; MoniHorn v2

; -------------------------------------------------------

; CircSym mode

; Throat adapter

Throat.Ext.Angle = 5

Throat.Ext.Length = 22.5

R-OSSE = {

R = 197.15

a = 39

r0 = 9.5

a0 = 23

m = 0.76

r = 0.30

q = 3.65

k = 18.6

b = 0.0

arcterm = 160

}

Rot = 0

; -------------------------------------------------------

Mesh.AngularSegments = 64

Mesh.LengthSegments = 40

Mesh.SubdomainSlices=

Mesh.RearShape = 1

Mesh.WallThickness = 5.0; [mm]

; -------------------------------------------------------

ABEC.SimProfile = 0

ABEC.SimType = 2

ABEC.f1 = 250 ; [Hz]

ABEC.f2 = 20000 ; [Hz]

ABEC.NumFrequencies = 100

ABEC.MeshFrequency = 40000 ; [Hz]

ABEC.Polars:SPL = {

MapAngleRange = 0,180,37

NormAngle = 20 ; [deg]

Distance = 3 ; [m]

}

; -------------------------------------------------------

Output.SubDir = "monihorn"

Output.STL = 0

Output.ABECProject = 1

Report = {

Title = "MoniHorn throatring v2"

NormAngle = 15 ;

Width = 1400

Height = 900

SPL_Range = 50

MaxRadius = 90

PolarData = "SPL"

OffsetFR = 0 ; [dB]

GnuplotCode = 2x2n+w.gpl

}Attachments

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design - The Practical Way