if it is so difficult to measure to the point that not even companies have been able to define a model, then it is not convenient to just say so it sounds so it does not sound in short if the system is chaotic using the empirical model is the best thing. I reduce them I complain the panel. Gentlemen we do not make a case of it an important one let's just make us like it

let's just make us like it[/QUOTE]

I had trouble understanding your last post,(lost in translation)

But I'll go with "let's just make us like it"😀

Steve.

I had trouble understanding your last post,(lost in translation)

But I'll go with "let's just make us like it"😀

Steve.

I am aware of the translation

I just wanted to say

if you like this type of speaker, why are you measuring them just listen to your ears

I just wanted to say

if you like this type of speaker, why are you measuring them just listen to your ears

Pixel1.

So far I have not used EQ (except in testing sometimes) to permanently correct a panel response.

I have not needed to because I've managed to get the sound and luckily the response how I want them from the start .

It has taken a lot of time and effort to understand how to do this.

Some are using too much EQ to correct a poorly designed and matched panel,

If you compound this by measuring from a single point in front of the panel and then EQ ing using this response,you could be making matters worse.

I personally ,prefer to try to make panels that have a good sound and hopefully good response without the need for EQ.

If it's not broken ,don't fix it.

Steve.

So far I have not used EQ (except in testing sometimes) to permanently correct a panel response.

I have not needed to because I've managed to get the sound and luckily the response how I want them from the start .

It has taken a lot of time and effort to understand how to do this.

Some are using too much EQ to correct a poorly designed and matched panel,

If you compound this by measuring from a single point in front of the panel and then EQ ing using this response,you could be making matters worse.

I personally ,prefer to try to make panels that have a good sound and hopefully good response without the need for EQ.

If it's not broken ,don't fix it.

Steve.

I am in total agreement with you, on everything.

I will do my tests using your experience but I don't want to go crazy with electronic adjustments and corrections.

I will do my tests using your experience but I don't want to go crazy with electronic adjustments and corrections.

Pixels.

Which material and thickness are you going to experiment with first.?

And what size ?

You have ordered a very powerful and quite heavy exciter.

Steve.

Which material and thickness are you going to experiment with first.?

And what size ?

You have ordered a very powerful and quite heavy exciter.

Steve.

I was just on the parts express site and noticed the pdf specifications for the Dayton exciters were measured on a 1/2inch foamcore board in an infinite baffle box!

And not plain xps .

Lordtarquin.

I suddenly realised that I'm a little confused as to which material you were measuring ?

Was it the 25mm x60x40cm hd eps?

Steve.

And not plain xps .

Lordtarquin.

I suddenly realised that I'm a little confused as to which material you were measuring ?

Was it the 25mm x60x40cm hd eps?

Steve.

Lordtarquin.

Also how many sets of exciters do you have to experiment with?

And also for comparison purposes.

Steve.

Also how many sets of exciters do you have to experiment with?

And also for comparison purposes.

Steve.

I was thinking of sizes like 60x40 cm, tectonic uses carbon fiber with honeycomb, I believe in aluminum, but before spending those figures I wanted to try some kind of different material but I don't know yet

Pixel1.

This will be my last recordings of ply panels.

2 recordings fullrange and 2 recording using the dav 550 with sub.

The last is classical violin for lordtarquin

As you know, ply is not my first choice of panel material .

Heavy panels tend to sound restrained and lacking life (in my opinion anyway ).

You need to make experiments for yourself and make your own choices.

Steve.

This will be my last recordings of ply panels.

2 recordings fullrange and 2 recording using the dav 550 with sub.

The last is classical violin for lordtarquin

As you know, ply is not my first choice of panel material .

Heavy panels tend to sound restrained and lacking life (in my opinion anyway ).

You need to make experiments for yourself and make your own choices.

Steve.

Attachments

I should have mentioned that I moved the panels further into the room by about 2 or so feet.

To clean up the sound a bit.

Steve.

To clean up the sound a bit.

Steve.

Pixel1.

It is difficult to tell which exciter is best from parts express as all the measurements are done on xps.

Xps seams to have a poor mid to high response,rolling off very early,so I can't tell what the hf response is for the exciter?

If someone has a good response plot of xps without eq this would be very helpful.

I believe the 25mm coil is supposed to have better hf than the 30mm coil but this needs to be confirmed?

Steve.

Not trying to be a contrarian but I have found XPS to have excellent mid to mid-high response, especially when sanded and glue treated 1:1. This is 1/2" R3 XPS, mind you. The timbre isn't as warm as say 3mm birch but the clarity and efficiency is fantastic. I use 10w 25mm drivers on 12x9.5 panels and think they sound great. Thicker panels and larger ones definitely take a hit, though. And regardless they do seem to dip pretty significantly above 8k then peak back a bit above 12. At least in my experience. In the end it all comes down to the combination of driver, material dimensions, prep, and mounting, so my experiences can certainly differ from yours.

Hi everyone, a total beginner, here, but I've learned so much from all of you. I have a long way to go too. For my first dive in, I'm planning (everything ordered, wicked excited!) the now seemingly old fashioned shellacked cardboard panels. After that, it's the canvas panels that OffTheGridKindaGuy champions/championed.

In the meantime, I wanted to get your take on something. I decided to search around after reading about the constant challenge of a bass sound with any heft, and came upon this:

It reads a bit like a class experiment in getting bass flat panel speakers rather than anything scientific, but it's still interesting. Their goal was to "create a bass panel with a natural resonance at 40Hz and at mode 1. The idea behind this was to disperse this low end frequency at 180 degrees throughout a room." They used 3 magnetic transducers on a polypropylene sheet 490mm by 600mm, and declared their project a success.

Any thoughts about technique and/or materials?

In the meantime, I wanted to get your take on something. I decided to search around after reading about the constant challenge of a bass sound with any heft, and came upon this:

It reads a bit like a class experiment in getting bass flat panel speakers rather than anything scientific, but it's still interesting. Their goal was to "create a bass panel with a natural resonance at 40Hz and at mode 1. The idea behind this was to disperse this low end frequency at 180 degrees throughout a room." They used 3 magnetic transducers on a polypropylene sheet 490mm by 600mm, and declared their project a success.

Any thoughts about technique and/or materials?

Negativeghostrider

I have only ever used 5mm xps about 900x600mm in size.

The response if I remember rightly extended well beyond 10k before gently rolling off.

My query was with measurements (not mine)that showed very early roll offs such as 2and3k?

On the last page I corrected that dayton use 1/2 inch xps for the response test ,it is actually a type of 1/2 inch foamcore in an infinite baffle ?

I think we are in agreement that thicker xps has a tendency to roll off earlier? ,it is the same with eps ,but less severe.

Steve

I have only ever used 5mm xps about 900x600mm in size.

The response if I remember rightly extended well beyond 10k before gently rolling off.

My query was with measurements (not mine)that showed very early roll offs such as 2and3k?

On the last page I corrected that dayton use 1/2 inch xps for the response test ,it is actually a type of 1/2 inch foamcore in an infinite baffle ?

I think we are in agreement that thicker xps has a tendency to roll off earlier? ,it is the same with eps ,but less severe.

Steve

Measuring DMLs driven by Hypex plate amps

Those who have follow know that I assembled a pair of DMLs guided by the generous thought and discussion herein.

You can find discussion and pictures of the speakers over the past couple of months in the thread.

It has now come time to measure speakers.

See attached overview of what I have put together to use on this.

Equipment includes:

Software:

The REW help files state:

So I think I've got that part of the configuration right.

Theoretically, (I think) REW should have the ability to send signals through the Mac Pro to the FA 123s and the microphone can pick up the signal?

But, this doesn't seem to work.

Maybe some issue with the "computer audio" setup?

Thoughts and suggestions of how to go about this appreciated.

Those who have follow know that I assembled a pair of DMLs guided by the generous thought and discussion herein.

You can find discussion and pictures of the speakers over the past couple of months in the thread.

It has now come time to measure speakers.

See attached overview of what I have put together to use on this.

Equipment includes:

Behringer ECM800 microphone (mounted on a tripod)

Behringer U-PHORIA UMC22 microphone preamp connected by USB to ...

MacPro (this also serves as my music server) connected by optical audio to ...

Hypex FA123 amps (bridged teach operate in mono), which drive the ...

DMLs (w/aluminum honeycomb panels)

Behringer U-PHORIA UMC22 microphone preamp connected by USB to ...

MacPro (this also serves as my music server) connected by optical audio to ...

Hypex FA123 amps (bridged teach operate in mono), which drive the ...

DMLs (w/aluminum honeycomb panels)

Software:

REW, which I have this installed on both the Mac Pro and my Windows laptop running the ...

Hypex Filter Design app.

Hypex Filter Design app.

The REW help files state:

"Connections

... If you are using a USB microphone you do not need to make any connections to the soundcard inputs, just connect the mic to a USB port on your computer."

... If you are using a USB microphone you do not need to make any connections to the soundcard inputs, just connect the mic to a USB port on your computer."

So I think I've got that part of the configuration right.

Theoretically, (I think) REW should have the ability to send signals through the Mac Pro to the FA 123s and the microphone can pick up the signal?

But, this doesn't seem to work.

Maybe some issue with the "computer audio" setup?

Thoughts and suggestions of how to go about this appreciated.

Attachments

Can you make a audio file with your phone and upload it? At a normal distance, where you sit? Like to get the subjective feeling of your speakers. 🙂

Color me embarrassed, everyone. Here's the link to the article/study/experiment I mentioned above. Any reactions appreciated.

I shall apply a second coat of embarrassment.Color me embarrassed, everyone. Here's the link to the article/study/experiment I mentioned above. Any reactions appreciated.

Test-Setup Draft on Canvas DMLs

Hi fellows,

After reading through the whole thread, I am so excited to finally start my own basic testing on OffGridKindaGuy's Canvas DML Design.

I am really grateful about you guys sharing your knowledge and helping me in this process!

Being fairly new to loudspeaker building, I am trying to come up with a test-setup that gives me a basic understanding of core principles, meaningful correlations and data.

To reduce complexity, I first just want to focus on the wooden material - birch plywood.

----------------------

Test-Goal:

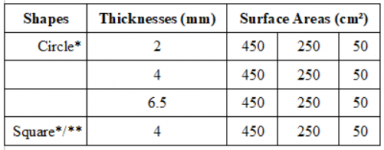

Basic understanding of the correlation of different Shapes, Thicknesses & Surface Areas of birch plywood; see table.PNG

as well as

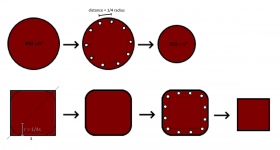

* without & with holes (Ø 6mm, 1/4 radius-distance apart) drilled into the surface area that is to be cut off for the next surface area reduction

** square & rounded (r = 1/4 side length) corners

see shapes.png

on SPL(@2.83V & 1m), Frequency Response, Impulse Response, Spectral Decay

Test-Assumptions:

Panel: freely suspended

Exciter:

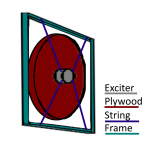

see panel.png

Hardware-Setup:

UMIK-1 (Microphone) - Laptop (REW) - USB Audio Interface UCA222 + SPDIF Cable - Hifiberry Dac+ DSP (stacked ontop of a Raspberry Pi 3B) - Amp: Wondom AA-AB32178 - Exciters: 4* Dayton DAEX25FHE-4

REW Measurements of Exciter-Plywood Performance:

What do you guys think about this setup? Anything I should change or add to it?

Regards, Bern

Hi fellows,

After reading through the whole thread, I am so excited to finally start my own basic testing on OffGridKindaGuy's Canvas DML Design.

I am really grateful about you guys sharing your knowledge and helping me in this process!

Being fairly new to loudspeaker building, I am trying to come up with a test-setup that gives me a basic understanding of core principles, meaningful correlations and data.

To reduce complexity, I first just want to focus on the wooden material - birch plywood.

----------------------

Test-Goal:

Basic understanding of the correlation of different Shapes, Thicknesses & Surface Areas of birch plywood; see table.PNG

as well as

* without & with holes (Ø 6mm, 1/4 radius-distance apart) drilled into the surface area that is to be cut off for the next surface area reduction

** square & rounded (r = 1/4 side length) corners

see shapes.png

on SPL(@2.83V & 1m), Frequency Response, Impulse Response, Spectral Decay

Test-Assumptions:

- SPL

- the bigger the surface area, the more SPL

- the thinner the plywood, the more SPL

- circular < rectangular shape

- Frequency Range

- the smaller the surface area, the higher the low frequency roll-off

- the smaller the surface area, the higher the high frequency roll-off

- the thinner the plywood, the lower the high frequency roll-off

- the thinner the plywood, the lower the low frequency roll-off

- circular < rectangular shape

- higher high frequency roll-off for rounded corner rectangles than the other shapes

- Spectral Decay

- the smaller the surface area, the shorter the spectral decay

Panel: freely suspended

Exciter:

- 'top-heavy' therefore mounted to frame with strings

- attached dead-center onto plywood panel with adhesive tape pulled off and using superglue

- Break-In: around 20 hours with a high-pass filter @200Hz

- half-way between floor and ceiling to maximize the delay of 1st room reflection

see panel.png

Hardware-Setup:

UMIK-1 (Microphone) - Laptop (REW) - USB Audio Interface UCA222 + SPDIF Cable - Hifiberry Dac+ DSP (stacked ontop of a Raspberry Pi 3B) - Amp: Wondom AA-AB32178 - Exciters: 4* Dayton DAEX25FHE-4

REW Measurements of Exciter-Plywood Performance:

- gated Measurements before & after Exciter Break-In on

- SPL (@2.83V & 1m), Frequency Response, Impulse Response, Spectral Decay

What do you guys think about this setup? Anything I should change or add to it?

Regards, Bern

Attachments

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker