Yes...and compressive strength through the thickness at the point of excitation is also critical I believe.An other characteristic near the exciter might an higher local stiffness.

Christian

Eucy

I have called this recording, card headphones as they sound like wearing headphones.

i had to hold one panel on the left by holding the exciter ,and holding the phone in my right hand, so i was wobbling about a bit.

hope it sounds ok ?

the panels were about 2.5 ft apart with me holding the phone in the middle.

i had to roll the panels off at 50hz to stop the panels wobbling too much.

i will round the corners next.

steve.

i had to hold one panel on the left by holding the exciter ,and holding the phone in my right hand, so i was wobbling about a bit.

hope it sounds ok ?

the panels were about 2.5 ft apart with me holding the phone in the middle.

i had to roll the panels off at 50hz to stop the panels wobbling too much.

i will round the corners next.

steve.

Attachments

Sorry don't remember from the previous posts... do you have a technique to increase the compressive strength at the point of excitation.Yes...and compressive strength through the thickness at the point of excitation is also critical I believe.

Eucy

Christian

My friend just told me about this new material.

https://www.wki.fraunhofer.de/en/departments/hnt/profile/research-projects/wood-foam.html

I sent him leobs videos of his panels at the whatever its called? He is into things like that.

Steve.

https://www.wki.fraunhofer.de/en/departments/hnt/profile/research-projects/wood-foam.html

I sent him leobs videos of his panels at the whatever its called? He is into things like that.

Steve.

Hi ChristianSorry don't remember from the previous posts... do you have a technique to increase the compressive strength at the point of excitation.

Christian

It's more of a recognition that the hf response is directly related to the speed of sound of the panel material, which in turn is dependent on the density and elastic modulus of the material. In ply, the s.o.s transverse to the grain is about 1/3 of the longitudinal speed. EPS/XPS doesn't have this issue and is 'faster' than ply in the transverse direction.

With ply, impregnating the local area with very thin lacquer will help. I tried using pressure with a plunger but it's hard to check the results.

Routing out a thin layer at the rear and replacing with an aluminium disc is also worth a try

Try it on the front also

Cheers

Eucy

That's pretty impressive I'd say 👍I have called this recording, card headphones as they sound like wearing headphones.

i had to hold one panel on the left by holding the exciter ,and holding the phone in my right hand, so i was wobbling about a bit.

hope it sounds ok ?

the panels were about 2.5 ft apart with me holding the phone in the middle.

i had to roll the panels off at 50hz to stop the panels wobbling too much.

i will round the corners next.

steve.

Steve...I've been listening to your recordings again, and at the photo of your room full of panels (🤭😧😆👍).

Can you please advise the exciters you use, and how you rate the differences, (if you in fact use different ones on different panels)

Thanks

Eucy

Can you please advise the exciters you use, and how you rate the differences, (if you in fact use different ones on different panels)

Thanks

Eucy

Hi EucyHi Christian

It's more of a recognition that the hf response is directly related to the speed of sound of the panel material, which in turn is dependent on the density and elastic modulus of the material. In ply, the s.o.s transverse to the grain is about 1/3 of the longitudinal speed. EPS/XPS doesn't have this issue and is 'faster' than ply in the transverse direction.

With ply, impregnating the local area with very thin lacquer will help. I tried using pressure with a plunger but it's hard to check the results.

Routing out a thin layer at the rear and replacing with an aluminium disc is also worth a try

Try it on the front also

Cheers

Eucy

Have you already tested the aluminum patch? An advice of thickness? Dimensions? Effect on the efficiency? Epoxy as glue?

Easier to rise question from my sofa than to test today! Lazy guy I am?

I have somewhere a FR of an XPS membrane (low HF by itself...) on which I added a CD between the XPS and the exciter. The result was not fantastic. See #5127 . It was perhaps not properly glued (thin double side tape)

Christian

Eucy.

Parts express were doing a very cheap sell-off of the 10watt exciters.

So I bought 40 of them 😁

I gave some to friends who wanted to build some panels as well.

Tectonic sell one that looks pretty similar but is expensive now .

I bought 2 hdn8 exciters which were pretty bad, but OK for screwing into a stud wall.

But that is all .

I have been tempted to buy a more powerful exciter ,but the response plots have put me off.

At least my exciters have a good frequency response.

Steve.

Parts express were doing a very cheap sell-off of the 10watt exciters.

So I bought 40 of them 😁

I gave some to friends who wanted to build some panels as well.

Tectonic sell one that looks pretty similar but is expensive now .

I bought 2 hdn8 exciters which were pretty bad, but OK for screwing into a stud wall.

But that is all .

I have been tempted to buy a more powerful exciter ,but the response plots have put me off.

At least my exciters have a good frequency response.

Steve.

I'm looking forward to test Dayton Audio exciters. I'm going to use a small class-d amp and bolt the exciter on with screws. I'm going to test different panel materials. I appreciate sound quality and full(ish) range performance.

Dayton Audio alone has many models with no real description for intended use. Are there any suggestions which exciter to choose?

Dayton Audio alone has many models with no real description for intended use. Are there any suggestions which exciter to choose?

Hi ChristianHi Eucy

Have you already tested the aluminum patch? An advice of thickness? Dimensions? Effect on the efficiency? Epoxy as glue?

Easier to rise question from my sofa than to test today! Lazy guy I am?

I have somewhere a FR of an XPS membrane (low HF by itself...) on which I added a CD between the XPS and the exciter. The result was not fantastic. See #5127 . It was perhaps not properly glued (thin double side tape)

Christian

Different to your #5127 example

If you can be patient, I'll be better able to answer when I return home

Cheers

Eucy

Well Heavens to Murgatroyd Steve!!!Eucy.

Parts express were doing a very cheap sell-off of the 10watt exciters.

So I bought 40 of them 😁

I gave some to friends who wanted to build some panels as well.

Tectonic sell one that looks pretty similar but is expensive now .

I bought 2 hdn8 exciters which were pretty bad, but OK for screwing into a stud wall.

But that is all .

I have been tempted to buy a more powerful exciter ,but the response plots have put me off.

At least my exciters have a good frequency response.

Steve.

If you borrow back the ones you've given away, fit them all to the panels in the room, couple them with a steam driven amplifier or two and you'll have enough noise to bring on a thunderstorm 👍😆😁

Eucy.

I was intending to have about 8 exciters per panel .

But I found that one exciter on my 7ft EPS panels, was already more thunderstorm than I could handle 🤪🤣

They were loud 🔊 very loud 😱

Steve.

I was intending to have about 8 exciters per panel .

But I found that one exciter on my 7ft EPS panels, was already more thunderstorm than I could handle 🤪🤣

They were loud 🔊 very loud 😱

Steve.

OK, I thought I would use some bracing on the sides of the panel to increase the performance below 300hz ?

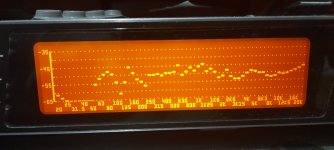

Pic 1

Is a strip of wood used for bracing.

Pic2

Is plot without any bracing.

Pic3

Is plot with bracing.

Pic4

Is very light bracing ,foam strip.

Pic5

Is the foam plot.

As can be seen in pic 2 and 3 the bracing has moved the about 50hz resonance up to about 100hz, which has also moved the resonance about 100hz up in frequency too.

The very light foam has moved the lower resonance up to 70hz or so and the other resonance up to about 140hz.

Can we see a pattern here.

The resonances are being crunched up above the 100hz point filling the dips in the sub 300hz area.

But everything below 100hz has gone !

I also tried much thicker foam with the same outcome.

I prefer the sound of the panel with the resonance left at 50hz for full range.

But I can't say I like the idea of moving the resonance up into the lower midrange, just to fill in the dips ?

It does change the sound of the whole panel.

I might get away with the thin foam strips though ?

But for what purpose?

Steve.

Pic 1

Is a strip of wood used for bracing.

Pic2

Is plot without any bracing.

Pic3

Is plot with bracing.

Pic4

Is very light bracing ,foam strip.

Pic5

Is the foam plot.

As can be seen in pic 2 and 3 the bracing has moved the about 50hz resonance up to about 100hz, which has also moved the resonance about 100hz up in frequency too.

The very light foam has moved the lower resonance up to 70hz or so and the other resonance up to about 140hz.

Can we see a pattern here.

The resonances are being crunched up above the 100hz point filling the dips in the sub 300hz area.

But everything below 100hz has gone !

I also tried much thicker foam with the same outcome.

I prefer the sound of the panel with the resonance left at 50hz for full range.

But I can't say I like the idea of moving the resonance up into the lower midrange, just to fill in the dips ?

It does change the sound of the whole panel.

I might get away with the thin foam strips though ?

But for what purpose?

Steve.

Attachments

Steve,Eucy.

Parts express were doing a very cheap sell-off of the 10watt exciters.

So I bought 40 of them 😁

I gave some to friends who wanted to build some panels as well.

Tectonic sell one that looks pretty similar but is expensive now .

I bought 2 hdn8 exciters which were pretty bad, but OK for screwing into a stud wall.

But that is all .

I have been tempted to buy a more powerful exciter ,but the response plots have put me off.

At least my exciters have a good frequency response.

Steve.

Knowing how frugal you are, they must have been really cheap! 😀

Eric

Here's an article I found just now. Apparently I saw a reference to it back in 2020 and requested a copy from the author on Research Gate. But I noticed only now (almost two years later) that they had uploaded it in November 2020!

The title is promising: Optimization of Aspect Ratio and Material Parameters of a DML Membrane, and Zenker is a co-author so I had pretty high hopes.

Sadly, it doesn't talk about optimizing material properties in terms of maximizing efficiency as I had hoped.

It does address the issue of aspect ratio, and shows how high aspect ratio is advantageous from the perspective of density and even spacing of modal frequencies (and hence flatter frequency response) compared to low aspect ratios, but at the cost of an increased fundamental frequency (given a panel of constant area).

The article also addresses the issue of aspect ratio and Elastic Modulus anisotropy that Eucy and I have been discussing. Their conclusion is that for high aspect ratio panels, an isotropic panel is preferred over a highly anisotropic panel. Again this preference is from the perspective of modal density and even spacing. However, as far as I can tell, they consider only panels in which the higher elastic modulus is oriented in the panel's long direction, and don't consider the opposite case where the panel's higher elastic modulus is in the short direction.

Also, they only consider panels with clamped edges, which few (if any) of us use.

Eric

The title is promising: Optimization of Aspect Ratio and Material Parameters of a DML Membrane, and Zenker is a co-author so I had pretty high hopes.

Sadly, it doesn't talk about optimizing material properties in terms of maximizing efficiency as I had hoped.

It does address the issue of aspect ratio, and shows how high aspect ratio is advantageous from the perspective of density and even spacing of modal frequencies (and hence flatter frequency response) compared to low aspect ratios, but at the cost of an increased fundamental frequency (given a panel of constant area).

The article also addresses the issue of aspect ratio and Elastic Modulus anisotropy that Eucy and I have been discussing. Their conclusion is that for high aspect ratio panels, an isotropic panel is preferred over a highly anisotropic panel. Again this preference is from the perspective of modal density and even spacing. However, as far as I can tell, they consider only panels in which the higher elastic modulus is oriented in the panel's long direction, and don't consider the opposite case where the panel's higher elastic modulus is in the short direction.

Also, they only consider panels with clamped edges, which few (if any) of us use.

Eric

Attachments

Thank you Eric,Here's an article I found just now. Apparently I saw a reference to it back in 2020 and requested a copy from the author on Research Gate. But I noticed only now (almost two years later) that they had uploaded it in November 2020!

The title is promising: Optimization of Aspect Ratio and Material Parameters of a DML Membrane, and Zenker is a co-author so I had pretty high hopes.

Sadly, it doesn't talk about optimizing material properties in terms of maximizing efficiency as I had hoped.

It does address the issue of aspect ratio, and shows how high aspect ratio is advantageous from the perspective of density and even spacing of modal frequencies (and hence flatter frequency response) compared to low aspect ratios, but at the cost of an increased fundamental frequency (given a panel of constant area).

The article also addresses the issue of aspect ratio and Elastic Modulus anisotropy that Eucy and I have been discussing. Their conclusion is that for high aspect ratio panels, an isotropic panel is preferred over a highly anisotropic panel. Again this preference is from the perspective of modal density and even spacing. However, as far as I can tell, they consider only panels in which the higher elastic modulus is oriented in the panel's long direction, and don't consider the opposite case where the panel's higher elastic modulus is in the short direction.

Also, they only consider panels with clamped edges, which few (if any) of us use.

Eric

I have also this document but I haven't paid really attention to it... To read again.

My approach is not a constant area but rather a maximum width that fits the room I want to have the panels. Something like 30cm/33cm. The height is limited by the fact not having something to high with in the lower part an area for a bass loudspeaker (Ripole?)

Christian

The postage to the UK cost more than the exciters 😢Steve,

Knowing how frugal you are, they must have been really cheap! 😀

Eric

some of my best sounding panels have been free ,because I use scrap materials.

Or JohnnoG sends them to me for free 👍

a panel either sounds good or it does not , how much it costs ,doesn't not come into it.

another thing I noticed when testing my card panels.

I thought , is moving the resonance up in frequency changing the frequency of the panel when playing music ?

So I put test tones through the panels, and the frequencies seemed fine with no problems.

But I did notice that the 50hz tone was causing a tone at 100hz .?

The 100hz tone was causing a 200hz tone.

And the 200hz tone was, you can guess the answer.

I lost the second tone above about 500hz , I think it just dropped off my scale.

all very interesting.

can anyone make similar test tones with their panels to see if this is a general problem with DML ?

Although I can't say that I have noticed anything while playing music.

Steve.

I'll bet that wood/foam sounds amazing for orchestral type music.My friend just told me about this new material.

https://www.wki.fraunhofer.de/en/departments/hnt/profile/research-projects/wood-foam.html

I sent him leobs videos of his panels at the whatever its called? He is into things like that.

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker