Jeeeej the 400e post... well i get some synthetic paper tomorow. stupid is i ordered it online and after i paid i noticed this company is in my city....again wasted some money 🙂 im really good at that game. its 55 grams Tyvek paper and 105 grams. 2 complete differend version verry verry light and medium. so should be able to make a good comparison.

i just need to think of a nice way to sandwich the whole and create a solid coil carier. maybe 2 part epoxy although that takes rather long to dry, and i do lack patience.

got some 2 part foam stuf as well, might try to make a small mould. its heavy but still not as heavy as solid epoxy.

i just need to think of a nice way to sandwich the whole and create a solid coil carier. maybe 2 part epoxy although that takes rather long to dry, and i do lack patience.

got some 2 part foam stuf as well, might try to make a small mould. its heavy but still not as heavy as solid epoxy.

Hi Sergui,

I have a few questions about your voice coil.

Starting with a few facts.

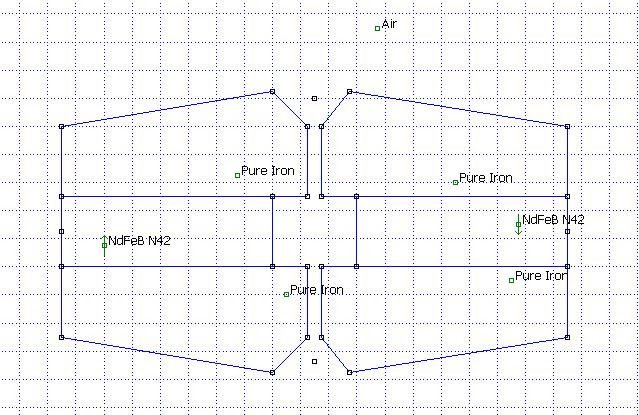

I simulated the voice coil in your model here

The amount of turns depends on the diameter of the copper wire.

The width of this voice coil has a maximum of 5mm for 0,224mm wire.

The force on the voice coil is 8.43 Newton.

2,4mm for the 0,18mm wire. F=5.57 N

1,3mm for the 0,15mm wire. F=3.17 N

The moving mass of the total membrane is approximately:

Mass[paper]x55% + Mass[voice coil] + Mass[glue or epoxy resin] + Mass[reinforcement].

Why 55%? 45% doesn't move only partly bends.

For example:

Your Janus50 paper area is (0,5 x 0,4)*2 = 0,4 sqm * 55% = 13,2 gram of moving paper mass if you use the 60 gram/sqm.

If you use 0,224 mm wire:

You have 0,45 gram/N

If you use 0,18 mm wire:

You have 0,348 gram/N

If you use 0,15 mm wire:

You have 0,254 gram/N

As you can see, a heavier voice coil is more efficient then the lighter one.

The heavier the paper the more efficient the heavy voice coil. (relative to the lighter coils of course)

In this case 0,224 is the maximum, because the maximum width is 5mm, if you want to have a underhung motor and a p-p stroke of 4mm.

My question is:

How would you achieve this with an alu foil voice coil?

What do you use as a voice coil carrier?

Or do glue them right on the paper?

Why these questions?

I want to protect you for the pitfalls I was in.

BR,

Henjo

Hi Henjo,

I want to try allot of configs. Ex: 60,80,120 gr paper, 0.18 and 0.22mm copper wire.

In the end I think I will end with the Al voice coil because as you have seen in earlier posts if you want more gain in the hight frecv you need the best and the biggest contact surface between the coil and membrane that you can obtain.

For the 60 and 80 gr membrane im sure I will need a harder support or reinforcement for the coil and the membrane for the coil zone.

On the 120gr paper I will try to stick the coil dirrectly on the paper.

Cheers

Sergiu

Jeeeej the 400e post... well i get some synthetic paper tomorow. stupid is i ordered it online and after i paid i noticed this company is in my city....again wasted some money 🙂 im really good at that game. its 55 grams Tyvek paper and 105 grams. 2 complete differend version verry verry light and medium. so should be able to make a good comparison.

i just need to think of a nice way to sandwich the whole and create a solid coil carier. maybe 2 part epoxy although that takes rather long to dry, and i do lack patience.

got some 2 part foam stuf as well, might try to make a small mould. its heavy but still not as heavy as solid epoxy.

Hi Wrine,

I was in a case like you when i did some shopping for my amp... 🙂

I have a question: have you tryied double sided coil for this speaker?

Please post some results about that paper.

Cheers

Sergiu

Hi Wrine,

I was in a case like you when i did some shopping for my amp... 🙂

I have a question: have you tryied double sided coil for this speaker?

Please post some results about that paper.

Cheers

Sergiu

funny, i thought about that idea today to sandwich 2 of my coils back to back.... would it result in anything except for higher impedance and higher power handling ?,

so far i **** up one of the papers. and then i came again to the conclusion that using 4 cylinders sucks. freq responce goes all over the place.

but ofc using 2 cylinders has there own problems , like hoe to keep the coil stable.

I now tried cutting the back 2 cylinders of, and leave few cm top mid and bot along the coil. i foild them back to the steel and use it as spider. with this. i dont need the strings, and the coil is more stable.

further the damping with the foam tape is a must for me, i tried many diferent papers and they all have resonances. no mater if its aramide, or synthetic paper, print paper, expensive japanese paper or a toilet roll for that matter. some damp a bit more some less. but still there are loads of resonances left. (although the toilet paper would have much less resonances 🙂 ) the thicker the paper less resonances and less high freq response 🙂 but damping lighter paper is more easy then making thick paper lighter.

Last edited:

funny, i thought about that idea today to sandwich 2 of my coils back to back.... would it result in anything except for higher impedance and higher power handling ?,

so far i **** up one of the papers. and then i came again to the conclusion that using 4 cylinders sucks. freq responce goes all over the place.

but ofc using 2 cylinders has there own problems , like hoe to keep the coil stable.

I now tried cutting the back 2 cylinders of, and leave few cm top mid and bot along the coil. i foild them back to the steel and use it as spider. with this. i dont need the strings, and the coil is more stable.

further the damping with the foam tape is a must for me, i tried many diferent papers and they all have resonances. no mater if its aramide, or synthetic paper, print paper, expensive japanese paper or a toilet roll for that matter. some damp a bit more some less. but still there are loads of resonances left. (although the toilet paper would have much less resonances 🙂 ) the thicker the paper less resonances and less high freq response 🙂 but damping lighter paper is more easy then making thick paper lighter.

Hi Wrine,

When you use a single sided voice coil, you get full volume in one cilinder and abit of damping in the other.. 😉

I think that maybe you will get more high frecvencies or improve abit the efficiency.

Cheers

Sergiu

well made one today, 2 x 4 ohm coils, so i am at 8 ohm in series and looks like i did not lose much output. its even nicer since the are only 4mm width now so a good underhung for the 8 mm steel bars. i gave them both wires since you can also passive eq one coil. like for instance use highpass or low pass. in paralel. if you amp is fine with 2 ohm loads that is.

you could taylor the freq response a bit. for instance use 4 ohm load from 500 hz and up and combine the second coil from 500 hz and down to increase the low end... but this strains the copper a bit and ur amplifier.

i dont have more high output to be honest. 🙁, but i must admit i taped the membrame to the coil this time since i only got material for 2 more. and i dont want to trow away more. not before i got some new foil... 🙂

futhermore. the shape of the cylinders makes for a really weird top end with a huge sine wave shape Dip and peak . i can imagine its phasing. and i got rid of it once. but i cant reproduce that result 🙁 with this materials

you could taylor the freq response a bit. for instance use 4 ohm load from 500 hz and up and combine the second coil from 500 hz and down to increase the low end... but this strains the copper a bit and ur amplifier.

i dont have more high output to be honest. 🙁, but i must admit i taped the membrame to the coil this time since i only got material for 2 more. and i dont want to trow away more. not before i got some new foil... 🙂

futhermore. the shape of the cylinders makes for a really weird top end with a huge sine wave shape Dip and peak . i can imagine its phasing. and i got rid of it once. but i cant reproduce that result 🙁 with this materials

Last edited:

ok, measured output when using one coil 4 ohm or 2 in series to get to 8 Ohm, i gain about 3db when in series. thats pretty good , since i increase power handling as well. doing them in parelel will gain even more but ofc we dont want a 2 ohm load.

now for the highs... it remains a problem. and i finally got sort of the result i had early to 20khz. but its not so much of getting the same ouput upt till 20khz but rather losing the overshoot in the mid area. at least if you want a straight curve....

i thought yes finally to 20khz. but i looked at a measurement i took a bit early, and i just lost 5 db or so from 500 to 14 khz. wich resulted in a flatter curve....

still if you got a sinewave curve around 15 khz ur cylinders have a to big curve (are to round) a posible solution could be make the part where the to cylinders are glued together bigger, so it comes more towards you, so the sorth of mouth formerd by the 2 cylinders becomes wider. and the curve will flat out.

Then last but not least. adding a baffle does sort of nothing to the low end. if it gains anyhting its no more then 0.5-1 dB. thats weird, since it is an open baffle speaker. it could be it acts more like a bending wave thingy. where a baffle did not do much either with the exciters ?

i only did a baffle on one side, but usually with ESL's this will give a result wich you can hear pretty well.

now for the highs... it remains a problem. and i finally got sort of the result i had early to 20khz. but its not so much of getting the same ouput upt till 20khz but rather losing the overshoot in the mid area. at least if you want a straight curve....

i thought yes finally to 20khz. but i looked at a measurement i took a bit early, and i just lost 5 db or so from 500 to 14 khz. wich resulted in a flatter curve....

still if you got a sinewave curve around 15 khz ur cylinders have a to big curve (are to round) a posible solution could be make the part where the to cylinders are glued together bigger, so it comes more towards you, so the sorth of mouth formerd by the 2 cylinders becomes wider. and the curve will flat out.

Then last but not least. adding a baffle does sort of nothing to the low end. if it gains anyhting its no more then 0.5-1 dB. thats weird, since it is an open baffle speaker. it could be it acts more like a bending wave thingy. where a baffle did not do much either with the exciters ?

i only did a baffle on one side, but usually with ESL's this will give a result wich you can hear pretty well.

Last edited:

ok, measured output when using one coil 4 ohm or 2 in series to get to 8 Ohm, i gain about 3db when in series. thats pretty good , since i increase power handling as well. doing them in parelel will gain even more but ofc we dont want a 2 ohm load.

now for the highs... it remains a problem. and i finally got sort of the result i had early to 20khz. but its not so much of getting the same ouput upt till 20khz but rather losing the overshoot in the mid area. at least if you want a straight curve....

i thought yes finally to 20khz. but i looked at a measurement i took a bit early, and i just lost 5 db or so from 500 to 14 khz. wich resulted in a flatter curve....

still if you got a sinewave curve around 15 khz ur cylinders have a to big curve (are to round) a posible solution could be make the part where the to cylinders are glued together bigger, so it comes more towards you, so the sorth of mouth formerd by the 2 cylinders becomes wider. and the curve will flat out.

Then last but not least. adding a baffle does sort of nothing to the low end. if it gains anyhting its no more then 0.5-1 dB. thats weird, since it is an open baffle speaker. it could be it acts more like a bending wave thingy. where a baffle did not do much either with the exciters ?

i only did a baffle on one side, but usually with ESL's this will give a result wich you can hear pretty well.

Hi Wrine,

Your findings are very interesting.

Keep up the good work.

I also buyed some nuts and screws for the project.. I'm am waiting for a company from Romania to answer my mail for a carbon steel order.

Cheers

Sergiu

I made a 1/4 Rubanoide 2-3 years ago:

[/IMG]

[/IMG]

[/url][/IMG]

[/url][/IMG]

[/url][/IMG]

[/url][/IMG]

Roven made a Linear motion transducer LMT.

Above is my clone.

A link to a tread here:http://www.diyaudio.com/forums/planars-exotics/221571-linear-motion-transformer.html

Bernt

Roven made a Linear motion transducer LMT.

Above is my clone.

A link to a tread here:http://www.diyaudio.com/forums/planars-exotics/221571-linear-motion-transformer.html

Bernt

I made a 1/4 Rubanoide 2-3 years ago:

[/IMG]

[/url][/IMG]

[/url][/IMG]

Roven made a Linear motion transducer LMT.

Above is my clone.

A link to a tread here:http://www.diyaudio.com/forums/planars-exotics/221571-linear-motion-transformer.html

Bernt

thats sort of a 1/4 rubanoid and driven on both ends? how will it stay in the gap ? it is also a bit more expensive 🙂 2 the steel and 2 the magnets 🙁

as for me , im having a break with fidling. i ran out of money and i go on vacation 🙂 i will take a new fresh look at it after

btw it starts to look more and more like a normal speaker 🙂 but with a huge coil area 🙂 instead of round its square.

Last edited:

With this kind of configuration:

and with N42 and a 3 mm gap I get 1.32 T,

with N52 and a 3 mm gap I get 1.43 T,

with N42 and a 2 mm gap I get 1.64 T,

and with N52 and a 2 mm gap I get 1.76 T.

Again, easy to simulate but a hell to build:

Also, at these levels, the iron must be more or less carbon free.

Hello my friends,

Yesterday a got a quotation for the olc15x (aisi1017) and I was blown away. I have to buy 800kg of steel because the producer didnt want to remain with stocks.... I am really sad right now.

I started to reorientate to pure iron. Can someone give me some dimensions for the above design?

I really need you help guys.

Thanks in advance

Sergiu

Hi Sergui,

I would not worry too much about the quality of the steel strip.

This determines only 1% or 2% of the quality of the speaker.

I would use cold rolled steel, which is probably for sale with any metal shop.

Here is a chart showing the differences in magnetic flux.

Use your energy for the coil and the membrane there is more to be gained.

BG,

Henjo

I would not worry too much about the quality of the steel strip.

This determines only 1% or 2% of the quality of the speaker.

I would use cold rolled steel, which is probably for sale with any metal shop.

Here is a chart showing the differences in magnetic flux.

Use your energy for the coil and the membrane there is more to be gained.

BG,

Henjo

Hi Sergui,

I would not worry too much about the quality of the steel strip.

This determines only 1% or 2% of the quality of the speaker.

I would use cold rolled steel, which is probably for sale with any metal shop.

Here is a chart showing the differences in magnetic flux.

Use your energy for the coil and the membrane there is more to be gained.

View attachment 495586

BG,

Henjo

i think you are right about that!. if you want the same coild for instance as i used buy a solid ink printer for 50 euro with ink. and some chemicals for instance. dirt cheap but gained a solid way of making coils consistend for instance. just to name a thing. or buy beter material for membrame or glue whatever.

dont let ur whole project going to waste because of the metal. you will have sound in the end maybe few db less then you predicted. but this is a gambling anyway with materials used etc. you got 300 euro of mangets laying around. do something with it. maybe the right metal comes around and you replace it later?

Hello my friends,

Thanks for the advices, I am just worried about the flux saturation point in steel... You are right, the internet is full of cold rolled stell, but what to look for when buying this cold rolled steel: low quantity of carbon steel, structural steel, enameled steel, or steel for car industry? This steel is made for diffrent purposes and has diffrent quality and formula for each purpose.

Thanks

Sergiu

Thanks for the advices, I am just worried about the flux saturation point in steel... You are right, the internet is full of cold rolled stell, but what to look for when buying this cold rolled steel: low quantity of carbon steel, structural steel, enameled steel, or steel for car industry? This steel is made for diffrent purposes and has diffrent quality and formula for each purpose.

Thanks

Sergiu

i just went to a local metal shop bought the right size colled rolled steel. done 🙂 it cost 20 euro max. and you can play with it instead of endless searching, maybe it is suficient to.

Hello my friends,

Yesterday a got a quotation for the olc15x (aisi1017) and I was blown away. I have to buy 800kg of steel because the producer didnt want to remain with stocks.... I am really sad right now.

I started to reorientate to pure iron. Can someone give me some dimensions for the above design?

I really need you help guys.

Thanks in advance

Sergiu

Every dot is 0.5 mm.

So the Neos are 40x10 mm and the gap is 3 mm.

I've attached the corresponding dxf file. You'll have to change the file extension to dxf.

If it doesn't work, I can mail you the femm file and dxf file. PM me your mail address.

Otherwise I agree with Wrinex, a local metal shop is the best bet to get the steel. Perhaps they even can make it from the dxf file.

Attachments

Hello there!

I am baking some voice coils for the rubanoid, starting today.

If there are people who are interrested, I'll bake a few more.

Diameters available 0,15 - 0,2 -0,22 mm.

Please give your center tot center distance of your metal strips and the height of your membrane or total height of the magnets and required resistance.

It's for free without warranty.

No shipping costs if it less then €6,00.

BR,

Henjo

I am baking some voice coils for the rubanoid, starting today.

If there are people who are interrested, I'll bake a few more.

Diameters available 0,15 - 0,2 -0,22 mm.

Please give your center tot center distance of your metal strips and the height of your membrane or total height of the magnets and required resistance.

It's for free without warranty.

No shipping costs if it less then €6,00.

BR,

Henjo

- Home

- Loudspeakers

- Planars & Exotics

- A DIY Ribbon Speaker of a different Kind