Change one factor at a time so you'll know what did what 😉.That's no problem, I will do it. I'm also tempted to add a "sunburn warping" at the same time.

There's a chance to test both at once. If it works, I don't mind to make another one to figure out what helped. If neither works, we save a lot of time. 🙂

This calculation should beJust dialing in the numbers:

- First assumed diffraction bump, fc is 2.7 kHz: 343*0,0027=0,926 m

Distance from compression driver: 92,6 cm/2 = 46,3 cm

- Second assumed diffraction bump, fc is 3.7 kHz:

343*0,0037=1,269 m

Distance from compression driver: 126,9 cm/2 = 63,45 cm.

Could be reflections from the back if the 460 ...

343/2700= 0.1274 M

Etc

Probably they are (which means this must indeed reach the diaphragm) -These things MUST be seen in impedance...

The frequency resolution is probably still somewhat limited, this would need a bigger room.

Last edited:

What would it look like if one hooked up a sound card mic input (Low Z mode, no phantom) to the speaker terminals via an resistive attenuator and run the normal sweep by say REW and look at the Waterfall results... I need to do this one day. Better use a laptop not hooked up to mains....

Another version is to hook it up to a low ohmic serial resistance connected to one of the driver terminals and get rid of the attenuator to see the current (I) version of whats going on...

//

Another version is to hook it up to a low ohmic serial resistance connected to one of the driver terminals and get rid of the attenuator to see the current (I) version of whats going on...

//

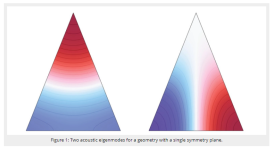

Frankly, that's hard to believe. The models can use symmetry because the system is symmetric.

Besides that, how could a non-axisymmetric mode develop for an axisymmetric device, where everything is axisymmetric including the source?

This article by René Christensen shows the examples in the picture above. I did not think it possible either/was not aware of the possibility. I still don't know if there is any possibilities for this with an axissymmetric design. Just trying to think about any reason why it does not show in your simulations. There should be a reason for this.

If it is sound from the backside of the driver enclosure, you could model it in your simulations.

If it is a mode going around the WG and back in, it might be due to symmetries, for some reason I do not yet understand either

It is due to transient behaviour, which is not modelled.

But then I don't believe the source was symmetric wrt that plane. Of course we can drive a round horn with an asymmetric source (i.e. higher-order modes), then we would have to use a full-3D model, depending on the source. But this is not our case at the moment (below 3 kHz I think we can safely ignore possible source HOMs here).This article by René Christensen shows the examples in the picture above.

Transient (time) or frequency, we have both in the sim data, as far as I'm aware. But I still can't reproduce the same behaviour, that's right.It is due to transient behaviour, which is not modelled.

Last edited:

This is the Peerless, SPL and electrical impedance:

Zoomed-in, again this is highly stable:

Zoomed-in, again this is highly stable:

Last edited:

Sunburn warping? Is that the edge treatment that sortof looks like flames? That looked neat as well but would probably complicate printing a bit.That's no problem, I will do it. I'm also tempted to add a "sunburn warping" at the same time.

Sorry, I wrote kHz where it should have been ms/milliseconds. It's speed of sound in meters per second divided by the timing of the reflection in seconds (2.7/3.7 ms) that gives the distance in meters.This calculation should be

343/2700= 0.1274 M

Etc

It would resemble a golf ball surface, only a larger scale. That's what happened when I handled the 520 waveguide in summer sunlight (thin black PLA). But that's just a guess, I can't quite see how could a few millimeter deep dents change that much. But who knows, it could cause a "decoherence" just big enough. The fact is that the 520 I have is amazingly clean through the whole midrange. I expected the same quality from both 460 and 400 (there's nothing in the sims suggesting they should be any different) but they appear to have these little wiggles around 2 kHz that seem pretty systematic now and not so easy to get rid of.Sunburn warping?

Has anyone else already measured a A520G2, so we could confirm it's still that smooth without any surface warping?

Last edited:

A520G2 with DFM2535 by vineethkumar01:

- https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7767347

- https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7767347

Here's my latest measurement with an improved setup:It would resemble a golf ball surface, only a larger scale. That's what happened when I handled the 520 waveguide in summer sunlight (thin black PLA). But that's just a guess, I can't quite see how could a few millimeter deep dents change that much. But who knows, it could cause a "decoherence" just big enough. The fact is that the 520 I have is amazingly clean through the whole midrange. I expected the same quality from both 460 and 400 (there's nothing in the sims suggesting they should be any different) but they appear to have these little wiggles around 2 kHz that seem pretty systematic now and not so easy to get rid of.

Has anyone else already measured a A520G2, so we could confirm it's still that smooth without any surface warping?

My print is slightly warped at the connection between petals and base due to the petals lifting off the build plate (less than 1 mm). Also treated with spray filler.

Measured 1 m from bug screen, angles are approximated (+-2 degrees).

Where do you all define the acoustical centre to rotate your measurement around? Maybe the question was up before - sorry...

//

//

oops.. This is not a measurement from an A520G2 i have. At the time, i just took the measurement that mabat provided and EQd it flat to get the decay plots..A520G2 with DFM2535 by vineethkumar01:

- https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7767347

That's rather arbitrary and it's not always easily repeatable with different adapters, but I thought about it and for my quick takes of the 4 angles, I should probably always adjust the angles so that I get e.g. 0, -2, -4 and -8 dB @ 10 kHz (for that particular WG body). That would make the most sense to me. But it's not really critical, IMO.Where do you all define the acoustical centre to rotate your measurement around?

Thanks! Do I see correctly that there are some midrange wiggles as well?Here's my latest measurement with an improved setup: [...]

I do roughly 0-10-20-30 deg and when zoomed in, this should be clearly visible.

Here is my A520 with a JBL2453 driver.

How do you interpret my impulse response? Measured at 30cm from horn mouth and ca 15 degrees off axis. Center of horn mouth is 90cm above the floor.

At around 1ms the impulse response wriggles a bit. What may cause this?

How do you interpret my impulse response? Measured at 30cm from horn mouth and ca 15 degrees off axis. Center of horn mouth is 90cm above the floor.

At around 1ms the impulse response wriggles a bit. What may cause this?

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)