I can't say I'm convinced by that patentWhy only four drives?

https://patents.google.com/patent/JP2008109541A/en?oq=JP2008-109541A

Thanks...I remembered your example but couldn't find it again...far too many posts in this thread 😵💫Tried it with good result. See https://www.diyaudio.com/community/...ll-range-speaker.272576/page-406#post-7224227

It’s a full range that playes from 30 to close to 20k. It’s used in a 40 sqm living room. Possible sound level can easily destroy your hearing…

It’s quite easy to eq it to a flat response. I think it’s possible to make it play down to 20 Hz, haven’t tried it yet though.

Thomas

That's the road I'm travelling on.

Your tests were done in-wall...have you carried out any on a free standing basis?

That's some serious punch in a smallish panel 👍😃

So balsa cored with CF skins

I'm a bit surprised it doesn't go even lower...I wonder what the effect of a heavier panel may be?

How did you make the U shaped surround?

Thanks again

Eucy

”Thanks...I remembered your example but couldn't find it again...far too many posts in this thread 😵💫

That's the road I'm travelling on.

Your tests were done in-wall...have you carried out any on a free standing basis?

That's some serious punch in a smallish panel 👍😃

So balsa cored with CF skins

I'm a bit surprised it doesn't go even lower...I wonder what the effect of a heavier panel may be?

How did you make the U shaped surround?

Thanks again”

****************************

It’s nice road to explore!

Yes, I have played it free standing with a small box and without. The box was roughly 4 liter, so quite small resulting in a somewhat reduced bass output. However it was easy to eq it with a linquist transform.

well, it’s the size of a 15 inch woofer with xmax of 10 mm so…

yes, it’s balsa with cf skin.

currently it’s going down to 30Hz without eq. most likely due to quite small ”box” volume in the wall. I’m planning to eq it to 20 Hz.

Yes, mass might have something to do with or not it’s only one 1/10 of a regular woofer. It’s one area to explore.

I am using EVA foam which is used in regular speaker surronds. I’m heat forming using 3D printed forms (pressing it between a positive and negative form) and heatgun. It’s bit tricky. I’m planning to change to vacuum forming instead In the version.

Thomas

That's the road I'm travelling on.

Your tests were done in-wall...have you carried out any on a free standing basis?

That's some serious punch in a smallish panel 👍😃

So balsa cored with CF skins

I'm a bit surprised it doesn't go even lower...I wonder what the effect of a heavier panel may be?

How did you make the U shaped surround?

Thanks again”

****************************

It’s nice road to explore!

Yes, I have played it free standing with a small box and without. The box was roughly 4 liter, so quite small resulting in a somewhat reduced bass output. However it was easy to eq it with a linquist transform.

well, it’s the size of a 15 inch woofer with xmax of 10 mm so…

yes, it’s balsa with cf skin.

currently it’s going down to 30Hz without eq. most likely due to quite small ”box” volume in the wall. I’m planning to eq it to 20 Hz.

Yes, mass might have something to do with or not it’s only one 1/10 of a regular woofer. It’s one area to explore.

I am using EVA foam which is used in regular speaker surronds. I’m heat forming using 3D printed forms (pressing it between a positive and negative form) and heatgun. It’s bit tricky. I’m planning to change to vacuum forming instead In the version.

Thomas

Please comment.

I have never reeeelly bought into the idea of 'running in' speakers of any kind.

In my experience, speakers perform the same they do when you buy them as when they're older, barring depleted wallets, hopeful psychological issues and perishing surrounds of course. Same as when you overhaul your old Cosworth racing engine just before a race, as opposed to racing it 3 months down the line when the valves and rings are stuffed to hell-n-gone.

I measured my 'Gig Panels' (4 x DAEX25Q-4's each in 2 x 1,400mm x 450mmx 5mm Twinwall panels) beginning Feb just after assembling them, and I was a bit 'meh'—they were a lot better, bandwidth-wise, than the high power 30HESFs and "32QMB-4 Mega-bass" drivers in the same panels. But I still had to EQ them quite a bit to make them palatable for general stage use.

This has changed.

I find I have to EQ them less and less to get the sound that I want.

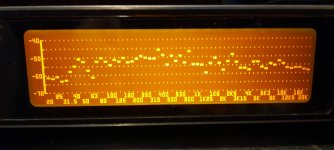

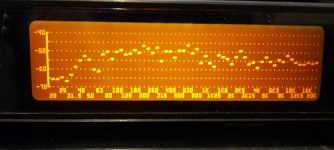

I've just compared them to the measurements I did a month ago (after A LOT of very loud abuse) and there are differences. I stand corrected: Drivers DO need to be run-in.View attachment 1148526

And as you can see, there is definitely a 450hz peak that might disagree with any other signal source with a similar peak.

Oh. And check out the bass end... Unless I'm driving very loudly indeed on stage, I don't need a sub.

50hz on the bottom is wayy enough for almost everything I consume at home.

Could the increase above 5k be due to the glue holding the exciter on hardening.

I have to wait at least 3 days before measuring my panels when gluing using pva, and will continue to harden over time.

The HF will always sag until the glue has dried out properly.

Do the sticky pads dry off over time?

Steve.

It seems the DS tape on those drivers does not adhere nicely to polycarb. I've tried everything to make it stick properly, but the drivers fall off after a while.Do the sticky pads dry off over time?

When I ws still supporting the drivers with a brace I could not figure out where the rattling was coming from... It was from the VCs coming adrift from the polycarb panel, but the drivers were still in place because of the bracing.

So now I use superglue. And the drivers, all 8 of them, are still in place, without bracing.

Maybe it takes a while to harden, maybe not. I'm not sure.

My suspicion is that the spider on the driver loosens up with lots of movement. It's also possible that the spray paint on the panels cures over time, and gets a little harder and lighter.

Andre and Eucy.

This is the square fluted polypropylene panel.

Yes there is a hot spot at about 400hz in the first picture and suck outs below ,causing a uneven response

Using 4 weights improves this response bringing up the lower frequencies to match the hot spot.

There is still a sharp peak though in picture 2 , I think this is an exciter problem that shows up moving around the room.

There is also one at about 2.5k.

The third picture shows the 400hz peak pretty much gone Using a fifth weight.

That does not mean that the problem has gone , it is just buried below the higher panel volume.

The last two pictures show the positions of the 4 and 5 weights.

I made these measurements in only a few minutes, so I would hope better responses could be attainable.

You can also hear the panel sound change as you move the weights around the panel , which also can change the panels resonant trademark sound, if you are lucky.

The weights in the pictures are magnets which are very easy to slide around the panel( this only works if the panel is thin enough and a smooth surface) and watch the response change in real time.

If I had to position the weights and measure ever time it could take days if not more.

Steve.

This is the square fluted polypropylene panel.

Yes there is a hot spot at about 400hz in the first picture and suck outs below ,causing a uneven response

Using 4 weights improves this response bringing up the lower frequencies to match the hot spot.

There is still a sharp peak though in picture 2 , I think this is an exciter problem that shows up moving around the room.

There is also one at about 2.5k.

The third picture shows the 400hz peak pretty much gone Using a fifth weight.

That does not mean that the problem has gone , it is just buried below the higher panel volume.

The last two pictures show the positions of the 4 and 5 weights.

I made these measurements in only a few minutes, so I would hope better responses could be attainable.

You can also hear the panel sound change as you move the weights around the panel , which also can change the panels resonant trademark sound, if you are lucky.

The weights in the pictures are magnets which are very easy to slide around the panel( this only works if the panel is thin enough and a smooth surface) and watch the response change in real time.

If I had to position the weights and measure ever time it could take days if not more.

Steve.

Attachments

Hello AndréIt seems the DS tape on those drivers does not adhere nicely to polycarb. I've tried everything to make it stick properly, but the drivers fall off after a while.

When I ws still supporting the drivers with a brace I could not figure out where the rattling was coming from... It was from the VCs coming adrift from the polycarb panel, but the drivers were still in place because of the bracing.

So now I use superglue. And the drivers, all 8 of them, are still in place, without bracing.

Maybe it takes a while to harden, maybe not. I'm not sure.

My suspicion is that the spider on the driver loosens up with lots of movement. It's also possible that the spray paint on the panels cures over time, and gets a little harder and lighter.

Have you used super glue with primer for plastic ? see link in post #6455

Is polycarbonate easier to glue than polypro?

Christian

Hi Christian,Have you used super glue with primer for plastic ? see link in post #6455

Is polycarbonate easier to glue than polypro?

I clean the polycarb surface with acetone. I take any traces of DS tape off the exciter voice coil, and then apply very thin superglue to the VC flange. I apply it to the panel with a bit of pressure for a few seconds and then let it stand for an hour or so.

If I find I need to remove the driver then I have to apply a very sharp 2" chisel very carefully between the VC flange and the polycarb surface... Push-and-twist... Invariably some of the polycarb panel comes off as well. But it's a last resort.

I have used hot glue in the past. Using hot glue it's easier to take the driver off, but it does not cure as hard as the superglue, and I think it reduces HF a little.

this is a recording of what happens when you reverse the phase on one channel of a dml panel.

i have noticed that very little happens below about 100hz there are variations in dips between about 100hz and 200hz.

but these are not identical canvas panels, so if anyone has identical panels that go down to 40hz or lower it would be interesting to know if you could test this out to confirm.

it was the same with my square and round proplex panels.

the recording is from my hifi news test cd.

pistonic action would cause heavy cancelations below 100hz ?

this could be very interesting for anyone building a sub dml panel .

steve.

i have noticed that very little happens below about 100hz there are variations in dips between about 100hz and 200hz.

but these are not identical canvas panels, so if anyone has identical panels that go down to 40hz or lower it would be interesting to know if you could test this out to confirm.

it was the same with my square and round proplex panels.

the recording is from my hifi news test cd.

pistonic action would cause heavy cancelations below 100hz ?

this could be very interesting for anyone building a sub dml panel .

steve.

Attachments

In the documentation for the Dayton exciters I've looked at on Parts Express, they show the frequency response and say it was produced with a "12" x 12" x 1/2" foam core board in an infinite baffle setup."

Any idea what an infinite baffle means for an exciter + foam?

I'm not sure I entirely understand an infinite baffle for a regular speaker; just a big box or separator of some kind that prevents waves from back from interfering with waves from front? In all the DML projects I've seen I'm not sure I've seen anything that approximates such an enclosure.

Any idea what an infinite baffle means for an exciter + foam?

I'm not sure I entirely understand an infinite baffle for a regular speaker; just a big box or separator of some kind that prevents waves from back from interfering with waves from front? In all the DML projects I've seen I'm not sure I've seen anything that approximates such an enclosure.

What is a infinite baffle?infinite baffle

"In conceptual terms an infinite baffle is a flat baffle that extends out to infinity – the so-called "endless plate". A genuine infinite baffle cannot be constructed but a very large baffle such as the wall of a room can be considered to be a practical equivalent."

So they probably mean free hanging a few feet from a wall.

What is a infinite baffle?

Here is an example of an infinite baffle. It is in a Fibonacci spiral, giving a length of 60 inches, (152,4 cm). It is enclosed in a 12 inch (30.5cm) by 13 inch (33cm) by 7 inch (17.8 cm) box, made of 3/8 inch (1 cm) foamcore (1cm foam faced with paper cardstock), with a 6.5 inch (16.5 cm) speaker, and gives a bottom Hz of 35 Hz. It's what I use right now instead of my canvas DML panels, as I am currently unable to do the switch back to DML, due to medical problems. They sound very natural, and I am very pleased with them. Thanks to xrk971 for the design.

Here is an example of an infinite baffle. It is in a Fibonacci spiral, giving a length of 60 inches, (152,4 cm). It is enclosed in a 12 inch (30.5cm) by 13 inch (33cm) by 7 inch (17.8 cm) box, made of 3/8 inch (1 cm) foamcore (1cm foam faced with paper cardstock), with a 6.5 inch (16.5 cm) speaker, and gives a bottom Hz of 35 Hz. It's what I use right now instead of my canvas DML panels, as I am currently unable to do the switch back to DML, due to medical problems. They sound very natural, and I am very pleased with them. Thanks to xrk971 for the design.

Attachments

certainly an interesting design, not sure I get what's going on with it. I'm still interested in what an infinite baffle might mean in context of a DML panel.

----

I had done a preliminary test with small thin piece of foam and worth going bigger, so today I made a 20x20 frame (because that's the size of scrap plywood I had) and glued to a nearly full size piece of project foamular. If I go this rout it would be a 24x24" frame to fit exactly. Anyway, it makes a huge sound difference. The bass punches and has a thicker and warmer sound. On one of those left-right audio tests, at 80hz and 120hz, its night and day with the frame. I'm just testing with my cell phone. As the frequency gets higher, the free-floater is a little louder, but not night-and-day. Glued to frame it's closer to the sound with headphones. Sometimes the free-floaters just sound so brilliant and dazzling, but I kind of think that's the bathroom effect.

Maybe I need to learn to do real sound tests and get some PC software. I have an SM-57 mic, but I think specialized mics are used for this.

anyway, has anyone tried something like in the pic before?

----

I had done a preliminary test with small thin piece of foam and worth going bigger, so today I made a 20x20 frame (because that's the size of scrap plywood I had) and glued to a nearly full size piece of project foamular. If I go this rout it would be a 24x24" frame to fit exactly. Anyway, it makes a huge sound difference. The bass punches and has a thicker and warmer sound. On one of those left-right audio tests, at 80hz and 120hz, its night and day with the frame. I'm just testing with my cell phone. As the frequency gets higher, the free-floater is a little louder, but not night-and-day. Glued to frame it's closer to the sound with headphones. Sometimes the free-floaters just sound so brilliant and dazzling, but I kind of think that's the bathroom effect.

Maybe I need to learn to do real sound tests and get some PC software. I have an SM-57 mic, but I think specialized mics are used for this.

anyway, has anyone tried something like in the pic before?

Attachments

Infinite baffle in a theory setting means just that - a planar reflective baffle extending out to infinity, so only the front wave need be considered for the analysis.

Infinite baffle in practice includes various means to reduce the back wave to a negligible level. This can include a setup where the backwave is fed to another room or other large architectural void, like a roof-space or (ideally) the sky outside. It can also include large-enough boxes, or long tapered tubes to contain the back wave via damping.

My own ruminations on the possible usefulness of DML for subs stemmed from these observations:

(1) Multiple subs or 'swarms' of subs are reportedly much better than one, due the the distributed nature of room modes

(2) DML exciters are far less costly than subwoofer drivers, but move much less volume, which would require multiple units anyway.

(3) It should be relatively easy to tune the fundamentals of multiple DML speakers to a required frequency, to complement each other and the prevailing room modes.

(4) Performance should increase markedly if the panels could be successfully (ie with no audible sound conducted through the building structure) installed in a wall, so the back wave is eliminated.

Infinite baffle in practice includes various means to reduce the back wave to a negligible level. This can include a setup where the backwave is fed to another room or other large architectural void, like a roof-space or (ideally) the sky outside. It can also include large-enough boxes, or long tapered tubes to contain the back wave via damping.

My own ruminations on the possible usefulness of DML for subs stemmed from these observations:

(1) Multiple subs or 'swarms' of subs are reportedly much better than one, due the the distributed nature of room modes

(2) DML exciters are far less costly than subwoofer drivers, but move much less volume, which would require multiple units anyway.

(3) It should be relatively easy to tune the fundamentals of multiple DML speakers to a required frequency, to complement each other and the prevailing room modes.

(4) Performance should increase markedly if the panels could be successfully (ie with no audible sound conducted through the building structure) installed in a wall, so the back wave is eliminated.

Last edited:

jm,On one of those left-right audio tests, at 80hz and 120hz, its night and day with the frame.

That's the main benefit of a frame. It boosts the low frequency considerably.

I've never glued a panel to a frame before, but otherwise, yes. As I recall, these were attached to the frame with a 3M double side tape.anyway, has anyone tried something like in the pic before?

Eric

okay, thanks for that V, I think I'm seeing the light at the end of the tunnel.

now since I already have the back nearly enclosed, can't I seal it up and stuff fiberglass insulation in there and now I have an "infinite baffle?"

So, full disclosure, I already tried all this with smaller, thin pieces of xps and a 5w exciter, but I could barely tell the difference between it and the control piece.

But yeah, the frame for my thrusters makes a huge difference. absorbing the sound from the back might not be as easy.

----

random note, xps cuts nicely on table saw, bandsaw, and even with a router. The problem with it is not just that it's a little spongey, but the pieces aren't perfectly flat. With the frame, I'm expecting it to route nicely.

now since I already have the back nearly enclosed, can't I seal it up and stuff fiberglass insulation in there and now I have an "infinite baffle?"

So, full disclosure, I already tried all this with smaller, thin pieces of xps and a 5w exciter, but I could barely tell the difference between it and the control piece.

But yeah, the frame for my thrusters makes a huge difference. absorbing the sound from the back might not be as easy.

----

random note, xps cuts nicely on table saw, bandsaw, and even with a router. The problem with it is not just that it's a little spongey, but the pieces aren't perfectly flat. With the frame, I'm expecting it to route nicely.

I stand sorely corrected.Please comment.

I have never reeeelly bought into the idea of 'running in' speakers of any kind.

...

This has changed.

I stand corrected: Drivers DO need to be run-in.

I have dissed the DAEX30HESF-4 in the past as over-priced, mid-range-heavy drivers lacking bass and treble. Today I hang my head in shame and embarrassment.

Because of the surprising improvement I experienced with the 25Q-4's I thought I'd drive the HESF's with a customised "break-in" signal over-night. to see if they would do the same. Yes they did... The missing bass end has Arrived, and the top end is significantly better than it used to be.

I remember also dissing the 32QMB-4 MEGAS-BASS as utterly useless for bass.

Well I will be tackling those next.

REW can do a very nice break-in signal. To set it up, go to the REW Generator tab, and select Noise, then Pink Random, and then click on the Octave radio button. Dial the frequency range down to 16 or 32hz, and choose the Filter Type according to how much noise you want to hear. (You can make it sound like a soothing background rumble if you like.) This very low frequency is just to let the suspension and the glues loosen up, and a large excursion is needed for this. High frequencies for a break-in signal probably won't do much except irritate everybody within earshot.

I let mine run overnight so I chose the BU8 filtering, which gives a very sharp cut-off outside the frequency range chosen. This means the coils will move significantly, but you won't hear them. I had 4 drivers glued to a single panel, so I connected them series/parallel but I ran two of them out of phase to reduce the panel movement and the ambient noise even further. I ran them with about 10W of power, but because of the frequency range and the out-of-phase set up, the panel hardly moved at all, while the magnets were flapping around like crazy. Awesome! I gave them 15minutes or so to check that they were not heating up, and then let them run overnight.

This quick clip is with the power cranked right up just to show off, and you can hear the panel and the croc-clips complaining. But a nice break-in does not need so much power. Just make sure the magnets (or the VC's if they are not mounted onto a panel) move 2 or 3mm or so. About half Xmax.

My friend bought me a new digital amp , which he thinks sounds fantastic.

He has bought a lot of these , as they are very cheap .

I have no complaints so far , and sounds very similar to my digital amp.

Then he asked me to wire up this 3.7watt digital amp for him( second picture), which he also thinks has a fantastic sound.

I should have known it wouldn't be a free gift 😄

He is really into low wattage amps, even though he has some very expensive powerful amps.

He says he pushes then quite hard and upsets the neighbours.

He is now talking of building some eps panels to get a lot more volume out of the amps.

I'm glad I don't live next door to him.

Steve.

He has bought a lot of these , as they are very cheap .

I have no complaints so far , and sounds very similar to my digital amp.

Then he asked me to wire up this 3.7watt digital amp for him( second picture), which he also thinks has a fantastic sound.

I should have known it wouldn't be a free gift 😄

He is really into low wattage amps, even though he has some very expensive powerful amps.

He says he pushes then quite hard and upsets the neighbours.

He is now talking of building some eps panels to get a lot more volume out of the amps.

I'm glad I don't live next door to him.

Steve.

Attachments

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker