This is one way of dealing with the distortion , but it all depends on panel type.Further to post #8,691,

This,

View attachment 1132436

gives credence to @Eucyblues99 Eucydome and what @spedge had been doing adding weights to stop distrotion in his panels.

steve.

Hi again lordtarquin.This is a very interesting find! The cheaper ones with the thinner aluminium facings look like very good value. I do wonder how they would compare with my 2mm ceiba plywood panels though. £9.95 delivery charge for <£150 orders.

I will be rehousing my 15" Monacor PA drivers in H frames when the weather gets better (i.e. I can get the panels cut at B&Q and into the car without being rained/snowed on). I will then be in the market to replace my current 30x40cm ceiba panels with something a bit larger. My previous 55x40 poplar panels seemed to have better midrange detail, so 55x40 ceiba seems like a possibility.

With active crossovers & EQ, my current hybrid setup is +/-1.5db from 35hz to 18khz with a drop off above that. Whilst the overall tonality is fine, things seem to get a bit confused with complex orchestral passages. it is, however, very revealing of recording quality (and lack thereof).

The sound from the exciter area can get pretty mashed up , especially at high volumes.

Have you tried any of my methods to try and reduce these problems ?

Steve.

Sure, I will. In time.I am all for enthusiasm, but when one does nothing and does not accomplish anything time after time the enthusiasm turns into annoyance. If he is as smart as he thinks he is he should be able to build a better sounding DML panel then everyone here.

Any achievement to talk about? Other than carpets? 🙂

Thinner the better. If possible less than 3mm, and a composite. Have you tried pressboard, by any chance?This is one way of dealing with the distortion , but it all depends on panel type.

steve.

Carpets are the pudding.....still waiting for your carpet, if you ever build a good sounding DML panel. 😉Sure, I will. In time.

Any achievement to talk about? Other than carpets? 🙂

In time? Didnt you say if you dont build one in around 6 months or so you are giving up aka quitting? 🤣

Hi Steve.Hi again lordtarquin.

The sound from the exciter area can get pretty mashed up , especially at high volumes.

Have you tried any of my methods to try and reduce these problems ?

Steve.

It's been a while! I'm only recently getting back into the speaker side of the hifi, having been concentrating on getting my Thorens TD150 mk1 fully set up in my self-designed skeletal plinth.

Your post is a timely reminder to apply the pea sized bit of blutak to the exciter area (I think this was one of the methods you mentioned, the others have escaped me a little.)

My panel arrangement differs from the norm insofar as I've gone for the old DMBLES method of attaching the panel to a 30x40cm canvas frame minus canvas, attaching the panel using a series of short lengths of 6mm neoprene foam with similar sized gaps between them.

Picture attached. They are a pig ugly prototype, but once the bass drivers go into H Frames, I'll be able to experiment far more easily with different approaches including minimal contact areas such as your approach. I can perch them on top of the H frame. I'm thinking of something like a retort stand type arrangement with the panels resting on a couple of old washing up sponges and against the top of the 'retort' stand, again with a bit of old sponge between top of panel and the retort stand post. Some sort of isolation arrangement between bottom of stand and the top of the H frame could help reduce unwanted vibrations from the H frame.

Attachments

Are you using a crossover for the DM panel?My panel arrangement differs from the norm insofar as I've gone for the old DMBLES method of attaching the panel to a 30x40cm canvas frame minus canvas, attaching the panel using a series of short lengths of 6mm neoprene foam with similar sized gaps between them.

Last edited:

Eric,Dave,

Thanks for sharing those. The thing I find most remarkable is that I don't see any evidence of "ringing" at the panel's natural frequencies, in either spectrogram. I kind of expected that perhaps the "before EQ" might show more ringing than the "after EQ". But I don't see clear evidence of ringing in either spectro. What I mean by "evidence of ringing" is what I showed here:

https://www.diyaudio.com/community/...ing-of-dml-speaker-panels.394465/post-7234486

in my first two spectrograms, where the damping was apparently poor, there are vertical lines in the spectrograms, corresponding to frequencies that "ring" long after the signal is gone. Only the third one, with a well damped perimeter, approaches either of you spectrograms.

Can you tell me what is the foam you have around the perimeter? I would not have guessed that a strip of foam around the edge (but not attached to a frame) would be as effective as your foam appears to be. Did you ever do a measurement before adding the foam? If so I'd be really interested to see that too!

I guess another possibility is that your core (nomex, right?) has good damping properties. But I never recall hearing that about nomex before.

I also don't quite understand exactly how the panel is mounted. I know it's a "temporary mount" but still I'm curious exactly what you've done there.

Thanks

Eric

I used 1/4"x1/2" foam strips along the two long edges. The "temporary mount" is actually duct tape attached at the center and wrapped around behind the exciter which is against a horizontal piece of wood. I've attached photos. If I have time this weekend I will try to take measurements with the foam strips removed.

Thanks, Dave

Attachments

Thanks Dave, pretty (haha, I know it's a mockup!).Eric,

I used 1/4"x1/2" foam strips along the two long edges. The "temporary mount" is actually duct tape attached at the center and wrapped around behind the exciter which is against a horizontal piece of wood. I've attached photos. If I have time this weekend I will try to take measurements with the foam strips removed.

Thanks, Dave

And that look like the soft gray window sealing foam, Frost King or similar, right?

I'll be really interested to see the spectrogram without the foam.

As I recall, you had that panel made for you from China, nomex,/CF right? What were the specs? (i.e. thicknesses of the core and skins? Do you know the areal density, or have you weighed it?

Eric

Burnt,@aagas ...just a thought in case the prices or spec are better https://signtradesupplies.co.uk/col...luminium-composite-sign-blanks-standard-sizes

This company produces signage blanks as an Aluminium/EPS/Aluminium composite material. There are many stock sizes and the price looks reasonable. The Aluminium Skin is very thin at 0.21 but the blanks are described as very rigid. I am tempted to test a small sample

I couldn't find anything in the link that said that the core is EPS. Did you find that info somewhere on the link, or know from experience?

In the US I have only found sign materials of this sort with a solid plastic or corrugated plastic (PE or PP I think) core. The ones I tried were too heavy or too stiff or both. But thin alu over EPS could be interesting.

Eric

Eucy.

I have decided to do the dome tests on an old 20inchx14inch x 3mm ply panel coated in paint.

I might try my thinner dome first as it is at hand.

I took some quick measurements .

I have to post them separately as I cannot type using my phone since the Samsung update, I believe.

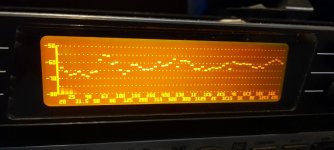

Pic1 hopefully will be the response at 12inches in front of the exciter area.

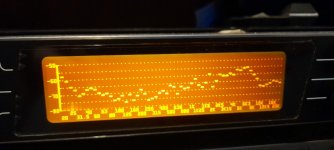

Pic 2 will be at 12inches in front, but 2ft up .

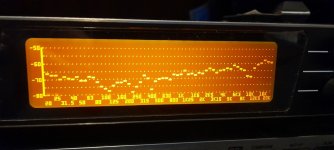

Pic 3 will also be 12inches in front But 2ft from the side.

The last 2 were just to show the response from different angles.

Steve.

I have decided to do the dome tests on an old 20inchx14inch x 3mm ply panel coated in paint.

I might try my thinner dome first as it is at hand.

I took some quick measurements .

I have to post them separately as I cannot type using my phone since the Samsung update, I believe.

Pic1 hopefully will be the response at 12inches in front of the exciter area.

Pic 2 will be at 12inches in front, but 2ft up .

Pic 3 will also be 12inches in front But 2ft from the side.

The last 2 were just to show the response from different angles.

Steve.

Actually, I don't know much about wave speed on the surface of the water, so I really can't say. But to the extent that surface waves are at least partly transverse waves, while "sound waves" underwater are longitudinal waves, they are somewhat analogous.So would that be analogous to wave speed underwater vs wave speeds on the surface?

Eric

I remember finding that info on the website, but I've had some brain fog recovering from a bout of Covid.Burnt,

I couldn't find anything in the link that said that the core is EPS. Did you find that info somewhere on the link, or know from experience?

In the US I have only found sign materials of this sort with a solid plastic or corrugated plastic (PE or PP I think) core. The ones I tried were too heavy or too stiff or both. But thin alu over EPS could be interesting.

Eric

Could one could use contact adhesive to fix aluminum to EPS?

Alternatively, here in the US one can find a number of types of foil faced insulation board. Also see SilveRboard.

That's right down your alley @chdsl, right?Alternatively, here in the US one can find a number of types of foil faced insulation board. Also see SilveRboard.

Eric

I can get something like this,That's right down your alley @chdsl, right?

Eric

3mm composite sheet, two 0.3mm aluminium sheet bonded with expanded polyethylene called Dibond cut to size, already covered with foil on both sides, factory pressed. That's how they normally sell, anyway. 🙂

About 20EUR for 2 sheets 40cm x 60cm including transport. Even, if I buy in 3-4 months time, it won't cost more, if at all few EUR.

The idea of foil cover comes from registered patents. 🙂

Last edited:

Hi. Eric,Burnt,

I couldn't find anything in the link that said that the core is EPS. Did you find that info somewhere on the link, or know from experience?

In the US I have only found sign materials of this sort with a solid plastic or corrugated plastic (PE or PP I think) core. The ones I tried were too heavy or too stiff or both. But thin alu over EPS could be interesting.

Eric

I contacted the company and asked them to confirm. They told me it was expanded polyethylene so on that basis I have ordered a sample. I’ll update when I get the sample.

Burnt

I'm using a miniDSP for active XO and EQ duties. Butterworth 24db/oct @ 400hz for each unit.Are you using a crossover for the DM panel?

I think he got banned from just about every forum some time ago!Who? 😉

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker