Thanks again for the round flueted panels.Looking at the Flutes, I can't help but think that for the purposes of the DML, a lighter Panel is achievable if the Corrugated Infill was to be perforated, the stiffness of the panel should be maintained.

As for the Fluted Panels I have given to @spedge, I was wondering if sanding down one Face might increase the flexion of the panel and further enhance the experience that has already been enjoyed.

I will also reintroduce the idea of using a Panzerholz for its notable Damping and Dissipation Properties.

A Panzerholz Disc / Rosette may prove valuable if produced to a Sandwich Layer between Panels and Exciter or other placement to help manage energy being transferred.

All recommendations are specific to being experimentalist only and are on the table following Five Mugs of Coffee 😎 .

I presume I'm not getting the next batch ?, but no problems.

I think it is the round fluting that could be the cause of the good performance from this panel.

They sound very natural with a clean clear sound, with full frequency performance.

I think that 3D printing smaller scaled-down round flueted panels could be a cheaper option similar to leobs first test panels .

This would be interesting to test, but I would probably not get around to it, as I do not own a printer.

Steve.

Loeb,A few dB difference in a few bumps here and there will matter a lot less than the prolonged impulse response a larger plate will have.

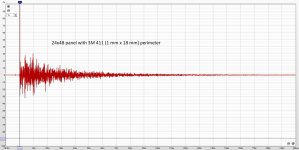

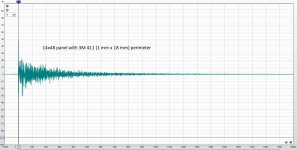

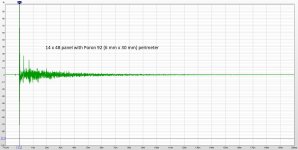

Indeed, it looks like the narrower panel has a bit better impulse response. See below the impulse responses I measured for the 24" wide panel, the 14" wide panel. and finally the same exact 14" wide panel, but with better damping (Poron 92 foam) on the perimeter, in place of the original 3M 411 double sided tape. The IR of the 24" wide panel is poor, while the the 14" wide panel is slightly better. But improving the perimeter damping made a much bigger improvement in IR than narrowing the panel did.

The 3M 411 is actually a decent perimeter material, but I hadn't learned to optimize it yet. Using a narrower strip (and 2 or 3 layers thick), would likely have given results closer to the Poron 92.

Also, a nice secondary effect of using the Poron perimeter was a slight extension of the low end frequency range. The much softer, thicker Poron constrains the edges less than the 3M 411 did, shifting the natural frequencies a bit lower and hence extending the low end by maybe 10 Hz.

Eric

Hi Steve, I got lost in work commitments, they crept in, taking myself to the point that all personal interests were being overlooked.

The Seasons Holiday Period has certainly opened up how unbalanced things have been.

The Boards offered are still available stored safely.

The reason I suggested sanding is because I am sure a board of very similar type (impact resistant) to the one you are now familiar with, has been met in use with a lesser dimension as the thickness / diameter dimension on the flute?

As this board was being used in a Main Entrance as a Flooring Protection, I did not investigate it, neither did I look to discover if spare has been available, as I would struggle to get it home in a large board dimension.

Now my work load will not be as intense in early 2024, maybe I can take the time to see what can be achieved with my DML Interests.

The Seasons Holiday Period has certainly opened up how unbalanced things have been.

The Boards offered are still available stored safely.

The reason I suggested sanding is because I am sure a board of very similar type (impact resistant) to the one you are now familiar with, has been met in use with a lesser dimension as the thickness / diameter dimension on the flute?

As this board was being used in a Main Entrance as a Flooring Protection, I did not investigate it, neither did I look to discover if spare has been available, as I would struggle to get it home in a large board dimension.

Now my work load will not be as intense in early 2024, maybe I can take the time to see what can be achieved with my DML Interests.

Good size depends on material, suspension, etc, but I found that really small panels (< 300-400mm or so on the long end) would give an uneven response. But like I said I have not really done the kind thorough tests Eric has, so I might be wrong.Leob.

What is a large plate, and what is a small plate.

I have used small panels down to 3 or 4inches.

Large panels up to 4ft x 8ft , where is the transition between the two, what can be used and what cannot be used.

The efficiency of the panel in the low end ,will drop off somewhat as you move to the side of the panel , especially if it has been reduced in width.

The harshness in the top end can be caused by many things, and cured, does anyone listen to a word I say ?

Steve.

I'm not interested in panels that cannot go down to 150Hz at least. Subs don't work well going up to mid range and I really don't want extra crossovers...one of the benefits of DML speakers is the ability to cover full range above sub an upwards.

When it comes to HF slope, it seems like you have a very different understanding of how to tune a system. The way I know it, you decide on a target curve...how you want to tilt the FR to get the right amount of treble and right amount of bass for the system to sound good. Then you can do tweaks to get to that target, but the idea that the target has to be flat is just not correct. Very often that can be something close to a 6dB per octave slope. If a system has distorted HF reproduction I would turn it down more, but DML speakers indeed have very smooth and pleasant treble and you can go for a bit more treble than usual without it becoming overbearing. But a flat response is certainly not desirable IMO, and typically prefer a warmer sound.

If it is anything that needs curing I think it is the perception that a flat curve is "right", and that there is one correct target for all systems for all occasions on all locations.

I guess that when you talk about efficiency of the panel in relation to listeners position you mean that FR that the listener will experience? I noticed that response around 100-400Hz shifts quite a bit depending on both distance and angle. You are probably correct that FR would improve with a larger plate, but not sure I think it is worth it when taking time domain into account as well...and especially not when it comes to practicality for something that should be transportable.

That is quite the difference between the different suspension materials!Loeb,

Indeed, it looks like the narrower panel has a bit better impulse response. See below the impulse responses I measured for the 24" wide panel, the 14" wide panel. and finally the same exact 14" wide panel, but with better damping (Poron 92 foam) on the perimeter, in place of the original 3M 411 double sided tape. The IR of the 24" wide panel is poor, while the the 14" wide panel is slightly better. But improving the perimeter damping made a much bigger improvement in IR than narrowing the panel did.

The 3M 411 is actually a decent perimeter material, but I hadn't learned to optimize it yet. Using a narrower strip (and 2 or 3 layers thick), would likely have given results closer to the Poron 92.

View attachment 1254113View attachment 1254114View attachment 1254115

Also, a nice secondary effect of using the Poron perimeter was a slight extension of the low end frequency range. The much softer, thicker Poron constrains the edges less than the 3M 411 did, shifting the natural frequencies a bit lower and hence extending the low end by maybe 10 Hz.

Eric

View attachment 1254119

If feel that is the easiest area to focus on when trying to tweak the FR of my design at least. I was set back by the distorting exciters when trying to evaluate an updated design, but decided against the foam material I was using since it seemed to loose stiffness with time, and instead now print suspension pads with TPU. By adjusting wall thickness and infill density, firmness can be adjusted and they should keep stiffness well over time.

Looking at the Poron I would be weary of how that holds up over time...but most materials that do, like 411 and more rubbery materials, indeed seems too hard.

When all is said and done ....

I believe that it is likely possible that some GENIUS MEMBER could derive an equation using

the factors: AREA , WEIGHT and SUPENSION COMPLIANCE, also using various exciter parameters.

Using simple digital scales, I intend to quote my panel weight.

I am hoping that other members also start quoting weight 🙂

PS.

Such an equation need not be perfect to aid general understanding.

I believe that it is likely possible that some GENIUS MEMBER could derive an equation using

the factors: AREA , WEIGHT and SUPENSION COMPLIANCE, also using various exciter parameters.

Using simple digital scales, I intend to quote my panel weight.

I am hoping that other members also start quoting weight 🙂

PS.

Such an equation need not be perfect to aid general understanding.

Loeb, could you elaborate a bit more on how you do this and what it looks like please? Maybe a picture or two.print suspension pads with TPU

Hello LeobGood size depends on material, suspension, etc, but I found that really small panels (< 300-400mm or so on the long end) would give an uneven response. But like I said I have not really done the kind thorough tests Eric has, so I might be wrong.

I'm not interested in panels that cannot go down to 150Hz at least. Subs don't work well going up to mid range and I really don't want extra crossovers...one of the benefits of DML speakers is the ability to cover full range above sub an upwards.

When it comes to HF slope, it seems like you have a very different understanding of how to tune a system. The way I know it, you decide on a target curve...how you want to tilt the FR to get the right amount of treble and right amount of bass for the system to sound good. Then you can do tweaks to get to that target, but the idea that the target has to be flat is just not correct. Very often that can be something close to a 6dB per octave slope. If a system has distorted HF reproduction I would turn it down more, but DML speakers indeed have very smooth and pleasant treble and you can go for a bit more treble than usual without it becoming overbearing. But a flat response is certainly not desirable IMO, and typically prefer a warmer sound.

If it is anything that needs curing I think it is the perception that a flat curve is "right", and that there is one correct target for all systems for all occasions on all locations.

I guess that when you talk about efficiency of the panel in relation to listeners position you mean that FR that the listener will experience? I noticed that response around 100-400Hz shifts quite a bit depending on both distance and angle. You are probably correct that FR would improve with a larger plate, but not sure I think it is worth it when taking time domain into account as well...and especially not when it comes to practicality for something that should be transportable.

Interesting you point that and enter the topic in the DML world.

Since the work from M Floyd and others, there are design rules for loudspeakers that ask for a flat on axis response, a smooth power response with a linear decreasing to the HF, a smooth directivity.

M Floyd pointed also the fact that our hearing is sensitive to high Q peaks.

With DML, we are still in the phase to make measurements that are the equivalent of energy measurements. Even if it is measurements in the axis, the time window is hundreds of millisecond so the reflections from the room are in this response (not excluded).

Currently my reading of such FR "is it smooth enough?"; getting the desired slope comes in a second time... and this time is coming as I think, we should have a look to the spectrogram in order to have a view of the on axis "quasi-ananechoic" FR.

Could you explain a bit more "shifts around 100-400Hz"? I observed also in my measurements some "shifts" of this area, visible in room, not in outside measurements. They are not visible in Eric's measurements. I wonder if there is an effect of the position of the panel in the room (distance to the boundaries).

Christian

Could it be this one?

https://www.parts-express.com/Dayto...erchangable-Hardware-Mount-295-275?quantity=1

Although this is a mid-bass exciter.

Last edited:

Doubt it.Could it be this one?

It could be a number of arrangements. There isn't enough detail / contrast in the image to tell. The white dots need an explanation as well.

They just look like little blocks 🙂 I currently have them 10x30x6mm.Loeb, could you elaborate a bit more on how you do this and what it looks like please? Maybe a picture or two.

Here is a screenshot from slicer showing how they look on the inside:

So basically you can adjust the density and how compliant they are. You can also get TPU of different hardness, but usually it is like a hard rubber and a completely filled block would be too stiff.

I think smoothness is generally desirable, although not always worth compensating too much to get it ruler flat. But tilt or the overall balance between lows, mids and treble is a different matter and definitely depends. I'm not that familiar with hi-fi, but I guess those often go for a quite flat response. PA systems almost never do afaik, because while a lot of treble might sound shiny and sharp at regular levels, at war levels for hours on end it doesn't.Hello Leob

Interesting you point that and enter the topic in the DML world.

Since the work from M Floyd and others, there are design rules for loudspeakers that ask for a flat on axis response, a smooth power response with a linear decreasing to the HF, a smooth directivity.

M Floyd pointed also the fact that our hearing is sensitive to high Q peaks.

With DML, we are still in the phase to make measurements that are the equivalent of energy measurements. Even if it is measurements in the axis, the time window is hundreds of millisecond so the reflections from the room are in this response (not excluded).

Currently my reading of such FR "is it smooth enough?"; getting the desired slope comes in a second time... and this time is coming as I think, we should have a look to the spectrogram in order to have a view of the on axis "quasi-ananechoic" FR.

Could you explain a bit more "shifts around 100-400Hz"? I observed also in my measurements some "shifts" of this area, visible in room, not in outside measurements. They are not visible in Eric's measurements. I wonder if there is an effect of the position of the panel in the room (distance to the boundaries).

Christian

About the shifts around 100-400Hz, I just noticed that there is quite a difference off axis compared to on axis in that region, measured outdoors. There is also a region in the HF showing a stronger response off axis, which is somewhat unusual and unexpected.

Wow, thank you Leob. This is very interesting. Do you print this with a 3D printer? I'm still not shure how you use these blocks to mount the panel. I am thinking hard of ways to mount a panel using silicone blocks or extrusions. Of course silicone can also be cast into moulds, so you can make your own blocks or brackets.

I got some silicone strips, but they where too hard, and also you need special glue to fix silicon. I fix the blocks to my frame with UHB tape, then fix the plate to the blocks, again with tape so plate is clamped and fixed between blocks from two sides on four contact points.

You need a printer that can print at high enough temp for TPU, which excludes some of the very cheapest models. I can help out if you only need some blocks....there very cheap and fast to print, but not sure about postage to SA.

You need a printer that can print at high enough temp for TPU, which excludes some of the very cheapest models. I can help out if you only need some blocks....there very cheap and fast to print, but not sure about postage to SA.

Very cool Leob!They just look like little blocks 🙂 I currently have them 10x30x6mm.

Here is a screenshot from slicer showing how they look on the inside:

View attachment 1254390

So basically you can adjust the density and how compliant they are. You can also get TPU of different hardness, but usually it is like a hard rubber and a completely filled block would be too stiff.

Regarding the TPU materials, I am not very familiar with them so I don't know what options are available, or especially what details are given in their specs. But if you want good damping from them (which I think you do), then you would want the TPU with a glass transition temperature (Tg) that is as close to room temperature as possible. Polymeric materials provide the best damping when they are at their glass transition temperature. Since TPU's are described as elastomers, the Tg's are probably typically well below room temperature. In that case, I'd look for ones with the highest Tg available.

Eric

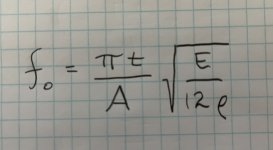

The size (area) of a panel strongly influences its fundamental frequency, which in turn is a lower bound for the panel's low frequency capability. Hence, size is indeed a critical panel measure. The larger the area, the lower the fundamental frequency. So if you want a panel to reach down to, say, 100 Hz, it has to be large enough for its fundamental frequency to be 100 Hz (or less).What is a large plate, and what is a small plate.

I have used small panels down to 3 or 4inches.

Large panels up to 4ft x 8ft , where is the transition between the two, what can be used and what cannot be used.

So I don't really think of a panel's size in terms of its raw area, but rather, in terms of whether or not it is large enough to have a fundamental frequency that is at least as low as the lowest frequency I want the panel to reach.

In addition to area, the panel properties that most strongly determine the panel's fundamental frequency are its thickness (t), elastic modulus (E) and density (ρ). Other factors that affect it are suspension, aspect ratio, and exciter characteristics, but these are relatively minor effects compared to the first three.

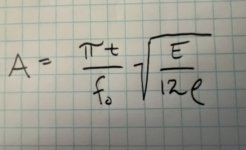

There is an equation for estimating the natural frequency of a panel, which is this:

Rearranging gives this:

Using the second version, you can simply enter the panel properties (thickness, elastic modulus and density), along with the frequency you wish to reach (fo) into the equation, and have a pretty good idea if your panel is "large enough". That is, as long as your panel is larger than "A", it is large enough.

Even without doing a single calculation, just examining the equation gives some valuable insights. You might wonder, for example, how does using a thinner panel effect the necessary size? Examining the equation tells you that a panel of half the thickness can be half the size and still reach the same fundamental. What about elastic modulus (stiffness)? The equation reveals that a panel that is four times stiffer will need to be two times larger.

Those equations are only approximations (except for the case of a square, isotropic panel on simple (hinged) supports), but are a good starting point for virtually any configuration.

Eric

Might it be an evidence of the coincidence frequency? We could expect at this frequency an increase of the SPL off axis and a deep on axis.There is also a region in the HF showing a stronger response off axis, which is somewhat unusual and unexpected.

Can you define what you mean by elastic modulus. Or even better how to measure it on a sample.Those equations are only approximations (except for the case of a square, isotropic panel on simple (hinged) supports), but are a good starting point for virtually any configuration.

That modulus tends to get mixed up with Young's which effectively tests to destruction.

They are typically rated in Shore hardness, and with no figures for Tg.Very cool Leob!

Regarding the TPU materials, I am not very familiar with them so I don't know what options are available, or especially what details are given in their specs. But if you want good damping from them (which I think you do), then you would want the TPU with a glass transition temperature (Tg) that is as close to room temperature as possible. Polymeric materials provide the best damping when they are at their glass transition temperature. Since TPU's are described as elastomers, the Tg's are probably typically well below room temperature. In that case, I'd look for ones with the highest Tg available.

Eric

The softer ones are more expensive and can be a bit harder to print. The filament becomes quite flexible there can be trouble feeding it through the extruder. So the easiest way to adjust the stiffness for a block like this is really to modify structure.

Christian,Might it be an evidence of the coincidence frequency? We could expect at this frequency an increase of the SPL off axis and a deep on axis.

True. See this image from one of Ben Zenker's papers. Note the high off axis (+/-90) SPL at about the coincidence frequency, which is at 6kHz for this panel.

I've actually been looking for this effect in any of my own panels for some time now but have not been able to clearly detect it.

Eric

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker