100% infill is not a good idea, it may cause trouble while printing and could resonate more. I do not think there would be any ringing with around 20 % infill, maybe even less would work. My ST260 printed in one piece is dead as it can get due to the shape. One could experiment with the print sertings, but even 2 perimeter petals with 20 % rectilinear infill as I printed them are close to perfect. IMHO the piecewise construction, petal shape and therefore varying infill orientation provides sufficient strength and damping. I never had any visible / audible / measurable ringing on any of my printed horns or waveguides.

Most probably not, if you have a printer that can print it perfect otherwise. I made it hollow mainly because it printed so nicely that way (no retraction marks, etc.). With 20% infill, it's all just fine, IMO.Is going through the trouble of filling a hollow print like this worth the effort?

I'm not sure I posted this already, the STL files I finally used: https://at-horns.eu/ext/ST260-petals.zip

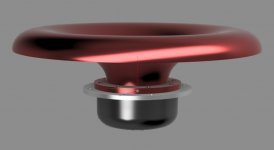

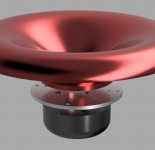

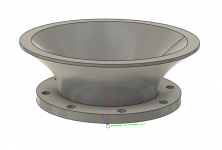

The flange accommodates a driver up to ⌀100 mm in diameter, with mouting holes on ⌀76 mm.

The flange accommodates a driver up to ⌀100 mm in diameter, with mouting holes on ⌀76 mm.

Last edited:

Need suppors then. I've used this many times then adjusted mounting plate thickness to actual print.

Free hand gluing is not recommended🙂 Actually, the picture looks worse than it really is. Even like this it would be usable with a bit of filler and dremel sanding. So I believe that with a simple alignment jig as mabat showed above it would be really easy to build a large horn like this.

Attachments

Thanks for trying 🙂 It definitely looks usable.

I came to a conclusion that the steps on the petals are actually not the best idea. A simple flat top face will probably work just fine, with a simple jig template. Once the first petal is placed and fixed, the rest is simple.

I came to a conclusion that the steps on the petals are actually not the best idea. A simple flat top face will probably work just fine, with a simple jig template. Once the first petal is placed and fixed, the rest is simple.

Attachments

Last edited:

The thing is it's not warped, like at all. It would be much harder to make it from larger pieces (as virtually all ST260 prints so far were warped to a degree, it seems almost inevitable when doing it from halves).

The petals are still hollow. I will try to "cast" a polyurethane glue inside. It makes kind of a foam when wet. Or I will just leave them hollow...

Very interesting.

So it seems that by assembling it from a series of smaller pieces you get BETTER accuracy?

That's an interesting thought. I've noticed with my largest printer that the sheer size of the print tends to exacerbate curling.

IE, if you have a print that's 20cm wide and it curls up a bit, that might be a centimeter on one edge. But if the print is 40cm wide, the curling can be as much as 3-4cm.

Sure, that's the point. My understanding is that the warping&curling is mainly due to different cooling rates of different portions of the printed object. The smaller it is, the less it is an issue. The accuracy of the petals may be on the order of a few 1/10s of mm. It will probably get a bit worse with bigger petals. The base seems quite resistant to warping because of its symmetric and sturdy shape, that should stay pretty accurate overall.

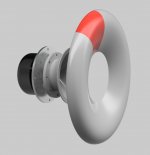

Printing the first set of CE360 (still improving on the sclicing)...

Printing the first set of CE360 (still improving on the sclicing)...

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)