In fact, you could use resin alone on a polyester skinned polypropylene honeycomb core - no fiberglass or carbon fiber. An 8x4 sheet is around $40-$80 locally depending on thickness and the resin is $75(?).

Personally, I won't spend much more than that because in my magical thinking I think I've run into diminishing returns on materials. I might already be past the point of diminishing returns with what I've used. I did use carbon fiber but only because I already had it. It's possible that I degraded the panel by using CF, I have no idea.

Have you tried that PP honeycomb, either with or without a skin? I actually ordered some (I can't find it locally), but that was weeks ago and it has not yet arrived. I'm going to have to check on that.

I was planning to try it with either CF or wood veneer skins, or both. Might have to consider fiberglass too. What I ordered (or so I thought) is 1/4" thick, which is the thinnest it comes as far as I know. But I think that's borderline thick for carbon skins. This could be one of the cases where fiberglass is a better fit.

What can you tell us about the panel you degraded by using CF? Was it with this PP honeycomb core or something else? Is it something you've shared here before but I just don't recall?

Thanks,

Eric

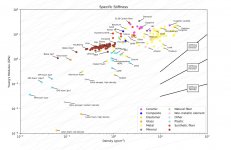

Spent a good part of the morning trying to find information on the relationships between Modulus of elasticity and density, area density and volumetric density. I found this chart on a Wikipedia page on area density. I am still mulling over the chart and all of its significance but taking into account then general observation that the XPS panels( (Foamular 150) sound so good, check out where XPS and EPS lie on the graph relative to other materials. Look specifically at CF, balsa and XPS. XPS is a huge outlier. Conclusions? Share them. I am not an engineer. Is there something about the combination of modulus and density that make it good and potentially make those properties a goal for those trying other materials.

Attachments

So, that quote and equation tells us the panel must be light and stiff. It also tells us the panel must be isotropic( same mechanical properties in length and width.

Close. Technically, I think it just says that in all directions the "T ratio" (their name for the index) must be greater than 10. It doesn't say that it has to be the same in all directions.

Veleric. I looked this one up and need to know what units are being used for the calculations of bending strength and mass per cubic area to be sure calls are correct.

The units for bending stiffness are Nm and the units for wt/unit area are kg/m^2.

Eric

Have you tried that PP honeycomb, either with or without a skin?

Yes, with the polyester skin. With resin on only one side the panel is bendable which might make it useful for low frequency infinite panels. The panel is very stiff when resin is applied to both sides which probably makes it better for modal panels.

My panels are BMR so the extra weight of CF may have degraded their performance without supplying benefit in the audible frequency range. Polyester fiber reinforced resin might be just as good or better than an additional layer of CF in my application.

XPS is a huge outlier. Conclusions? Share them. I am not an engineer. Is there something about the combination of modulus and density that make it good and potentially make those properties a goal for those trying other materials.

Yes, what's special about XPS is that it's specific stiffness is very high compared to most other materials. As your graph suggests, specific stiffness can be expressed as stiffness/density or stiffness/(density squared) or stiffness/(density cubed). Which of the three is most applicable depends on the application. The Heron patents I've been referring to are basically saying that, in the case of a panel speaker (as he envisions it, anyway), the parameter that matters most is stiffness/density^3.

The T index from those patents that I've been talking about (B/µ^3), is effectively the same as E/rho^3 (where E is Young's Modulus and rho is density). In fact, for a homogeneous material:

(B/µ^3) = (E/rho^3) /12

So, at least for a homogeneous material, comparing materials based on "B/µ^3" is exactly the same as comparing them based on "E/rho^3".

Then, to interpret your graph: Locate the dot for the material you are interested in, then draw a line through that point that is parallel to the line on the right side of the graph that is labelled "stiffness/density^3". Look at your new line. Any material whose dot is above (and left) of the new line is "better" (based on E/rho^3), while anything falling below (and right) of the line, is "worse". On that basis, at least according to the data used in the chart, EPS, XPS and Balsa all fall pretty close to each other, and way better than anything else.

I've been going through exactly the same though process as you: What is it about PS foam that makes it radiate sound so effectively, and how do I find other materials that might also radiate as well? My best answer so far is to find (or construct) materials that also have a similarly high T ratio.

Eric

Yes, with the polyester skin. With resin on only one side the panel is bendable which might make it useful for low frequency infinite panels. The panel is very stiff when resin is applied to both sides which probably makes it better for modal panels.

My panels are BMR so the extra weight of CF may have degraded their performance without supplying benefit in the audible frequency range. Polyester fiber reinforced resin might be just as good or better than an additional layer of CF in my application.

Thanks, I get it now. The effect in a BMR would be different.

Eric

Yes, with the polyester skin. With resin on only one side the panel is bendable which might make it useful for low frequency infinite panels. The panel is very stiff when resin is applied to both sides which probably makes it better for modal panels.

My panels are BMR so the extra weight of CF may have degraded their performance without supplying benefit in the audible frequency range. Polyester fiber reinforced resin might be just as good or better than an additional layer of CF in my application.

I thought BMR is different than DML in that it doesn't use a flat panel for sound transmission and instead sound comes from the driver (which is typically mounted in a box). Maybe I'm missing something in my understanding of BMR but how does it relate to the DML flat panel materials/designs being discussed here.

Thanks.

@intaud I found this was a helpful description of BMR's

https://www.parts-express.com/pdf/AnIntroductiontoBMR.pdf

https://www.parts-express.com/pdf/AnIntroductiontoBMR.pdf

@intaud I found this was a helpful description of BMR's

https://www.parts-express.com/pdf/AnIntroductiontoBMR.pdf

That's an excellent resource. After reading it I decided I do not have a BMR. I have a panel that vibrates and moves forward and backward. It's only a BMR in a superficial sense.

Really, a BMR is tuned a specific way. I cheated the panel tuning process by using DSP.

@intaud I found this was a helpful description of BMR's

https://www.parts-express.com/pdf/AnIntroductiontoBMR.pdf

Burnt,

That's a great find, thanks.

Eric

@intaud I found this was a helpful description of BMR's

https://www.parts-express.com/pdf/AnIntroductiontoBMR.pdf

Thank-you @BurntCoil. Very informative and helped with my understanding.

My pleasure, this thread has developed amazingly recently, great contributions all round.

@bradleypnw- any cheat that works is called a method : )

Burnt

@bradleypnw- any cheat that works is called a method : )

Burnt

After listening to 1/4 “ thick plexiglass(PMMA) panels 24” by 48” and noticing marked improvement in treble subjectively, I began a thought experiment.

Why would a PMMA panel which by MOE is 200 times more stiff ( 2.55 GPa) than XPS ( .01 GPa) and approx 200 times more dense ( 1.17g/cc, .023g/cc ) sound as good if better than XPS ????

Metals would make a bad DML panel ( 50 GPa, 5 gm/cc averaged)

So what gives. I have read multiple articles on wave propagation in solid isotropic plate DMLs it is apparent that DMLs function with bending waves( sheer waves ) propagating over the plate and as a point source at the exciter.

Before going on. Here’s my disclaimer. I am NOT an engineer or even a mathematician.

Bending waves( as opposed to longitudinal waves) in isotropic materials are dependent only on material density and a modulus called sheer modulus( resistance to sheering force)

C^2 = sheer modulus/ density = speed of bending wave

The sheer modulus of XPS is 4

The sheer modulus is balsa is 1.1

The sheer modulus of PMMA is 1.08

The sheer modulus is of EPS is 11

( EPS and XPS sheer modulus depend on thickness so I assumed 1” )

The sheer modulus of metals 30-50

The sheer modulus of glass is 29

Notice a trend that relates to my observations?

Maybe sheer modulus is more important as a physical property( than MOE or density) for the suitability of a material( isotropic) for DML panels since they function by bending waves( sheer)?????

Dave Lang

Why would a PMMA panel which by MOE is 200 times more stiff ( 2.55 GPa) than XPS ( .01 GPa) and approx 200 times more dense ( 1.17g/cc, .023g/cc ) sound as good if better than XPS ????

Metals would make a bad DML panel ( 50 GPa, 5 gm/cc averaged)

So what gives. I have read multiple articles on wave propagation in solid isotropic plate DMLs it is apparent that DMLs function with bending waves( sheer waves ) propagating over the plate and as a point source at the exciter.

Before going on. Here’s my disclaimer. I am NOT an engineer or even a mathematician.

Bending waves( as opposed to longitudinal waves) in isotropic materials are dependent only on material density and a modulus called sheer modulus( resistance to sheering force)

C^2 = sheer modulus/ density = speed of bending wave

The sheer modulus of XPS is 4

The sheer modulus is balsa is 1.1

The sheer modulus of PMMA is 1.08

The sheer modulus is of EPS is 11

( EPS and XPS sheer modulus depend on thickness so I assumed 1” )

The sheer modulus of metals 30-50

The sheer modulus of glass is 29

Notice a trend that relates to my observations?

Maybe sheer modulus is more important as a physical property( than MOE or density) for the suitability of a material( isotropic) for DML panels since they function by bending waves( sheer)?????

Dave Lang

Another interesting post. I have seen little on the effect of shear in the published material on DML’s

As I understand it the shear force is another measure of stiffness like the Young’s Modulus or the Poisson ratio. In this case it is a measure of how much a material deforms under lateral pressure before transmitting the strain to surrounding regions. The higher the shear modulus the less the material deforms before transmitting the applied force.

This is just my intuition shouting at me, but material damping is inversely correlated with the shear modulus. A material with a high shear modulus has low damping for the same reason, the ‘stiffness’’ of regions within the material transmitting energy efficiently versus a ‘soft’ material which deforms more for a longer period of time before transmitting the force on.

The effect on high frequencies are that a ‘fast’ material with low damping would transmit energy more efficiently than a ‘slow’ material with high damping. Bare in mind that the speed of the bending wave is frequency dependent as well, with high frequencies having a higher speed than low frequencies.

How that effects DML’s in the chaotic state I do not know, but it seems logical that an efficient energy transmitter would also be beneficial.

All the above is conjecture so sceptical filters should be firmly set to 'on' at this point.

Burnt

As I understand it the shear force is another measure of stiffness like the Young’s Modulus or the Poisson ratio. In this case it is a measure of how much a material deforms under lateral pressure before transmitting the strain to surrounding regions. The higher the shear modulus the less the material deforms before transmitting the applied force.

This is just my intuition shouting at me, but material damping is inversely correlated with the shear modulus. A material with a high shear modulus has low damping for the same reason, the ‘stiffness’’ of regions within the material transmitting energy efficiently versus a ‘soft’ material which deforms more for a longer period of time before transmitting the force on.

The effect on high frequencies are that a ‘fast’ material with low damping would transmit energy more efficiently than a ‘slow’ material with high damping. Bare in mind that the speed of the bending wave is frequency dependent as well, with high frequencies having a higher speed than low frequencies.

How that effects DML’s in the chaotic state I do not know, but it seems logical that an efficient energy transmitter would also be beneficial.

All the above is conjecture so sceptical filters should be firmly set to 'on' at this point.

Burnt

Last edited:

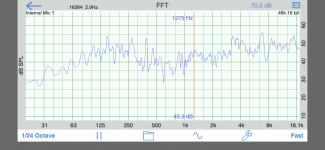

An additional thought on shear modulus and damping. The Impulse response measurement in REW should provide a useful tool to measure the different material damping rates.

Burntcoil.

Whenever I pull out my old large eps panels,which isn't that often,there is always that wow! Factor and that is just with the bog standard panel I posted the last frequency response pics,this is the material I'm always trying to beat , I've come close in some respects with my small (down to 4inches in some cases) panels,but nothing matches the shear enjoyment of the large eps panel.

I went down memory lane and visited nxt Rubbish on ac ,I joined that in 2009 but had been testing dml panels for quite a few years before.

It saddened me to see how things haven't changed , still talking about the same old panel materials and all those equations nothing has moved on!

Eps seems to have been mostly ignored for more costly heavy materials .

Eps produces the light and delicate sounds but with huge dynamics and atmosphere that heavier panels lack,and the exciter has to do very little to achieve this.

When it comes to full range ,even if a had a panel and and exciter that could play loud LF would I use it all the way down to 20hz and below? It might be ok for chamber music and the like but for heavy rock or electronic or close mic recordings the exciter and panel would struggle to play the rest of the frequency spectrum cleanly.

I believe eps to produce a combination of direct radiated and dml sound ,and believe that the combination is important,heavier more rigid type panels (including podiums) tilt more towards dml,that is probably why layeredsound by s Katz uses a postonic speaker in parallel to the podiums.

Don't mean to rock the boat but things do need to move on !

Steve

Whenever I pull out my old large eps panels,which isn't that often,there is always that wow! Factor and that is just with the bog standard panel I posted the last frequency response pics,this is the material I'm always trying to beat , I've come close in some respects with my small (down to 4inches in some cases) panels,but nothing matches the shear enjoyment of the large eps panel.

I went down memory lane and visited nxt Rubbish on ac ,I joined that in 2009 but had been testing dml panels for quite a few years before.

It saddened me to see how things haven't changed , still talking about the same old panel materials and all those equations nothing has moved on!

Eps seems to have been mostly ignored for more costly heavy materials .

Eps produces the light and delicate sounds but with huge dynamics and atmosphere that heavier panels lack,and the exciter has to do very little to achieve this.

When it comes to full range ,even if a had a panel and and exciter that could play loud LF would I use it all the way down to 20hz and below? It might be ok for chamber music and the like but for heavy rock or electronic or close mic recordings the exciter and panel would struggle to play the rest of the frequency spectrum cleanly.

I believe eps to produce a combination of direct radiated and dml sound ,and believe that the combination is important,heavier more rigid type panels (including podiums) tilt more towards dml,that is probably why layeredsound by s Katz uses a postonic speaker in parallel to the podiums.

Don't mean to rock the boat but things do need to move on !

Steve

Thanks for this spedge. I actually enjoy the direction the thread is heading currently, but then again - I'm just an observer currently, not building or testing any DML at the moment and cannot comment on any panel material comparison. However, could you give us more details on your EPS panels for the record please? Grade, size, thickness, exciters and placing and how are they mounted etc. Thanks, I try to keep notes on all of this.Burntcoil.

Whenever I pull out my old large eps panels,which isn't that often,there is always that wow! Factor and that is just with the bog standard panel I posted the last frequency response pics,this is the material I'm always trying to beat , I've come close in some respects with my small (down to 4inches in some cases) panels,but nothing matches the shear enjoyment of the large eps panel.

I went down memory lane and visited nxt Rubbish on ac ,I joined that in 2009 but had been testing dml panels for quite a few years before.

It saddened me to see how things haven't changed , still talking about the same old panel materials and all those equations nothing has moved on!

Eps seems to have been mostly ignored for more costly heavy materials .

Eps produces the light and delicate sounds but with huge dynamics and atmosphere that heavier panels lack,and the exciter has to do very little to achieve this.

When it comes to full range ,even if a had a panel and and exciter that could play loud LF would I use it all the way down to 20hz and below? It might be ok for chamber music and the like but for heavy rock or electronic or close mic recordings the exciter and panel would struggle to play the rest of the frequency spectrum cleanly.

I believe eps to produce a combination of direct radiated and dml sound ,and believe that the combination is important,heavier more rigid type panels (including podiums) tilt more towards dml,that is probably why layeredsound by s Katz uses a postonic speaker in parallel to the podiums.

Don't mean to rock the boat but things do need to move on !

Steve

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker