Sorry, lots of typos above. I'm replying from my phone and my thumb is too big for modern technology!🤣

Is there any guide that anyone would recommend for using REW software? I've looked at some YouTube guides, but a good written guide would be great.

Thanks

Is there any guide that anyone would recommend for using REW software? I've looked at some YouTube guides, but a good written guide would be great.

Thanks

Guys, based on all this collective experience wisdom, what should be recommended for DML used for just 5000-20000Hz? Best for purpose exciter, material, geometry?

Low-mids not important.

Low-mids not important.

Низкие и средние частоты обрезаны? материал сотовый картон 6-10 мм возбудители https://aliexpress.ru/item/32581104979.html?spm=a2g0s.9042311.0.0.274233edBFHdoy геометрия-размещение монакор

Низкие и средние частоты обрезаны? материал сотовый картон 6-10 мм возбудители https://aliexpress.ru/item/32581104979.html?spm=a2g0s.9042311.0.0.274233edBFHdoy геометрия-размещение монакор

English only please. Rules.

Low and mid-frequency trimmed? Material Cell Cardboard 6-10 mm pathogens geometry-placement monacor

excuse me.

Are the low and mid frequencies cut off? material honeycomb cardboard 6-10 mm exciters http://aliexpress.ru/item/32581104979.html?spm=a2g0s.9042311.0.0.274233edBFHdoy geometry-placement monacor

Are the low and mid frequencies cut off? material honeycomb cardboard 6-10 mm exciters http://aliexpress.ru/item/32581104979.html?spm=a2g0s.9042311.0.0.274233edBFHdoy geometry-placement monacor

Last edited:

Guys, based on all this collective experience wisdom, what should be recommended for DML used for just 5000-20000Hz? Best for purpose exciter, material, geometry?

Low-mids not important.

The Amina mobius 7i speakers apparently go up to 27hz, see below link for dimensions. From what I can see they are made from aluminium honeycomb and possibly a Kraft paper type skin. They are designed to be plastered over.

Has anyone heard these before?

I’m trying to source some 4mm thick aluminium honeycomb to test some skins. Not so easy to get a hold of, as most places sell 10mm thick aluminium honeycomb.

I will try it with some left over carbon fibre I have and will also make up some wooden veneer and some kind of paper versions (not to be installed in a wall and plastered over). Although I guess the aluminium honeycomb must resonate quite a lot, as the mobius use quite a lot of round discs on that back made from some form of metal for dampening.

I’m going to test my carbon fibre nomex honeycomb panel tonight, but don’t think it will get the highs. I did a rough test with a Dayton 40w exciter, but highs were not that great.

I’ve now put on 4-off Dayton 25mm exciters, so fingers crossed! I have been using a double sided tape for testing. Not sure how much a difference to high frequencies permanently bonding the panels to the exciters will make?

Charcoal.

In the first picture is a painters canvas,in the centre is a 6x4 balsa ply panel with a 10watt exciter with a 25mm coil.

The ply panel on it's own will go down to 500hz with no problem,the canvas just takes the response down to 40hz.

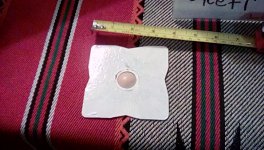

The second picture is a 9.5cmx1.5I'm card panel coated with pva ,I also applied some paint.

This panel went down to about 2k if I remember correctly?

They also go up to 20k and beyond ,but I can only measure up to 20k.

I found that for small panels ,thin card works very well and sounds very good and has a remarkable frequency response.

You can also place them closer to walls without the bad affects of the larger panels.

I have made recordings of various card and ply and eps panels on diy audio if you wish to have a listen before trying ,although they are quickly getting lost in all those pages.

If you do want more information just let me know.

Steve.

In the first picture is a painters canvas,in the centre is a 6x4 balsa ply panel with a 10watt exciter with a 25mm coil.

The ply panel on it's own will go down to 500hz with no problem,the canvas just takes the response down to 40hz.

The second picture is a 9.5cmx1.5I'm card panel coated with pva ,I also applied some paint.

This panel went down to about 2k if I remember correctly?

They also go up to 20k and beyond ,but I can only measure up to 20k.

I found that for small panels ,thin card works very well and sounds very good and has a remarkable frequency response.

You can also place them closer to walls without the bad affects of the larger panels.

I have made recordings of various card and ply and eps panels on diy audio if you wish to have a listen before trying ,although they are quickly getting lost in all those pages.

If you do want more information just let me know.

Steve.

Attachments

Last edited:

Is anything like this -

Polypropylene Honeycomb Panel 6mm - a good candidate for a 'sound board''?

Polypropylene Honeycomb Panel 6mm - a good candidate for a 'sound board''?

The Amina mobius 7i speakers apparently go up to 27hz, see below link for dimensions. From what I can see they are made from aluminium honeycomb and possibly a Kraft paper type skin. They are designed to be plastered over.

Has anyone heard these before?

I’m trying to source some 4mm thick aluminium honeycomb to test some skins. Not so easy to get a hold of, as most places sell 10mm thick aluminium honeycomb.

I will try it with some left over carbon fibre I have and will also make up some wooden veneer and some kind of paper versions (not to be installed in a wall and plastered over). Although I guess the aluminium honeycomb must resonate quite a lot, as the mobius use quite a lot of round discs on that back made from some form of metal for dampening.

I’m going to test my carbon fibre nomex honeycomb panel tonight, but don’t think it will get the highs. I did a rough test with a Dayton 40w exciter, but highs were not that great.

I’ve now put on 4-off Dayton 25mm exciters, so fingers crossed! I have been using a double sided tape for testing. Not sure how much a difference to high frequencies permanently bonding the panels to the exciters will make?

This link is interesting. They mention a 3mm wood panel at the front and minimum 60mm gap to the wall.

I haven’t tried polypropylene before.

The link you sent is also what interests me, as I would like to make a TV unit, which hides the speakers (WAF). I was planning on hiding the speaker with either a mesh or a speaker grill, but if I could get it to work like the video shown to install within wood, I could make it into a false door using mdf and a engineered wooden veneer. Although would need to figure out how to stop vibrations.

There’s just so much experimentation which makes this fun, but at some point I want some working speakers that I’m happy with! 🤣

I can source 4mm thick aluminium honeycomb, as per below, which has plenty of material to experiment.

4.0mm Thick – Aluminium Honeycomb core – 50 micron foil, 3/16” cell size throughout once expanded.

Supplied unexpanded. Size when expanded – 2500x1250x4.0mm (although often usuable size is slightly less).

The cost is £40+VAT and £20 shipping.

I’m trying to find out what type of paper/card to use. Alibaba had similar type of speaker to amina (lower quality) and I did ask if they could only supply the panel, but they only sell as a unit. One of the suppliers mentioned that it was Kraft paper used and a 3m backing. This would be really simple to make, but reckon the adhesive is going to play a big role for the sound.

Amina also use lots of weights on the back which I assume gives a flatter frequency response.

I’ll order the honeycomb, weights and some card/paper and give it a bash. Good to know spedge that you always got high frequency response using card. I’ll check out your recordings. Thanks.

The link you sent is also what interests me, as I would like to make a TV unit, which hides the speakers (WAF). I was planning on hiding the speaker with either a mesh or a speaker grill, but if I could get it to work like the video shown to install within wood, I could make it into a false door using mdf and a engineered wooden veneer. Although would need to figure out how to stop vibrations.

There’s just so much experimentation which makes this fun, but at some point I want some working speakers that I’m happy with! 🤣

I can source 4mm thick aluminium honeycomb, as per below, which has plenty of material to experiment.

4.0mm Thick – Aluminium Honeycomb core – 50 micron foil, 3/16” cell size throughout once expanded.

Supplied unexpanded. Size when expanded – 2500x1250x4.0mm (although often usuable size is slightly less).

The cost is £40+VAT and £20 shipping.

I’m trying to find out what type of paper/card to use. Alibaba had similar type of speaker to amina (lower quality) and I did ask if they could only supply the panel, but they only sell as a unit. One of the suppliers mentioned that it was Kraft paper used and a 3m backing. This would be really simple to make, but reckon the adhesive is going to play a big role for the sound.

Amina also use lots of weights on the back which I assume gives a flatter frequency response.

I’ll order the honeycomb, weights and some card/paper and give it a bash. Good to know spedge that you always got high frequency response using card. I’ll check out your recordings. Thanks.

Charcoal.

In the first picture is a painters canvas,in the centre is a 6x4 balsa ply panel with a 10watt exciter with a 25mm coil.

The ply panel on it's own will go down to 500hz with no problem,the canvas just takes the response down to 40hz.

.

Thanks for sharing. Does it decrease sensitivity on mid-highs, if one goes for such small panels?

Charcoal.

I'm not sure what you mean by reduced sensitivity on mids and highs.

But if you mean ,can small panels go loud,then the answer is yes.

All my recordings were done while playing at very high volumes, although even I couldn't tell from listening to the recordings ,that they were being played that loudly ,which is good I suppose, as it shows no distortion or strain.

It all depends on the design of the panels,and how they fit into your room.

WAF and the fact people kept saying small panels don't work,made me investigate to see if this was true,I like a challenge.

But if you stretch a small panel say 12inches ,down to 100hz ,don't expect a 10watt exciter to handle heavy metal for long periods of time!

Steve

I'm not sure what you mean by reduced sensitivity on mids and highs.

But if you mean ,can small panels go loud,then the answer is yes.

All my recordings were done while playing at very high volumes, although even I couldn't tell from listening to the recordings ,that they were being played that loudly ,which is good I suppose, as it shows no distortion or strain.

It all depends on the design of the panels,and how they fit into your room.

WAF and the fact people kept saying small panels don't work,made me investigate to see if this was true,I like a challenge.

But if you stretch a small panel say 12inches ,down to 100hz ,don't expect a 10watt exciter to handle heavy metal for long periods of time!

Steve

I have a question about coin type exciters. I would like to know the purpose of a part in the motor structure. In looking at the exciter there are several parts. The steel cup is first. Then there is a neodymium magnet slug. Then there is a steel plate that I believe acts like a top plate in a conventional ferrite magnet design. On top of the steel plate that is the top plate, there is another smaller slug of steel. What is the purpose of this small steel slug?

I haven’t tried polypropylene before.

I can source 4mm thick aluminium honeycomb, as per below, which has plenty of material to experiment.

4.0mm Thick – Aluminium Honeycomb core – 50 micron foil, 3/16” cell size throughout once expanded.

Supplied unexpanded. Size when expanded – 2500x1250x4.0mm (although often usuable size is slightly less).

The cost is £40+VAT and £20 shipping.

Hello Stimper!

Could you please share the source of Aluminium Honeycomb core?

I would like to order and do some experiments by myself.

Last edited:

I have made up a carbon fibre skin, no med honeycomb panel based on the size of the dml-10 tectonics speakers (577 x 400mm), annoyingly I didn’t get the rectangle square, so I will need to trim a little more off the length, as found out when making up a test frame..Hopefully will be able to test the CF/nomex honeycomb this weekend and ill post full details of exciter used, positioning, etc along with Rew readings.

Stimper,

I'm interested to hear more details, about both your construction and your results. I have been playing around myself with CF and Fiberglass skins over various lightweight cores. And coincidentally based on the DML-10 dimensions (approximately at least). Shortly I plan to build up a plate with CF skins (3K twill weave, 200g/m2,.010" thick) over 1/16" basla.

What are your CF skins? Thickness, weave, layup, etc? Are you making them yourselves or buying premade plates? They look great! How are you adhering them to the nomex? What nomex are you using (thickness/density/source)? I have some of the 1/8" 3.0 lb nomex from Composite Envisions. So far I've only tried it between skins of wood veneer. But I didn't know how to properly glue the veneer to the nomex and it turned out way too heavy and not fully adhered so it was a poor test. I have been thinking about trying the nomex with carbon skins myself, but haven't gotten around to that yet. So I'm really interested to hear how it goes for you.

Thanks,

Eric

Hello Stimper!

Could you please share the source of Aluminium Honeycomb core?

I would like to order and do some experiments by myself.

Hi dmltux,

See below contact details for the aluminium honeycomb.

I haven’t ordered yet, but will do next week.

Normanton Laminating Services Ltd.

Composite Panel Engineers

T: +44 (0)1759 322160

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker