Sure, I only want to finish and measure it first. Such a big waveguide is no small endeavour, and I want to be sure it's fine.

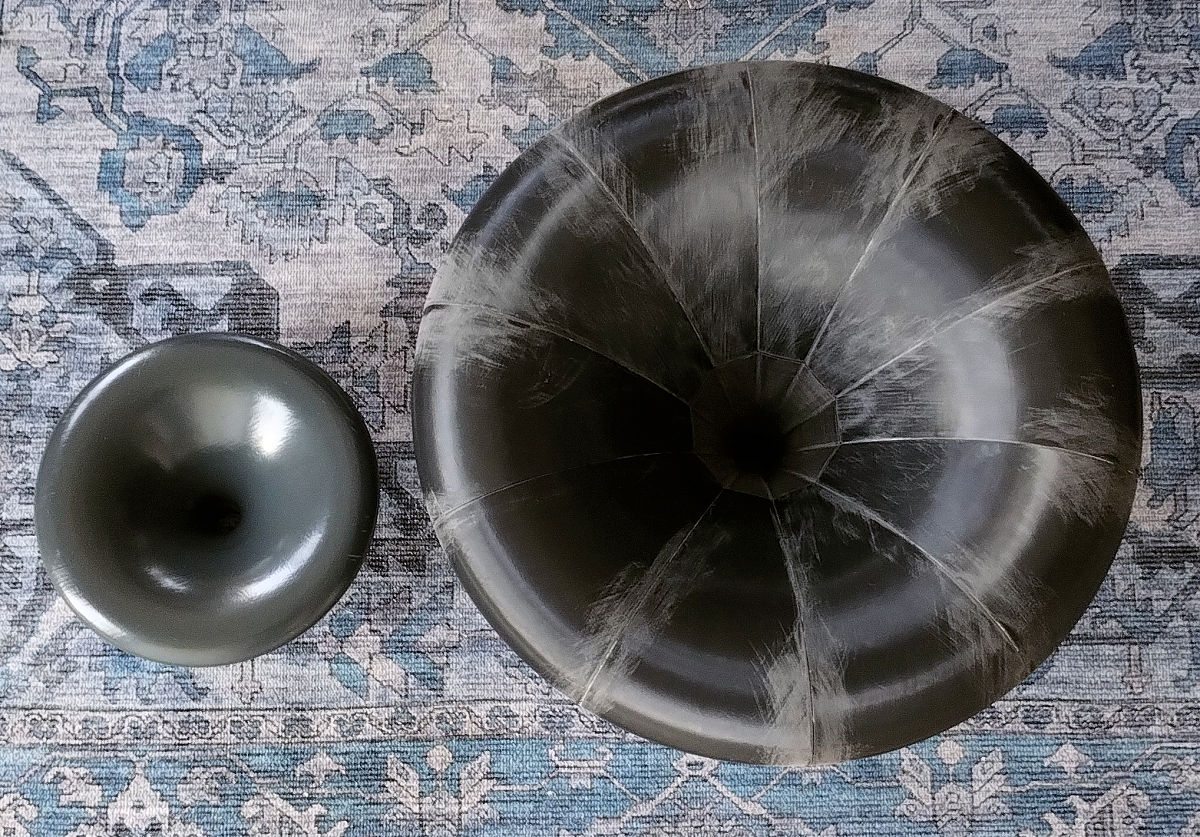

- And I mean it's really big. This is with an ATH280EX:

- And I mean it's really big. This is with an ATH280EX:

Last edited:

BTW, I also assembled the new EXAR 400 and failed badly this time. I first glued together the petals to make the two halves of the horn, and even though everything seemed fine during the assembly, I found out at the end that they don't fit at all to each other - they were just twisted too much.

So, petal by petal, as shown here, is really the best procedure, as it doesn't allow the inaccuracies to add up. It's not a big problem to handle all the small imperfections separately with a suitable glue. I will update the kit so it includes the central jig for this. It simplifies the whole process a great deal.

So, petal by petal, as shown here, is really the best procedure, as it doesn't allow the inaccuracies to add up. It's not a big problem to handle all the small imperfections separately with a suitable glue. I will update the kit so it includes the central jig for this. It simplifies the whole process a great deal.

Last edited:

Now that this has been sorted out (the assembly procedure), I can easily make an odd number of petals as well, it doesn't matter.

Nine petals seem fine to me. Some say it should improve things, I'm not sure but it costs nothing 🙂

Nine petals seem fine to me. Some say it should improve things, I'm not sure but it costs nothing 🙂

Last edited:

For optical appearance I still love round horns. So....what about 20 petals? Does not really matter for printing

I can make a purely round version as well, that's the least problem. The real problem is that seldom the printed parts will be so accurate that they form a perfectly round horn without the seams apparent. That was the idea behind the segmented shape in the first place - make the seams intentionally sharp so the dimensional imperfections don't show up so obviously. I can make a round version, but I had to warn you. It depends on what you expect.

Understand... Well it is in first place now for the listening experience. If I finally like it...will see. Many possible ways to manufacture it

BTW, the round version is already available. Not an STL kit yet, "just" the drawing (DXF file) and a printable template : https://cults3d.com/en/3d-model/various/ath-550ex

Yes I saw this. I like round more than segmented. But I must be realistic: Job/family/.... So better go for your petal-version as soon it is released. That way at least some progress 🙂

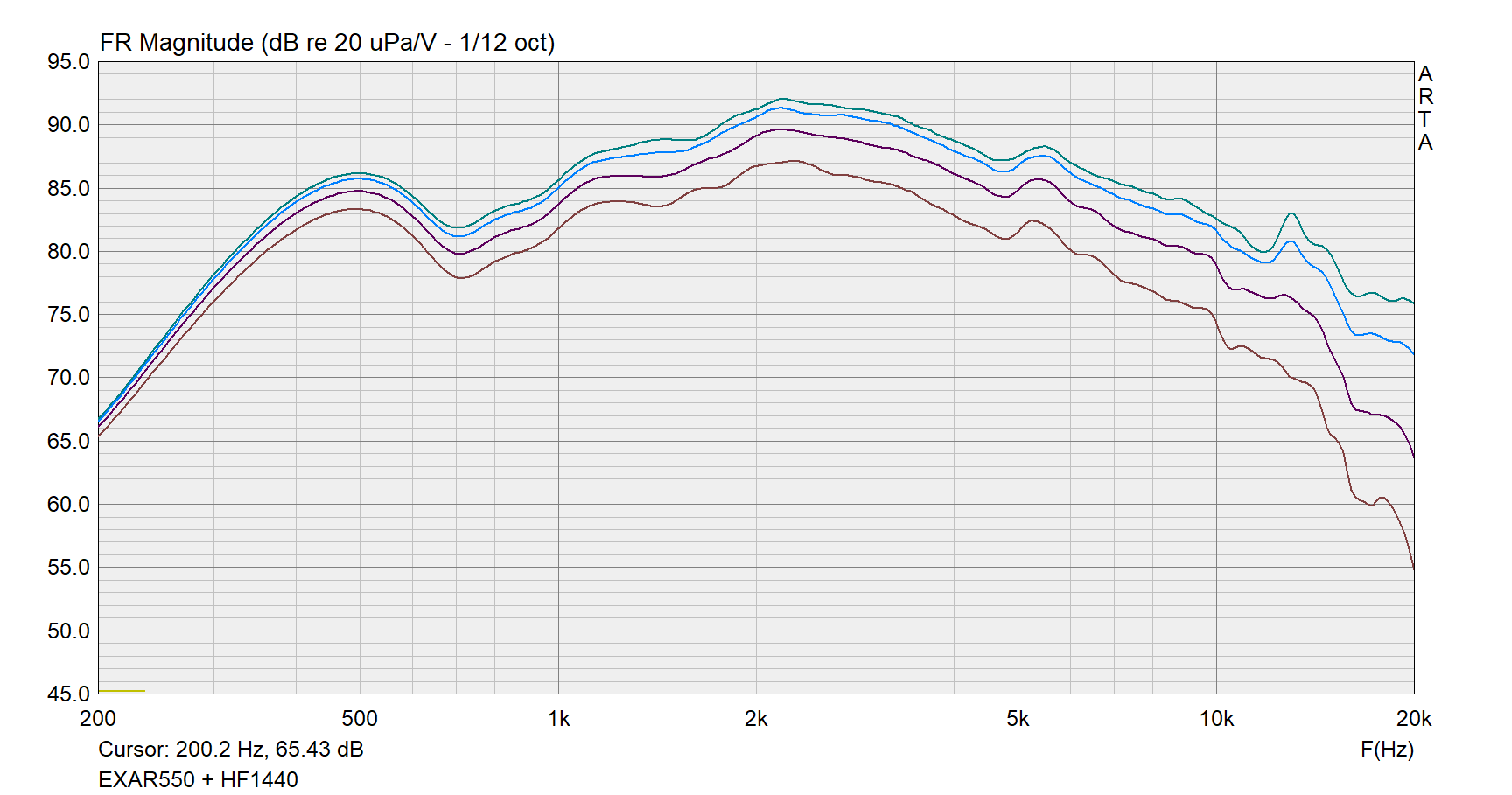

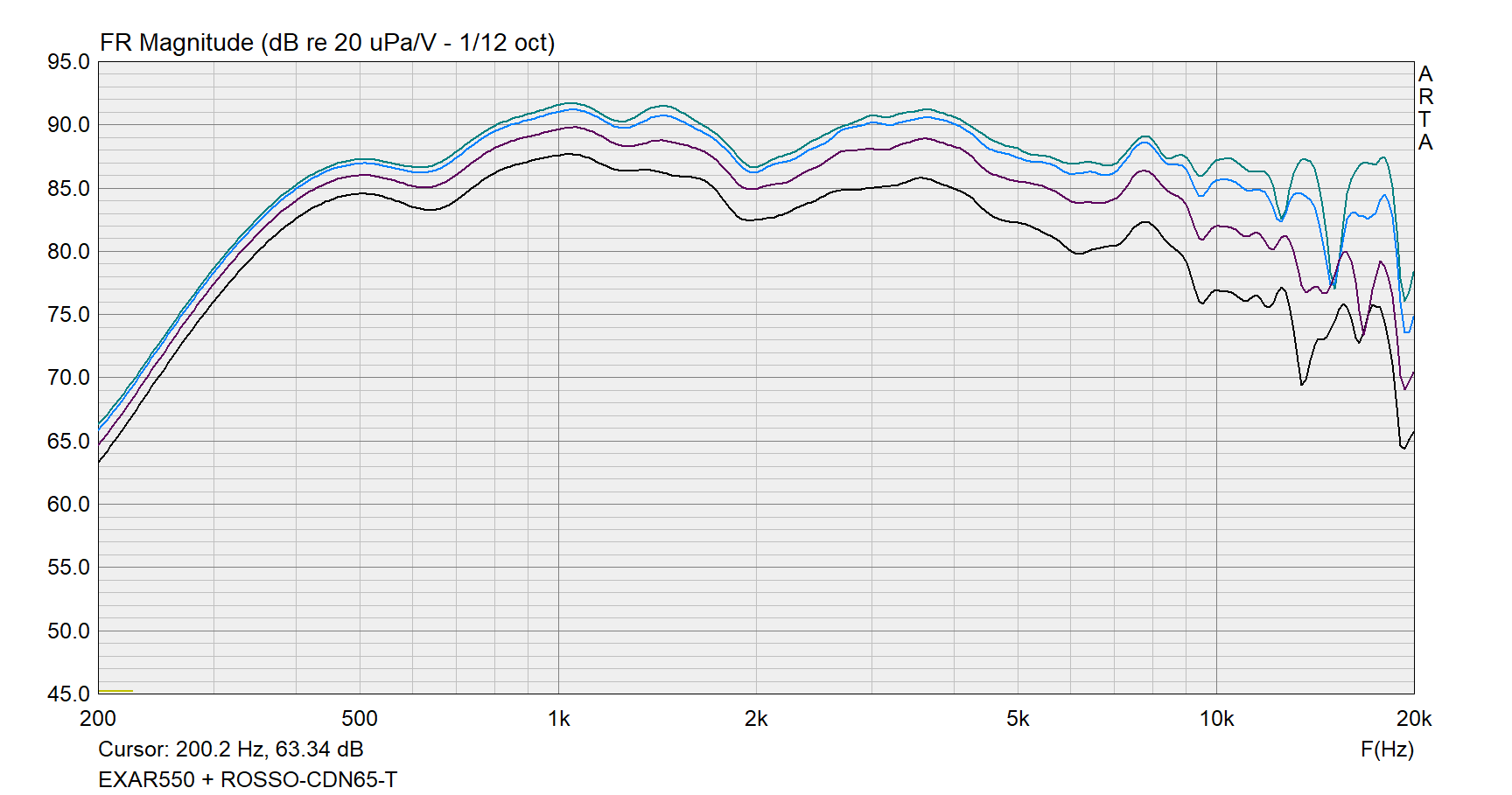

First quick measurements of EXAR 550. The angles can be roughly 0/10/20/30 but not exactly.

HF1440 and ROSSO-65CDN-T

Maybe for the HF1440 it could be shorter. Hmm, still to be surprised.

Both should do 500 Hz crossover with ease. I don't have a DSP at hand now but both will be very clean after EQ to flat between 500-10k.

HF1440 and ROSSO-65CDN-T

Maybe for the HF1440 it could be shorter. Hmm, still to be surprised.

Both should do 500 Hz crossover with ease. I don't have a DSP at hand now but both will be very clean after EQ to flat between 500-10k.

Last edited:

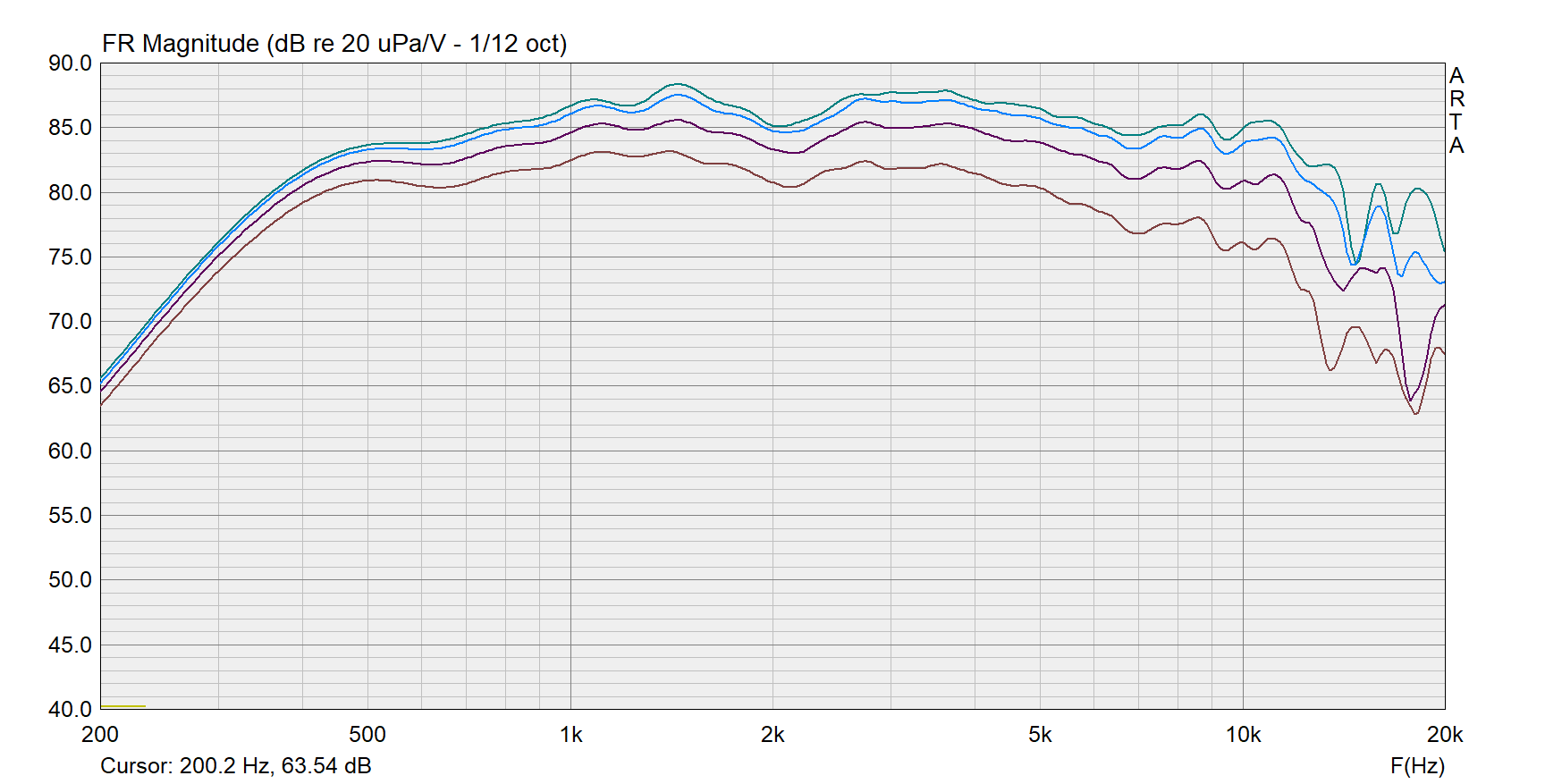

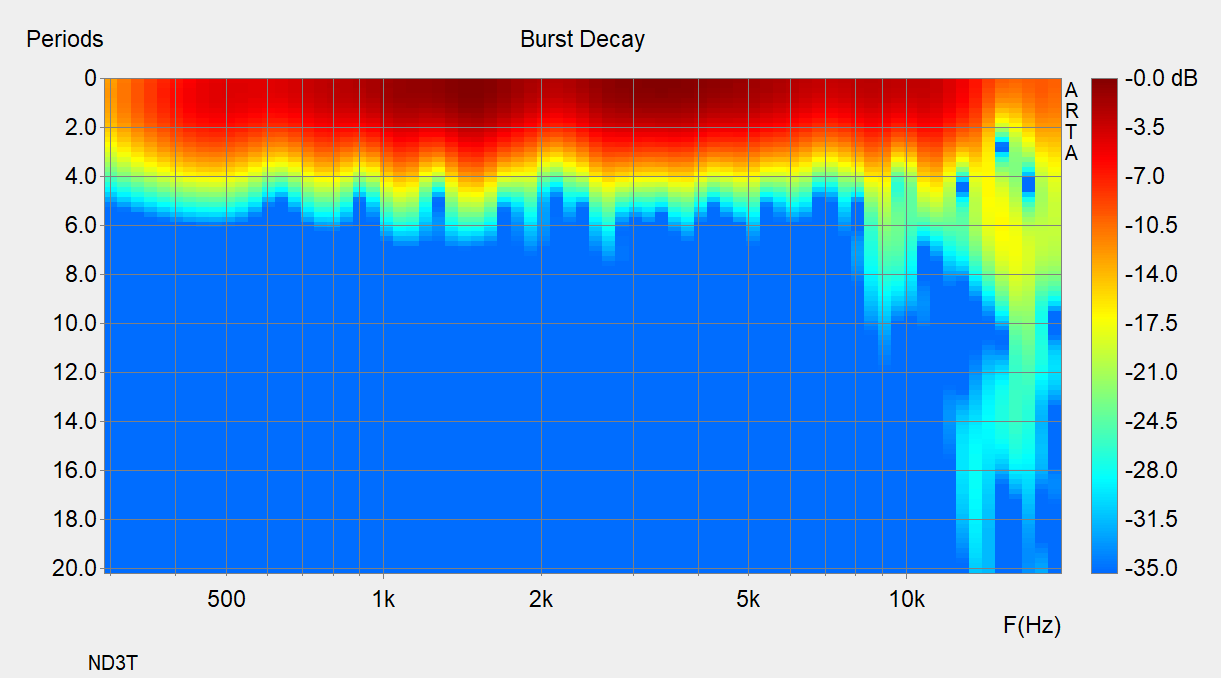

EXAR 550 + 18Sound ND3T (not at the same level as the two above)

This is the right length for the driver (or whatever does it) 🙂

This is the right length for the driver (or whatever does it) 🙂

You think the notch at 700hz with Rosso/hf1440 is too long extension?

Maybe still necessary for different inserts to match drivers

Maybe still necessary for different inserts to match drivers

I will measure the electrical impedances, free air and with the horn, if there's some kind of hint. This must be possible to design in advance, it's just that I'm still hesitant to dive deeper. For me, this means still to learn so much of the theory...

HF1440 has quite an atypical main resonance for a compression driver (not a lot damped), that's well known.

HF1440 has quite an atypical main resonance for a compression driver (not a lot damped), that's well known.

Stupid question: isnt it just the added internal length? They differ a lot from cd to cd...

For sure internal volume could add some influence as well as diaphragm dampening characteristics. Just assuming zhere is one major influencing parameter

For sure internal volume could add some influence as well as diaphragm dampening characteristics. Just assuming zhere is one major influencing parameter

That's certainly a factor, to a degree, but here we're adding much longer piece of duct after that...

Understand...

I wonder that HF1440 and Rosso show both this notch. HF1440 is ring dia and therefore just completely different inside 😱

I wonder that HF1440 and Rosso show both this notch. HF1440 is ring dia and therefore just completely different inside 😱

Here are the HF1440 and ND3T measured in a non-extended waveguide, only a bit smaller: https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7427264

In the extended horn, the resonance of HF1440 drops from 900 Hz to 500 Hz. This makes me think that a shorter extension would only move the resonance up, but the shape of the response would not change much.

In the extended horn, the resonance of HF1440 drops from 900 Hz to 500 Hz. This makes me think that a shorter extension would only move the resonance up, but the shape of the response would not change much.

Last edited:

Well....anything in decay/waterfall that bothers you? Otherwise perfect for a powerfull 2-way. The notch itself in frequency domain...if it does not hurt somewhere just eq it. That is the easy part. Cover such a range with a single driver is awesome basically.

No, I still haven't found anything suspicious (see the raw ND3T below). But in my workroom I have only about 4 ms reflection-free time, so that's still quite limited. I was just impatient to see the overall frequency response. Going to measure also some of the smaller waveguides today.

Last edited:

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)