Steve,

I went back and scanned from page 88 to about 150 or so and didn't find the reference. I'm pretty sure, though, that I got the 4x6" measurement from you, as you had done so much research on them, so I figured you were the best resource for that measurement. I distinctly do remember seeing someone (I was pretty sure it was offgrid) say that the additional bracing offgrid put directly on the canvas was unnecessary. Too, I read in one post that pva was strong enough to fasten the disc strongly enough to the canvas that the caulking was not needed. I believe you did not caulk the frame-to-canvas edges, so I didn't either. I heard no buzzing from my canvasses, even at substantial volume and deep bass. So, in fact, you may have been the source of my info! Sorry if I sent you off on a wild goose chase!

I went back and scanned from page 88 to about 150 or so and didn't find the reference. I'm pretty sure, though, that I got the 4x6" measurement from you, as you had done so much research on them, so I figured you were the best resource for that measurement. I distinctly do remember seeing someone (I was pretty sure it was offgrid) say that the additional bracing offgrid put directly on the canvas was unnecessary. Too, I read in one post that pva was strong enough to fasten the disc strongly enough to the canvas that the caulking was not needed. I believe you did not caulk the frame-to-canvas edges, so I didn't either. I heard no buzzing from my canvasses, even at substantial volume and deep bass. So, in fact, you may have been the source of my info! Sorry if I sent you off on a wild goose chase!

i just clicked on it and the pictures came up ?

steve.

They asked me for money.

I made this dome and had it up and running in about half an hour, with the use of a hair dryer.

Or would have ,if I had not ripped the first dome 🙄

I was in a hurry, so it's not my best effort.

This is the first epoxy panel .

Is it a canvas panel painted with epoxy? Did the response improve with 50/50 acrylic paint? What size the panel?

Tried again, and this time I could see Offgrid's photos.

Did you use the same technique to hold the resonator and placement? Also with the wood stripe glued to the canvas? I think I saw something like that several pages ago on one of your photos. Or am I confusing them?

The wood is balsa?

Attachments

Jaxboy.

No problem, I did wonder if it was me who said those things?

Carlmart.

I wouldn't worry about the pictures , this was probably an early test panel, and as I've said , it is better to keep it simple without all the woodwork and silicon damping.

Steve.

No problem, I did wonder if it was me who said those things?

Carlmart.

I wouldn't worry about the pictures , this was probably an early test panel, and as I've said , it is better to keep it simple without all the woodwork and silicon damping.

Steve.

OK, let's be clear on what do you mean by "simple".

Just the resonator glued to the back directly, no paint of anything?

I'm afraid my resonator, the one I can get, might be too heavy to just glue it.

Just the resonator glued to the back directly, no paint of anything?

I'm afraid my resonator, the one I can get, might be too heavy to just glue it.

Carlmart,

For what it's worth, this is how I did my 12x16" canvas panels, and they go down to 40Hz. I used a thin 4x6" piece of ply glued on with pva in the center of the back of the canvas. I painted both front and back with acrylic paint thinned to 40-50% with water. The color was very deep, and one coat would have given a complete elimination of the white of the canvas. I used the DAE25FHE-4 from PE. I put a yardstick-type piece of wood across the middle of the back for a spline, stepped away with spacers to clear the exciter, and clipped them to 2 1/2' x 1/2x1" wood risers from my desk in front of my double window. My canvasses are about a foot from the window, or about an inch from the curtain. I made 2 mats from melamine sponges that I put behind the curtains directly behind the canvasses for dampening. My canvasses sound great all the way down to 40Hz, but I have 100uf caps in line with them to rolloff the freq response to about 50Hz, as heavy bass will drive the exciter so hard it hits the spline.

For what it's worth, this is how I did my 12x16" canvas panels, and they go down to 40Hz. I used a thin 4x6" piece of ply glued on with pva in the center of the back of the canvas. I painted both front and back with acrylic paint thinned to 40-50% with water. The color was very deep, and one coat would have given a complete elimination of the white of the canvas. I used the DAE25FHE-4 from PE. I put a yardstick-type piece of wood across the middle of the back for a spline, stepped away with spacers to clear the exciter, and clipped them to 2 1/2' x 1/2x1" wood risers from my desk in front of my double window. My canvasses are about a foot from the window, or about an inch from the curtain. I made 2 mats from melamine sponges that I put behind the curtains directly behind the canvasses for dampening. My canvasses sound great all the way down to 40Hz, but I have 100uf caps in line with them to rolloff the freq response to about 50Hz, as heavy bass will drive the exciter so hard it hits the spline.

Attachments

Last edited:

Carlmart.

If you only need your panel to go down to 300hz.

You can just glue the exciter to the panel, but you will need a cross brace to glue the heavy magnet to for support .

This is about as basic as it gets.

But if you want a panel that can go down to 40hz then you will need to have a say 2mm ply 6x4 inch attached to the panel first.

This ply panel might be able to support the exciter weight, but if it sags you could always add the back Brace if needed.

My exciter only weighs about 90g and was OK.

If your exciter is the sort with a flat disc ,it would be very easy to just glue it to the ply with pva ,and also to the brace or spline as you call it.

Those are the two basic art panel types.

I think the disc type exciter mounting should go well with the ply, but that's just a guess.

You can make a picture painting as long as you don't make the canvas too heavy.

Jaxboy.

I'm a little confused, because you say the exciter hits the spline if driven too hard.

Is your exciter not glued to the spline ?

Steve.

If you only need your panel to go down to 300hz.

You can just glue the exciter to the panel, but you will need a cross brace to glue the heavy magnet to for support .

This is about as basic as it gets.

But if you want a panel that can go down to 40hz then you will need to have a say 2mm ply 6x4 inch attached to the panel first.

This ply panel might be able to support the exciter weight, but if it sags you could always add the back Brace if needed.

My exciter only weighs about 90g and was OK.

If your exciter is the sort with a flat disc ,it would be very easy to just glue it to the ply with pva ,and also to the brace or spline as you call it.

Those are the two basic art panel types.

I think the disc type exciter mounting should go well with the ply, but that's just a guess.

You can make a picture painting as long as you don't make the canvas too heavy.

Jaxboy.

I'm a little confused, because you say the exciter hits the spline if driven too hard.

Is your exciter not glued to the spline ?

Steve.

I thought I'd show everone how I make a dome.

Feel free to give it a go ,it's not hard ,but nimble fingers helps, which is a pity as I have a bunch of bananas 😀

The first two photos are of a dome made from a tea bag 😀

You can see I have trimmed around the exciter ring.

I managed to find a glass marble just the right size for the dome.

The third is a thin muslin cloth which is better I think as I can stretch the material to make a perfect dome , weather it sounds better is another matter?

The fourth is the dome after being wetted with 50x50 mix of pva .

The fifth is the now dry dome and it keeps it's shape well.

These are now ready to be mounted on a panel or on the exciter ring ,and then onto the panel,depending on the panel thickness?

I'm not sure if the 5mm xps is too thick, but I might try and see if I can remove the exciter without too much damage to the panel ,and try mounting the dome to the exciter ring .

I've then tried both ways to see which might be best ?

The panel will be more efficient than the dome on xps and eps.

But will probably be more efficient on ply ,so you will hear a greater output from the dome,I think ?

Anyway that's how I do it.

I found that sheet metal and paper for the dome have a higher output but set off the cavity resonance badly and sounded quite harsh.

I did try gluing the material flat over the exciter coil but that didn't sound that great either.

Steve.

.

Feel free to give it a go ,it's not hard ,but nimble fingers helps, which is a pity as I have a bunch of bananas 😀

The first two photos are of a dome made from a tea bag 😀

You can see I have trimmed around the exciter ring.

I managed to find a glass marble just the right size for the dome.

The third is a thin muslin cloth which is better I think as I can stretch the material to make a perfect dome , weather it sounds better is another matter?

The fourth is the dome after being wetted with 50x50 mix of pva .

The fifth is the now dry dome and it keeps it's shape well.

These are now ready to be mounted on a panel or on the exciter ring ,and then onto the panel,depending on the panel thickness?

I'm not sure if the 5mm xps is too thick, but I might try and see if I can remove the exciter without too much damage to the panel ,and try mounting the dome to the exciter ring .

I've then tried both ways to see which might be best ?

The panel will be more efficient than the dome on xps and eps.

But will probably be more efficient on ply ,so you will hear a greater output from the dome,I think ?

Anyway that's how I do it.

I found that sheet metal and paper for the dome have a higher output but set off the cavity resonance badly and sounded quite harsh.

I did try gluing the material flat over the exciter coil but that didn't sound that great either.

Steve.

.

Attachments

Steve,

No, I did not glue the exciter to the spline. I wasn't aware that I needed to do so. I must have missed reading that when I was trying to emulate your canvasses. I put a piece of melamine sponge between the exciter and the spline. Please explain why and how I should do so. It will be easy enough to do it. Please include how to figure the spacing needed when I am locating the spline in relation to the exciter.

No, I did not glue the exciter to the spline. I wasn't aware that I needed to do so. I must have missed reading that when I was trying to emulate your canvasses. I put a piece of melamine sponge between the exciter and the spline. Please explain why and how I should do so. It will be easy enough to do it. Please include how to figure the spacing needed when I am locating the spline in relation to the exciter.

Jaxboy.

If you place the canvas panel face down on a flat surface ,this should set the correct distance for the exciter to your spline .

Depending on the gap size you could either use maybe three of four blobs of silicone in the gap to give support and a little damping for the spline ,and also allowing the vent hole on some exciters to breathe.

You could also glue a spacer strip of wood to fill the gap if too large.

Whether you mount the exciter rigidly with pva or have a little flexibility with silicone is up to you.

Or use some other type of filler?

If the gap is too small and you want to allow the vent hole to breathe ,you can always drill a hole in the spline.

This should hopefully solve your exciter banging on your spline problem.

Or you could just remove the spline if it is not needed ?

The choice is yours.

Steve

If you place the canvas panel face down on a flat surface ,this should set the correct distance for the exciter to your spline .

Depending on the gap size you could either use maybe three of four blobs of silicone in the gap to give support and a little damping for the spline ,and also allowing the vent hole on some exciters to breathe.

You could also glue a spacer strip of wood to fill the gap if too large.

Whether you mount the exciter rigidly with pva or have a little flexibility with silicone is up to you.

Or use some other type of filler?

If the gap is too small and you want to allow the vent hole to breathe ,you can always drill a hole in the spline.

This should hopefully solve your exciter banging on your spline problem.

Or you could just remove the spline if it is not needed ?

The choice is yours.

Steve

Jaxboy

I did the hole in the brace/spline/spine approach when I tried one with my ply panels. I also used the four holes on the exciter to mount it to the brace via some hardboard and tried to cushion any vibrations with a bit of draught sealer. As to the brace, I also tried to reduce vibration by using some rubber washers between the brace and the frame.

I did the hole in the brace/spline/spine approach when I tried one with my ply panels. I also used the four holes on the exciter to mount it to the brace via some hardboard and tried to cushion any vibrations with a bit of draught sealer. As to the brace, I also tried to reduce vibration by using some rubber washers between the brace and the frame.

I still do not understand where or how the dome is placed on the panel.

Neither which is the idea behind it, what you expected to achieve, if you did and how it affected the audio quality.

Neither which is the idea behind it, what you expected to achieve, if you did and how it affected the audio quality.

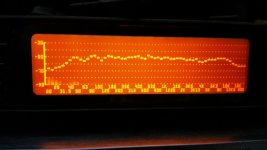

I thought I would get an old xps panel our and do a comparison to the epoxy panel.

As you can see the old panel has been badly bashed about (probably by a hoover?) And lost its lower half.

But the frequency plot still shows a good response.

This panel is quite heavily damped (by my standards anyway ) with pva and then vinyl silk paint.

Hence the smoother response.

It has an Ali dome which has reduced the 9k peak ,but i think the 2.5k peak has moved down to about 1.5 k ?

But is reduced.

The panels sound very similar but the old panel does sound smoother and sounds like it goes down lower.

Steve

As you can see the old panel has been badly bashed about (probably by a hoover?) And lost its lower half.

But the frequency plot still shows a good response.

This panel is quite heavily damped (by my standards anyway ) with pva and then vinyl silk paint.

Hence the smoother response.

It has an Ali dome which has reduced the 9k peak ,but i think the 2.5k peak has moved down to about 1.5 k ?

But is reduced.

The panels sound very similar but the old panel does sound smoother and sounds like it goes down lower.

Steve

Attachments

Steve,

Thanks for the super-fast reply, and for the info. You are such a great font of information and inspiration. Thanks. Right now, I have a piece of melamine sponge wedged in between the exciter and the spline. It was trimmed so that there is a firm fit, but it is not restrictive or pushing the exciter out of position. I had laid the canvas face down on a flat surface to get the exciter-to-spline gap. The banging was only when listening to a heavy bass song at a much louder volume than I would be using them, and it was only on the very deep bass notes. I figured the semi-firm melamine would keep the exciter in position while still allowing it to have the ability to move. I have the 100uf caps in series with the exciters now, so the deep bass has been cut. I use a sub for that duty. I am using the spline as my point for connection to the stand that holds it in position. On a side note, if you ever have to get an EEG, nowadays the leads are one-time use, so they throw them out after one use. Each of the 5 wires is thin very flexible 18-20 gauge coax with multi-strand ground wrapping, and is high-quality wire, perfect for wiring to the DMLs. Mine was about 5 feet long, so it is perfect for my application.

Thanks for the super-fast reply, and for the info. You are such a great font of information and inspiration. Thanks. Right now, I have a piece of melamine sponge wedged in between the exciter and the spline. It was trimmed so that there is a firm fit, but it is not restrictive or pushing the exciter out of position. I had laid the canvas face down on a flat surface to get the exciter-to-spline gap. The banging was only when listening to a heavy bass song at a much louder volume than I would be using them, and it was only on the very deep bass notes. I figured the semi-firm melamine would keep the exciter in position while still allowing it to have the ability to move. I have the 100uf caps in series with the exciters now, so the deep bass has been cut. I use a sub for that duty. I am using the spline as my point for connection to the stand that holds it in position. On a side note, if you ever have to get an EEG, nowadays the leads are one-time use, so they throw them out after one use. Each of the 5 wires is thin very flexible 18-20 gauge coax with multi-strand ground wrapping, and is high-quality wire, perfect for wiring to the DMLs. Mine was about 5 feet long, so it is perfect for my application.

Jaxboy.

I've now got a vision of me slipping into the great beyond clutching an EEG cable 😱

Shouting ,NO, don't throw it away I'll take it with me 😂

On a lighter note,😀 the exciter will have very large movements at low frequencies back AND forwards , gathering momentum to slam into the spacer.

But as you say you do not use your exciter the low.

Steve.

I've now got a vision of me slipping into the great beyond clutching an EEG cable 😱

Shouting ,NO, don't throw it away I'll take it with me 😂

On a lighter note,😀 the exciter will have very large movements at low frequencies back AND forwards , gathering momentum to slam into the spacer.

But as you say you do not use your exciter the low.

Steve.

Carlmart.

I wouldn't worry too much about The dome as the exciter you are going to use has a disc which mounts to your panel.

So no cavity between the exciter and panel and hopefully a better response maybe from the centre of the exciter area ?

It would be interesting to see a frequency plot of your exciter on a ply panel just to see how this works.

Steve.

I wouldn't worry too much about The dome as the exciter you are going to use has a disc which mounts to your panel.

So no cavity between the exciter and panel and hopefully a better response maybe from the centre of the exciter area ?

It would be interesting to see a frequency plot of your exciter on a ply panel just to see how this works.

Steve.

quick question. I have two 120cm x 60cm xps panels and four exciters. Would I achieve better results putting two exciters on each of the panels, or cutting the two panels lenght-wise and putting each exciter on each half? (I will be using a sub, but am not sure if the smaller panels would reach down to where the sub begins)

Also, from my understanding, the optimal exciter placement is on the golden ratio. So If I had two exciters on one panel, where would the second one go then? Or with the split panel scenario, where would be the optimal position for the second exciter for the smoothest response? I'm assuming it's not dead in the center of the panel..

Also, from my understanding, the optimal exciter placement is on the golden ratio. So If I had two exciters on one panel, where would the second one go then? Or with the split panel scenario, where would be the optimal position for the second exciter for the smoothest response? I'm assuming it's not dead in the center of the panel..

I am running 2 exciters per panel on 600x600mm XPS panels, and they start to roll off around 300 Hz I think. IMO when it comes to panels go as big as possible.

Blobfish.

The response of the panel will depend on the exciter and panel material.

If you have read this thread you will know that some exciters have a limited hf frequency responce and a thick xps can also have a limited responce as well.

So what is your exciter and what is your xps thickness?

How high does your sub go?

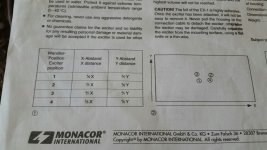

The picture is of the nxt exciter positions for up to 4 exciters.

You could maybe try one exciter first on your large panel and if a second is needed, it can be easily added.

Xps is very efficient so you should get plenty of volume from a single exciter.

I have only used xps in a 5mm thickness.

Steve.

The response of the panel will depend on the exciter and panel material.

If you have read this thread you will know that some exciters have a limited hf frequency responce and a thick xps can also have a limited responce as well.

So what is your exciter and what is your xps thickness?

How high does your sub go?

The picture is of the nxt exciter positions for up to 4 exciters.

You could maybe try one exciter first on your large panel and if a second is needed, it can be easily added.

Xps is very efficient so you should get plenty of volume from a single exciter.

I have only used xps in a 5mm thickness.

Steve.

Attachments

Carlmart.

On page 343 from post 3424 onwards there are pictures of my basic art panel , frequency plots and recordings.

The exciter is rigidly mounted to the spline with pva, which takes all of the exciter weight, so there is no added stress on the canvas and exciter coil.

I didn't bother with a spline on the ply and canvas panel but if a heavier exciter is used it might be necessary?

Steve.

On page 343 from post 3424 onwards there are pictures of my basic art panel , frequency plots and recordings.

The exciter is rigidly mounted to the spline with pva, which takes all of the exciter weight, so there is no added stress on the canvas and exciter coil.

I didn't bother with a spline on the ply and canvas panel but if a heavier exciter is used it might be necessary?

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker