Hi Marcel,

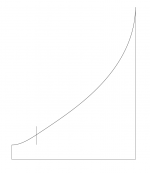

I noticed that your program does not appear to match curvature between the OS section and the termination. The error is pretty small in most cases, but becomes obvious if Depth.ConicSectionPart is set to a low value (<0.3 or so).

I noticed that your program does not appear to match curvature between the OS section and the termination. The error is pretty small in most cases, but becomes obvious if Depth.ConicSectionPart is set to a low value (<0.3 or so).

Hi,

Yes, I realized this just after I released the tool... It's still tangent but curvatures at the joint may be (and will be) different. It's because I forgot to take the OS curvature into account - I just assumed it low enough, which is not allways true - especially near the throat, as you say. I will correct this. The solution is simple - to find the corresponding curvature on the clothoid and make the join at that point (now it's allways the origin of the spiral).

Thanks. At least someone is looking closely 😉

Yes, I realized this just after I released the tool... It's still tangent but curvatures at the joint may be (and will be) different. It's because I forgot to take the OS curvature into account - I just assumed it low enough, which is not allways true - especially near the throat, as you say. I will correct this. The solution is simple - to find the corresponding curvature on the clothoid and make the join at that point (now it's allways the origin of the spiral).

Thanks. At least someone is looking closely 😉

Last edited:

Glad to help. I noticed the issue after adding clothoid termination to my own waveguide generator script since I had made the same assumption that you did. I use a simple iterative algorithm to match the curvature, but I wouldn't be surprised if there's a better way (my math skills are a bit lacking compared to some others here 😱).

BTW, if an OS waveguide is terminated by just a circular arc (a simple radius), there will be a big step change in curvature ("2nd derivative") at this joint. It can be made much smoother with the spiral but as you can see, care must still be taken...

Last edited:

Ha ha, it won't be so easy after all - what must match is a curvature, tangency and a size at the same time. I guess some iterative algorithm will be necessary...

Here's a 3D printed waveguide built using your software: Metlako: A Small, Affordable Two-Way Unity Waveguide

This is the 2nd I've done. I need to dig up pictures and measurements of the first.

This is the 2nd I've done. I need to dig up pictures and measurements of the first.

Cool! Aren't you afraid of the sharp edges on the bigger one? I would guess it could wreak havoc on the frequency response (OK, the slits will do it anyway 😉 ).

Great feature would be split model at printer table size then able to generate different throat size section and angle for particular driver.

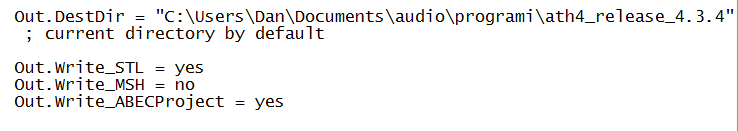

does the ath4 generate STL file which can be opened by STL viewers.

If not what is "Out.Write_STL = yes"

If not what is "Out.Write_STL = yes"

Of cource it does. The parameter Out.Write_STL controls whether this file will be created or not. Only beware you must correctly specify the Out.DestDir parameter as well.does the ath4 generate STL file which can be opened by STL viewers.

If not what is "Out.Write_STL = yes"

Your STL file should be in the project's root directory, i.e. "kvmoj". The files under the subdirectory "ABEC_project" are solely for the purpose of simulation - the mesh (.msh) file there corresponds to the STL but has some additional features required by ABEC to run properly.

Last edited:

Yes. Your PC has just a different default association for .stl files, i.e. thinks it is something different. That's OK, you can change it or leave it as it is. Just open this STL file in an appropriate program (CAD, MeshMixer, etc.).

I'm working on a new way how to construct the mesh (STL and MSH files). It will be no longer of constant angular segments but driven by a required element size and angle change so that the mesh density will be more adapted to the whole surface. That will significantly improve the overall smoothness without an excessive number of triangles near the throat.

I'm also exploring the possibilities of Autodesk Fusion 360 - there's probably a completely different and much better way of constructing the final waveguide surface to work with further. I only have to find some more time to finish.

I'm also exploring the possibilities of Autodesk Fusion 360 - there's probably a completely different and much better way of constructing the final waveguide surface to work with further. I only have to find some more time to finish.

Last edited:

BTW, regarding just the viewing of STL files - before I got used to Meshmixer (and set an association for STL files for it, so now I just double-click and see), I used the online viewer at Free online STL viewer

No need to install anything and for a quick inspection it is perfectly fine.

No need to install anything and for a quick inspection it is perfectly fine.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)