I meant reflection/diffraction from an edge (presumably) at the back of an enclosure. It works the same way as the front edges, only with much lower amplitudes. This way the sound can make the full circle around the box but I would assume this to be even much lower effect.

Last edited:

I can provide more step by step instructions on and suggestions on the how to if anyone is interested.

Can you add some dampening and see if it makes a difference?I meant reflection/diffraction from an edge (presumably) at the back of an enclosure. It works the same way as the front edges, only with much lower amplitudes. This way the sound can make the full circle around the box but I would assume this to be even much lower effect.

Just dialing in the numbers:

- First assumed diffraction bump, fc is 2.7 kHz: 343*0,0027=0,926 m

Distance from compression driver: 92,6 cm/2 = 46,3 cm

- Second assumed diffraction bump, fc is 3.7 kHz:

343*0,0037=1,269 m

Distance from compression driver: 126,9 cm/2 = 63,45 cm.

Could be reflections from the back if the 460 ...

- First assumed diffraction bump, fc is 2.7 kHz: 343*0,0027=0,926 m

Distance from compression driver: 92,6 cm/2 = 46,3 cm

- Second assumed diffraction bump, fc is 3.7 kHz:

343*0,0037=1,269 m

Distance from compression driver: 126,9 cm/2 = 63,45 cm.

Could be reflections from the back if the 460 ...

If something arrives ~2.6 ms after the direct sound, it simply means it traveled ~0.9 m longer path. That's enough to go around the whole A400G2 or to reflect off the driver and return back...

- Some modified version(s) of the A400G2. Any volunteers? 🙂

Honestly I don't have any idea how much it can improve things. It definitely proved better in a simulation.

- Some modified version(s) of the A400G2. Any volunteers? 🙂

Honestly I don't have any idea how much it can improve things. It definitely proved better in a simulation.

Last edited:

Afterall, people buy Purifi woofers for their superior performance; why wouldn't they want to add a device on top that strains the eye some more?

Honestly that was my first though as well - it could look quite ugly haha.

Regardless, as a crude proof of concept, you could theoretically use the random() function in Fusion to create a circular pattern of random length/angle segments defines that profile, then wrap that profile around the outside perimeter. Although a pseudorandom pattern might be better that creates a more uniform distribution of distances.

Regardless, as a crude proof of concept, you could theoretically use the random() function in Fusion to create a circular pattern of random length/angle segments defines that profile, then wrap that profile around the outside perimeter. Although a pseudorandom pattern might be better that creates a more uniform distribution of distances.

If sound is radiated from the backside of the driver you should be able to dampen the waves effectivly with some blanket etc. Not sure you tried that? You mentioned it several times as a possible conclusion.Or just a reflection from the back of the enclosure. All of this eventually reach the microphone. The cleaner the "direct" sound, the more noticeable this is. In case of these waveguides it simply stands out, even it's still on the order of 1 dB (may be more with a longer gate)...

I hope a more sophisticated mouth edge will help to further reduce this effect. It's strange I can't reproduce this in a sim, no matter how I try, though.

I assume the simulation is axissymmetric? Then trying a full 3d simulation might show differnt results. Using symmetries sometimes suppresses certain modes. In a triangle with two sides of the same length for example you could not solve all eigenmodes when using the symmetry plane.

Last edited:

I like the idea but I am not sure that would work, first bump is at 1.9 kHz that is around 0.18 m. If we would try to create a phase difference of at least 90° ( this would mean only 3dB summation or oncoherent soundsources) 1/6th wich is 0.045 m. Since the the WG is 0.46 m the differences are almost 1/10thHonestly that was my first though as well - it could look quite ugly haha.

Regardless, as a crude proof of concept, you could theoretically use the random() function in Fusion to create a circular pattern of random length/angle segments defines that profile, then wrap that profile around the outside perimeter. Although a pseudorandom pattern might be better that creates a more uniform distribution of distances.

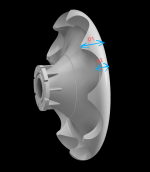

View attachment 1403469

Everything is a compromise so even if the first bump would not be completely reduced others in higher frequency would.

But I would first be interested in finding out what the real cause is.

Last edited:

Those look super cool if nothing else!- Some modified version(s) of the A400G2. Any volunteers? 🙂

If only such a petal was made for the A460G2 as I have just today begun the printing of my first A460G2-Base part. 😉

Frankly, that's hard to believe. The models can use symmetry because the system is symmetric.Using symmetries sometimes suppresses certain modes. In a triangle with two sides of the same length for example you could not solve all eigenmodes when using the symmetry plane.

Besides that, how could a non-axisymmetric mode develop for an axisymmetric device, where everything is axisymmetric including the source?

You know, it's still a bit strange to me, mainly the weak spatial dependency. If it was really due to a diffraction around the mouth, I would expect the effect to vary a lot more for different off-axis angles. What if the high midrange efficiency of the G2s is more sensitive to a mouth reflection towards the throat (even if very weak), which then affects the output? This would behave more like a resonance, which is kind of what we observe. Then only a foam plug filling the whole waveguide could help. The only unknown would be why is the 520 immune to this. Maybe the sunburn, further reducing the coherency of the reflection, and maybe a weaker reflection from a bigger roundover in the first place.

I should still have enough foam somewhere, it's worth a try. But this should be possible to simulate with an electro-acoustical driver model included, I guess.

I should still have enough foam somewhere, it's worth a try. But this should be possible to simulate with an electro-acoustical driver model included, I guess.

Last edited:

That's no problem, I will do it. I'm also tempted to add a "sunburn warping" at the same time.If only such a petal was made for the A460G2 as I have just today begun the printing of my first A460G2-Base part. 😉

Once again has "nature" played its tricks to advance science (vaccine, radiation....) - come the "sunburn" feature 🙂

//

//

It still doesn't have to make any difference, we don't know.

The same horn, different drivers (polar angles and SPLs do not match):

It still doesn't make a lot of sense to me. Here the physical differences are only in what's behind the mouth (different adapter+driver).

The depths are also a bit different (!) - which can be a clue. It seems to be shifted a bit lower in frequency with the DH450. It's probably the longer one.

Based on this I would think it must have to do something with a soundwave returning towards the throat. Most probably from the mouth edge.

The same horn, different drivers (polar angles and SPLs do not match):

It still doesn't make a lot of sense to me. Here the physical differences are only in what's behind the mouth (different adapter+driver).

The depths are also a bit different (!) - which can be a clue. It seems to be shifted a bit lower in frequency with the DH450. It's probably the longer one.

Based on this I would think it must have to do something with a soundwave returning towards the throat. Most probably from the mouth edge.

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)