Stimper,

I'm interested to hear more details, about both your construction and your results. I have been playing around myself with CF and Fiberglass skins over various lightweight cores. And coincidentally based on the DML-10 dimensions (approximately at least). Shortly I plan to build up a plate with CF skins (3K twill weave, 200g/m2,.010" thick) over 1/16" basla.

What are your CF skins? Thickness, weave, layup, etc? Are you making them yourselves or buying premade plates? They look great! How are you adhering them to the nomex? What nomex are you using (thickness/density/source)? I have some of the 1/8" 3.0 lb nomex from Composite Envisions. So far I've only tried it between skins of wood veneer. But I didn't know how to properly glue the veneer to the nomex and it turned out way too heavy and not fully adhered so it was a poor test. I have been thinking about trying the nomex with carbon skins myself, but haven't gotten around to that yet. So I'm really interested to hear how it goes for you.

Thanks,

Eric

Hi Valerie,

I attempted to make my own spread tow fibre sheet, from a single ply but I didn't use enough epoxy and it didn't have finished surface. Also, the spread tow came apart leaving tiny gaps. Ifi had made it 2 ply, this would have avoided the gaps and 2nd attempt I would have used more 2 part epoxy. It's a pity, as I think the spread tow carbon fibre would have been better as it is thinner, but reckon you need to use a vacuum pump to evenly distribute the epoxy to ensure a clean finished side.

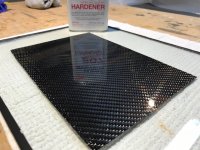

Because of this, undecided to buy some premade carbon fibre sheet, 0.25 thick.as per the below link:

Real Carbon Fibre Veneer Sheet 0.25mm - Easy Composites

I used nomex 3.2mm cell, 29kg, 3mm honeycomb, as per below:

3.2mm Cell 29kg/m3 Nomex Honeycomb Core; 2mm, 3mm - Easy Composites

And I used ET515 2part epoxy, which apparently is semi flexible. I had ordered et538 2 part epoxy, but was supplied ET515. I would make sure to use ET538 for future bonding, as reckon high frequency might have been compromised with the semi flexible 2 part epoxy.

I basically just applied the expoxy to the back of the carbon fibre panel, then laid the honeycomb on top. Then put some wood over the top and weighed it down with some heavy monitor speakers. Then repeated the process for the 2nd skin 24 hours later.

I made the mistake of not protecting the finished carbon fibre by covering it with tape and some film, which was a pain to get the epoxy off afterwards, so I would make sure to do that on any future panels. I didn’t expect it to get so messy when you run against the clock to get it out together.

You can do both sides at the same time, but I was running out of time faffing about getting one skin on. I reckon I could get both skins done on one go next time.

The panel with only one skin seemed really flimsy, but once the 2nd skin was on it became solid.

If you have any questions, give me a shout. It was pretty straight forward to do.

I would add that the carbon fibre sheet supplied does come with a protective backing, but you actually need to pull it off with quite a bit of force, so recommend removing this first, then put on some kind of protection form any adhesive.

I also used acetone to clean the carbon fibre panel before applying the adhesive.

Note, one side of the panel needs to be roughed up, this wasn’t necessary on the sheets I bought, as one side had a peel ply face ready for bonding.

I also used acetone to clean the carbon fibre panel before applying the adhesive.

Note, one side of the panel needs to be roughed up, this wasn’t necessary on the sheets I bought, as one side had a peel ply face ready for bonding.

Attachments

For info, the carbon fibre sheet didn’t have the 3m backing, and was plain. If this was used instead of adhesive, the panel wouldn’t be stiff and would be able to bend.

I just regret not sending the semi flexible adhesive back.

I just regret not sending the semi flexible adhesive back.

I contacted an Anima installer about them fixing the panels to wood. On their video they show that the panels are fitted with a 3m backing, and they said they no longer recommended this as high frequency was lost and now they use a 2 part epoxy adhesive.

I'm curious to see if you get a better high frequency using carbon fibre and aluminium honeycomb core. The Nomex does dampen the CF well, as I did buy a premade composite panel from easy composites with a foam core, but this ringed too much and easy composites kindly agreed to return the panel. Not sure if aluminum will ring or not. If I order the aluminium panel I'll have plenty to test a few materials and also have enough CF to make up a smaller panel which will be just under 500x400mm.

Easy composites have been really helpful with advice on making up wet lay CF and for making up my Nomex and CF panels. FYI, I have no connection to easy composites in UK.

I put 4-off Dayton 25mm exciters on the panel to test, but I think 2-off them are damaged so will redo with 2 exciters and will post results using REW. The panels do start dropping off around 10k. I'm also using a double sided tape to temp fix the exciters, so I'm sure this along with the Flexi adhesive is effecting the high frequency.

I'm curious to see if you get a better high frequency using carbon fibre and aluminium honeycomb core. The Nomex does dampen the CF well, as I did buy a premade composite panel from easy composites with a foam core, but this ringed too much and easy composites kindly agreed to return the panel. Not sure if aluminum will ring or not. If I order the aluminium panel I'll have plenty to test a few materials and also have enough CF to make up a smaller panel which will be just under 500x400mm.

Easy composites have been really helpful with advice on making up wet lay CF and for making up my Nomex and CF panels. FYI, I have no connection to easy composites in UK.

I put 4-off Dayton 25mm exciters on the panel to test, but I think 2-off them are damaged so will redo with 2 exciters and will post results using REW. The panels do start dropping off around 10k. I'm also using a double sided tape to temp fix the exciters, so I'm sure this along with the Flexi adhesive is effecting the high frequency.

I would add that the carbon fibre sheet supplied does come with a protective backing, but you actually need to pull it off with quite a bit of force, so recommend removing this first, then put on some kind of protection form any adhesive.

I also used acetone to clean the carbon fibre panel before applying the adhesive.

Note, one side of the panel needs to be roughed up, this wasn’t necessary on the sheets I bought, as one side had a peel ply face ready for bonding.

I found in Australia this supplier of fibre glass products.

Charcoal.

I should have also pointed out that the small panel was made from a card beer mat I picked up in Brugge.

My second picture is of a panel I made out of a papier mache egg carton.

The circular mat I picked up at an audio show,thought it would look good(a record playing music)on the wall.

You don't have to use vastly expensive materials to produce great sounds,pulped paper has been used for cone drivers for good reasons.

Thin card is very light and fairly rigid and does not need any support,just glue the card to the exciter and mount your exciter to whatever ,and that's it.

Another good reason not to use over sized panels is to help reduce colorations .

Steve

I should have also pointed out that the small panel was made from a card beer mat I picked up in Brugge.

My second picture is of a panel I made out of a papier mache egg carton.

The circular mat I picked up at an audio show,thought it would look good(a record playing music)on the wall.

You don't have to use vastly expensive materials to produce great sounds,pulped paper has been used for cone drivers for good reasons.

Thin card is very light and fairly rigid and does not need any support,just glue the card to the exciter and mount your exciter to whatever ,and that's it.

Another good reason not to use over sized panels is to help reduce colorations .

Steve

Attachments

I recently found 2 aluminum honey comb panels on the street in Manhattan.

70 3/4" x 28 1/4" x 1/4"

The came from a high-end kitchen store.

They have a beautiful satin finish, probably some kind of polymer on the aluminum.

They additionally appear to have an internal frame around the edge.

Light weight. Very rigid.

Would these work?

Recommended exciter?

They would make some very cool monolithic DML's

70 3/4" x 28 1/4" x 1/4"

The came from a high-end kitchen store.

They have a beautiful satin finish, probably some kind of polymer on the aluminum.

They additionally appear to have an internal frame around the edge.

Light weight. Very rigid.

Would these work?

Recommended exciter?

They would make some very cool monolithic DML's

Attachments

Last edited:

aagas.

Mmmmmmm a freebie,a man after my own heart.

Unless someone else has tried this material it is very difficult to predict how it will sound.

I would class this as a heavy material like the podiums speaker,or a 3mm ply,so would expect a similar sort of sound?

As such ,I would use ONE of the higher powered exciters ,to start with,to check how it sounds.

Have you tried placing a magnet on the panel to make sure it is pure aluminium(to make sure the exciter is not attracted to the panel).

Hope all goes well.

Steve.

Mmmmmmm a freebie,a man after my own heart.

Unless someone else has tried this material it is very difficult to predict how it will sound.

I would class this as a heavy material like the podiums speaker,or a 3mm ply,so would expect a similar sort of sound?

As such ,I would use ONE of the higher powered exciters ,to start with,to check how it sounds.

Have you tried placing a magnet on the panel to make sure it is pure aluminium(to make sure the exciter is not attracted to the panel).

Hope all goes well.

Steve.

spedge

You wouldn't believe the things I find in Manhattan!

Non-magnetic confirmed.

Ordered a pair of Dayton Audio DAEX32EP-4 Thruster 32mm Exciters (40W 4 Ohm).

I have a pair of Hypex 3 way amps that I can bridge.

Working out a way to hang/support the panels. First thoughts:

I'll post a drawing later today.

If this makes sense and works, I could support the panels at just 3 points and do so without needing to drill into the panels.

I've got high ceilings and radiators at the base of the wall a few feet behind where I typically place speakers. The radiators set up a convective air current, so if I suspended the panels from the ceiling they would blow about in the wind.

Thoughts?

You wouldn't believe the things I find in Manhattan!

Non-magnetic confirmed.

Ordered a pair of Dayton Audio DAEX32EP-4 Thruster 32mm Exciters (40W 4 Ohm).

I have a pair of Hypex 3 way amps that I can bridge.

Working out a way to hang/support the panels. First thoughts:

- Set the bottom edge of each panel on the points of a pair of speaker spikes (got some of these laying about).

- Then a frame behind the panel from T-slot aluminum (found this too) set several inches behind the panel.

- Horizontal pieces extending forward, just over the aluminum panels, with another speaker spike clamping the panel in place.

I'll post a drawing later today.

If this makes sense and works, I could support the panels at just 3 points and do so without needing to drill into the panels.

I've got high ceilings and radiators at the base of the wall a few feet behind where I typically place speakers. The radiators set up a convective air current, so if I suspended the panels from the ceiling they would blow about in the wind.

Thoughts?

Panel support thoughts attached.

Attachments

Last edited:

aagas,

That works something like 4.53kg/m2 and 7224kg/m3. That is almost 10x the weight of Nomex that are about 80kg/m3. For this size and weight, maybe more than one exciter would be better? I am thinking out loud that with more exciters, to have it be-amped with one or two 4 channel amp and some of the exciters to be used with a hi-pass filter only for the high frequencies - either passive or with a DSP.

But with the DMLs it is hard to bring in scientific arguments. Please keep us in the loop, definitely they will look awesome.

That works something like 4.53kg/m2 and 7224kg/m3. That is almost 10x the weight of Nomex that are about 80kg/m3. For this size and weight, maybe more than one exciter would be better? I am thinking out loud that with more exciters, to have it be-amped with one or two 4 channel amp and some of the exciters to be used with a hi-pass filter only for the high frequencies - either passive or with a DSP.

But with the DMLs it is hard to bring in scientific arguments. Please keep us in the loop, definitely they will look awesome.

aagas.

13lb does seem a little heavy.

I have now got a picture in my head of you legging it down a Manhattan street with 26lb of large panels under your arms,with a chef scratching his head wondering where his newly scrubbed panels have gone 😀

😀

It's going to be one of those suck it and see moments when you get your exciters .

I'd suggest using the nxt 3/7x4/9 position for best spread of frequencies.

I presume you do not have any way of measuring the response?

You will probably need a sub of some sort and maybe a tweeter to realise there full potential.

All depending on the internal damping and the weight of the panel material +rigidity.

It will be interesting to hear your thoughts on the sound the panels produce.

All the best .

Steve

13lb does seem a little heavy.

I have now got a picture in my head of you legging it down a Manhattan street with 26lb of large panels under your arms,with a chef scratching his head wondering where his newly scrubbed panels have gone

😀

😀It's going to be one of those suck it and see moments when you get your exciters .

I'd suggest using the nxt 3/7x4/9 position for best spread of frequencies.

I presume you do not have any way of measuring the response?

You will probably need a sub of some sort and maybe a tweeter to realise there full potential.

All depending on the internal damping and the weight of the panel material +rigidity.

It will be interesting to hear your thoughts on the sound the panels produce.

All the best .

Steve

Sonnar/Steve --

I have a pair of Hypex FA123's driving my current system:

FA123 Specs

The FA123 has built in DSP, so easy to setup crossovers and levels of each section.

I could easily use up to 3 exciters per speaker.

I have a microphone and some basic software to measure the system.

Just for you Steve --

Sometime ago, just 1/2 a block away from my loft, I also found a pair of 1/4" x 21" x 52 3/4" white translucent glass table tops. Maybe too narrow from a beaming perspective, but this city just supplies lots of resources ;-)

So I have a few things to try.

More importantly...

I'd like to have a model or explanation of how these things do what they so I could think more clearly and productively about things like:

This topic has lots of great speculation about these kinds of questions and lots of super innovative/imaginative empirical experiments that point to answers.

That said, I don't yet have (in my head) a concise set of:

Can anyone begin to concisely summarize such information?

What we know.

What we think.

What we can/should explore.

Thoughts?

I have a pair of Hypex FA123's driving my current system:

FA123 Specs

Power (4Ω) 2x 125 Wrms + 1x 100 Wrms

Power (8Ω) 2x 75 Wrms + 1x 100 Wrms

Channels 1 channel / 3 way

Power (8Ω) 2x 75 Wrms + 1x 100 Wrms

Channels 1 channel / 3 way

The FA123 has built in DSP, so easy to setup crossovers and levels of each section.

I could easily use up to 3 exciters per speaker.

I have a microphone and some basic software to measure the system.

Just for you Steve --

Sometime ago, just 1/2 a block away from my loft, I also found a pair of 1/4" x 21" x 52 3/4" white translucent glass table tops. Maybe too narrow from a beaming perspective, but this city just supplies lots of resources ;-)

So I have a few things to try.

More importantly...

I'd like to have a model or explanation of how these things do what they so I could think more clearly and productively about things like:

Sizing panels

Shaping panels

Placement of exciters

Types of exciters

Number of exciters

Running exciters in series or parallel

Do I want multiple exciters on a given panel to excite the panel with the same vibrations (maybe not the right word)?

How to approach crossovers for single panels with multiple exciters?

How to think about using different sizes of panels or even different panel materials to assemble multi-panel speakers.

Shaping panels

Placement of exciters

Types of exciters

Number of exciters

Running exciters in series or parallel

Do I want multiple exciters on a given panel to excite the panel with the same vibrations (maybe not the right word)?

How to approach crossovers for single panels with multiple exciters?

How to think about using different sizes of panels or even different panel materials to assemble multi-panel speakers.

This topic has lots of great speculation about these kinds of questions and lots of super innovative/imaginative empirical experiments that point to answers.

That said, I don't yet have (in my head) a concise set of:

Conjectures to deliberately test,

Explanations about what such conjectures mean, or

Practical theory that one could use to model a solution.

Explanations about what such conjectures mean, or

Practical theory that one could use to model a solution.

Can anyone begin to concisely summarize such information?

What we know.

What we think.

What we can/should explore.

Thoughts?

I basically just applied the expoxy to the back of the carbon fibre panel, then laid the honeycomb on top. Then put some wood over the top and weighed it down with some heavy monitor speakers. Then repeated the process for the 2nd skin 24 hours later.

Stimper,

Thanks for sharing the details of your construction. When I tried Nomex (with wood veneer skins in my case), I applied the glue pretty much the same way that you did with the epoxy. But apparently the better way is to spread the glue on a separate temporary sheet (i.e. not your carbon sheet) first, then press the nomex onto the sheet. Then pull the Nomex (and glue) off the temporary sheet and press it onto the carbon sheet. That way you use much less glue and end up with a lighter (and hence more efficient) panel.

The technique is shown in these videos.

Making Guitar Double Tops with Nomex Part 1 - Luthier Tips du Jour Episode 46 - YouTube

Making Guitar Double Tops with Nomex Part 2 - Luthier Tips du Jour Episode 47 - YouTube

The whole thing is pretty interesting, but the note that the details about the adhesive method start about 2 minutes into the second video (Part 2).

I have not tried it myself but I will if I try Nomex again. I have enough leftover for one panel.

Eric

Thanks Eric,

Really interesting videos, especially when it discusses the benefits of nomex.

Only downside, is using a vacuum pump as these are quite expensive. I’m sure you could just weigh it down with something heavy, but risk of not getting a full bond (I’m certainly no expert on this!). I wonder if you could make up a cheap version of a vacuum pump by just connecting a Hoover to the bag? Using one of those adaptors for bags to tightly pack clothes etc that you see on tv adverts late at night!

Really interesting videos, especially when it discusses the benefits of nomex.

Only downside, is using a vacuum pump as these are quite expensive. I’m sure you could just weigh it down with something heavy, but risk of not getting a full bond (I’m certainly no expert on this!). I wonder if you could make up a cheap version of a vacuum pump by just connecting a Hoover to the bag? Using one of those adaptors for bags to tightly pack clothes etc that you see on tv adverts late at night!

Eric / Stimper

3M's VHB (Very High Bond) tape can permanently bond a wide range of materials.

Hardware stores also carry small sheets of this VHB stuff.

I expect that one can get larger sheets commercially.

Perhaps more interesting, can one get the adhesive the 3M uses in the VHB tape that one could apply or spray on directly?

Grainger's has the tape in 12" widths. It comes with and without foam.

A couple of examples...

Also...

3M's VHB (Very High Bond) tape can permanently bond a wide range of materials.

Hardware stores also carry small sheets of this VHB stuff.

I expect that one can get larger sheets commercially.

Perhaps more interesting, can one get the adhesive the 3M uses in the VHB tape that one could apply or spray on directly?

Grainger's has the tape in 12" widths. It comes with and without foam.

A couple of examples...

3m acrylic double sided vhb tape products - Grainger Industrial Supply

3M Double Sided VHB Tape

Use 3M™ VHB™ double-coated foam tape rolls for prepowder-coat paint applications and attaching vinyl trim, bonding vinyl extrusions and prepainted truck and trailer skins. Adhesive foam tape using VHB Material offers a permanent seal against water, moisture, and salt. Strong enough to replace spot welds, screws, rivets, and liquid adhesives with long-term durability, indoors and out. This general-purpose acrylic adhesive bonds well to metal substrates.

3M Double Sided VHB Tape

Use 3M™ VHB™ double-coated foam tape rolls for prepowder-coat paint applications and attaching vinyl trim, bonding vinyl extrusions and prepainted truck and trailer skins. Adhesive foam tape using VHB Material offers a permanent seal against water, moisture, and salt. Strong enough to replace spot welds, screws, rivets, and liquid adhesives with long-term durability, indoors and out. This general-purpose acrylic adhesive bonds well to metal substrates.

Also...

3M Tape Width 12 in, Tape Length 12 in, Adhesive Transfer Tape, Liner Material Kraft Paper - 15C892'|'12SQ-12-467MP - Grainger

3M

Tape Width 12 in, Tape Length 12 in, Adhesive Transfer Tape, Liner Material Kraft Paper

Featuring a special release liner, this pressure-sensitive adhesive works with thin, flexible materials where gap filling is not needed. For hand applications only, it bonds graphic nameplates and overlays to metal and high surface energy plastics in the aerospace, medical and industrial equipment, automotive, appliance, and electronic markets.

3M

Tape Width 12 in, Tape Length 12 in, Adhesive Transfer Tape, Liner Material Kraft Paper

Featuring a special release liner, this pressure-sensitive adhesive works with thin, flexible materials where gap filling is not needed. For hand applications only, it bonds graphic nameplates and overlays to metal and high surface energy plastics in the aerospace, medical and industrial equipment, automotive, appliance, and electronic markets.

Thanks aagas.

I considered to try an adhesive film after I was getting covered in epoxy adhesive. I purchased some double sided thin tape for temporary mounting exciters for testing, it’s not 3m and I’m not sure how it compares, but I did a small test piece square with the tape onto some carbonfibre, and nomex honeycomb. The tape didn’t cure and the test piece wasn’t stiff like with adhesive.

Also, I contacted amina and they mentioned they previously used a 3m adhesive sheet when fixing the panel to wood, and they now recommend not to use it as they lost high frequency. They now recommend using a 2 part epoxy.

There are many types of 3m tape, so I couldn’t say for sure if you would loose HF or that the panel wouldn’t be stiff.

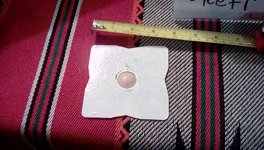

I’ve attached a pic of the adhesive tape I used. This came next day, as I was trying to get the recommended 3m tape for exciters and didn’t manage. See post 2624 from Jarrodhaas for the proper tape.

I considered to try an adhesive film after I was getting covered in epoxy adhesive. I purchased some double sided thin tape for temporary mounting exciters for testing, it’s not 3m and I’m not sure how it compares, but I did a small test piece square with the tape onto some carbonfibre, and nomex honeycomb. The tape didn’t cure and the test piece wasn’t stiff like with adhesive.

Also, I contacted amina and they mentioned they previously used a 3m adhesive sheet when fixing the panel to wood, and they now recommend not to use it as they lost high frequency. They now recommend using a 2 part epoxy.

There are many types of 3m tape, so I couldn’t say for sure if you would loose HF or that the panel wouldn’t be stiff.

I’ve attached a pic of the adhesive tape I used. This came next day, as I was trying to get the recommended 3m tape for exciters and didn’t manage. See post 2624 from Jarrodhaas for the proper tape.

Attachments

I wonder if you could make up a cheap version of a vacuum pump by just connecting a Hoover to the bag? Using one of those adaptors for bags to tightly pack clothes etc that you see on tv adverts late at night!

Stimper,

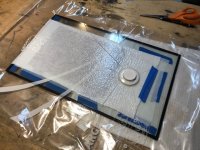

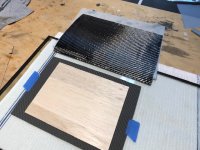

You absolutely can. I've done exactly that to make some Balsa core prototype panels with CF and FG skins. I have not tried it with the nomex but I see no reason it would not work.

Using the clothes bags is super simple and easy. Previously I was using FoodSaver bags and they work great too, but they are limited in size. You can get the clothes storage bags in much larger sizes. As far as a vacuum pump, when I tried the "Hoover" it pulled about 6 in Hg, which is a pretty weak vacuum, but probably enough. What I do now is use my Foodsaver pump to pull the vacuum on the clothes storage bag and it pulls about 21 in Hg.

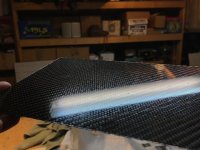

Here are some pics of my CF/balsa/CF prototype, made using the storage bag method.

Eric

Attachments

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker