Woop, bempp-t also supports CUDA... time to wangle some access to a big GPU.

@Dmitrij_S how did your RAM usage look during computation? Guessing one will need a lot of VRAM if going to GPU route.

Anyone have an idea how important doing these calculations with FP64 is? Would be very nice if it could be paired down to BF16.

Unfortunately, I'm a little busy right now. However, I really can't wait to explore BEMPP in more detail, at first glance BEMPP looks very promising. Maybe it makes sense to create a separate topic for discussing open source software for acoustic modeling?

Really? Assembly in Solidworks should be/is straight forward. You only need one petal - can use 'Linear pattern'.Hi, i bought the ath exar-400-25 files, i now want to try out printing a mold for a version out of fiberglass. However. Its a lot of work importing the seperate petals and extensions as stls in to solidworks to then assemble it again. Is there a stl or better a . sldprt of the complete horn?

He guys, I am really curious about something; I have printed the exar-400-25 waveguide but made a mistaken, my BMS 4550 cd's have an output angle of 14 and the waveguide 6... I thought my drivers were 7 degrees so I thought it wouldn't be a problem if it's off 1 degree, but how about being off 8 degrees? Will this have a lot of negative impact on the performance?

nijts

nijts

Are you going to update the ATH-280EX too?I've updated the Cults download file (added a STEP file), you should be able to re-download. If not, send me a message.

Tx!

The flat faces of the petals don’t come out as 1 face in the stl. But now with the step file i managed to make a tooling split. The core part is now in the 3d printer.Really? Assembly in Solidworks should be/is straight forward. You only need one petal - can use 'Linear pattern'.

He guys, I am really curious about something; I have printed the exar-400-25 waveguide but made a mistaken, my BMS 4550 cd's have an output angle of 14 and the waveguide 6... I thought my drivers were 7 degrees so I thought it wouldn't be a problem if it's off 1 degree, but how about being off 8 degrees? Will this have a lot of negative impact on the performance?

nijts

Are you going to print an extension duct? If so, no problem.

I think the best approach is to take the diameter of the phase plug exit and start the whole WG geometry with a straight tube from there (can be made any length required). A piece of a spline (e.g. a cubic Bezier) can be used to connect such extension to an extisting WG. This should work well for any diameter of a particular phase plug, IMO.

@CinnamonRolls was able to get a great HF response that way.

@CinnamonRolls was able to get a great HF response that way.

Last edited:

You aren't changing the initial diameter are you? Aren't you just seeking to elongate the initial throat section with a very steep wall angle?

No, the idea is to use the smallest initial diameter available - typically the exit of the phase plug, but it's driver dependent. For this you need an open conical section at the exit of the driver, and "replace" it with a tubular segment.Aren't you just seeking to elongate the initial throat section with a very steep wall angle?

This way you can make most of the 1.4" drivers to behave roughly like a 1", regarding the HF directivity. Or you can improve upon the HF response of a 1" driver (that's what @CinnamonRolls did, as far as I remember; or analogously for any other nominal exit size 🙂 )

Last edited:

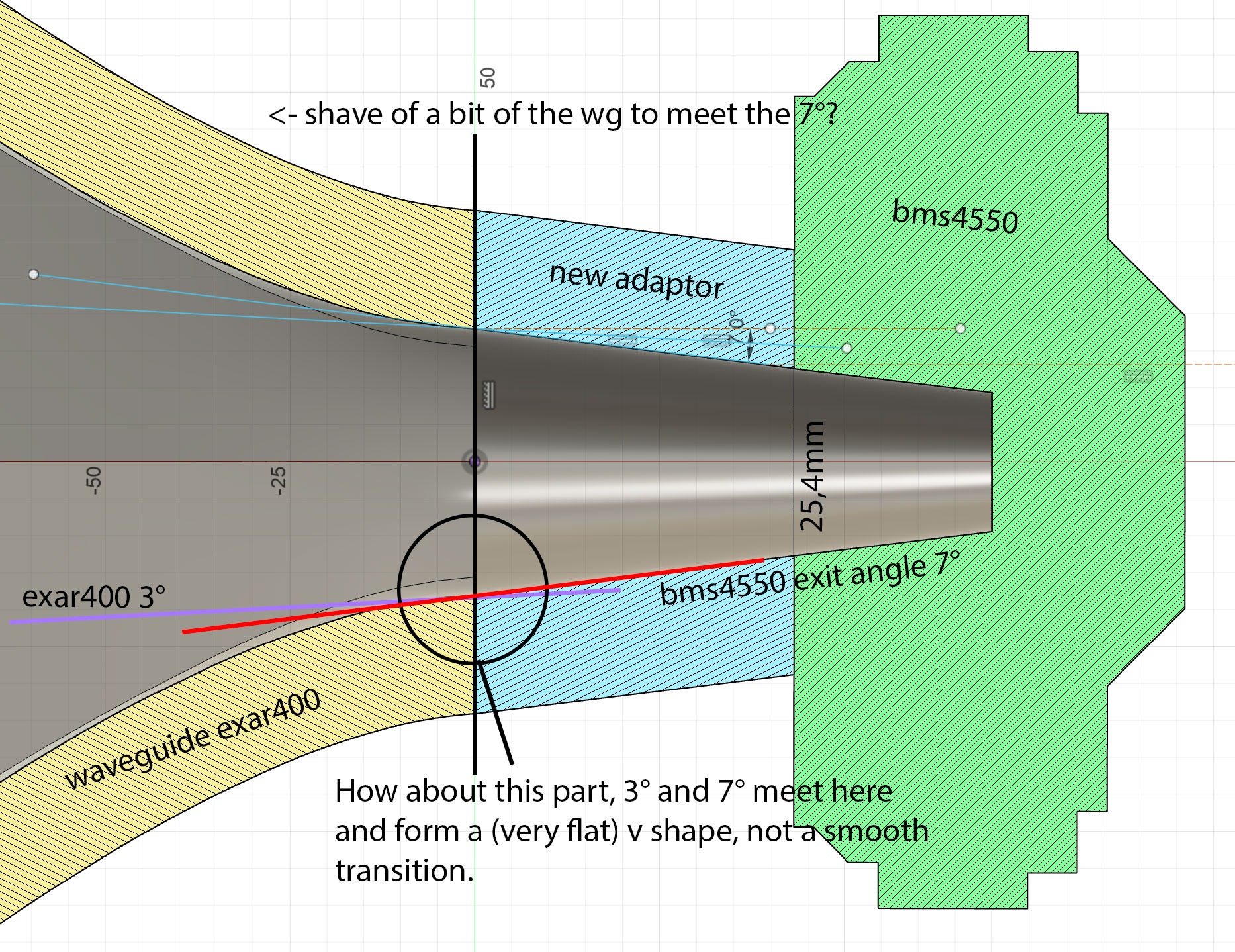

My concern is mostly, that if I am drawing a new adaptor plate for the wg, the initial start angle of the wg is still 6° instead of the exit angle of the cd.

I tried to visualize this to make it a bit clearer. What could be done is to shave of a bit of the wv throat until you meet the required angle but this is not a very good solution I think...

Stijn

I tried to visualize this to make it a bit clearer. What could be done is to shave of a bit of the wv throat until you meet the required angle but this is not a very good solution I think...

Stijn

I think that the extension could be longer, at least it seems to me it's quite a bit shorter than the original. I would make it longer and then wouldn't worry too much about that angle mismatch. It's not so big.

It would be easier it the entry angle of the waveguides was higher, of course. This is what worked so well, so I left it as it was.

It would be easier it the entry angle of the waveguides was higher, of course. This is what worked so well, so I left it as it was.

It’s a bit shorter to match the angle of the cd exit. This predicts the length of the adaptor right? The bigger the angle the shorter the adaptor?

I will first try the original version!

I will first try the original version!

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)