Very interesting with the offset cone. I did try to figure out how to do this but couldn't quite figure out mounting of the internal cone (orange).Yes, because it either makes higher frequency chuffing noises, distorts and/or it transmits higher frequencies through the port.

It's quite hard to avoid high frequencies exiting the port. One possible way is making the speaker a mass loaded transmission line with offset port. I made some tests here.

Edit: by the way a vertical bracing is better in most and also your case. Better not to divide the longest dimension of a speaker box.

Attachments

I always put my braces at random intervals to make sure any left frequencies in the panels are at least different. I imagine spacing them evenly would leave you with 2-3 sections all resonating at the same frequency right?

Yes, exactly! That's why I don't understand why enclosure builders are cherished who do extremely elaborate and well made, all cnc routed parts and fail miserably on understanding standing waves / resonances. And if you point that flaw out, you're branded as envious and not understanding the marvel of this enclosure.

That's why I mentioned "minimum port diameter away from walls / edges". I thought your comment was the port "Entrace" in the box being in close proximity to the shelf brace.

No, it's the proximity to the back wall. The brace just indicated how extremely close it is.

Very interesting with the offset cone. I did try to figure out how to do this but couldn't quite figure out mounting of the internal cone (orange).

Put stand off struts on the baffle, back wall (but there it will be broken off easily because of the leverage) or put it on the port.

You'd be surprised how many professionals do not have a conceptual understanding of what they do. My father runs and owns a starter/alternator rebuilding company. He has no idea how a starter or alternator works. Not a clue. I ask him if he wanted to learn one day and he just flat told he didn't care. I said it would take 5 minutes to explain it. Still.... did not care.Yes, exactly! That's why I don't understand why enclosure builders are cherished who do extremely elaborate and well made, all cnc routed parts and fail miserably on understanding standing waves / resonances. And if you point that flaw out, you're branded as envious and not understanding the marvel of this enclosure.

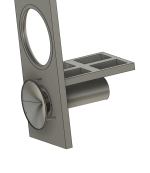

I mean... it looks cool.... but it would never print. You cannot print in midair and this is a crazy extreme overhang.

It's not nearly as difficult as you think. print it with the baffle down, make the diffusor a separate part and don't make the cross brace at 90° but 45° with a rectangle hole (on one corner pointing to the baffle). Voilà, all problems solved.

I wouldn't do it. I could not measure or hear any benefit of a cone and the small distance rods will cause chuffing noises.but it would never print

I wouldn't do it. I could not measure or hear any benefit of a cone and the small distance rods will cause chuffing noises.

I agree. That benefits extreme port dimensions but if you have reasonable port locations and dimensions, you barely get any benefit from it. Don't misunderstand me, the research and principle is solid and I apprechiate that big time. For proper port dimensions and placement, the advantages diminish in returned value. That doesn't make it bad but it also doesn't make it a 'must have'. It's still a very good solution if other options can't be realized. I like the principle and I'll likely realize it in one of my projects when that's the best option.

...My father runs and owns a starter/alternator rebuilding company. He has no idea how a starter or alternator works. Not a clue. I ask him if he wanted to learn one day and he just flat told he didn't care.

Your father is a practical and a capable businessman. I respect that.

If one starts to do so much thinkering into ports, printing useless and harmfull inserts, has problem getting the length/ diameter right and high frequency exiting, he should simply install a passive radiator. All these unsolvable problems are suddenly gone.

I know, in DIYS there is a strong opposition to reasonable, simple and perfect solutions, but maybe it might help a single soul. The cost compared to the advantages is rediculous. Tuning to the point is done in a few minutes (mounting the radiator outside in for that).

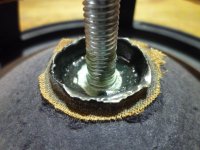

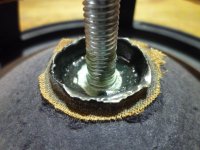

Frequent speaker builder may even have a number of defective or in other ways useless chassis. Just removing the magnet and fixing a screw with some epoxy in the dustcap/ voice coil makes them adjustable passive radiators.

I know, in DIYS there is a strong opposition to reasonable, simple and perfect solutions, but maybe it might help a single soul. The cost compared to the advantages is rediculous. Tuning to the point is done in a few minutes (mounting the radiator outside in for that).

Frequent speaker builder may even have a number of defective or in other ways useless chassis. Just removing the magnet and fixing a screw with some epoxy in the dustcap/ voice coil makes them adjustable passive radiators.

Frequent speaker builder may even have a number of defective or in other ways useless chassis. Just removing the magnet and fixing a screw with some epoxy in the dustcap/ voice coil makes them adjustable passive radiators.

That's right, I even snatch defective drivers off of ebay and I usually get them for 1 buck + postage. 😉

Don't take posts too serious.They are not.

And also PRs have some disadvantages.

In most cases a vented cabinet is no problem at all. You simulate, design, build, measure, tune and that's it.

If you love to complicate things, fine, do it, it's DIYS. There is no supervisor to set you a time line.

On the other hand, if a vented cabinet get's over your head and you think about hiring a rocket scientist to solve your DIYS problem, a passive radiator may help you a great deal.

The main disadvantage of a passive radiator is it's cost.

Yes, PRs have disadvantages too. Everything in speaker building is a compromise. You have to decide what's the best or most practical solution. I'm just surprised why so many ppl don't even consider the options that are possible and just run into the same path everyone goes even if that's not a good or even acceptable solution for their problem. Speakers are not a religion and DIY invites to try new things.

Maybe some don't know how simple such a "PR" is adjusted. Even a simple impedance curve will tell you the tuning, no need for fancy measurements. Of course, it should all be in some reasonable, hopefully well simulated region.

Here a commercial and a DIYS version of a 8" passive radiator. For tuning, you can mount them the wrong way, so you can change weight without taking out the PR for every try.

Here a commercial and a DIYS version of a 8" passive radiator. For tuning, you can mount them the wrong way, so you can change weight without taking out the PR for every try.

Uhm, that's not how you should do a PR. You've killed the spider, which removes almost all of the control of the piston movement. And to make it worse, you've extended it further to the back. The weight angles the membrane, it will stick out on the bottom and is pulled in on the top. Congratulations, you have managed to perfectly remove all possible linear excursion from the PR! The PR can now only do tumbling motions.

- Home

- Loudspeakers

- Multi-Way

- A boring 2 way build