Maybe such an array (with a WG on the horizontal) could be made with some small form-factor compression drivers by using adapters that would guide the waves from the circular exits to small discrete segments of the circular arc of the CBT (i.e. one per shading level). How low in frequency could one get, say with 10 - 12 CDs at home listening levels? 🤔

Last edited:

I’m interested to know if it worth per suing a “ribbon emulator” -

two columns of 48pcs (96 total)

6mm dia

8mm pitch

12 groups of 4 rows (2x4 pcs parallel )

on a small arc to emulate a ribbon but with a slightly delayed & curved wavefront to be perpendicular to top and bottom horn faces.

two columns of 48pcs (96 total)

6mm dia

8mm pitch

12 groups of 4 rows (2x4 pcs parallel )

on a small arc to emulate a ribbon but with a slightly delayed & curved wavefront to be perpendicular to top and bottom horn faces.

Solely on displacement available, if one driver is capable of 800 Hz, ten drivers would handle ~250 Hz. In a CBT it's not that simple, it will be higher.

I don't think that a frequency-dependent delay or gain is really necessary, certainly not in a curved array as a CBT, which would be the only construction I would go for anyway (a tall one). I commented on the rectangular source in my previous post.

Well, maybe with the drivers it's not that simple...

I don't think that a frequency-dependent delay or gain is really necessary, certainly not in a curved array as a CBT, which would be the only construction I would go for anyway (a tall one). I commented on the rectangular source in my previous post.

Well, maybe with the drivers it's not that simple...

Last edited:

Sorry missed that comment. Thanks!

The low frequency capabilities will not get better significantly. Not sure why but what I see at a friend who did 2m tall straight lines.

The low frequency capabilities will not get better significantly. Not sure why but what I see at a friend who did 2m tall straight lines.

Here's the version for rectangular elements, including an example.

https://www.at-horns.eu/release/ath-beta-221115.zip

https://www.at-horns.eu/release/ath-beta-221115.zip

In observation.txt you can manually set the basic weights and delays (the default is the Legendre shading as used by Don Keele (page 6) - which has a typo, as I've just noticed):

Driving_Values

DrvType=Acceleration; Value=1.0

401 DrvGroup=1001 Weight=1 Delay=0.0

402 DrvGroup=1002 Weight=0.9978 Delay=0.0 // -0.02 dB

403 DrvGroup=1003 Weight=0.9841 Delay=0.0 // -0.14 dB

404 DrvGroup=1004 Weight=0.9597 Delay=0.0 // -0.36 dB

405 DrvGroup=1005 Weight=0.9256 Delay=0.0 // -0.67 dB

406 DrvGroup=1006 Weight=0.8826 Delay=0.0 // -1.08 dB

407 DrvGroup=1007 Weight=0.8317 Delay=0.0 // -1.60 dB

408 DrvGroup=1008 Weight=0.7738 Delay=0.0 // -2.23 dB

409 DrvGroup=1009 Weight=0.7099 Delay=0.0 // -2.98 dB

410 DrvGroup=1010 Weight=0.6407 Delay=0.0 // -3.87 dB

411 DrvGroup=1011 Weight=0.5672 Delay=0.0 // -4.93 dB

412 DrvGroup=1012 Weight=0.4903 Delay=0.0 // -6.19 dB

413 DrvGroup=1013 Weight=0.4110 Delay=0.0 // -7.72 dB

414 DrvGroup=1014 Weight=0.3301 Delay=0.0 // -9.63 dB

415 DrvGroup=1015 Weight=0.2486 Delay=0.0 // -12.09 dB

416 DrvGroup=1016 Weight=0.1673 Delay=0.0 // -15.53 dB

417 DrvGroup=1017 Weight=0.0871 Delay=0.0 // -21.20 dB

418 DrvGroup=1018 Weight=0.0090 Delay=0.0 // -40.93 dB

- Nobody would waste a real driver as a source at -40 dB but in the simulation we can easily afford that 🙂

I'll implement some trimming/averaging/normalizing across the arc groups...

Driving_Values

DrvType=Acceleration; Value=1.0

401 DrvGroup=1001 Weight=1 Delay=0.0

402 DrvGroup=1002 Weight=0.9978 Delay=0.0 // -0.02 dB

403 DrvGroup=1003 Weight=0.9841 Delay=0.0 // -0.14 dB

404 DrvGroup=1004 Weight=0.9597 Delay=0.0 // -0.36 dB

405 DrvGroup=1005 Weight=0.9256 Delay=0.0 // -0.67 dB

406 DrvGroup=1006 Weight=0.8826 Delay=0.0 // -1.08 dB

407 DrvGroup=1007 Weight=0.8317 Delay=0.0 // -1.60 dB

408 DrvGroup=1008 Weight=0.7738 Delay=0.0 // -2.23 dB

409 DrvGroup=1009 Weight=0.7099 Delay=0.0 // -2.98 dB

410 DrvGroup=1010 Weight=0.6407 Delay=0.0 // -3.87 dB

411 DrvGroup=1011 Weight=0.5672 Delay=0.0 // -4.93 dB

412 DrvGroup=1012 Weight=0.4903 Delay=0.0 // -6.19 dB

413 DrvGroup=1013 Weight=0.4110 Delay=0.0 // -7.72 dB

414 DrvGroup=1014 Weight=0.3301 Delay=0.0 // -9.63 dB

415 DrvGroup=1015 Weight=0.2486 Delay=0.0 // -12.09 dB

416 DrvGroup=1016 Weight=0.1673 Delay=0.0 // -15.53 dB

417 DrvGroup=1017 Weight=0.0871 Delay=0.0 // -21.20 dB

418 DrvGroup=1018 Weight=0.0090 Delay=0.0 // -40.93 dB

- Nobody would waste a real driver as a source at -40 dB but in the simulation we can easily afford that 🙂

I'll implement some trimming/averaging/normalizing across the arc groups...

Last edited:

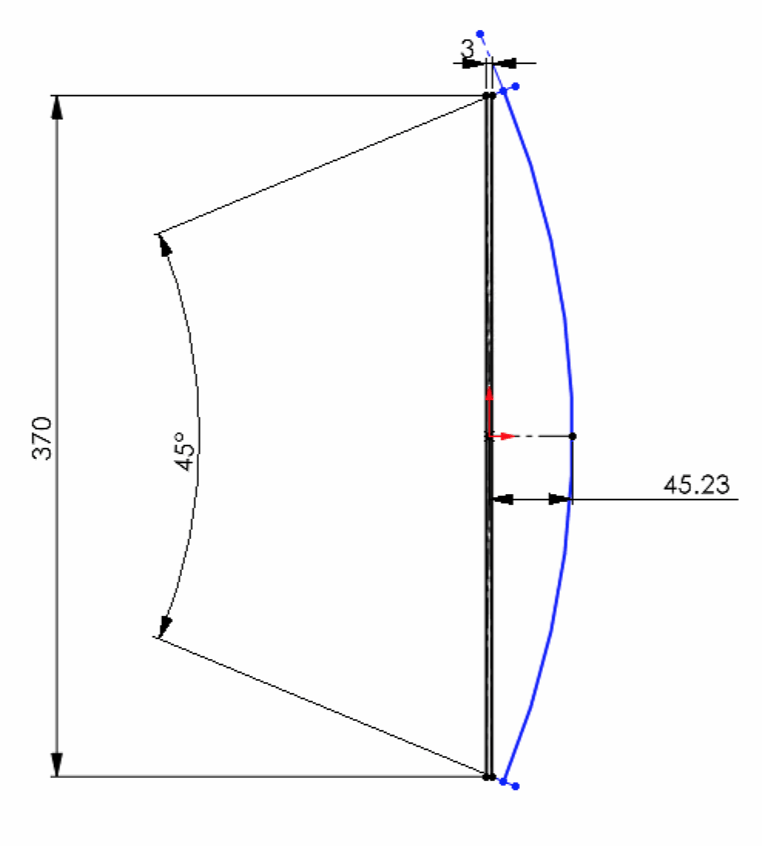

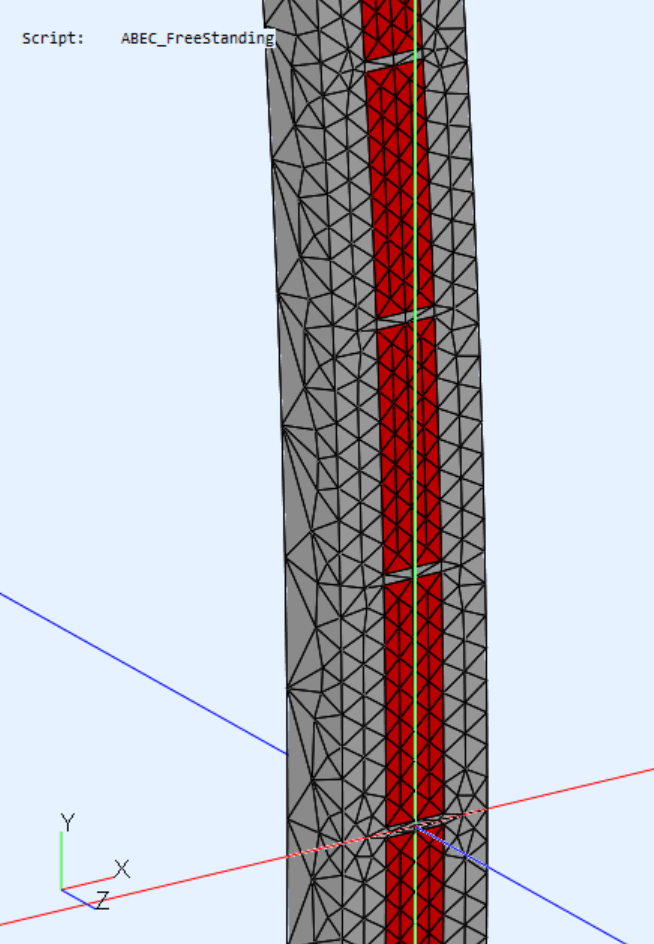

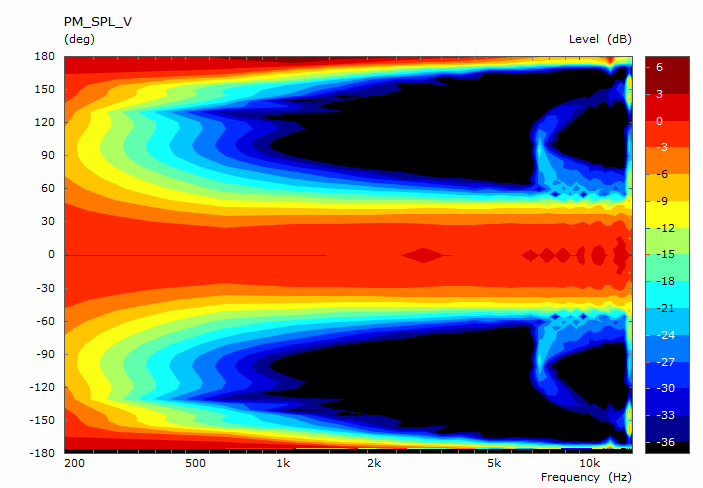

The previous example (22mm circles, 30mm c-c) changed to 12x45 rectangles, 47mm c-c:

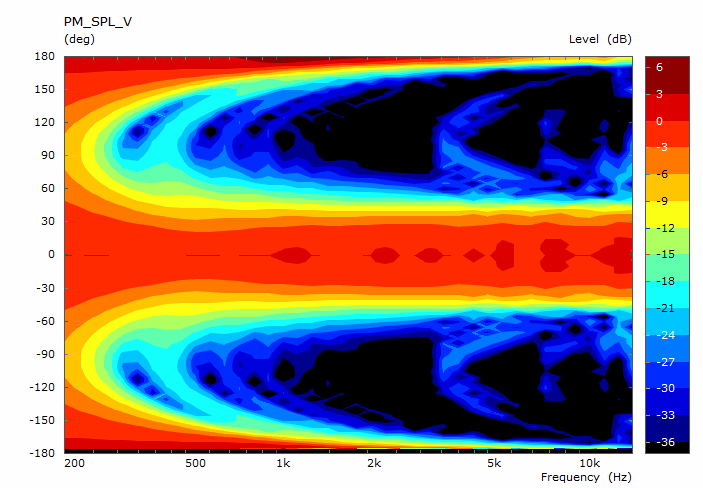

The same from discrete elements 12x90 mm, 92mm c-c, I think the pattern is obvious.

-So, some basic analysis of various CBTs is now possible via Ath, now it's time to return back to big horns...

-So, some basic analysis of various CBTs is now possible via Ath, now it's time to return back to big horns...

Nobody has tried the ST260 BLD?

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7087469

The simulation promised it to be exceptionally good.

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7087469

The simulation promised it to be exceptionally good.

Good for 1”? I’ll give it a go with HF10AKNobody has tried the ST260 BLD?

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7087469

The simulation promised it to be exceptionally good.

Might split up to into 4pcs in my X=33cm x Y=18.5cm Z=40cm - Phrozen Mega 8K.Here's a link for a 3D preview: https://a360.co/3USnCXg

Quick question about printing, how to specify more infil on the flange than on the waveguide part? I'm not too familiar with printing and have to order prints from some company, would like to specify/communicate this on next order. Already ordered one set of prints and its fine other than would like to have stronger flange not to be afraid to put some torque on the mounting nuts.

Sorry to muddy the waters again, but for a while I've been thinking that instead of using 2" drivers, it should be possible to use 2x1" drivers and combine them in the throat.

Looking at he 3d print you just posted, it reminds a bit of two throats 😀

Looking at he 3d print you just posted, it reminds a bit of two throats 😀

I don't think this is a good idea for home audio but am keen on work and discussion in this area. I have a design for a dual 2" driver adapter I am working on: https://www.diyaudio.com/community/...per-scripts-and-m200-fun.385493/#post-7167590 . I have had a hard time making the geometry where the rounded corners transition to square (the simulation linked avoids this by not fully transitioning) but am almost done on another attempt to fix it. I'm not sure yet if my adapter will work at all well!Sorry to muddy the waters again, but for a while I've been thinking that instead of using 2" drivers, it should be possible to use 2x1" drivers and combine them in the throat.

Looking at he 3d print you just posted, it reminds a bit of two throats 😀

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)