Diogenes-

Indeed 🙂

GeeVee-

Wow, thank you George

Made several steps forward, and one step back this weekend. First up was the cutting table for the foil. I bartered some labor with my brother and he spanked one together for me...

... and I machined a couple of guide pin blocks for the straight edge...

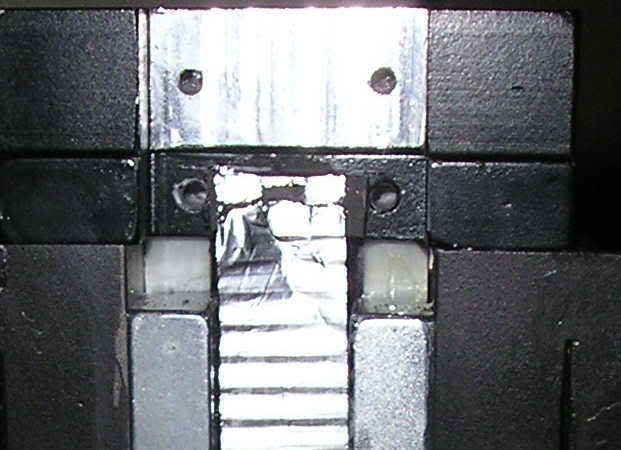

Next I went to work on a crimper to corrugate the foil. After playing around a bit I realized that if I wanted the corrugations to be square with the edge of the foil I needed to come up with something other than relying on my eye-hand coordination to feed the foil straight. I was up till 2 AM working on my gizmo, but it was worth it....

It works perfect...

I later discovered it works best pulling the foil through rather than rolling the top gear. It corrugates and stretches it out at the same time making for a truly straight ribbon.

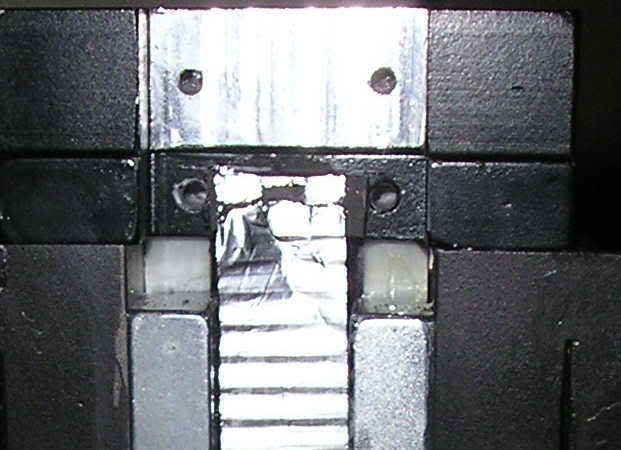

So, I get the ribbons strung up and happily went to work wiring up resistors so that my amp could drive them at low power for their maiden voyage. This is were my balloon deflated. I wasn't getting continuity through the ribbon...hmmm. It turns out that the Sorbothane on the insulator blocks was the culprit...

As the rubber was compressed its width expanded tearing the foil...on both ends of both ribbons. Oh well, live and learn. I have a couple ideas I'm kicking around to address this but I'm going to think on it a bit.

I'm getting really close now 😀

Casey

There's just something awesome about a pair of speakers that instill a bit of fear of severe injury.

Indeed 🙂

GeeVee-

I have following this thread ever since you took delivery of your "back beaking pile of steel & big ol' pile of scary magnets" .... I wish you all the very best success with this project, and I am sure that you will be richly rewarded.

Wow, thank you George

Made several steps forward, and one step back this weekend. First up was the cutting table for the foil. I bartered some labor with my brother and he spanked one together for me...

... and I machined a couple of guide pin blocks for the straight edge...

Next I went to work on a crimper to corrugate the foil. After playing around a bit I realized that if I wanted the corrugations to be square with the edge of the foil I needed to come up with something other than relying on my eye-hand coordination to feed the foil straight. I was up till 2 AM working on my gizmo, but it was worth it....

It works perfect...

I later discovered it works best pulling the foil through rather than rolling the top gear. It corrugates and stretches it out at the same time making for a truly straight ribbon.

So, I get the ribbons strung up and happily went to work wiring up resistors so that my amp could drive them at low power for their maiden voyage. This is were my balloon deflated. I wasn't getting continuity through the ribbon...hmmm. It turns out that the Sorbothane on the insulator blocks was the culprit...

As the rubber was compressed its width expanded tearing the foil...on both ends of both ribbons. Oh well, live and learn. I have a couple ideas I'm kicking around to address this but I'm going to think on it a bit.

I'm getting really close now 😀

Casey

Casey, This is like some suspense novel. All we need now is a major earthquake or flood. Self control is needed. Too close for hurried repairs.

I like your little corrugator gizmo. More corian or just spare plastic? Why is the foil a brown color? How about the gears. Tad

I like your little corrugator gizmo. More corian or just spare plastic? Why is the foil a brown color? How about the gears. Tad

kuroguy-

As the geometry stands...yes. I set it up so that each piece of rubber needs .025" of crush(.05" total) in order to place the ribbon in the center of the gap and to bring the clamp flush with the mounting block (for bezel clearance). I have to replace the current rubber with something else.

tryonziess-

Tell me about it. I currently have 2 nearly completed ribbons sitting in my living room...I can guarantee you nobody wants these babies to sing more than I. I have to force my calm and take it slow.

Yep Corian, I love the stuff.

Only in the picture. must be a reflection.

I had a hard time finding a plastic gear wide enough and ended up buying four compound gears. The wider gear was a 1/2" so I cut off the smaller gear and glued two gears together to make a 1" wide gear.

Casey

Do those blocks really need to be that tight? Don't clamp it down so hard.

As the geometry stands...yes. I set it up so that each piece of rubber needs .025" of crush(.05" total) in order to place the ribbon in the center of the gap and to bring the clamp flush with the mounting block (for bezel clearance). I have to replace the current rubber with something else.

tryonziess-

Casey, This is like some suspense novel. All we need now is a major earthquake or flood. Self control is needed. Too close for hurried repairs.

Tell me about it. I currently have 2 nearly completed ribbons sitting in my living room...I can guarantee you nobody wants these babies to sing more than I. I have to force my calm and take it slow.

More corian or just spare plastic?

Yep Corian, I love the stuff.

Why is the foil a brown color?

Only in the picture. must be a reflection.

How about the gears.

I had a hard time finding a plastic gear wide enough and ended up buying four compound gears. The wider gear was a 1/2" so I cut off the smaller gear and glued two gears together to make a 1" wide gear.

Casey

Casey, The sorbathane might be a little bit soft. Try something like neoprene or silicone hose. The nylon fibers should help maintain shape during compression preventing the edge from curling in. You could cut some strips and give it a try. Maybe even latex rubber. Tad

Try something like neoprene or silicone hose.

Automotive vacuum line...BINGO! Here I was conjuring some elaborate scheme and you drop a "Duh" bomb on me 😀 . Thanx Tad.

Casey

Casey, If you were in Washington DC instead of the State of Washington I could probably here them down here when you crank them up. Maybe if I get up in a tall building. Keep it up Tad

Excellent stuff.

Don't forget to report back when they are working - and don't forget to eat because you are spending all your time listening either...😀

James

Don't forget to report back when they are working - and don't forget to eat because you are spending all your time listening either...😀

James

jrevillug-

Based on how many times I forgot to eat while working on them, that is a legitimate concern 😉

tryonziess-

I do understand 😀

illnastyimpreza-

I can't speak in absolute terms since I haven't got them online yet..but..the only real question is how low I can get away crossing them over to the sub.With as much surface area as a 10" driver, and as intense as the gap flux is I should get around .25" of linear excursion, I'm thinking (baffle size considerations aside) I should be able to get away with 150hz-300hz (ideally 150hz) with a 4th order crossover. I'll know soon enough

Casey

...and don't forget to eat because you are spending all your time listening either..

Based on how many times I forgot to eat while working on them, that is a legitimate concern 😉

tryonziess-

I want a pair of these.

I do understand 😀

illnastyimpreza-

...do they really have the responce that normal speakers do though ??

I can't speak in absolute terms since I haven't got them online yet..but..the only real question is how low I can get away crossing them over to the sub.With as much surface area as a 10" driver, and as intense as the gap flux is I should get around .25" of linear excursion, I'm thinking (baffle size considerations aside) I should be able to get away with 150hz-300hz (ideally 150hz) with a 4th order crossover. I'll know soon enough

Casey

valveitude said:With as much surface area as a 10" driver, and as intense as the gap flux is I should get around .25" of linear excursion, I'm thinking (baffle size considerations aside) I should be able to get away with 150hz-300hz (ideally 150hz) with a 4th order crossover. I'll know soon enough

Casey [/B]

If I didn't want one before, I do now.

Regards,

David

If you look closely at the magnetic gap where the floor trim is, you can see that these things are so powerful that space-time is distorted, causing the trim to length contract and making the trim look shorter than on the outsides.

Ok maybe not, but really there is some kind of optical illusion there.

Ok maybe not, but really there is some kind of optical illusion there.

gtforme00-

No illusion my friend..I walked in to the living room this morning just in time to watch a worm hole formed between the two ribbons collapse. I'm running an inventory now to see what got sucked in

Ok maybe not, but really there is some kind of optical illusion there.

No illusion my friend..I walked in to the living room this morning just in time to watch a worm hole formed between the two ribbons collapse. I'm running an inventory now to see what got sucked in

Casey, Would not the effective ribbon excursion be close to the 25mm width of the magnet face. It will still be in the magnetic field. I know this is quite a large distance, but is it not within parameters?

On another note. How hard would it be to implement a bass version of this design. Roughly 2 feet high with a ribbon approaching 3 inches in width. Hold on --- I know that is kind of wide. So what amount of flux would it take? Maybe electromagnet. Just filling in here while you play with the vacuum hose and resistors. Tad

On another note. How hard would it be to implement a bass version of this design. Roughly 2 feet high with a ribbon approaching 3 inches in width. Hold on --- I know that is kind of wide. So what amount of flux would it take? Maybe electromagnet. Just filling in here while you play with the vacuum hose and resistors. Tad

tryonziess-

As you travel out from the center of the gap to the edge, the flux lines get progressively more curved and further apart creating a non-linear field. As the ribbon travels into this region the distortion level increases the further it goes. Based on FEMM, and my experience with other ribbons, I believe that I should be able to go +/- .125" (.25" p-p) with very little distortion easily.

The magnets/steel would be HUGE!!

Afraid the vacuum line is a bust. Bought a piece of the smallest I could find and no-go. On to plans "B" thru "D" 🙂

Casey

Casey, Would not the effective ribbon excursion be close to the 25mm width of the magnet face. It will still be in the magnetic field. I know this is quite a large distance, but is it not within parameters?

As you travel out from the center of the gap to the edge, the flux lines get progressively more curved and further apart creating a non-linear field. As the ribbon travels into this region the distortion level increases the further it goes. Based on FEMM, and my experience with other ribbons, I believe that I should be able to go +/- .125" (.25" p-p) with very little distortion easily.

On another note. How hard would it be to implement a bass version of this design. Roughly 2 feet high with a ribbon approaching 3 inches in width. Hold on --- I know that is kind of wide. So what amount of flux would it take? Maybe electromagnet.

The magnets/steel would be HUGE!!

Just filling in here while you play with the vacuum hose and resistors.

Afraid the vacuum line is a bust. Bought a piece of the smallest I could find and no-go. On to plans "B" thru "D" 🙂

Casey

Just speaking out of turn here, it could be possible if done in a fashion closer to what's described in patent #US5212735. Or maybe done as a panel of multiple ribbons such as with US20070263894? With bass frequencies, I would suspect that a pure foil ribbon element would be shredded in short order, but as reproduction at higher frequencies isn't part of the design, perhaps a quasi-ribbon element using a Teonex or Kapton backing would work fine.tryonziess said:On another note. How hard would it be to implement a bass version of this design. Roughly 2 feet high with a ribbon approaching 3 inches in width. Hold on --- I know that is kind of wide. So what amount of flux would it take? Maybe electromagnet. Just filling in here while you play with the vacuum hose and resistors. Tad [/B]

Question is, how low could it go with reasonable reproduction and where does the trade-off point occur where a simple monopole would perform better with much less effort and expense?

- JP

Casey, They make O rings awful small. Maybe they could be used. They also come in a gazillion materials and hardness. Tad

What about silicone impregnated fiberglass like the kind that is used in transistor insulators? It should maintain dimension fairly well, and it is designed to insulate. You may have to add shims to make up the thickness difference. If you PM me your mailing address, I'll send you an envelope full of some for you to try.

Regards,

David

Regards,

David

Casey, They make O rings awful small. Maybe they could be used

What about silicone impregnated fiberglass like the kind that is used in transistor insulators?

I believe I have my solution. This morning while on break at work, a friend that runs a print shop adjacent to my work saw me pacing and figured I was thinking about my problem (he has been following the thread) and suggested I try "printng blanket". This is the material that is wrapped around a print drum with a semi-hard plastic surface and a cloth like backing. Turns out that a piece of this (he gave me some end cuts) with a piece of double sided foam tape stuck on the back is exactly 1/8" thick (the dimension of my Sorbothane) with just the right amount of give (provided by the foam tape) to crush to .1". It should work great.

I don't know if I'll get back to the ribbons 'till this weekend or not. I have a 4 day weekend and I'm trying to get some stuff cleared off the deck so I can marathon some ribbon work 😀

Oh, and thank you for the offer David. If this doesn't pan out I'll take you up on it.

Casey

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- A 60" Ribbon w/TL Loaded Extremis Hybrid