a word on crossovers

Hi,

First let me just say that this is amazing work as I just read through the thread.

Secondly, I noticed you were thinking about running the ribbon down to as low as 150Hz and using a high order xover. I don't recommend this for two reasons. 1) The coloration from whatever bass driver you are using will be quite different from the ribbon, which will be very low in coloration as you are hoping. Now I know it seems intuitive that you would want the ribbon to cover as wide a range as possible and not get "polluted" by the bass/lower mid driver; however, what you do with a higher order slope is make a sharp transition and due to different driver colorations you will also then get an abrupt change in instrument tone as it straddles this transition.

With my own planar magnetic hybrids that I built 2 years ago I have found that you need a gentle transition at the crossover frequency so that it becomes much more difficult to localize the two distinctly different drivers. This also means using a somewhat higher xover frequency (like an octave higher should work or 300Hz). This also means selecting a bass/mid with FLAT frequency response up to about 1Khz with NO breakup (or at least minimal). This is important to minimize coloration from the bass/mid driver, which will invariably be the weakest link.

To evaluate this I used a Behringer DCX2496, which allows you to have total control over the slope, the frequency and the phase relationship between the drivers (in 5 degree steps!) as well as some parametric equalization and time alignment. It is a great tool kit for learning what filter you need but in stock form it sounds BAD. I recommend to use it to find what you really need and then use something better.

For my own system I started at 180Hz with a 4th order L-R and the distinction between the two drivers was obvious and even tweaking phase didn't help much. Then I went to 3rd order Butterworth and same problem. Then I went to a 2nd order L-R and it worked pretty fine but a 2nd order Butterworth was even better, especially with the phase adjusted correctly (based on impulse response measurements). By this time I had the xover frequency at 250Hz. I also tried 1st order butterworth at 500hz but this was then too much sound from the bass driver (10" Peerless CSX...very good driver) and some resolution was lost so I backed off to the 2nd order as the best overall balance between the sound characteristics of the two drivers.

The lack of coherence between the two drivers with the higher order slopes really turned me off to using them as I also listen with full range electrostats where the coherence is total. I am picky about this.

I am now using an Accuphase F-25 active xover at 290hz with a 2nd order Gaussian filter. This gives a very transparent sound and a great soundstage with natural tone. Amplifiers are two stereo SET amps from KR Audio (model VA350). As the sensitivity of your ribbons will be very high you won't need much power for them so I recommend top notch tube amps.

2) You will find that if you push the driver down to its lower limit it will not perform dynamically as well as you would like and your lower mids will end up sounding somewhat thin and strained even though they measure fine with test equipment.

I found at the higher order slopes at 180Hz that my lower mids were lacking a fullness in sound (ie. they were thin sounding) and could sound a bit harsh when pushed hard...a sure sign of increasing distortion. Maybe your ribbon will be more robust but the excursions can get fairly large down at the lower end.

I just wanted to share a bit of my experience with tuning hybrid systems for when you get them up and working. It might take just as long to get the xover, slope and such as it did to build them in the first place. I think if you get the balance between drivers right you will have one of the finer sounding speakers out there.

good luck!

Hi,

First let me just say that this is amazing work as I just read through the thread.

Secondly, I noticed you were thinking about running the ribbon down to as low as 150Hz and using a high order xover. I don't recommend this for two reasons. 1) The coloration from whatever bass driver you are using will be quite different from the ribbon, which will be very low in coloration as you are hoping. Now I know it seems intuitive that you would want the ribbon to cover as wide a range as possible and not get "polluted" by the bass/lower mid driver; however, what you do with a higher order slope is make a sharp transition and due to different driver colorations you will also then get an abrupt change in instrument tone as it straddles this transition.

With my own planar magnetic hybrids that I built 2 years ago I have found that you need a gentle transition at the crossover frequency so that it becomes much more difficult to localize the two distinctly different drivers. This also means using a somewhat higher xover frequency (like an octave higher should work or 300Hz). This also means selecting a bass/mid with FLAT frequency response up to about 1Khz with NO breakup (or at least minimal). This is important to minimize coloration from the bass/mid driver, which will invariably be the weakest link.

To evaluate this I used a Behringer DCX2496, which allows you to have total control over the slope, the frequency and the phase relationship between the drivers (in 5 degree steps!) as well as some parametric equalization and time alignment. It is a great tool kit for learning what filter you need but in stock form it sounds BAD. I recommend to use it to find what you really need and then use something better.

For my own system I started at 180Hz with a 4th order L-R and the distinction between the two drivers was obvious and even tweaking phase didn't help much. Then I went to 3rd order Butterworth and same problem. Then I went to a 2nd order L-R and it worked pretty fine but a 2nd order Butterworth was even better, especially with the phase adjusted correctly (based on impulse response measurements). By this time I had the xover frequency at 250Hz. I also tried 1st order butterworth at 500hz but this was then too much sound from the bass driver (10" Peerless CSX...very good driver) and some resolution was lost so I backed off to the 2nd order as the best overall balance between the sound characteristics of the two drivers.

The lack of coherence between the two drivers with the higher order slopes really turned me off to using them as I also listen with full range electrostats where the coherence is total. I am picky about this.

I am now using an Accuphase F-25 active xover at 290hz with a 2nd order Gaussian filter. This gives a very transparent sound and a great soundstage with natural tone. Amplifiers are two stereo SET amps from KR Audio (model VA350). As the sensitivity of your ribbons will be very high you won't need much power for them so I recommend top notch tube amps.

2) You will find that if you push the driver down to its lower limit it will not perform dynamically as well as you would like and your lower mids will end up sounding somewhat thin and strained even though they measure fine with test equipment.

I found at the higher order slopes at 180Hz that my lower mids were lacking a fullness in sound (ie. they were thin sounding) and could sound a bit harsh when pushed hard...a sure sign of increasing distortion. Maybe your ribbon will be more robust but the excursions can get fairly large down at the lower end.

I just wanted to share a bit of my experience with tuning hybrid systems for when you get them up and working. It might take just as long to get the xover, slope and such as it did to build them in the first place. I think if you get the balance between drivers right you will have one of the finer sounding speakers out there.

good luck!

Hello morricab,

I won't go point by point (you made a lot of them), but I will just say that I agree with all you said in principle. Seamlessly transitioning from ribbon to dynamic is no cake walk and I suspect I will be experimenting with many x-over points/slopes.

My apologies for not posting an update sooner...been to busy listening/tweaking to a pair of glorious ribbons 😀. I don't have time for a detailed report right now (have to get to work), but I just wanted to let you all know that they live and are freaking awesome. They are usable down to 75hz at low to moderate volume (ever hear a 3/4" ribbon convincingly recreate a kettle drum?) and 150hz at ear damaging volume. Huge sound stage, amazing detail (duh..it's a ribbon), and a mid range to die for.

I'll post more when I can.

Casey

I won't go point by point (you made a lot of them), but I will just say that I agree with all you said in principle. Seamlessly transitioning from ribbon to dynamic is no cake walk and I suspect I will be experimenting with many x-over points/slopes.

My apologies for not posting an update sooner...been to busy listening/tweaking to a pair of glorious ribbons 😀. I don't have time for a detailed report right now (have to get to work), but I just wanted to let you all know that they live and are freaking awesome. They are usable down to 75hz at low to moderate volume (ever hear a 3/4" ribbon convincingly recreate a kettle drum?) and 150hz at ear damaging volume. Huge sound stage, amazing detail (duh..it's a ribbon), and a mid range to die for.

I'll post more when I can.

Casey

valveitude said:

My apologies for not posting an update sooner...been to busy listening/tweaking to a pair of glorious ribbons 😀. I don't have time for a detailed report right now (have to get to work), but I just wanted to let you all know that they live and are freaking awesome. They are usable down to 75hz at low to moderate volume (ever hear a 3/4" ribbon convincingly recreate a kettle drum?) and 150hz at ear damaging volume. Huge sound stage, amazing detail (duh..it's a ribbon), and a mid range to die for.

I'll post more when I can.

Casey

pics or it didn't happen!

pics or it didn't happen!

I didn't take as many pictures as usual because things moved to fast. I must of strung up a dozen pairs of foil experimenting with crossover limits/foil thickness.

I'll try to pry myself away from the listening chair to post a more complete log.

Casey

Kettle drums, I hope maybe Into the Night by Phil Collins. Real nice drum part there.

Casey when you get time explain some how you configured the resistors to run from standard amplifiers without using output transformers.

Also, how efficient do you think the ribbons are. Did you have to lay in the current to drive them? How much tension did you apply to the foil? Enough questions. I bet as you said they sound real nice.

I want some. Tad

I want some. Tad

Casey when you get time explain some how you configured the resistors to run from standard amplifiers without using output transformers.

Also, how efficient do you think the ribbons are. Did you have to lay in the current to drive them? How much tension did you apply to the foil? Enough questions. I bet as you said they sound real nice.

I want some. Tad

I want some. TadOne of the most interesting thread ever! Come here every day to check if there is more pics and real time data how this monster works.

Keep on good work. Thanks 🙂

Keep on good work. Thanks 🙂

You going to just leave us dangling out here Casey????

That wasn't my intent, but I realize I have 🙁 . I have literally spent every spare moment this last week trying different things (ribbon tension/thickness, x-over points/slope, ect.), and haven't had the time for one of my standard posts. I'm working on some transformers now (2nd attempt).

I promise to have a comprehensive post by the end of the weekend to bring everyone up to date.

Casey

Ok..it's a little past the weekend but I creamed myself with a marathon transformer winding episode that I started Saturday morning and didn't finish until 4:00 AM Sunday..Sunday was spent sleeping/recovering.

The last 2 weeks has been a blur of activity, but I'll try to recap. The first obstacle that I had to overcome was getting a ribbon strung that didn't rub the sides. No matter how I tried I couldn't get the foil to clear both sides. I figured at first it was me not cutting accurately, but after a few ribbons I decided to go back and do some careful measuring. I had 2 problems. First, due to the insulating tape, glue, and slightly out of spec magnets my .8" gap is actually .78". Second, my straight edge is bowed .015"...the combination shrunk my .05" clearance to .015" clearance. The first thing I did was to re-drill my spacing block on my cutting table to slice a .73" ribbon. This gave me back most of my clearance, but my ribbons were coming out bowed making tensioning them evenly impossible. I compensated for this by flipping my straight edge over on the second cut giving my foil a slight convex. Not ideal, but workable. Once i had a foil that didn't touch either side I cobbled together a couple of composite resistor of 5 ohms out of a bunch of wire wounds i had in the junk pile. Hearing these things come alive for the first time was magic. I then fasioned some make due baffles by clamping some 20" wide mdf to the frames...

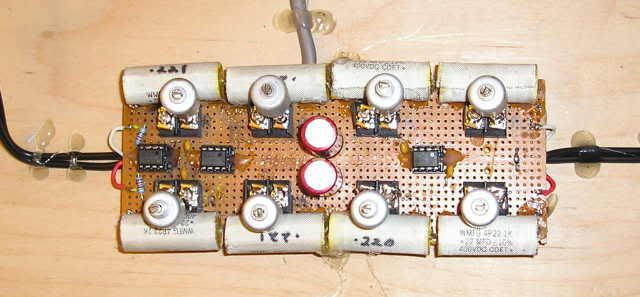

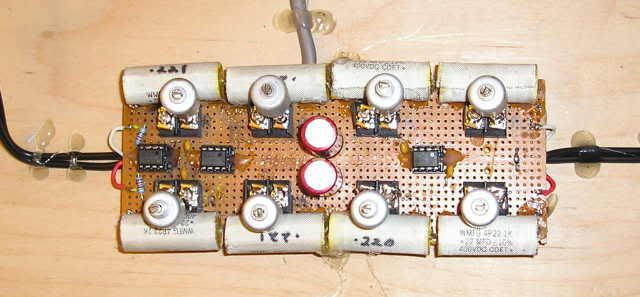

Even tough I only had around 1 watt making it to the ribbons I was mesmerized enough to stop work for a coupe lof days and just listen. During this time I was using a line level 6dB/octave @ 150 Hz fasioned with a cap between the CDP and amp. Other than an upward tilt in the frequency response it sounded damn good. As I mentioned before the bass was suprizing. No doubt some of this is due to baffle step and room gain, but I could follow the bass line easily. I knew that I needed a better high pass, so the next leg of my journey was to fabricate an active filter. I dug through my parts bins and came up eith the components to build the high pass portion of a 24dB/octave LR crossover...

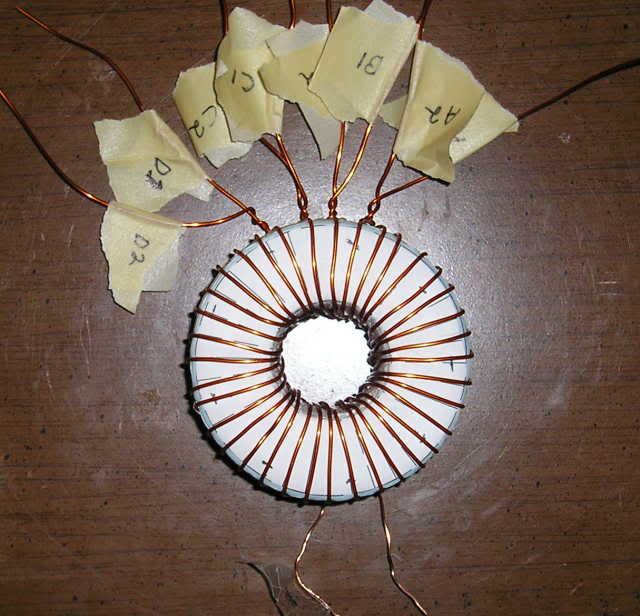

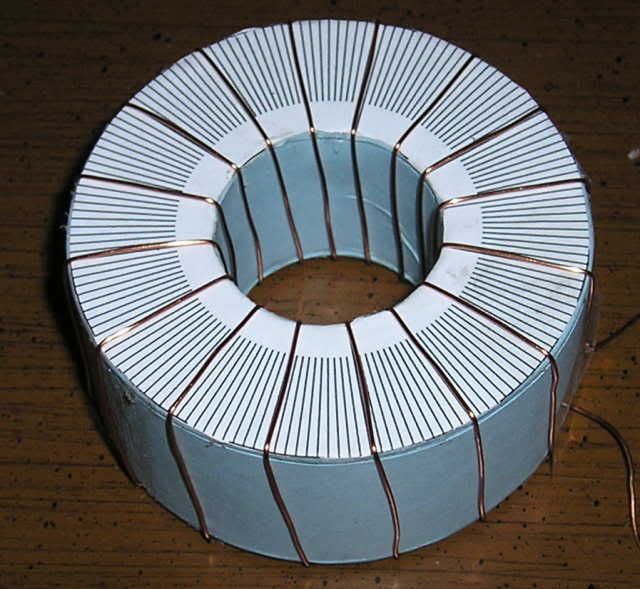

I had purchased a bunch of Soviet surplus trim pots and used these to make an infinitely variable filter between 20-500 Hz. I found that I could go as low as 75 Hz before frapping them with my 1 watt of power. Oh..with the 6 micron foil the efficiency is in the high nineties so 1 watt gave a reasonable volume. I knew that the next step was to match the amp with a transformer and I tried a quicky without properly wrapping the core and managed to cut into the insulation shorting it out. On a lark I decided to try some 115v-40V toroid power transformers I had and OOFTA!!..they sounded suprisingly good. The exaggerated top end dissapeared and the midrange became, for lack of a better word, lush. I dicovered in short order that 75 Hz was to low of a cut off point and stretched the ribbon. I then turned back to winding a proper tranformer. Here is one of the cores. I purchased a pair of surplus power transformers a while back to get the cores for this purpose. They are rated at 30VA...

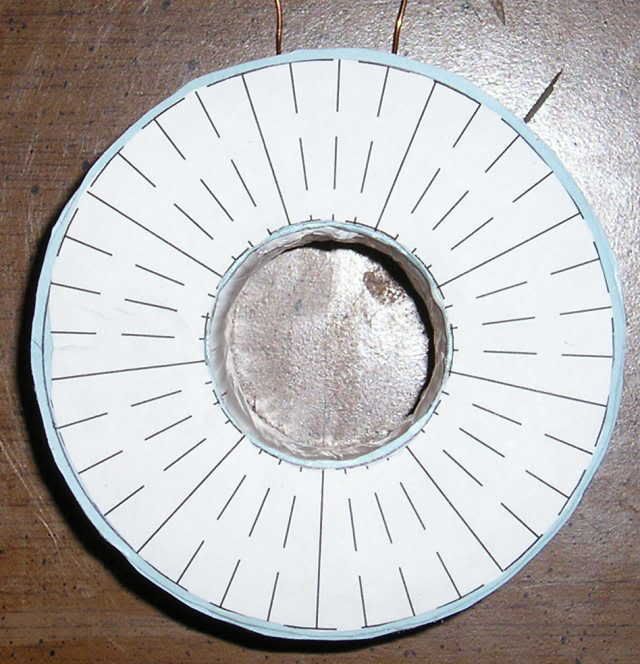

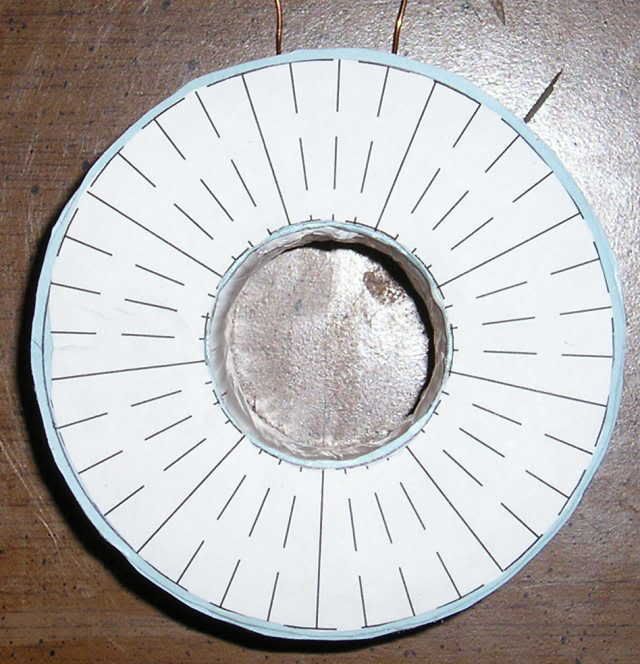

This time I carefully covered the cores in layeres of heavy paper...

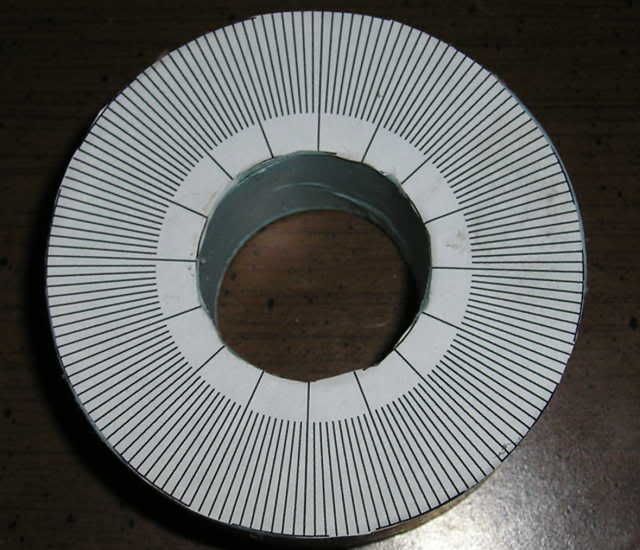

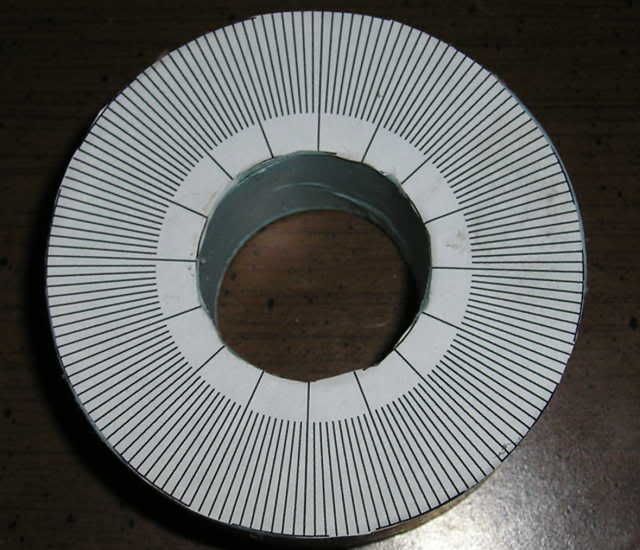

Since I didn't want the tranformers cutting off the low end while I determine my crossover point I made them full range with around 160 mH primary inductance. This required 160 turns on the primary. I drafted a turns template in CAD and glued it on...

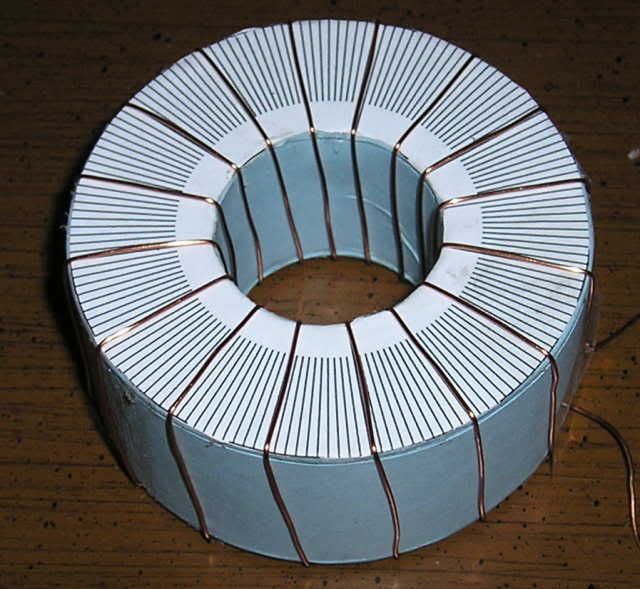

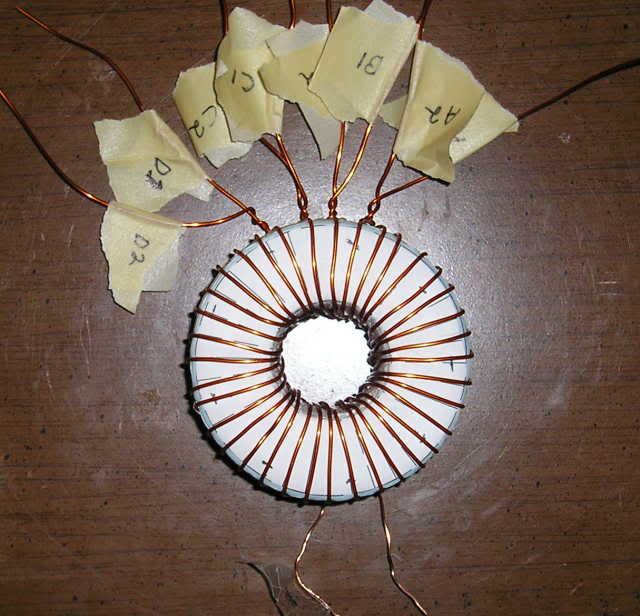

I wanted to keep the capacitance of the windings a low as possible so I went around in groups of 16 ten times. Here is the first group of turns...

Half way done...

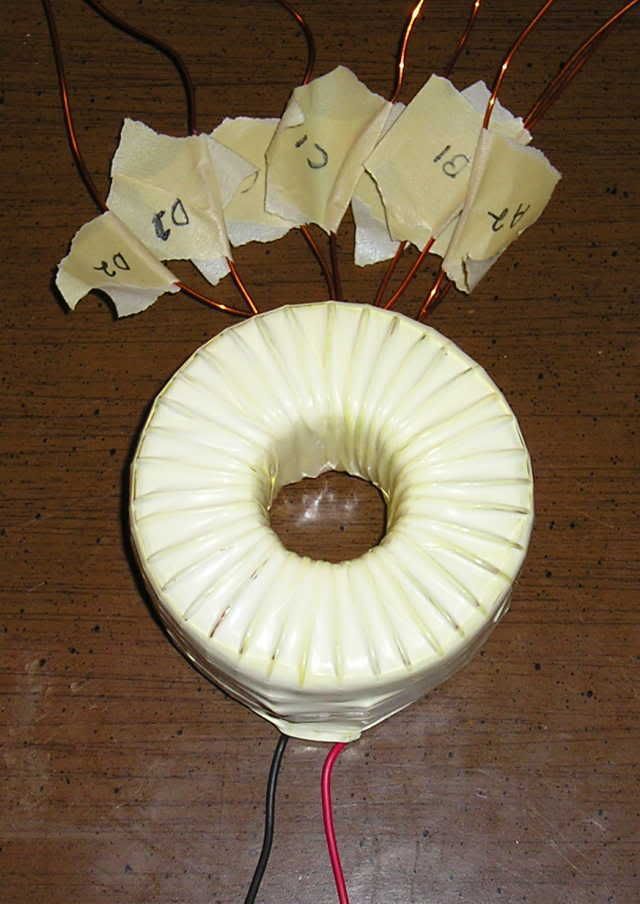

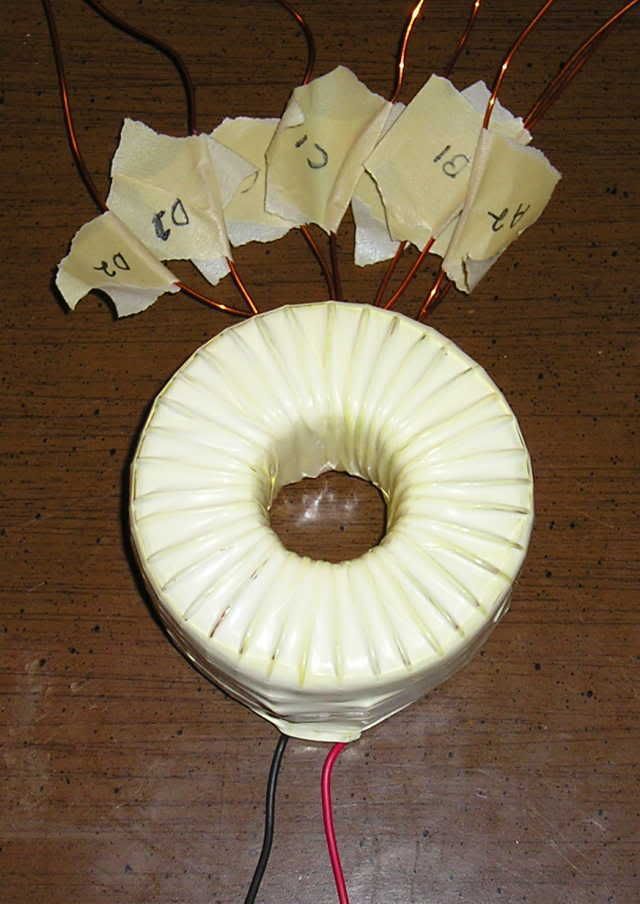

And some time later, one completed primary...

I then wrapped it in Teflon tape and glued the secondary template on. I decided on 4 seperat windings of nine turns so that I could match different foils of of different thicknesses, as well as give me different loads to the amp by using different series/parallel combinations...

After the secondaries were turned...

..I soldered on leads to the primary and wrapped the assembly heavily in heavy duty Teflon tape used in gas fittings. One completed transgformer...

Currently I have the first 12 dB/octave section of the crossover set to 75 Hz, and the second section set to 125 Hz. This allows me to play at a reasonable volume and still hear enough of the bass to enjoy them until I get a bass unit hooked up.

I still have a couple of things to work out, but the bottom line is that they are a success, and I now have the best speakers I have ever owned..with the potential of being truly world class.

I'm probably forgetting something..it's getting late and I'm still trying to catch up on my sleep...so ask any questions you may have and I'll get back with an answer.

Casey

The last 2 weeks has been a blur of activity, but I'll try to recap. The first obstacle that I had to overcome was getting a ribbon strung that didn't rub the sides. No matter how I tried I couldn't get the foil to clear both sides. I figured at first it was me not cutting accurately, but after a few ribbons I decided to go back and do some careful measuring. I had 2 problems. First, due to the insulating tape, glue, and slightly out of spec magnets my .8" gap is actually .78". Second, my straight edge is bowed .015"...the combination shrunk my .05" clearance to .015" clearance. The first thing I did was to re-drill my spacing block on my cutting table to slice a .73" ribbon. This gave me back most of my clearance, but my ribbons were coming out bowed making tensioning them evenly impossible. I compensated for this by flipping my straight edge over on the second cut giving my foil a slight convex. Not ideal, but workable. Once i had a foil that didn't touch either side I cobbled together a couple of composite resistor of 5 ohms out of a bunch of wire wounds i had in the junk pile. Hearing these things come alive for the first time was magic. I then fasioned some make due baffles by clamping some 20" wide mdf to the frames...

Even tough I only had around 1 watt making it to the ribbons I was mesmerized enough to stop work for a coupe lof days and just listen. During this time I was using a line level 6dB/octave @ 150 Hz fasioned with a cap between the CDP and amp. Other than an upward tilt in the frequency response it sounded damn good. As I mentioned before the bass was suprizing. No doubt some of this is due to baffle step and room gain, but I could follow the bass line easily. I knew that I needed a better high pass, so the next leg of my journey was to fabricate an active filter. I dug through my parts bins and came up eith the components to build the high pass portion of a 24dB/octave LR crossover...

I had purchased a bunch of Soviet surplus trim pots and used these to make an infinitely variable filter between 20-500 Hz. I found that I could go as low as 75 Hz before frapping them with my 1 watt of power. Oh..with the 6 micron foil the efficiency is in the high nineties so 1 watt gave a reasonable volume. I knew that the next step was to match the amp with a transformer and I tried a quicky without properly wrapping the core and managed to cut into the insulation shorting it out. On a lark I decided to try some 115v-40V toroid power transformers I had and OOFTA!!..they sounded suprisingly good. The exaggerated top end dissapeared and the midrange became, for lack of a better word, lush. I dicovered in short order that 75 Hz was to low of a cut off point and stretched the ribbon. I then turned back to winding a proper tranformer. Here is one of the cores. I purchased a pair of surplus power transformers a while back to get the cores for this purpose. They are rated at 30VA...

This time I carefully covered the cores in layeres of heavy paper...

Since I didn't want the tranformers cutting off the low end while I determine my crossover point I made them full range with around 160 mH primary inductance. This required 160 turns on the primary. I drafted a turns template in CAD and glued it on...

I wanted to keep the capacitance of the windings a low as possible so I went around in groups of 16 ten times. Here is the first group of turns...

Half way done...

And some time later, one completed primary...

I then wrapped it in Teflon tape and glued the secondary template on. I decided on 4 seperat windings of nine turns so that I could match different foils of of different thicknesses, as well as give me different loads to the amp by using different series/parallel combinations...

After the secondaries were turned...

..I soldered on leads to the primary and wrapped the assembly heavily in heavy duty Teflon tape used in gas fittings. One completed transgformer...

Currently I have the first 12 dB/octave section of the crossover set to 75 Hz, and the second section set to 125 Hz. This allows me to play at a reasonable volume and still hear enough of the bass to enjoy them until I get a bass unit hooked up.

I still have a couple of things to work out, but the bottom line is that they are a success, and I now have the best speakers I have ever owned..with the potential of being truly world class.

I'm probably forgetting something..it's getting late and I'm still trying to catch up on my sleep...so ask any questions you may have and I'll get back with an answer.

Casey

been following this thread for a while now and i must say, well done awsome job. u must be really happy to have them finished.

Hi Casey,

Thank you for all of the great information that you have provided.

I'm fairly new to speaker building but have done a lot of high frequency power transformer design.

A couple things to consider. The total wire area of the primary and secondary should be about the same. If your turns ratio is 5:1 then the wire on the secondary would have 5 times the area as the primary. A simple way to do this is to use all the same wire and parallel the secondary windings.

Your secondary looks a bit light. You could parallel a few more windings to reduce the losses on the output.

What is the core area and saturation flux density of the material you are using? I wouldn't worry as much about primary inductance as I would about the linearity of the core. A low primary inductance puts more load on the amplifier but in an audio transformer, if you design to stay away from saturation, you won't have problems with low inductance.

The teflon is fine but keep in mind that a ribbon tweeter is low voltage and high current so the insulation on the wire is more than adequate. The more tightly coupled the primary and secondary are, the lower the leakage inductance will be. What you have should be fine.

You might consider filling the window a bit more to lower the wire and/or core loss. A low leakage method is to wind one layer of primary, then two layers of secondary and then a second layer of primary. Then hook the two primary layers in series. This minimizes skin and proximity effect in the wire as well as the leakage inductance.

Thank you for all of the great information that you have provided.

I'm fairly new to speaker building but have done a lot of high frequency power transformer design.

A couple things to consider. The total wire area of the primary and secondary should be about the same. If your turns ratio is 5:1 then the wire on the secondary would have 5 times the area as the primary. A simple way to do this is to use all the same wire and parallel the secondary windings.

Your secondary looks a bit light. You could parallel a few more windings to reduce the losses on the output.

What is the core area and saturation flux density of the material you are using? I wouldn't worry as much about primary inductance as I would about the linearity of the core. A low primary inductance puts more load on the amplifier but in an audio transformer, if you design to stay away from saturation, you won't have problems with low inductance.

The teflon is fine but keep in mind that a ribbon tweeter is low voltage and high current so the insulation on the wire is more than adequate. The more tightly coupled the primary and secondary are, the lower the leakage inductance will be. What you have should be fine.

You might consider filling the window a bit more to lower the wire and/or core loss. A low leakage method is to wind one layer of primary, then two layers of secondary and then a second layer of primary. Then hook the two primary layers in series. This minimizes skin and proximity effect in the wire as well as the leakage inductance.

Casey, I do not envy you in the least when it came to pulling all that wire through that donut core. Not fun.

After purchasing the neodymium magnets --- and finally realizing there strength-- do you think that much magnetic flux was necessary for this application. I only ask because they are not cheap.

It seems that a rather low output amp like some of NP first watt items would very easily power this beast, any comments on required power.

Now get one of Glenn Miller's old recordings and sit back and listen to the horns. That should be right in the sweet spot. Thanks much for all of this. Tad

ps. what is next up to build?

After purchasing the neodymium magnets --- and finally realizing there strength-- do you think that much magnetic flux was necessary for this application. I only ask because they are not cheap.

It seems that a rather low output amp like some of NP first watt items would very easily power this beast, any comments on required power.

Now get one of Glenn Miller's old recordings and sit back and listen to the horns. That should be right in the sweet spot. Thanks much for all of this. Tad

ps. what is next up to build?

dark_avenger-

Thank you..I am very happy with my results so far, but I am far from done yet. I still need to optimize the foil ribbon, build my baffles, integrate a woofer (the TL part of the thread), and determine my final crossover point.

DamageG-

Yep..you are correct sir with all your pointers. These transformers qualify as "good enough" for their intended application...testing. My material choices (wire size) was determined by what I could find locally. I plan on a double-C amorphous core implementing all the techniques you mentioned for the final design.

tryonziess-

The stronger the field, the more linear the field, the lower the distortion...you need to decide for yourself how far you want to take it. Remember, the Apogee's used the lowly ceramic magnets.

I figure that I'll be working (and posting) on this project for some months to come yet . My "it's a success" comment had a finality to it that I didn't intend. While playing with different foils/tension I discovered a range of subtle voice changes. A lot of experimenting is yet to be done.

Casey

been following this thread for a while now and i must say, well done awsome job. u must be really happy to have them finished.

Thank you..I am very happy with my results so far, but I am far from done yet. I still need to optimize the foil ribbon, build my baffles, integrate a woofer (the TL part of the thread), and determine my final crossover point.

DamageG-

Yep..you are correct sir with all your pointers. These transformers qualify as "good enough" for their intended application...testing. My material choices (wire size) was determined by what I could find locally. I plan on a double-C amorphous core implementing all the techniques you mentioned for the final design.

tryonziess-

After purchasing the neodymium magnets --- and finally realizing there strength-- do you think that much magnetic flux was necessary for this application. I only ask because they are not cheap.

The stronger the field, the more linear the field, the lower the distortion...you need to decide for yourself how far you want to take it. Remember, the Apogee's used the lowly ceramic magnets.

ps. what is next up to build?

I figure that I'll be working (and posting) on this project for some months to come yet . My "it's a success" comment had a finality to it that I didn't intend. While playing with different foils/tension I discovered a range of subtle voice changes. A lot of experimenting is yet to be done.

Casey

Wow.

That's about all I can say. Just Wow.😀

Looking excellent - it will be interesting to see how the TL build goes, too.

Did you eat?

James

That's about all I can say. Just Wow.😀

Looking excellent - it will be interesting to see how the TL build goes, too.

Did you eat?

James

Why do you not go retail with these. Should easily fetch 25,000 dollars per pair. Really. There is nothing out there to compare to this. All you audiophiles beware DIY is here to stay.

wow really says it all. Tad

wow really says it all. Tad

jrevillug & chinsettawong-

Thanx for the "wow's" 😉. Inspiring envy is almost as enjoyable as listening to them (ya..I'm shallow)

tryonziess-

3 sources:

1) cheapo "dollar store" wrapping foil..around 12 micron.

2) harvestng capacitors...5-7 micron.

3) the generosity of member fperra who has shared some of his stash with me.

Oh, and no jrevillug, I haven't eaten on schedule for weeks now..blurring vision is usually my first clue that I better find a soup bowl 😀

Casey

Thanx for the "wow's" 😉. Inspiring envy is almost as enjoyable as listening to them (ya..I'm shallow)

tryonziess-

Casey, Where did you get the foil for the ribbons?

3 sources:

1) cheapo "dollar store" wrapping foil..around 12 micron.

2) harvestng capacitors...5-7 micron.

3) the generosity of member fperra who has shared some of his stash with me.

Oh, and no jrevillug, I haven't eaten on schedule for weeks now..blurring vision is usually my first clue that I better find a soup bowl 😀

Casey

Casey, Have you experimented with the pleating, ie, depth, pitch, etc. to see if there is any noticeable change.

You must know by now that you are the test bed for this type of thing. Therefore many, many questions. I do not know of any other setup -- anywhere -- like this one.

Do you think they will run on less than 30 watts? Tad

You must know by now that you are the test bed for this type of thing. Therefore many, many questions. I do not know of any other setup -- anywhere -- like this one.

Do you think they will run on less than 30 watts? Tad

Casey, Have you experimented with the pleating, ie, depth, pitch, etc. to see if there is any noticeable change.

Not yet. I believe that there is a lot of room for experimentation here though.

I do not know of any other setup -- anywhere -- like this one.

Well ya, mine are unique, but mostly just in scale and attention to detail. There have been many, many similiar ribbons built. Search the web and this forum for examples.

Do you think they will run on less than 30 watts?

Yes..much less. With the thinner foil I was able to go to a dangerous ear numbing volume playing Stevie Ray Vaughn with about 15 watts. It was so clean that I didn't realize how loud it was until I turned it down and felt the ear numbness..gotta be careful.

Casey

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- A 60" Ribbon w/TL Loaded Extremis Hybrid