AjohnL,Can you define what you mean by elastic modulus. Or even better how to measure it on a sample.

That modulus tends to get mixed up with Young's which effectively tests to destruction.

Sure can. In words, Elastic modulus is essentially the intrinsic resistance of a material to small tensile and compressive deformations. By "intrinsic" I mean that it is a property of the material itself, normalized for its dimensions. So Elastic modulus is a material property like density, that is, a material's elastic modulus is the same, regardless of how wide, or long, or thick the piece in your hand is.

Confusingly, engineers use a lot of different terms that essentially mean the same thing. Elastic modulus, Young's modulus, tensile modulus, flexural modulus all actually mean virtually the same thing. All are referred to as "E" and the dimensions will be in Pa or psi (or more commonly as GPa or mpsi because they are awkwardly large numbers otherwise). And you can use any of these in the equations I shared above.

So yes, we are talking about Young's modulus. And, while the Young's (i.e. Elastic) modulus can come from the same test that tests a sample to destruction, the Young's modulus actually comes from the very beginning of that test, long before there is any permanent deformation of the material, let alone outright failure. In "engineer-speak" the Modulus is the slope of the stress/strain curve.

The simplest practical way to measure Elastic Modulus is in a three point point bend test. This anyone can do at least a crude version of in their own home.

Support a long narrow and skinny beam of the material across two points of support, near the ends. Apply a weight (P) to the center, and measure how far the center of the beam deflects down due to the addition of the weight.

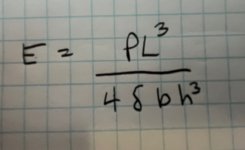

Calculate the Elastic Modulus (E) using the equation below, where b is the beam width and t is the beam thickness. The deflection (small greek delta), is the deflection in the center with the applied load small load (P).

The trick is to use a small enough weight that you don't come close to breaking your beam, but heavy enough that the deflection can be measured. Without lab equipment, it's hard to get great measurements, but you can get in the ballpark.

There is actually a better way, but it requires having REW software and a microphone, and is based on this principle: https://en.wikipedia.org/wiki/Impulse_excitation_technique

There's another thread about that....

Eric

Eric,I've actually been looking for this effect in any of my own panels for some time now but have not been able to clearly detect it.

I have in my do list to have a look to my measurement in the REW spectrogram view. Usually, I have look to the FR with a time window of some hundred milliseconds (500ms?). This gives a view of the direct sound plus the reflections. One possibility is to reduce this time window but then the resolution in frequency is also reduced. For example if the time window is set to 3ms (which is a bit too high to exclude the floor reflection), the resolution is 300Hz. It is an illusion of the tool to give something more precise. I haven't investigate a lot around it but I think the wavelets don't suffer of the same problem. So the idea is to have a look of REW measurements made on axis and let say 60 to 70° in the spectrogram mode. Looking in the first milliseconds (1 to 2ms?) should show a deep on axis and a peak off axis... at least for an isotropic material. For an orthotropic material, the effect of the coincidence frequency should be less "local" (one patent says it is an advantage of orthotropic material to spread the coincidence frequency). All of that is assumption but directivity of DML is a topic by itself.

Christian

Christian,So the idea is to have a look of REW measurements made on axis and let say 60 to 70° in the spectrogram mode. Looking in the first milliseconds (1 to 2ms?) should show a deep on axis and a peak off axis... at least for an isotropic material.

That's worth trying. I've mainly trying (and failing) to see it by using the RTA mode off axis.

Eric

amenIf it is anything that needs curing I think it is the perception that a flat curve is "right", and that there is one correct target for all systems for all occasions on all locations.

Which I do have but wonder about packages other than REW. The docs don't seem to be very task orientated - but that might just be down to me as not used anything like it before. However I have seen better.There is actually a better way, but it requires having REW software and a microphone, and is based on this principle

The link makes me wonder about an adaptation. Move the supports to the end of the panel and drive one with an exciter. Ignoring constraining the panel some how and assuming there is a solution.

Part of the reason also relates to NXT's golden ratio and ideas on exciter placement that appear to have come from FEA., ie Finding a suitable position without actually attaching an exciter. If it also finds the low frequency resonance point fine.

Off axis DML performance as mentioned in some posts. One paper suggests that unless this is "perfect" the panel isn't optimised. This also implies it may not be as expected.

No problems 👌Hi Steve, I got lost in work commitments, they crept in, taking myself to the point that all personal interests were being overlooked.

The Seasons Holiday Period has certainly opened up how unbalanced things have been.

The Boards offered are still available stored safely.

The reason I suggested sanding is because I am sure a board of very similar type (impact resistant) to the one you are now familiar with, has been met in use with a lesser dimension as the thickness / diameter dimension on the flute?

As this board was being used in a Main Entrance as a Flooring Protection, I did not investigate it, neither did I look to discover if spare has been available, as I would struggle to get it home in a large board dimension.

Now my work load will not be as intense in early 2024, maybe I can take the time to see what can be achieved with my DML

Can you explain why you have a peak at about 14k on the poron and a massive downwards slope on the other material.Loeb,

Indeed, it looks like the narrower panel has a bit better impulse response. See below the impulse responses I measured for the 24" wide panel, the 14" wide panel. and finally the same exact 14" wide panel, but with better damping (Poron 92 foam) on the perimeter, in place of the original 3M 411 double sided tape. The IR of the 24" wide panel is poor, while the the 14" wide panel is slightly better. But improving the perimeter damping made a much bigger improvement in IR than narrowing the panel did.

The 3M 411 is actually a decent perimeter material, but I hadn't learned to optimize it yet. Using a narrower strip (and 2 or 3 layers thick), would likely have given results closer to the Poron 92.

View attachment 1254113View attachment 1254114View attachment 1254115

Also, a nice secondary effect of using the Poron perimeter was a slight extension of the low end frequency range. The much softer, thicker Poron constrains the edges less than the 3M 411 did, shifting the natural frequencies a bit lower and hence extending the low end by maybe 10 Hz.

Eric

View attachment 1254119

What distance were these measurements made.

For a dml to work properly you need the panel to vibrate freely, so surly a longer impulse response is expected.

If you can hear this delayed response, you have a problem.

There are ways to reduce the panels resonance without damping, damping by itself just causes problems, mainly to the sound of the panel, heavy panels are already restrained in dynamics, damping just makes it worse.

Steve.

Quick, rabbit-trail question:

What are the main TS parameters that determine the ultimate efficiency of a driver given the same panel parameters across different drivers?

I would assume Re, BL and Cms.

Comments?

What are the main TS parameters that determine the ultimate efficiency of a driver given the same panel parameters across different drivers?

I would assume Re, BL and Cms.

Comments?

Not for certain. That peak is fickle. It will show up in some measurements, and then not in others. It's not an effect of the Poron, as the same peak shows up in some measurements on other panels without Poron. Probably the biggest clue is that it coincides with a peak in the impedance curve of the exciter, no matter what it's mounted to. DAEX25FHE and DEAX25VT exciters both show the same peak in impedance. So my best guess is that this is the break up of the exciter voice coil. It may be that this peak has strong lobing, and shows up (or not) depending on the exact location of the mic. My hearing only goes up to about 11k, like most people of my age, so it's a curiosity for me, but of no real significance.Can you explain why you have a peak at about 14k on the poron and a massive downwards slope on the other material.

What distance were these measurements made.

All those measurements were taken at 1 meter.

We disagree on that point. Free vibration without damping is a recipe for spikes and dips in the frequency response, along with ringing at random resonance frequencies. Luckily, most materials have some internal damping, and the viscous resistance of the air provides a bit of damping too, so some seemingly "free" panels can have tolerable (though far from ideal) levels of it.For a dml to work properly you need the panel to vibrate freely,

Expected, yes, but that doesn't make it a good thing.so surly a longer impulse response is expected.

I am interested to know what those methods are.There are ways to reduce the panels resonance without damping.

I've not heard evidence of that. Do you have any to share?damping by itself just causes problems, mainly to the sound of the panel, heavy panels are already restrained in dynamics, damping just makes it worse.

http://www.soundright.org.uk/NXTchaos.pdf

This explains the impulse response question and also some others.

If you placed damping or clamping on a cone speaker would you not hear a difference ?

Dml is no different in this respect, you cannot damp a cone , dml , or any other type of transducer without affecting its sound.

It chokes the dynamics and excitement out of the drive unit, creating an unrealistic sounding speaker.

You only need your ears to tell you this, show me a patent or white paper that tells you how a panel or cone sounds.

I have discussed all of these topics over the years on this forum and others, to no avail obviously.

The proof of the pudding is in the eating, not the cooking!

Steve.

This explains the impulse response question and also some others.

If you placed damping or clamping on a cone speaker would you not hear a difference ?

Dml is no different in this respect, you cannot damp a cone , dml , or any other type of transducer without affecting its sound.

It chokes the dynamics and excitement out of the drive unit, creating an unrealistic sounding speaker.

You only need your ears to tell you this, show me a patent or white paper that tells you how a panel or cone sounds.

I have discussed all of these topics over the years on this forum and others, to no avail obviously.

The proof of the pudding is in the eating, not the cooking!

Steve.

Eric.

If you paid attention to my posts you would also know what is causing the 14k spike and how to cure it.

And why it is on one measurement and not the other.

Steve.

If you paid attention to my posts you would also know what is causing the 14k spike and how to cure it.

And why it is on one measurement and not the other.

Steve.

I have a basic & simple question >

( I may have missed something )

Apart from just 'advertising words', what is the difference between an Exciter and a Thruster?

( I may have missed something )

Apart from just 'advertising words', what is the difference between an Exciter and a Thruster?

All Thrusters are exciters, but not all exciters are Thrusters....what is the difference between an Exciter and a Thruster

All Chevvies are cars, but not all cars are Chevvies.

It's just advertising.

Every cone I have ever seen is dampened since the edges are connected to the frame.http://www.soundright.org.uk/NXTchaos.pdf

This explains the impulse response question and also some others.

If you placed damping or clamping on a cone speaker would you not hear a difference ?

Dml is no different in this respect, you cannot damp a cone , dml , or any other type of transducer without affecting its sound.

It chokes the dynamics and excitement out of the drive unit, creating an unrealistic sounding speaker.

You only need your ears to tell you this, show me a patent or white paper that tells you how a panel or cone sounds.

I have discussed all of these topics over the years on this forum and others, to no avail obviously.

The proof of the pudding is in the eating, not the cooking!

Steve.

And every DML plate I have tried sounds a lot better dampened. You might like the effect of ringing, but it does reduce the fidelity and is very material dependent if it sounds good or not. It can be nice on minimal tracks with vocals sometimes, but makes a mess of more complex material.

How do you explain the panels I listen to daily? This image shows a version that is different to mineIt chokes the dynamics and excitement out of the drive unit, creating an unrealistic sounding speaker.

https://www.diyaudio.com/community/attachments/1698683759695-png.1229146/

However in both cases a substantial piece of foam is effectively holding the panel against the frame.

There has also been instances of where some one has covered a panel with "oddly shaped" pieces of some material, Also cavities behind panels.

The first post in this thread has it's interesting aspects

https://www.diyaudio.com/community/...s-as-a-full-range-speaker.272576/post-4284038

What improvements have been made?

The exciter mounting shown in the image is also interesting. The same could be done with Dayton's framed exciters.

Fascinating claim: "Damping chokes the sound"

So does this explain why every single cone speaker ever produced has a ring around its edge connected it to the basket, and with very carefully-designed damping characteristics? Rubber surrounds with heavy rubber and high damping for some kinds of sound, and cloth or paper surrounds with low damping for different kinds of sound? Paper cones that have a certain level in self-damping, and carbon-fibre or kevlar cones only damped with rubber edges?

Weird claim.

OF COURSE the damping changes the sound! That's what it supposed to do!

Even acoustic instruments have carefully-crafted ribs and braces inside their sound boards, and are specifically engineered for the best damping: Not too much or it sounds dull; not too little or it sounds clangy, just like undamped DML panels.

So does this explain why every single cone speaker ever produced has a ring around its edge connected it to the basket, and with very carefully-designed damping characteristics? Rubber surrounds with heavy rubber and high damping for some kinds of sound, and cloth or paper surrounds with low damping for different kinds of sound? Paper cones that have a certain level in self-damping, and carbon-fibre or kevlar cones only damped with rubber edges?

Weird claim.

OF COURSE the damping changes the sound! That's what it supposed to do!

Even acoustic instruments have carefully-crafted ribs and braces inside their sound boards, and are specifically engineered for the best damping: Not too much or it sounds dull; not too little or it sounds clangy, just like undamped DML panels.

Dayton's most efficient exciter might give an indication but going on an amazon.uk review it's weight makes it difficult to use. Weight is almost bound to figure.Quick, rabbit-trail question:

What are the main TS parameters that determine the ultimate efficiency of a driver given the same panel parameters across different drivers?

I would assume Re, BL and Cms.

Comments?

https://www.daytonaudio.com/product/1184/daex25shf-4-steered-high-flux-25mm-exciter-20w

There's a lot wrong with the Amazon description (this driver is certainly not the "most powerful" of the range. It's only 20W!)Dayton's most efficient exciter might give an indication but going on an amazon.uk review it's weight makes it difficult to use. Weight is almost bound to figure.

https://www.daytonaudio.com/product/1184/daex25shf-4-steered-high-flux-25mm-exciter-20w

And the Dayton factory also seems to get it wrong. The factory curves show an SPL response that's 20dB higher than any other driver! That cannot be correct. The driver itself weighs in at around 270grams, vs the 30HESF-4 which is the next heaviest at around 180grams. But if the 25SHF has such an extremely heavy motor, and an Re of 4.3ohm (which is rather average) then why does it have a BL of only 4.29Tm?? In addition, with an Re of 4.3r, and a Bl of only 4.29Tm how is it possible to have a sensitivity 20db higher than all the others?

Maybe it's so heavy because it uses a ferrite magnet instead of neodymium like all the others? But this does not explain all the other apparent errors in this driver's specs.

Oh... Edit: Bottom line is that efficiency primarily depends on BL and Re. And BL depends on magnetic flux density and the length of coil wire inside that magnetic field (and the length of wire, of a certain gauge, determines Re and Pmax). So one can have a large, heavy magnet, but if it's a ferrite magnet, then it will have much much lower flux density than a neo magnet of the same weight.

But that's not all... if you have a wide pole gap then the flux density will be lower than a narrow pole gap. So looking at the magnet weight and material alone will not tell the whole story. That's why BL is the go-to parameter.

Last edited:

Another thing that makes me doubt the Dayton spec... The BillionSound OEM, who are the suppliers of these drivers to Dayton, specify the 30HESF-4 (rebranded equivalent?) as having a sensitivity of around 86.9db/W. This figure is derived from double-mass TS parameter tests and not from panel tests.

The 25SHF-4 (rebranded equivalent?) under discussion comes out at 85.8db/W.

This is much more in line with what I would expect given the other numbers.

DAEX-30HESF-4

DAEX-30HESF-4

DAEX-25SHF-4

DAEX-25SHF-4

The 25SHF-4 (rebranded equivalent?) under discussion comes out at 85.8db/W.

This is much more in line with what I would expect given the other numbers.

Last edited:

Yes I know. They make the claim based on SPL while mounted on rather small piece of foam. As all are rated that way ???????? meaningfulness. Perhaps stroke length figures as well. It is rather longAnd the Dayton factory also seems to get it wrong. The factory curves show an SPL response that's 20dB higher than any other driver!

High output exciter design Specially designed neodymium motor and proprietary 2layer voice coil 3M™ VHB™ adhesive ring with four mounting holes Low inductance motor for extended response

The review I mentioned states that it has good performance over a certain frequency range but weight makes it difficult to use.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker