Definitely meant XPS. Not sure what happened there. I really liked 1" XPS 12x12" panels for mids and highs when I was experimenting with early builds. Good clarity, almost like 3mm Ply but more open and much higher output, and less raspy than double wall cardboard. I made some 2 way panels with a 15w XPS top and a 30 watt 2" EPS lower panel for extended midbass response and I liked them pretty well. Ended up using the Birch Ply for my final build because the tonal quality was worth the trade for efficiency. I would be down to use smaller Ply panels but I know XPS is far more sensitive. Balsa may hit a middle ground between tone and efficiency... Anyway, I'll look into CF. I recall someone got excellent results bonding CF fabric to cardboard and using 2 part epoxy as a coating. That may be an option too.NG,

Did you mean "XPS" instead of "XPL"?

I'm not a big fan of the sound of extruded or expanded PS (XPS or EPS) for DMLs, but I suspect they might be your best bet for this application. It might be possible too with some fancy carbon fiber honeycomb core panel, but also probably not anything you could buy "off the shelf".

Eric

NG.

On my post 3410 i made recordings of two test eps panels, I thought the sound was quite remarkable.

Do you think these panels have a bad tone to them ?

Don't forget to use a good set of headphones when listening.

Eps has a higher frequency response than xps,at least 10k and that is with the very low grades, the HD grade will go up to 20k.

I have not found a material that has a higher efficiency than the eps , I used to run my very large 1inch panels with a 3watt digital amp chip from a 5volt supply.

I had no problems with my 10watt valve amp.

Or my 8watt or less digital amp that I am still using, which I have to turn all The way down when using eps.

The lower grades are more efficient but need a bit of work to improve the hf.

the epoxy 5mm xps works well but is less efficient.

I have been wondering how well the 1cm eps panel would sound with the epoxy treatment ?

but I would expect the efficiency to suffer.

that would be another future project 😁

Steve.

On my post 3410 i made recordings of two test eps panels, I thought the sound was quite remarkable.

Do you think these panels have a bad tone to them ?

Don't forget to use a good set of headphones when listening.

Eps has a higher frequency response than xps,at least 10k and that is with the very low grades, the HD grade will go up to 20k.

I have not found a material that has a higher efficiency than the eps , I used to run my very large 1inch panels with a 3watt digital amp chip from a 5volt supply.

I had no problems with my 10watt valve amp.

Or my 8watt or less digital amp that I am still using, which I have to turn all The way down when using eps.

The lower grades are more efficient but need a bit of work to improve the hf.

the epoxy 5mm xps works well but is less efficient.

I have been wondering how well the 1cm eps panel would sound with the epoxy treatment ?

but I would expect the efficiency to suffer.

that would be another future project 😁

Steve.

Thanks, Steve. Your results are interesting. I think I got opposite results. I'll have to see if I can dig up the screenshots.NG.

On my post 3410 i made recordings of two test eps panels, I thought the sound was quite remarkable.

Do you think these panels have a bad tone to them ?

Don't forget to use a good set of headphones when listening.

Eps has a higher frequency response than xps,at least 10k and that is with the very low grades, the HD grade will go up to 20k.

I have not found a material that has a higher efficiency than the eps , I used to run my very large 1inch panels with a 3watt digital amp chip from a 5volt supply.

I had no problems with my 10watt valve amp.

Or my 8watt or less digital amp that I am still using, which I have to turn all The way down when using eps.

The lower grades are more efficient but need a bit of work to improve the hf.

the epoxy 5mm xps works well but is less efficient.

I have been wondering how well the 1cm eps panel would sound with the epoxy treatment ?

but I would expect the efficiency to suffer.

that would be another future project 😁

Steve.

I tested several thicknesses of EPS and XPS, with various levels of 50/50 water/glue treatment on them and I really liked them for midrange and midbass, but to my ear the XPS gave better clarity and detail in the upper mid and high range, and a tonal quality I preferred. Not to say the EPS was bad but I preferred the XPS. They seemed to RTA about the same across the middle as I recall, but the XPS got better top extension and the EPS got better bottom. Seeing as I was going to run a 2.1 I figured highs were more valuable.

Good to know that 3wRMS will be adequate with the right design. Thanks again.

Also, personally I would not go any smaller than my 10watt 25mm exciters , I would think that the 25watt exciter would be quite similar to mine.

I believe tectonic are still selling them ?

You need to be able to drive the panel properly, and some of those smaller exciters look and feel a bit toy like.

I have a small exciter somewhere which would be ok for something like a talking clock, but thats about it.

Steve.

I believe tectonic are still selling them ?

You need to be able to drive the panel properly, and some of those smaller exciters look and feel a bit toy like.

I have a small exciter somewhere which would be ok for something like a talking clock, but thats about it.

Steve.

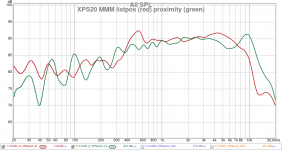

Hey Steve. Here are the graphs I found. Taken at center, on axis at 1m with a Dayton IMM-6. Extremely similar results but the XPS had better clarity and tone to my ear. I think these were all untreated at time of testing.

Anyway, I ended up using 3mm Birch Ply and different exciters for my "final" build anyway.

NG.

I have not personally tested 1inch xps, only the 5mm.

but all the response plots of xps I have seen show early roll off ?

that is why I use epoxy on the 5mm xps, which brings up the high frequency response.

I'm afraid I am at a loss as to the opposite responses you seem to be getting ?

strange ?

Steve.

I have not personally tested 1inch xps, only the 5mm.

but all the response plots of xps I have seen show early roll off ?

that is why I use epoxy on the 5mm xps, which brings up the high frequency response.

I'm afraid I am at a loss as to the opposite responses you seem to be getting ?

strange ?

Steve.

Good to know. I may try the amp on my existing panels then, just for grins. I'm new to the world of such low wattage and was afraid of being underpowered. I was looking at the 3w tectonics (TEAX19C01) and figured that I could always run multiples per panel if a single wasn't enough. These will be a small bookshelf size so I'm not expecting low extension without going point 1, but I would like reasonable output and good clarity.Also, personally I would not go any smaller than my 10watt 25mm exciters , I would think that the 25watt exciter would be quite similar to mine.

I believe tectonic are still selling them ?

You need to be able to drive the panel properly, and some of those smaller exciters look and feel a bit toy like.

I have a small exciter somewhere which would be ok for something like a talking clock, but thats about it.

Steve.

I think the "thick" was 1" Home Depot builder's grade XPS and 1" good craft grade EPS, and the "thin" was 1/2" or 5/8" EPS. This was before I got my 1/2" XPS, which sounded even better to my ear.NG.

I have not personally tested 1inch xps, only the 5mm.

but all the response plots of xps I have seen show early roll off ?

that is why I use epoxy on the 5mm xps, which brings up the high frequency response.

I'm afraid I am at a loss as to the opposite responses you seem to be getting ?

strange ?

Steve.

Apart from the thin eps the thicker eps and xps seem to roll off well before 8k ?

It's a little difficult to see with the 15db segments.

Interesting.

Steve.

It's a little difficult to see with the 15db segments.

Interesting.

Steve.

Yeah, they all roll off about 8 but the XPS dips less then rebounds from 12-16 or so.Apart from the thin eps the thicker eps and xps seem to roll off well before 8k ?

It's a little difficult to see with the 15db segments.

Interesting.

Steve.

NG.

the way I look at the plot ,the downward trend starts just above the 4k mark ,strangely the 10k ish exciter and panel resonance peak does not seem to appear on the thin eps.?

The peak is more pronounced on the thick eps ?

Steve.

the way I look at the plot ,the downward trend starts just above the 4k mark ,strangely the 10k ish exciter and panel resonance peak does not seem to appear on the thin eps.?

The peak is more pronounced on the thick eps ?

Steve.

When I finally get back to my old eps panels, it will be interesting to see what new upgrades will work with them, what size and finally what grade I will prefer ? pva or epoxy ?

there are too many types of panels ,let alone what you can do to them.

I need to be more focused .

Steve.

there are too many types of panels ,let alone what you can do to them.

I need to be more focused .

Steve.

NG.

as you say the 1inch eps and xps panels seem to match quite well in the grahp.

which leads me to think the roll off is more to do with the exciter roll off response, not the panels ?

your xps plots are the best I've seen ,does any one else have response plots of 1inch xps that reach 10k or 20k without the usual roll off ?

Just curious.

Steve.

as you say the 1inch eps and xps panels seem to match quite well in the grahp.

which leads me to think the roll off is more to do with the exciter roll off response, not the panels ?

your xps plots are the best I've seen ,does any one else have response plots of 1inch xps that reach 10k or 20k without the usual roll off ?

Just curious.

Steve.

Thanks. Probably just dumb luck? I don't recall if I was using the DAEX25QLP-4 or the DAEX32EP-4 exciters for those tests. I think the panels were cut relatively small, like 12"x24", max. Basic 2/5, 3/5 placement with no frame or damping or anything yet. I think they were just freestanding with some small clamps at the base. This was early on when I was still gathering and testing like 15 substrates. 😅NG.

as you say the 1inch eps and xps panels seem to match quite well in the grahp.

which leads me to think the roll off is more to do with the exciter roll off response, not the panels ?

your xps plots are the best I've seen ,does any one else have response plots of 1inch xps that reach 10k or 20k without the usual roll off ?

Just curious.

Steve.

NG.

I know that if I place my 10watt 25mm exciter on a wide band frequency panel I will get a full near field response of 20hz to 20k at least.

some or all of the 32mm ? are a little suspect ?

it is interesting how we all like different sounding panels eps, xps ,ply ,plexiglass,metal,CF. We design for our own tastes in music, and what we can live with ,with the self noise of the panel materials.

eps can sound bright and fast like a horn, heavier panels can sound soft ,slow or hard depending on materials.

eps needs to have its self noise reduced as much as possible(as do all panels) also the exciter noise comes through quite strongly ,the up side is the exciter does not have to work so hard to drive the panel.

Thinking about it ,I have spent a lot of time trying to sort out exciter problems just as much as panel problems, and the combination of the two.

It's difficult to generalise about the sound of a panel with different exciters and panels and treatments, there are too many variables.

The exciter is a major problem when it comes to panel sound ,and should be examined and put to the test more than it is at the moment.

Steve.

I know that if I place my 10watt 25mm exciter on a wide band frequency panel I will get a full near field response of 20hz to 20k at least.

some or all of the 32mm ? are a little suspect ?

it is interesting how we all like different sounding panels eps, xps ,ply ,plexiglass,metal,CF. We design for our own tastes in music, and what we can live with ,with the self noise of the panel materials.

eps can sound bright and fast like a horn, heavier panels can sound soft ,slow or hard depending on materials.

eps needs to have its self noise reduced as much as possible(as do all panels) also the exciter noise comes through quite strongly ,the up side is the exciter does not have to work so hard to drive the panel.

Thinking about it ,I have spent a lot of time trying to sort out exciter problems just as much as panel problems, and the combination of the two.

It's difficult to generalise about the sound of a panel with different exciters and panels and treatments, there are too many variables.

The exciter is a major problem when it comes to panel sound ,and should be examined and put to the test more than it is at the moment.

Steve.

Steve,NG.

as you say the 1inch eps and xps panels seem to match quite well in the grahp.

which leads me to think the roll off is more to do with the exciter roll off response, not the panels ?

your xps plots are the best I've seen ,does any one else have response plots of 1inch xps that reach 10k or 20k without the usual roll off ?

Just curious.

Steve.

Below are measurements I made with a 125x60cm XPS panel, 20mm thick. Watered PVA coating + watered white acrylic paint on the front face. The thickness at the exciter axis was reduced (see picture) to reduce the treble (too harsh before that), the exciter is Dayton Audio DAEX25FHE-4.

So in my experience no lack of treble with XPS 20mm (density 31kg/m3, mu after coating 0,8kg/m², D bending stiffness 22Nm - was 18Nm for the raw XPS).

As you mentioned I think it is to check the exciter. I have no experience with other exciters but the reasons of my choice of the Dayton Audio DAEX25FHE-4 are a low voice coil mass, low inductance which could be reason with other exciters of a more limited bandwith ?

Christian

Attachments

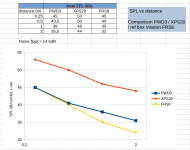

I measured a difference of about 9bB between a 3mm poplar plywood and a 20mm XPS. So the 3mm poplar ply is comparable to a 82dB standard loudspeaker and the XPS to a 91dB. I suspect a birch ply to be less efficient (heavier)....Ended up using the Birch Ply for my final build because the tonal quality was worth the trade for efficiency. I would be down to use smaller Ply panels but I know XPS is far more sensitive. Balsa may hit a middle ground between tone and efficiency...

A big difference between DML and a standard loudspeaker is the sound field decreases more slowly; a bit like a line array so an additional gain of about 3dB can be expected at the listening position.

Attached those measurements : pink noise at different distances for a 20mmXPS (125x60cm) panel, a 3mm poplar ply (120x45cm), a Visaton FRS8 speaker in a 1.2l closed box (I used it as a kind of reference).

I saw in different post the idea of panel made from balsa. I am interested by this idea. Does somebody have experience, construction ideas? Which balsa? which direction for the wood grain?...

Christian

Attachments

I think I hit the end of the road with DMLs for now. Just connected my 2nd pair of ceiling panels and I'm just not happy with the sound or measurements. Very interested in the GRS planar tweeters + high Qts big woofers in an OB setup. I have the space for the big baffes so I think I'm just gonna try it. Would be great if I could do away with EQing and my sub as well... just want a simple system. A little bummed but also excited for another project... just don't have the appetite for constant experimentation/tweaking.

Has anyone tried putting a DML panel in a box?

Even if there is no “short circuit” to box in, a cavity resonator would help to up the bass without excessively large panels.

Even if there is no “short circuit” to box in, a cavity resonator would help to up the bass without excessively large panels.

There was definitely a noticeable loss in sensitivity between the Ply and either of the polystyrenes but the warmth and tone of the Ply along with high detail was worth the tradeoff to me. Once I decided on the tone I liked it took a lot of experimenting with panel size, mounting type and damping to get a final result I was happy with. I ended up using a 12x30" panel, following burntcoil's Tall Blonde model, along with 25mm exciters. That was the best balance of practical size, efficiency, and FR for me, my listening room/acoustics, wattage available, etc. So many variables.I measured a difference of about 9bB between a 3mm poplar plywood and a 20mm XPS. So the 3mm poplar ply is comparable to a 82dB standard loudspeaker and the XPS to a 91dB. I suspect a birch ply to be less efficient (heavier).

A big difference between DML and a standard loudspeaker is the sound field decreases more slowly; a bit like a line array so an additional gain of about 3dB can be expected at the listening position.

Attached those measurements : pink noise at different distances for a 20mmXPS (125x60cm) panel, a 3mm poplar ply (120x45cm), a Visaton FRS8 speaker in a 1.2l closed box (I used it as a kind of reference).

I saw in different post the idea of panel made from balsa. I am interested by this idea. Does somebody have experience, construction ideas? Which balsa? which direction for the wood grain?...

Christian

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker