When I said small pieces , I ment 12inch widths or 6 inch widths.

I have only been in my room a few times since I took the photos what with Xmas and illness.

it's starting to warm up now so hopefully I will be able to crawl into my den .

Syeve.

I have only been in my room a few times since I took the photos what with Xmas and illness.

it's starting to warm up now so hopefully I will be able to crawl into my den .

Syeve.

Interesting!The idea for the cling film is loosely based on this patent.

Instead of the panel(film) being driven by the cone driver it is being driven by the panel surface .

The thin strips of paper I used do the same job.

This all stems from something a friend commented on his panels many years ago.

Steve.

https://patents.google.com/patent/US3164221A/en

I didn't know someone had written a patent on that. But, I don't know if cling film was available at that time. 🙂

The cling film idea came to my mind after seeing my wife covering some food in the kitchen, which in turn reminded me of the Gobel video. 🙂

I think there shouldn't be any air bubbles between the film and the panel. Anyway, how did it sound?Just found some pictures I took in November.

This was my first attempt with the art panel.

I did the same with the proplex but I did not have cling film big enough to cover the whole panel.

So decided to use small pieces instead.

Steve.

What if you glued the full range driver on the back of the panel without making a hole? Maybe with a double-sided tape? You might use the Hitachi idea of filling the cone with some foam, before attaching it, so that there's no air between the cone and the panel.It's a hole where I tried a fullrange driver, didn't work. If I had a small 19 mm exciter at hand I would try it on this spot tho, got a nice top end tap sound to it.

Last edited:

It is too early to say how the film sounds ,I have only had a little time playing around with sizes and air gaps.

The thickness of the film might be a problem too ?

When I first applied the film I thought it did make a difference , in a good way, but I do not want to waste anyone's time in case I was mistaken.

Only if I am 100% sure it works, and in a good way ,then I will give my opinion.

Feel free to try yourself, you will probably get there before me ,I'm very slow.

As I said , I was not going to say anything until I was sure it actually worked .

Steve.

The thickness of the film might be a problem too ?

When I first applied the film I thought it did make a difference , in a good way, but I do not want to waste anyone's time in case I was mistaken.

Only if I am 100% sure it works, and in a good way ,then I will give my opinion.

Feel free to try yourself, you will probably get there before me ,I'm very slow.

As I said , I was not going to say anything until I was sure it actually worked .

Steve.

I'm I missing something here, what is the purpose/ advantage of covering your panels in cling film? I must admit I switch off when you start taking patents, I'd rather try things myself than go over over complicated patent talk.

chdsl,might give some idea

I'm not exactly sure what you mean, but I'm pretty sure there is no cling film (or other plastic) in the Goebel panel shown in the video (or otherwise). At just before the 2 minute mark, they show the layer of white fiberglass cloth (not plastic) being rolled out onto the balsa. Later, they show the panel in a plastic vacuum bag, when she attaches the vacuum valve to the bag. And yes, that is a plastic bag but it is not part of the final product. The purpose of the vacuum bag is remove excess epoxy from the fiberglass/epoxy layers, and help press all the layers together. The panel is removed from the bag after the epoxy cures. Later, they show that the panel is smooth and glossy, and looking a lot like it would if there was a clear plastic fim over it. But in fact, that is how fiberglass/epoxy composite looks when it has curred against a smooth surface (most probably a glass plate that was also in the vacuum bag along with the panel). It's actually pretty cool that the nearly opaque white fiberglass cloth becomes as transparent as glass when it is saturated with epoxy, as in this case.

Eric

😄 I don't want to be filling some £200 fullrange drivers with foam thank you 😮 mind you I have got some cheap 4" ones I could try.What if you glued the full range driver on the back of the panel without making a hole? Maybe with a double-sided tape? You might use the Hitachi idea of filling the cone with some foam, before attaching it, so that there's no air between the cone and the panel.

View attachment 1130074

Sure, we saw something/film was rolled over the balsa sheet. That was a transparent film of some sort. I saw the cling film used in the kitchen, so the idea. That film clings and has very high surface tension. For testing you can just lay it on. If it works well, you can spray glue on the panel to keep it there permanently. I have black cling film, which is used to cover packages before couriering. I'll be testing that tomorrow, but until then I just let everyone know about the idea. spedge seems to have tested that in November. #8,519chdsl,

I'm not exactly sure what you mean, but I'm pretty sure there is no cling film (or other plastic) in the Goebel panel shown in the video (or otherwise). At just before the 2 minute mark, they show the layer of white fiberglass cloth (not plastic) being rolled out onto the balsa. Later, they show the panel in a plastic vacuum bag, when she attaches the vacuum valve to the bag. And yes, that is a plastic bag but it is not part of the final product. The purpose of the vacuum bag is remove excess epoxy from the fiberglass/epoxy layers, and help press all the layers together. The panel is removed from the bag after the epoxy cures. Later, they show that the panel is smooth and glossy, and looking a lot like it would if there was a clear plastic fim over it. But in fact, that is how fiberglass/epoxy composite looks when it has curred against a smooth surface (most probably a glass plate that was also in the vacuum bag along with the panel). It's actually pretty cool that the nearly opaque white fiberglass cloth becomes as transparent as glass when it is saturated with epoxy, as in this case.

Eric

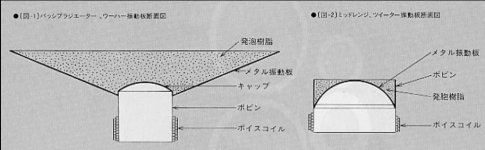

That's up to you. Hitachi had done that a long time ago. That was a cross section of their speaker driver, I posted earlier.😄 I don't want to be filling some £200 fullrange drivers with foam thank you 😮 mind you I have got some cheap 4" ones I could try.

Seems they used unmounted felt bobsI have those links but those dont show the disc used for tuning. There was another link clearly showed it but that link no longer works.

Together with wax seals (?)

Read this rather lengthy blog

https://theartofsound.net/forum/archive/index.php/t-59863.html

Basically a felt plug with a hole in it

Eucy

I believe you're talking at cross purposes hereSure, we saw something/film was rolled over the balsa sheet. That was a transparent film of some sort. I saw the cling film used in the kitchen, so the idea. That film clings and has very high surface tension. For testing you can just lay it on. If it works well, you can spray glue on the panel to keep it there permanently. I have black cling film, which is used to cover packages before couriering. I'll be testing that tomorrow, but until then I just let everyone know about the idea. spedge seems to have tested that in November. #8,519

chdsi is talking about cling wrap tightly wrapped as a surfacing material, Steve is trying a separated membrane with a small air gap which is "pumped" by the air displaced by the driver to provide bass.

This technique has been mentioned in one or more patents

Eucy

I am reading that patent spedge had posted. According to that you are supposed to have a stiff chamber in front of the driver diaphragm. I have not finished reading that yet, though. Yes, I meant sling film as another layer over the panel, or as a safeguard over the treated area.I believe you're talking at cross purposes here

chdsi is talking about cling wrap tightly wrapped as a surfacing material, Steve is trying a separated membrane with a small air gap which is "pumped" by the air displaced by the driver to provide bass.

This technique has been mentioned in one or more patents

Eucy

I think my time here is through. I thought I'd found a thread where we would share our builds, but it seems you are obsessed with patents and trying to work out / copy other people's designs, what happened to creative thinking? Trial and error, sharing those failings and successes. Very disillusioned with the ramblings on here. Off to listen to my near perfect panels.

Just thinking.

Is it possible to get mids and highs by using Joppe's method few years ago, that is, dividing the panel into two in the middle, shaving the cut at angle, using a flat coil magnetic driver, and for bass use the method from the patent spedge linked with another panel? In both methods, the panels have to be supported at the perimeter.

Link 1,

Link 2,

Link 3

Is it possible to get mids and highs by using Joppe's method few years ago, that is, dividing the panel into two in the middle, shaving the cut at angle, using a flat coil magnetic driver, and for bass use the method from the patent spedge linked with another panel? In both methods, the panels have to be supported at the perimeter.

Link 1,

Link 2,

Link 3

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker