Not heard about that with conventional speaker... but far to know everything. I crossed those techniques (and used them) years ago well before REW started. What is in the REW help (manual on line) with the speaker on a table is what we did in the past (late 80's for me) with a frequency generator (later with a CD with pure sine signals) and an AC voltmeter. The mass of the cone has to be taken into account. The mass added by the acoustic effect is low if I remember. what is changed after is the compliance due to the air in the cabinet which comes in addition to the suspension stiffness. For a DML it is the panelSo people will actually remove the cone to make a similar test on a conventional speaker driver?

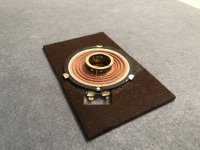

An other way is to go down in the papers referenced in the REW manual to see where the Sd has impacts. For sure in Vas which is the air volume equivalent to the machanical compliance of the loudspeaker. This is important for cabinet design, not for us. I think that until we don't use values of the acoustic domain (like Vas), Sd has no importance. If you can find (I have that somewhere...) papers showing the equivalent model of a loudspeaker you will see that Bl is the parameter that make the link between the electricity domain and the mechanical domain (in the general model, it is shown as a transformer of ration Bl... to be checked) and Sd between mechanical and acoustic domain. Our interest here is to measure the voice coil mass, spider compliance and damping, the inductance, the force factor.Yes, that is the surface area of a 32mm disc IF the voice-coil was covered.

But I think you've put your finger on an important point there.... The VC IS covered and sealed by panel material when one mounts it to a panel. Therefore the driver is probably designed to accommodate an acoustic boost in the VC cavity at some higher frequency (I think I picked up a 1.2kHz notch in some previous acoustic measurement with the VC uncovered. Ah, here it is: Post #9056.) But it's an acoustic resonance, not a mechanical one. And besides this, if one adds a cover (which is also an added mass) to the VC then the whole structure of the VC, its suspension and the moving mass also changes, and this will shift the mechanical Fs downwards.

Therefore, it appears that the right thing to do would be exactly that, i.e. cover the VC with the appropriate diameter of whatever material the panel is made of for base-line TS reference measurements.

The manufacturer's (dynamic) measurements in this case would be null and void.

Christian

It will depend on materials used and how many exciters used on each panel. Lighter materials (like EPS/XPS) are more diffused while heavier/denser materials (like plexiglass) will be less diffused. Also when using more then one exciter you can get resonance peaks especially on the denser materials causing more mic feed back.no I meant to ask why my dml even though it works fine doesn't seem immune to feedback? what should i check?

I built some DML speakers for my karaoke system a while back and no feed back even when standing in front of the speaker with the mic. I cant do this with conventional cone speakers.

There is huge difference between what I read, my expectations and what I experience when I build. Mostly my imagination builds expectations too high.Could you please write more about your creation? Some photos, if possible? Thanks

Attachments

-

3163F1DF-EEF1-4380-9952-74D17C507460.jpeg383.2 KB · Views: 112

3163F1DF-EEF1-4380-9952-74D17C507460.jpeg383.2 KB · Views: 112 -

8E351087-BF13-41D6-AD38-B141BA3B1C77.jpeg409.9 KB · Views: 115

8E351087-BF13-41D6-AD38-B141BA3B1C77.jpeg409.9 KB · Views: 115 -

F9C171C7-2CF5-4195-93CE-DE336AEB1551.jpeg340 KB · Views: 108

F9C171C7-2CF5-4195-93CE-DE336AEB1551.jpeg340 KB · Views: 108 -

9CE4BD8B-4AF2-4086-8FD1-C93C299FFC65.jpeg346.1 KB · Views: 105

9CE4BD8B-4AF2-4086-8FD1-C93C299FFC65.jpeg346.1 KB · Views: 105 -

F0893747-65CD-4655-AFE4-5DE1E827C4FC.jpeg540.9 KB · Views: 114

F0893747-65CD-4655-AFE4-5DE1E827C4FC.jpeg540.9 KB · Views: 114 -

5E2CEE97-D972-4532-B45A-6CAE0E13806C.jpeg280.8 KB · Views: 103

5E2CEE97-D972-4532-B45A-6CAE0E13806C.jpeg280.8 KB · Views: 103 -

596F69FF-F53D-41A4-9296-61540268AB91.jpeg609.5 KB · Views: 115

596F69FF-F53D-41A4-9296-61540268AB91.jpeg609.5 KB · Views: 115 -

18D369B3-865B-49E3-BA6E-ADEF2BA42F80.jpeg602 KB · Views: 114

18D369B3-865B-49E3-BA6E-ADEF2BA42F80.jpeg602 KB · Views: 114 -

72F747B9-6A93-4799-8A9E-909D9C1D0A55.jpeg761.8 KB · Views: 126

72F747B9-6A93-4799-8A9E-909D9C1D0A55.jpeg761.8 KB · Views: 126 -

41B3010D-2971-4F2B-8377-D196053A3383.jpeg350.8 KB · Views: 111

41B3010D-2971-4F2B-8377-D196053A3383.jpeg350.8 KB · Views: 111 -

AA87443B-E274-4C23-9F0A-E7E6EF56223A.jpeg385.6 KB · Views: 99

AA87443B-E274-4C23-9F0A-E7E6EF56223A.jpeg385.6 KB · Views: 99 -

814DE34B-1EB4-4142-9383-2B2408DA8671.jpeg445.3 KB · Views: 110

814DE34B-1EB4-4142-9383-2B2408DA8671.jpeg445.3 KB · Views: 110 -

1E6F7D1B-D093-4397-8C79-1330AEC782CE.jpeg483.2 KB · Views: 101

1E6F7D1B-D093-4397-8C79-1330AEC782CE.jpeg483.2 KB · Views: 101 -

0701F375-45CD-4038-A8BD-7722F1371265.jpeg597.1 KB · Views: 113

0701F375-45CD-4038-A8BD-7722F1371265.jpeg597.1 KB · Views: 113 -

AA4CF7EB-5AF7-4124-AAA7-5039D3A39CCA.jpeg365.1 KB · Views: 111

AA4CF7EB-5AF7-4124-AAA7-5039D3A39CCA.jpeg365.1 KB · Views: 111 -

3A843104-C722-42AC-83B9-5F547FA5E119.jpeg342 KB · Views: 112

3A843104-C722-42AC-83B9-5F547FA5E119.jpeg342 KB · Views: 112 -

9B34202B-7E1B-4738-AADE-C60EE01770D7.jpeg388.9 KB · Views: 101

9B34202B-7E1B-4738-AADE-C60EE01770D7.jpeg388.9 KB · Views: 101 -

9AF3A143-E098-4052-A6A6-CFDBAECC7861.jpeg413.9 KB · Views: 108

9AF3A143-E098-4052-A6A6-CFDBAECC7861.jpeg413.9 KB · Views: 108 -

7C8FBF89-E803-4908-92C9-54D59B81AABA.jpeg523.8 KB · Views: 108

7C8FBF89-E803-4908-92C9-54D59B81AABA.jpeg523.8 KB · Views: 108 -

B92ED5F3-B59F-41D7-90C7-4FAB68BE787B.jpeg586.4 KB · Views: 119

B92ED5F3-B59F-41D7-90C7-4FAB68BE787B.jpeg586.4 KB · Views: 119

Could you please write more about your creation? Some photos, if possible? Thanks

Attachments

-

FFBBFCD4-6763-44E7-BE7F-6B14FCDAC43B.jpeg437.4 KB · Views: 108

FFBBFCD4-6763-44E7-BE7F-6B14FCDAC43B.jpeg437.4 KB · Views: 108 -

D1BE4A8A-EC00-4019-B2A5-66E7A2D043A0.jpeg422.2 KB · Views: 111

D1BE4A8A-EC00-4019-B2A5-66E7A2D043A0.jpeg422.2 KB · Views: 111 -

0B2BF607-34B0-4DA9-95C0-041FB1C5D749.jpeg316.7 KB · Views: 115

0B2BF607-34B0-4DA9-95C0-041FB1C5D749.jpeg316.7 KB · Views: 115 -

428A2000-0037-43E3-BADC-FF4E496BDFFA.jpeg253.3 KB · Views: 103

428A2000-0037-43E3-BADC-FF4E496BDFFA.jpeg253.3 KB · Views: 103 -

F46C029C-0228-48AA-AD0D-34AEEF090A54.jpeg490.3 KB · Views: 104

F46C029C-0228-48AA-AD0D-34AEEF090A54.jpeg490.3 KB · Views: 104 -

CBF99BD8-FB3A-48D5-BCDE-786FC4B5A2EC.jpeg443 KB · Views: 105

CBF99BD8-FB3A-48D5-BCDE-786FC4B5A2EC.jpeg443 KB · Views: 105 -

382365E7-3B9A-4084-9D46-F0CF679440D1.jpeg300.5 KB · Views: 105

382365E7-3B9A-4084-9D46-F0CF679440D1.jpeg300.5 KB · Views: 105 -

807F5C0A-3E43-4B6C-B8EF-465FC48E5180.jpeg452.7 KB · Views: 113

807F5C0A-3E43-4B6C-B8EF-465FC48E5180.jpeg452.7 KB · Views: 113 -

54105546-72AF-45E3-A9A2-25CDC8063B9A.jpeg794.2 KB · Views: 110

54105546-72AF-45E3-A9A2-25CDC8063B9A.jpeg794.2 KB · Views: 110

Agreed!There is huge difference between what I read, my expectations and what I experience when I build. Mostly my imagination builds expectations too high.

Await your description of your creation and your imagination. 🙂

Sound and design are equally important to me. I will be in Munich High End show this May to touch and feel, get inspired.Agreed!

Await your description of your creation and your imagination. 🙂

A lot of things I had to learn with this hobby, like woodworking, 2d Cad drawing, CNC wood cutting, hand tools, material science, epoxy resin vacum lamination, acoustics, speaker design programs, industrial design and many more.

More things to learn or need to create contacts who can help me with measurements, painted surface finish, aluminium cnc milling, 3d printing, 3D CAD drawing, active filters, passive filters, digital EQ.

Test the panels on Klipell nearfield scanner would be valuable.

I use Lyngdorf amplifier with RoomPerfect wich helps to test the panels.

Attachments

-

525DC7E5-751E-4F36-AE73-4878B097FC73.jpeg229.2 KB · Views: 103

525DC7E5-751E-4F36-AE73-4878B097FC73.jpeg229.2 KB · Views: 103 -

EC75442F-EAAF-48EB-BC7B-2FC9A7CF63A0.jpeg179.4 KB · Views: 97

EC75442F-EAAF-48EB-BC7B-2FC9A7CF63A0.jpeg179.4 KB · Views: 97 -

1F79E692-B45C-4B7E-8D47-F860AEA0F31B.jpeg174.1 KB · Views: 104

1F79E692-B45C-4B7E-8D47-F860AEA0F31B.jpeg174.1 KB · Views: 104 -

2FF05871-76FB-4EA0-95D2-78C94FE870B9.jpeg146.2 KB · Views: 106

2FF05871-76FB-4EA0-95D2-78C94FE870B9.jpeg146.2 KB · Views: 106 -

627B9F90-919B-4271-A730-63AEDD817E15.jpeg189.3 KB · Views: 109

627B9F90-919B-4271-A730-63AEDD817E15.jpeg189.3 KB · Views: 109 -

E4A8DD0E-2D62-46D8-B065-0813CC439F0D.jpeg241.1 KB · Views: 107

E4A8DD0E-2D62-46D8-B065-0813CC439F0D.jpeg241.1 KB · Views: 107 -

3F8EBCE7-DDDB-469E-A0A3-0DA8A3F3E211.jpeg198.9 KB · Views: 105

3F8EBCE7-DDDB-469E-A0A3-0DA8A3F3E211.jpeg198.9 KB · Views: 105

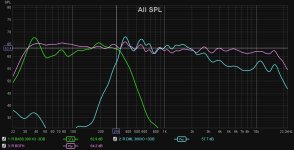

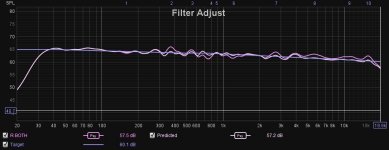

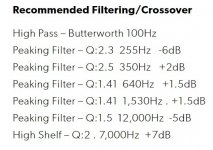

Here are my latest efforts with my OB bass / DML hybrids. I've attached a couple of images. The first shows uncorrected response curves with a 300hz 24/db octave Butterworth filter applied in the miniDSP HD together with the effects of driver EQ for both drivers run together. The second image shows the response with driver EQ applied and the predicted response with filters applied. All measurements were taken using the moving microphone method. The driver response curve EQ required some tinkering to get things right in the crossover region.

There's about a 6db difference between the efficiency of my 15" bass drivers in a topless asymmetrical U frame and the 2mm ceiba 30x40cm panels. Therefore, I reduced the bass driver output by 3db and increased the DML panel output by 3db in the miniDSP HD.

My previous efforts aimed for a 3db drop from 40hz to 20khz. However even at 67 years of age, I was finding this too bright overall. By switching to a 5db drop over the full frequency range, I still have good detail but also more warmth.

When the bass drivers go into H frames and the panels constructed rather more elegantly, I'll have to do it all again!

There's about a 6db difference between the efficiency of my 15" bass drivers in a topless asymmetrical U frame and the 2mm ceiba 30x40cm panels. Therefore, I reduced the bass driver output by 3db and increased the DML panel output by 3db in the miniDSP HD.

My previous efforts aimed for a 3db drop from 40hz to 20khz. However even at 67 years of age, I was finding this too bright overall. By switching to a 5db drop over the full frequency range, I still have good detail but also more warmth.

When the bass drivers go into H frames and the panels constructed rather more elegantly, I'll have to do it all again!

Attachments

Do you have a possibility to stop that pistonic motion of the voice coil?In slow motion you can see that the whole frame moves, attention has to be made to make it rock solid and damped at the same time.

You might as well contact your neighbour Sandasnickaren on that even before May. Maybe its better to PM him. You understand each other's language, I suppose.Sound and design are equally important to me. I will be in Munich High End show this May to touch and feel, get inspired.

A lot of things I had to learn with this hobby, like woodworking, 2d Cad drawing, CNC wood cutting, hand tools, material science, epoxy resin vacum lamination, acoustics, speaker design programs, industrial design and many more.

Yes, make the panel smaller, stiffer or thicker. It also lowers coincidence frequency. Compliant suspension on panels also increase pistonic motion even on stiff panels.Do you have a possibility to stop that pistonic motion of the voice coil?

Yes, I admire his work very much, he has scientific aproach.You might as well contact your neighbour @Sandasnickaren on that even before May. Maybe its better to PM him. You understand each other's language, I suppose.

The thing is, the voice coil shouldn't move the panel, the exciter must only transfer the vibrations. This is the tricky part. Have a look at all those patents, I posted in the post #9,094. Might help.Yes, make the panel smaller, stiffer or thicker. It also lowers coincidence frequency. Compliant suspension on panels also increase pistonic motion even on stiff panels.

Oh yes!Yes, I admire his work very much, he has scientific aproach.

You should contact him personally. Ask him. 🙂

Unless something has been lost in translation from some weird Himalayan Trans-Tibetian language that smells of Elderberries, that is utter BS.The thing is, the voice coil shouldn't move the panel, the exciter must only transfer the vibrations. This is the tricky part. Have a look at all those patents, I posted in the post #9,094. Might help.

Anything against Himalayan, Trans-Tibetan languages? Like in the '60s?Unless something has been lost in translation from some weird Himalayan Trans-Tibetian language that smells of Elderberries,

Last edited:

I would pay more attention to more important issues. I doubt you will even be able to measure or hear that small amount of magnet movement even if it was infinitely stiff with zero movement.In slow motion you can see that the whole frame moves, attention has to be made to make it rock solid and damped at the same time.

But if you were really worried about it, then rather use the REW Generator function to find out exactly which frequencies are resonating on the magnet. It might be a lot more efficient to simply add a specific damping mass that would solve a visual problem that is most likely inaudible and immeasurable.

In the last few weeks I found that the DML500 type had been tested upon thoroughly, as early as 2013 by some people and had been discarded as they need the help of a tweeter and a subwoofer. (All kinds of panel material had been used for the testing.)It confirms we are not following the same way.

DML500 and it's variants need crossovers.

Tectonic DML products are more useful in large buildings, such as conference halls, churches, stadiums, airport foyers, gymnasiums etc, where the HF and LF is not really desired. Tectonic Audio Labs, as the surviving successor/heir to NXT/HiWave, practically don't advertise those DML speakers for the general public.

So, while it is quite interesting to read NXT connected patents/documents (#9,094), they don't really direct you to the right direction in making a full-range DML, or at least. Tectonic hadn't produced that specific exciter yet, one of the reasons why NXT and HiWave failed, and why Tectonic emphasises practically on the BMR technology -- you open the Tectonic website, you are shown BMRs, directing you away from the DMLs, an advertising trick. And, why the scientists and engineers from NXT, who are still with Tectonic, concentrate mostly in other areas, rather than in the DM technology. It is stuck, more or less where it was in 2013.

So, my interest moved to those, who actually make saleable, practically Hi-End, tested by many, bought by many paying thousands of euros, DMLs (#9,101). There are a few products to study, a few documents to re-read, and few questions to ask. Certain trade secrets, of course, will not be disclosed, but...

So, time is not anymore a factor. Best follow those, who had succeeded.

Well, some had been digging in the wrong plot for quite a few years. 🙂

Those with "first principles, science-based understanding" can have a go at this work, >> Spin-orbit interactions of transverse sound by Shubo Wang of Department of Physics, City University of Hong Kong in 2021. Remember, who found that phenomenon before him? A whole two decades ago! Or, maybe even before that, "Extraneous Frequencies Generated in Air Carrying Intense Sound Waves" by A. L. Thuras, R. T. Jenkins, H. T. O'Neil, published in 1935.

Strange that the ancient native drummers knew that too... 🙂

Strange too that the BMR membrane itself haven't grown more than 100mm in diameter (from the edge of the surround to the other edge). By the way, what's a BMR? 🙂 (#8,959)

Last edited:

Hello Thomas,I have tested one of the solutions included in this patent application. I have included in one of my sandwich (carbon, balsa, carbon) a piece of homegenoius carbonfiber piece that is of the same size as the voice coil of the exciter 25mm. The CF piece is of the same thicknes as the balsa core 2mm. It’s Connecting the front and back CF skin with the exciter. It did help to extend the frequency range to 20k.

There are some more ideas in the application.

’Thomas

Interesting patent. thank you. In addition to the reinforcement of the voice coil area, it points to facts often reported here :

This patent refers to another interesting one (WO2000015000A1)for a variable thickness panel. In the advantages of non constant thickness:

- spreading of the coincidence frequency over a range

- adaptation to the edges impedance

The material in the example is a Rohacell core with a variable thickness with glass mat skins.

Christian

Where can I find more info on these?A successful implementation of NXT technology by those, who can analyse the patents well, and able to add their own analytical thinking to it...and with their own purpose-built exciters. At a Hi-End show in 2019...

View attachment 1137578

Dimensions: 1125mm х 640mm x 50mm

Frequency range: 45-18,000 Hz

Type DML (NXT). - impedance: 8 ohm - sensitivity: 93 dB - power: 2×200 watts

All by itself, without the help of a twitter or a subwoofer.

Thomas

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker