Agreed about the impulse over-hang and the damping problems. I think the rule-of-thumbsuck is that the more damping you have, the less efficient the panel is.I don't think DML speakers have much issue with group delay. There are no ports with alternative paths for different frequencies and less crossovers.

However, when analysing responses, DML does have an issue with decay times, which is not surprising due to the modal aspect. A highly dampened material would give a more accurate impulse response with reduced decay, but hardly no sound.

So I would disagree that the goal is to get the panel to return to zero as quickly as possible. If DML could be made to have an accurate impulse response it would sound like a regular speaker.

With regular speakers any modes or time domain smearing are issues one would like to cure, but with DML it is features of how the speakers works, and something to control instead of avoid.

I THNK that multiple exciters strategically placed on a small panel, and crossed over at a frequency related to the panel size, will go a long way to reducing decay times. I need to test this.

Yes, in general I think more damping is less efficient, but I think when you have completely undampened panels they can start vibrating in a way that cancels the actual internal wave in the plate material.Agreed about the impulse over-hang and the damping problems. I think the rule-of-thumbsuck is that the more damping you have, the less efficient the panel is.

I THNK that multiple exciters strategically placed on a small panel, and crossed over at a frequency related to the panel size, will go a long way to reducing decay times. I need to test this.

So in my tests at least, a slightly dampened panel tends to be louder that a completely free hanging panel.

A highly dampened material would give a more accurate impulse response with reduced decay, but hardly no sound.

Leob,

It seems so obvious that damping would reduce the sound level that I think many people are inclined to assume it must be true. But the literature suggests that the opposite is actually true.

From this:

https://www.researchgate.net/publication/272518312_Radiation_efficiency_of_damped_plates

And here

:

Basically, these sources show that between the fundamental frequency (the first hump in the efficiency curve), and the critical frequency (the second hump in the curve), increasing damping not only increases efficiency, but reduces the spikes and dips in the efficiency as well.

I should note that "damping/loss factor" being referred to in these papers is internal damping in the panels themselves, and not damping at the boundaries. But other sources suggest that damping at the boundaries has a similar effect.

For myself, I'm not yet even convinced that there is such a thing as "too much" much damping. I've seen nothing in the literature to suggest it. The challenge however, especially with respect to internal damping in the panel, may be introducing sufficient damping in a way that doesn't significantly decrease its stiffness or increase its weight, either of which does reduce sound output.

Adding damping at the boundaries, on the other hand, at least doesn't hurt panel stiffness or increase panel weight. But whether or not boundary damping is as effective as internal damping I have to wonder....

Eric

Hi Leob,I don't think DML speakers have much issue with group delay. There are no ports with alternative paths for different frequencies and less crossovers.

However, when analysing responses, DML does have an issue with decay times, which is not surprising due to the modal aspect. A highly dampened material would give a more accurate impulse response with reduced decay, but hardly no sound.

So I would disagree that the goal is to get the panel to return to zero as quickly as possible. If DML could be made to have an accurate impulse response it would sound like a regular speaker.

With regular speakers any modes or time domain smearing are issues one would like to cure, but with DML it is features of how the speakers works, and something to control instead of avoid.

Before being in the IR, the qualities of DML are the way the sound is radiated to the room (almost no directivity even in HF), the coherence along the frequency range (one source, no crossover). It is said also to be less sensitive to the room being a diffusive dipole.

FR and IR are the 2 sides of the same coin. A wide and smooth FR has a short IR. Long tail IR means there is some energy lasting in the system so some peaks somewhere in the FR (see #4558 and before ). The question might be is there a limit in that? I mean a kind of shortest IR, below it, the magic doesn't exist.

For the damping, as also mentionned by Eric, the relation to the efficiency is not obvious too me. I'm even not sure to be able to give a definition of damping everybody will agree on. Ripple (or smoothness) of the FR which results from the panel and its suspension, energy absorption of the panel material itself which is probably frequency dependent and play on how far a wave travel.

Christian

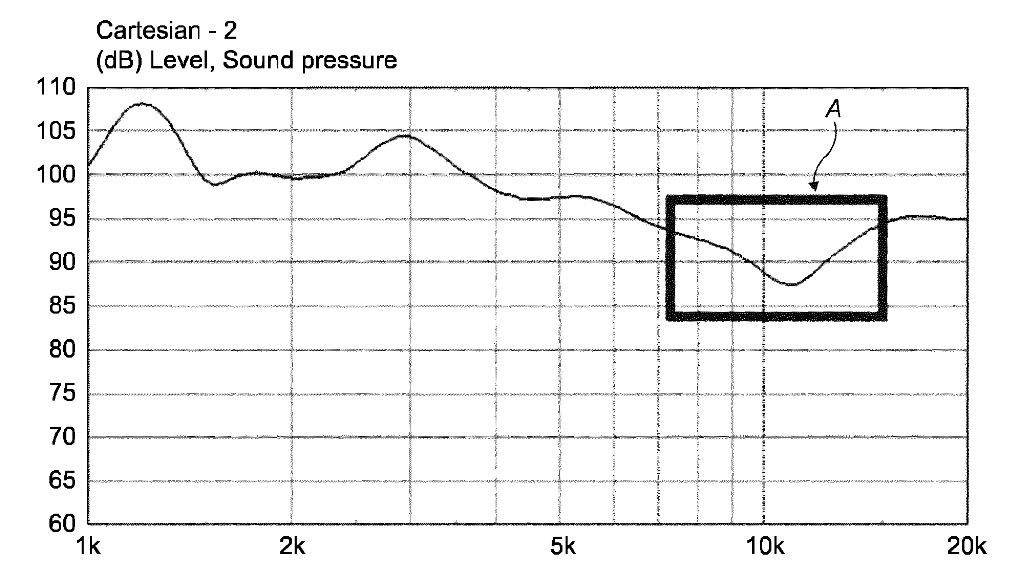

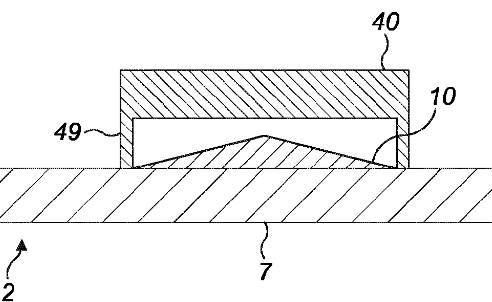

Some reading (I don't remember having seeing it here before) about countermeasure in the voice coil internal area : EP3101911A1

2 extracts that speak by themselves for the one having already deal with the topic.

2 extracts that speak by themselves for the one having already deal with the topic.

Christian.

I have seen these responses in fig 8 many times over the years.

The aluminium panel is already well damped in the central area by the glue holding the 2 aluminium sheets together.

The response in the central area is very dependent on the panel material used.

I personally would not use this method to try and damp the central area , but it does work , as shown.

I tried similar methods years ago, but did not like the way it affected the sound.

Steve.

I have seen these responses in fig 8 many times over the years.

The aluminium panel is already well damped in the central area by the glue holding the 2 aluminium sheets together.

The response in the central area is very dependent on the panel material used.

I personally would not use this method to try and damp the central area , but it does work , as shown.

I tried similar methods years ago, but did not like the way it affected the sound.

Steve.

so if this is true, wouldnt it make sense to reinforce xps or eps with glass fiber or even carbon fiber? would be cheap to make tooConcerning modeling, I've done a lot of searching for the factors that determine DML performance. One of the best sources IMO are the patents by Heron like this one:

https://patentimages.storage.googleapis.com/dc/fb/7b/46e5a02efc68f3/US6058196.pdf

According to this and other authors, the ratio:

(bending stiffness per unit width)/(weight per unit area)^3

determines radiation efficiency. And the ratio:

(bending stiffness per unit width)/(weight per unit area)

is one of the factors that determines the low frequency limit of the panel.

In both cases, higher stiffness and low weight are favorable.

Note, it's bending stiffness and not tensile strength that determines performance.

Because solid panels of any material (including titanium and aluminum) are quite heavy compared to composites with foam or honeycomb cores, the latter are preferable. That said, I think plywood actually performs pretty decently, despite being solid. The same patent also includes equations for the relationships between panel size and minimum frequency, and panel thickness and maximum frequency.

Regarding cores: The main concern with lightweight cores is not that they might resonate differently than the skins. Rather, it's that if their shear stiffness is too low, the composite may not end up with the stiffness that simple engineering estimates might suggest.

Regarding excitement: What happens (in theory) is that excitation causes the panel to bend as a unit (that is, the back face of the panel bending exactly the same and simultaneous with the face), and that these bending waves on the faces generate sound waves in the air. There's a pretty cool animation of it here (showing just one side of the plate).

Evanescent Waves (sound radiation from a plate)

In fact, this animation is really showing the importance of the factor (bending stiffness per unit width)/(weight per unit area), because that ratio determines the panel's "coincidence frequency" and hence effectively determines (in part) the frequency below which the generated sound waves become "evanescent", that is, decay with distance.

Hope this helps,

Eric

I think I might be using the wrong term. I was interested in the impulse response and resonances, so your charts were really useful.Hello Drkmatr,

Are you refering to post 6394 ?

I like spectrogram that are based on wavelet. The delays are quite easily visible and the need of damping also. I am not used to extract group delay. If you think it has an interest, it might be possible to extract it from different measurements made with REW.

I don't think I understand this. I would have assumed you'd want to keep time-domain smearing to a minimum, unless you're treating the speaker more like an instrument (which is perfectly valid of course)?With regular speakers any modes or time domain smearing are issues one would like to cure, but with DML it is features of how the speakers works

Last edited:

we can use those equations and easily calculate the optimal parameters for our materials used.Concerning modeling, I've done a lot of searching for the factors that determine DML performance. One of the best sources IMO are the patents by Heron like this one:

https://patentimages.storage.googleapis.com/dc/fb/7b/46e5a02efc68f3/US6058196.pdf

According to this and other authors, the ratio:

(bending stiffness per unit width)/(weight per unit area)^3

determines radiation efficiency. And the ratio:

(bending stiffness per unit width)/(weight per unit area)

is one of the factors that determines the low frequency limit of the panel.

In both cases, higher stiffness and low weight are favorable.

Note, it's bending stiffness and not tensile strength that determines performance.

Because solid panels of any material (including titanium and aluminum) are quite heavy compared to composites with foam or honeycomb cores, the latter are preferable. That said, I think plywood actually performs pretty decently, despite being solid. The same patent also includes equations for the relationships between panel size and minimum frequency, and panel thickness and maximum frequency.

Regarding cores: The main concern with lightweight cores is not that they might resonate differently than the skins. Rather, it's that if their shear stiffness is too low, the composite may not end up with the stiffness that simple engineering estimates might suggest.

Regarding excitement: What happens (in theory) is that excitation causes the panel to bend as a unit (that is, the back face of the panel bending exactly the same and simultaneous with the face), and that these bending waves on the faces generate sound waves in the air. There's a pretty cool animation of it here (showing just one side of the plate).

Evanescent Waves (sound radiation from a plate)

In fact, this animation is really showing the importance of the factor (bending stiffness per unit width)/(weight per unit area), because that ratio determines the panel's "coincidence frequency" and hence effectively determines (in part) the frequency below which the generated sound waves become "evanescent", that is, decay with distance.

Hope this helps,

Eric

also the second link mentions that the efficiency of the bending waves is determined by the sound speed in the material we can vary the thickness of the xps plate quite easily to match our needed profile

Sorry anyone other than tectonic has ever used carbon and nomex panels? if there is any video about it?

Anton,so if this is true, wouldnt it make sense to reinforce xps or eps with glass fiber or even carbon fiber? would be cheap to make too

In principle, yes. I'm not sure if eps or xps has enough shear stiffness to be a good core material, but you could try it.

I do think that a lightweight core reinforced with fiberglass (FG) or carbon fiber (CF) skins is a good way to go. Tectonic uses CF over a nomex core, and Goebel uses CF (or FG) over end grain balsa, so they seem to agree.

That said, I think it's very easy with such composites to make something that is actually much too stiff. My best result so far with a composite panel is using a 1.6 mm balsa core with 0.25 mm CF skins, and even that is on the border of being too stiff. Likely the next composite I try will be similar but with a core and skins that are half as thick as that.

Eric

Regarding the coupling of plate and air, if the speed of sound inside the plate is crucial to couple to air but the speed of sound is dependend on the frequency wouldnt it be possible to vary the thickness of xps plates to get areas with different speed of sound? very easy to do with xps.Anton,

In principle, yes. I'm not sure if eps or xps has enough shear stiffness to be a good core material, but you could try it.

I do think that a lightweight core reinforced with fiberglass (FG) or carbon fiber (CF) skins is a good way to go. Tectonic uses CF over a nomex core, and Goebel uses CF (or FG) over end grain balsa, so they seem to agree.

That said, I think it's very easy with such composites to make something that is actually much too stiff. My best result so far with a composite panel is using a 1.6 mm balsa core with 0.25 mm CF skins, and even that is on the border of being too stiff. Likely the next composite I try will be similar but with a core and skins that are half as thick as that.

Eric

we can use those equations and easily calculate the optimal parameters for our materials used.

anton,

For sure, there are equations we can and should use to guide our selection of materials.

Eric

Hello Drkmatr,I think I might be using the wrong term. I was interested in the impulse response and resonances, so your charts were really useful.

I don't think I understand this. I would have assumed you'd want to keep time-domain smearing to a minimum, unless you're treating the speaker more like an instrument (which is perfectly valid of course)?

The charts I shown are very easy to get with REW. I posted somewhere before a modest REW tuto to help on that if you need.

I think the second sentence is from Leob? I think it points the fact DML are the search of a trade off between 2 thinks :

- the target of a minimal smearing which is the time equivalence of a smooth FR

- the nature of DML based on modes which by themselves are peaks in frequency so long in the time domain.

Where DML are really strange is that we can get very pleasant listening with no nice FR.

By the way, FR of pistonic speakers are not so nice in a real room... but pistonic speakers can claim nice FR in the axis in an anechoic room. Tough reality.

Christian

Hello AntonRegarding the coupling of plate and air, if the speed of sound inside the plate is crucial to couple to air but the speed of sound is dependend on the frequency wouldnt it be possible to vary the thickness of xps plates to get areas with different speed of sound? very easy to do with xps.

I am just thinking about the same idea. Somewhere in this thread there are papers about "black holes". There is also a patent explaining that the key point of a bending wave panel is to offer a spacial aperture (limited dimensions) so that it can radiate sound and not having standing waves. The patent proposes different solutions to adapt the panel at the edges. I can say I have a full understanding of this patent but currently I am wondering why almost all the edges of panels terminates in a rectangular shape? The balck hole topic is pointed in the history file I posted before. Here is the patent : WO2002013575A1

The post #1484 from Veleric about it

Christian

hi and good morning everyone

I bought a 50x40 cm carbon / nomex panel for a total thickness of 3.8mm, I would like to try it with exciters, you could recommend the best and most powerful on the market and maybe in your opinion how many I need to take to maximize power.

Thank you all

I bought a 50x40 cm carbon / nomex panel for a total thickness of 3.8mm, I would like to try it with exciters, you could recommend the best and most powerful on the market and maybe in your opinion how many I need to take to maximize power.

Thank you all

How thick are the carbon skins?hi and good morning everyone

I bought a 50x40 cm carbon / nomex panel for a total thickness of 3.8mm, I would like to try it with exciters, you could recommend the best and most powerful on the market and maybe in your opinion how many I need to take to maximize power.

Thank you all

The premade plates I have seen have a very thick skin compared to what Tectonic use. Optimally it should probably be a few tenths of millimetres, not like most premade plates which are a mm or more.

That doesn't mean it will sound bad necessarily, but it will reduce efficiency a lot.

When it comes to how much exciter power a plate can handle, I haven't managed to push any hard enough get to the point where the plate is the limitation. I use 4x40w exciters (DAEX30HESF-4) per plate because that is the most powerful exciters I could find with low HF inductance, and hence good FR. Using amps that should deliver double that in RMS I pushed them to the max for many hours on end and the exciters didn't even get lukewarm and plates held up sounding clear and undistorted.

I'm not sure it seems worth using even more exciters per plate, so unless you can find exciters that can handle more power, I would say total rated power of 160w RMS per plate is the maximum, but you can probably push them harder than rating.

hello and thanks for the reply, the thickness of the carbon is 0.3mm + HoneyComb 3mm, I paid 85 euros.How thick are the carbon skins?

The premade plates I have seen have a very thick skin compared to what Tectonic use. Optimally it should probably be a few tenths of millimetres, not like most premade plates which are a mm or more.

That doesn't mean it will sound bad necessarily, but it will reduce efficiency a lot.

When it comes to how much exciter power a plate can handle, I haven't managed to push any hard enough get to the point where the plate is the limitation. I use 4x40w exciters (DAEX30HESF-4) per plate because that is the most powerful exciters I could find with low HF inductance, and hence good FR. Using amps that should deliver double that in RMS I pushed them to the max for many hours on end and the exciters didn't even get lukewarm and plates held up sounding clear and undistorted.

I'm not sure it seems worth using even more exciters per plate, so unless you can find exciters that can handle more power, I would say total rated power of 160w RMS per plate is the maximum, but you can probably push them harder than rating.

I will follow your advice for exciters, if there are no more powerful. Then if all goes well I would like to get a suitable amplifier with DSP to equalize the whole thing. I accept any suggestions

pixel1the thickness of the carbon is 0.3mm + HoneyComb 3mm, I paid 85 euros.

I agree with Leob that the skins should only be a few tenths of mm thick. So yours may indeed be a good find. Did you buy it online, and if so, do you have a link you could share? I'd be interested to see if they give any more details (density, etc).

Eric

Mostly I've been building individual speakers as one-off prototypes that get mesaured and then disassembled. But I decided I like the "high aspect ratio" concept enough to go ahead and build up a permanent pair. The main objective really was just to make a pair of working speakers for my basement speaker "lab". Since they werent going to be "on display" in our main living area, my original plan was to not work too hard on the finishing/woodworking aspects, and just kind of throw together a half decent looking pair. In the end, however, I spent a lot more time on the finishing aspects, and now I'm not sorry I did since I'm pretty pleased with how they turned out.

Eric

Here are a few pics from the construction:

Eric

Here are a few pics from the construction:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker