I didn't enter the Cms into Winisd. It generated it using other parameters so I think I'm ok. Madisounds example boxes does line up with the sims.On the 3rd picture the Cms can't be right?! Not on the PC to check the TSP right now.

Dave.

I did not break in the drivers. I will break them in overnight with pink noise. We will see tomorrow how they measure

This discrepancy is too much. Might as well be a different product. They measure pretty close to each other but not quite. Their resistance is off 0.1 ohm from driver to another.

I did not break in the drivers. I will break them in overnight with pink noise. We will see tomorrow how they measure

This discrepancy is too much. Might as well be a different product. They measure pretty close to each other but not quite. Their resistance is off 0.1 ohm from driver to another.

Last edited:

It would be more efficient to use a sine wave near Fs. You can also see that they are sitting on Xmax.I will break them in overnight with pink noise.

I didn't enter the Cms into Winisd. It generated it using other parameters so I think I'm ok. Madisounds example boxes does line up with the sims.

I suspected that. But that very likely suggests even more that the parameters are not correct. It's so far off it's probably one value in which the decimal point is ignored (comma vs point) or it's a wrong unit (m/ft or m instead of mm etc).

It would be more efficient to use a sine wave near Fs. You can also see that they are sitting on Xmax.

During the break in, the fs will drop. The sine wave is very good to see the Xmax, that is correct but it's better to use a wobble signal around the fs for the actual break in. That stretches out the spider more evenly too, it avoids possible null points (non stretch) in case of a resonance in the spider.

The idea of staying near Fs is to reduce voice coil heating during the process.

I know. But a wobble will do that too unless it's too wide.

I usually use this 10 hour track from YouTube that runs all sorts of sweeps and pink noise. Seems to do the trick. I leave it in my office at work. Probably drives the yoga place above my shop nuts. They are supposed to be learning zen though right?...It would be more efficient to use a sine wave near Fs. You can also see that they are sitting on Xmax.

I'll see if I can find posted specs elsewhere, however, when I enter the posted specs on madisound and run the simulations of their suggested boxes I get back exactly what they say.I suspected that. But that very likely suggests even more that the parameters are not correct. It's so far off it's probably one value in which the decimal point is ignored (comma vs point) or it's a wrong unit (m/ft or m instead of mm etc).

If it's this bad it might very well be a bad batch of drivers.

Might it be possible, when you've traced the impedance you've used the left y-axis values instead of the right?

ICG,

No, when I traced it I used vituixcad which has different bars for the impendence in the trace tool.

This has no bearing on the Theile Small parameter nor the WINISD simulations of which there is, currently, a huge descrepency between marketing and real life.

No, when I traced it I used vituixcad which has different bars for the impendence in the trace tool.

This has no bearing on the Theile Small parameter nor the WINISD simulations of which there is, currently, a huge descrepency between marketing and real life.

Why not stretch the suspension by hand? push to bottom, lift up to max, burn in done in a minute without noise?

It doesn't work that way. The suspension is elastic and one time stretching does next to nothing, that needs to be repeated a few thousand times up to a few ten thousand times or more. Aside from that, there are some drivers which absolutely not like that. Accuton drivers are a prime example for that, if you do that, their cone shatters instantly.Why not stretch the suspension by hand? push to bottom, lift up to max, burn in done in a minute without noise?

30Hz makes over 100k cycles in an hour so few thousand is easy, under a minute. Yeah perhaps it's driver dependent, it's not fun to blast 18" subs overnight, even with two in opposing polarity nulling out each others acoustic output the whole house still vibrates and no one sleeps. Perhaps few minutes is enough. On the other hand the delicate hifi drivers have not mucho output and if sensitive to fingering it's better do it that way.

Last edited:

Happens many times. here with Diy T/S tests.

Their is break in and temperature stability.

And usually expect 10% error with T/S parameters.

The surround and spider will change slightly

over few hours of normal music. Manufactures dont measure

fresh glued cold drivers

As with any driver manufactures bring up voice coil temp

to a expected operating average. the details i dont know.

Having heard various methods of white noise or signal.

10 or 15 minutes or whatever temp desired.

Dont think measured on a table either. Mounted or supported

Fs can get lower

Real life T/S shift with temp regardless.

So on a normal day starting cold.

Then measure hour after a short listen.

Expect a shift as well

Their is break in and temperature stability.

And usually expect 10% error with T/S parameters.

The surround and spider will change slightly

over few hours of normal music. Manufactures dont measure

fresh glued cold drivers

As with any driver manufactures bring up voice coil temp

to a expected operating average. the details i dont know.

Having heard various methods of white noise or signal.

10 or 15 minutes or whatever temp desired.

Dont think measured on a table either. Mounted or supported

Fs can get lower

Real life T/S shift with temp regardless.

So on a normal day starting cold.

Then measure hour after a short listen.

Expect a shift as well

Many members posting here seem to be somehow obsessed with burn in magic and voodoo.

On the opposite side, why does no one try out what really happens? I did, as it didn't take long and was nothing complicated, in fact quite simple:

Measure chassis once, fresh from the box, store the result. You don't need to take the second, mass or volume measurement for this test.

Then push the cone up and down by hand, a few times. Of course, do not destroy the chassis. Measure, store.

Next have the driver work heavyly on it's resonance frequency, for hours if you like. I left them work a night shift. The Fs ensures maximum excursion with minimum heating of the voice coil. Measure again.

You will see a drop in Fs after pushing the cone, but nothing of significance in the 3rd measurement, even after hours of high excursion.

You can wooble it for a week, nothing will change. All this white noise or whatever, even as complicated and time consuming, is 100% useless.

Surprisingly, after some time without movement, the Fs will rise again and go down after a few cycles medium excursion.

I really expected more to happen. I used a 6" carbon cone, a 18" paper- PA chassis and a 3.5" full range for my test.

Sorry if I hurt any feelings, but I prefer simple facts and have a distorted relationship to voodoo and overcomplication.

On the opposite side, why does no one try out what really happens? I did, as it didn't take long and was nothing complicated, in fact quite simple:

Measure chassis once, fresh from the box, store the result. You don't need to take the second, mass or volume measurement for this test.

Then push the cone up and down by hand, a few times. Of course, do not destroy the chassis. Measure, store.

Next have the driver work heavyly on it's resonance frequency, for hours if you like. I left them work a night shift. The Fs ensures maximum excursion with minimum heating of the voice coil. Measure again.

You will see a drop in Fs after pushing the cone, but nothing of significance in the 3rd measurement, even after hours of high excursion.

You can wooble it for a week, nothing will change. All this white noise or whatever, even as complicated and time consuming, is 100% useless.

Surprisingly, after some time without movement, the Fs will rise again and go down after a few cycles medium excursion.

I really expected more to happen. I used a 6" carbon cone, a 18" paper- PA chassis and a 3.5" full range for my test.

Sorry if I hurt any feelings, but I prefer simple facts and have a distorted relationship to voodoo and overcomplication.

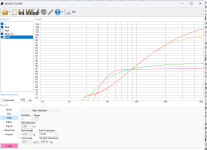

After burn in everything changed. Pink line is off of thiele parameters after a 10 hour burn in track. Green line is simulated off of specs posted on Madisound. The rest of the lines are taken off of new woofers that have never been played.

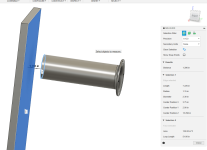

Now to build the most boring box ever..... actually not, I might do something fancy with the edges to reduce the diffraction but haven't totally decided yet.

Now to build the most boring box ever..... actually not, I might do something fancy with the edges to reduce the diffraction but haven't totally decided yet.

Attachments

- Home

- Loudspeakers

- Multi-Way

- A boring 2 way build