Twocents.

I know it's probably me being a bit negative (understatement)at the moment but I did all this over 10years ago on the nxt Rubbish forum , it's like being in groundhog day watching it all happening again over and over again, someone says has anyone tried this new material and all I can think is oh no not that one again!

I'm afraid it's the nature of forums ,that a couple of pages down the line whatever has been found is lost and becomes antient history,only to be regurgitated at a later date.

I've felt this for some years now but have no answers.

Steve

I know it's probably me being a bit negative (understatement)at the moment but I did all this over 10years ago on the nxt Rubbish forum , it's like being in groundhog day watching it all happening again over and over again, someone says has anyone tried this new material and all I can think is oh no not that one again!

I'm afraid it's the nature of forums ,that a couple of pages down the line whatever has been found is lost and becomes antient history,only to be regurgitated at a later date.

I've felt this for some years now but have no answers.

Steve

Hi Steve,

You rock the boat as often as you like, its great input!

I have no doubt large eps panels sound excellent and if I had a pair I would wheel them out often. I don’t have then yet, although I may well add them to the ply ones I have sometime in the future mainly because you speak so highly of them. I like ply personally because I got that wow factor from the first ones I built and they are still my favourite. I was puzzled for a while about why they sounded so good but I may have discovered the reason recently. The dirt cheap ply over here in France is made from Poplar which is circa half the density of Birch, 350 v 670 kg/m^3. Thats a significant difference.

I think the same may be true of eps grades which varies from 11 to 32 kg/m^3 from what I can see online. So even with eps, a relatively homogeneous material, there is a wide difference in the material you can buy. Same for XPS which varies from 28-45kg/m^3. It might go some way to explain why people have different reactions to these materials, they are listening to different grades. The second aspect is scale. Bigger panels more efficient. That means not only can they play louder for a given input but it also means their dynamic range is greater. It also means they reach deeper as you know. All very nice attributes to have for very little extra money.

I am not ignoring eps at all. Its just that at this point ( apart from being stuck inside with bugger all access to materials) I am exploring some surprising discoveries, like the effect of high ratios for panels plus the anisotropic nature of ply composites. I have no doubt one day I will have some big eps panels as well.

Burnt

You rock the boat as often as you like, its great input!

I have no doubt large eps panels sound excellent and if I had a pair I would wheel them out often. I don’t have then yet, although I may well add them to the ply ones I have sometime in the future mainly because you speak so highly of them. I like ply personally because I got that wow factor from the first ones I built and they are still my favourite. I was puzzled for a while about why they sounded so good but I may have discovered the reason recently. The dirt cheap ply over here in France is made from Poplar which is circa half the density of Birch, 350 v 670 kg/m^3. Thats a significant difference.

I think the same may be true of eps grades which varies from 11 to 32 kg/m^3 from what I can see online. So even with eps, a relatively homogeneous material, there is a wide difference in the material you can buy. Same for XPS which varies from 28-45kg/m^3. It might go some way to explain why people have different reactions to these materials, they are listening to different grades. The second aspect is scale. Bigger panels more efficient. That means not only can they play louder for a given input but it also means their dynamic range is greater. It also means they reach deeper as you know. All very nice attributes to have for very little extra money.

I am not ignoring eps at all. Its just that at this point ( apart from being stuck inside with bugger all access to materials) I am exploring some surprising discoveries, like the effect of high ratios for panels plus the anisotropic nature of ply composites. I have no doubt one day I will have some big eps panels as well.

Burnt

Sorry to hear about your negative feelings Steve and I think I can understand. I have not walked the road you walked, but the reason I am interested and value your observations is there are relatively few EPS builds mentioned here and on the other threads, yet it does appear that EPS performs better than the goto XPS panels. Was your username lordtarquin on the NXT Rubbish thread perhaps?Twocents.

I know it's probably me being a bit negative (understatement)at the moment but I did all this over 10years ago on the nxt Rubbish forum , it's like being in groundhog day watching it all happening again over and over again, someone says has anyone tried this new material and all I can think is oh no not that one again!

I'm afraid it's the nature of forums ,that a couple of pages down the line whatever has been found is lost and becomes antient history,only to be regurgitated at a later date.

I've felt this for some years now but have no answers.

Steve

Sorry spedge - ignore this question. Lordtarguin is a member of this forum.Was your username lordtarquin on the NXT Rubbish thread perhaps?

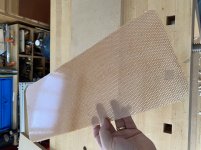

The panel glue up worked. It is stiffer than I thought it would be. Today I will heat shrink both sides to tighten it up a bit as I am seeing some luffing of the Mylar between cell walls.

Attachments

Has anyone tried putting two exciters on opposite sides of panel in same location and wired out of phase to increase output?

I have not tried it myself but some have. From memory people reported it didn't work too well. It suppressed output from the exciter region on the front of the panel.

Has anyone tried putting two exciters on opposite sides of panel in same location and wired out of phase to increase output?

I tried it on gatorboard, hoping to maybe help improve the sound quality, more so than to increase the output. It didn't seem to do anything to me but don't let that stop you from trying.

Eric

The panel glue up worked. It is stiffer than I thought it would be. Today I will heat shrink both sides to tighten it up a bit as I am seeing some luffing of the Mylar between cell walls.

That's too cool. Whether it sounds good or not!

Eric

Its pretty easy to bend. We will see. Maybe I can bend it around and make stereo DML headphones if nothing else.

If I do this again, I will probably try thicker mylar or nomex. I have some CF honeycomb that is very stiff. Might be worth a try.

After heat shrinking I need to figure out a nondestructive way to attach a very small vibrator.

dhl

If I do this again, I will probably try thicker mylar or nomex. I have some CF honeycomb that is very stiff. Might be worth a try.

After heat shrinking I need to figure out a nondestructive way to attach a very small vibrator.

dhl

Burntcoil.

Don't get me wrong , heavy rigid panels can sound very good,it took a good 15 to 20 minutes before I started to feel there was something missing when I first heard the podiums,and wasn't surprised when I felt the same about my ply panels, heavy panels sound different.

As for small eps panels being not as loud as large eps panels for the same input, when xo at about 100hz to a LF driver,they are about the same, I've run them side by side with the same volume settings,the difference I'd say is scale ,the larger the panel the larger the drum kit or guitar, bit like a TV screen ,if too big for the room it can be a bit overwhelming,but fun.

Steve

Don't get me wrong , heavy rigid panels can sound very good,it took a good 15 to 20 minutes before I started to feel there was something missing when I first heard the podiums,and wasn't surprised when I felt the same about my ply panels, heavy panels sound different.

As for small eps panels being not as loud as large eps panels for the same input, when xo at about 100hz to a LF driver,they are about the same, I've run them side by side with the same volume settings,the difference I'd say is scale ,the larger the panel the larger the drum kit or guitar, bit like a TV screen ,if too big for the room it can be a bit overwhelming,but fun.

Steve

Davelang.

Your panel is quite small ,so wouldn't recommend making it too rigid,a 6ft ply panel would be quite floppy ,but a 1ft ply panel would be quite stiff ,and would start to sound a bit like glass,hard sounding , small panels need a bit of flex .

Steve

Your panel is quite small ,so wouldn't recommend making it too rigid,a 6ft ply panel would be quite floppy ,but a 1ft ply panel would be quite stiff ,and would start to sound a bit like glass,hard sounding , small panels need a bit of flex .

Steve

Spedge

Thanks the advise. Mylar can be shrunk up to 50% depending on temp exposure time. My thought was 90 degrees C for just a few seconds. I think a 50% shrink would destroy the panel. Any suggestions on “how stiff” the panel should be?

A more general question is how stiff should any panel be depending on its size. Any ideas or documents. I surely don’t know. I can measure MOE with a standard deflection measurement jig.

Thanks the advise. Mylar can be shrunk up to 50% depending on temp exposure time. My thought was 90 degrees C for just a few seconds. I think a 50% shrink would destroy the panel. Any suggestions on “how stiff” the panel should be?

A more general question is how stiff should any panel be depending on its size. Any ideas or documents. I surely don’t know. I can measure MOE with a standard deflection measurement jig.

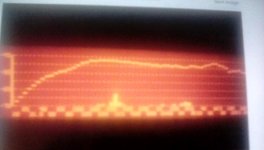

This is a very bad picture of a picture of a very floppy metal panel from my gallery over on audiocircle ,can't find the panel so must have thrown it away.

It was only a few ml thick,and comprised of 2 sheets glued together with spray adhesive which helped to dampen the panel.

Notice the smooth response ,took a lot to drive it,and it did sound smooth,too smooth!

Did wonder if I had made it smaller ,would it have sounded (performed) better?

Steve

It was only a few ml thick,and comprised of 2 sheets glued together with spray adhesive which helped to dampen the panel.

Notice the smooth response ,took a lot to drive it,and it did sound smooth,too smooth!

Did wonder if I had made it smaller ,would it have sounded (performed) better?

Steve

Attachments

That also raises another question...

There is a big difference between a floppy panel and the MOE of the material from which the panel is made.

My plexiglass DML panels are floppy but have a much higher MOE than My Foamular 150 panels which are stiff but have a very low MOE.

.... I think we need to be clear about what distance properties of a given panel we are speaking of.

There is a big difference between a floppy panel and the MOE of the material from which the panel is made.

My plexiglass DML panels are floppy but have a much higher MOE than My Foamular 150 panels which are stiff but have a very low MOE.

.... I think we need to be clear about what distance properties of a given panel we are speaking of.

Spedge

Thanks the advise. Mylar can be shrunk up to 50% depending on temp exposure time. My thought was 90 degrees C for just a few seconds. I think a 50% shrink would destroy the panel. Any suggestions on “how stiff” the panel should be?

A more general question is how stiff should any panel be depending on its size. Any ideas or documents. I surely don’t know. I can measure MOE with a standard deflection measurement jig.

To many variables,weight ,rigidity size,panel structure,best is just to listen to it,and go from there,don't know of any equation that will predict how it will sound,you probably had the same problem (learning curve) when you started making guitars, a frequency measurement would help,if only to make sure you xo in the right area

Steve

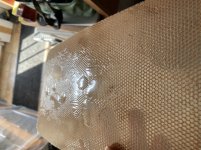

Honeycomb Mylar Followup

Trying to stiffen a Mylar panel with heat shrinkage...

I cooked the panel @90 degrees C for 5 seconds on each side. You could hear a popping sound that proved to be the cells inflating and delaminating. The picture shows consolidation of the expanded air. So, don’t do it this way. Once cooled I am gonna try a heat gun instead. This won’t salvage the panel but might not heat the air in the panel as much. If not.....DML headphones.

Trying to stiffen a Mylar panel with heat shrinkage...

I cooked the panel @90 degrees C for 5 seconds on each side. You could hear a popping sound that proved to be the cells inflating and delaminating. The picture shows consolidation of the expanded air. So, don’t do it this way. Once cooled I am gonna try a heat gun instead. This won’t salvage the panel but might not heat the air in the panel as much. If not.....DML headphones.

Attachments

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker