Not yet. The tests were the first power I had going through it.

Btw this driver is well broken in. I have a new one on order to build a second cabinet. I will test that as well with the brand new driver abs see if its any different.

I am also in the process of building active tops for these cabinets. Can't wait!!

Btw this driver is well broken in. I have a new one on order to build a second cabinet. I will test that as well with the brand new driver abs see if its any different.

I am also in the process of building active tops for these cabinets. Can't wait!!

I will post all the necessary dimms, and tb46 can make one of his nice CAD files to use as plans for this design for those who are interested in building some of these 🙂

I will post all the necessary dimms, and tb46 can make one of his nice CAD files to use as plans for this design for those who are interested in building some of these

Thanks- You sir, are a scholar and a gentleman.

Damnit, see what you made me do. I just bought some Lab12 drivers on ebay tonight for a build (decided to use my 3012LF from my BFM Titan39 in an Econowave deluxe build anyways)

LoL good that's the point of sharing designs!

I'll get you the rest of the dimms you need soon.

I'll get you the rest of the dimms you need soon.

Here is the updated sketch / layout....

A. 29 1/8" x 13.5"

B. 30" x 13.5"

C. 24 1/2" x 13.5" (subject to change with the keystone / different mouth size)

D. 21 7/8" x 13.5"

E. 13" x 13.5"

F. 28" x 13.5"

G. 23 7/8" x 13.5"

H. 9" x 13.5"

I. 16 3/4" x 13.5"

J/k. (Side Panels) 30" x 38"

Those dimms are all accurate, that's what I went by.

Board G is connected to board D at a right angle.

I H and F are all connected at right angles as well.

Board E (for caster mounting) is at a 45 deg angle with boards A and D.

All miter cuts on those boards, E, A and D are 45deg.

The distance between boards G and F at the base is 5cm. (S1)

S2 is 6.2cm.

Driver height is centered at 21cm from s1

Basically I need to give you the positioning of boards G and F relative to the front or rear of the cabinet.

Hi mRgSr,

I could give it a stab at drawing PAL12 in AutoCAD, but I would need the additional dimensions indicated in the attached picture, and I don't know when I'll be able to get to it. Would 23/32"[18.25mm] be OK for the material? Maybe epa or Xoc1 can take get to it faster than I can.

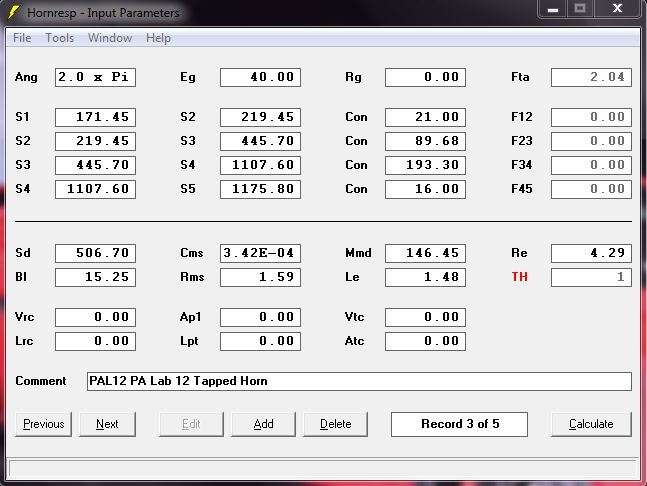

Also, where is the lastest greatest Hornresp input?

Regards,

I could give it a stab at drawing PAL12 in AutoCAD, but I would need the additional dimensions indicated in the attached picture, and I don't know when I'll be able to get to it. Would 23/32"[18.25mm] be OK for the material? Maybe epa or Xoc1 can take get to it faster than I can.

Also, where is the lastest greatest Hornresp input?

Regards,

Attachments

I'm pretty sure that's the material I used? I asked for 5x5 3/4" Baltic birch. Unless there are different thicknesses of Baltic in 3/4"?

I will get the dimms over the weekend.

No rush man, you'd be doing us all a favor by creating the drawing!

I will get the dimms over the weekend.

No rush man, you'd be doing us all a favor by creating the drawing!

Hi mRgSr,

It's a nice build, and I don't mind drawing it. If I were into PA work, I wouldn't mind building it. 🙂

Regards,

It's a nice build, and I don't mind drawing it. If I were into PA work, I wouldn't mind building it. 🙂

Regards,

at your service 🙂

materail thickness is always diffecult.

for the double 15 whe used birch 13 ply wich was 17.9 mm.😕

a few monts ago whe used birch 13 ply wich was 18.25 mm😱

i think its best to do 18mm .

ill do it this weekend.

first some more testing on the double 15 tomorrow 🙂

materail thickness is always diffecult.

for the double 15 whe used birch 13 ply wich was 17.9 mm.😕

a few monts ago whe used birch 13 ply wich was 18.25 mm😱

i think its best to do 18mm .

ill do it this weekend.

first some more testing on the double 15 tomorrow 🙂

Hmm ill

Measure with my caliper when I get a chance to get over to the workshop. I'm curious now what thickness they gave me.

Measure with my caliper when I get a chance to get over to the workshop. I'm curious now what thickness they gave me.

Here is the input screen...

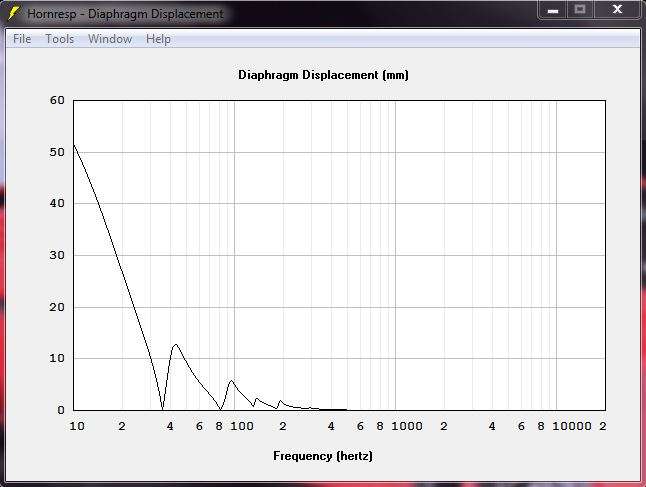

SPL at about 400 watts....i notice the large dip in the response. who knows if that will actually be there on the test cabinet; we will find out! (i know people say hornresp exaggerates the peaks and dips)

and it should be right around xmax at 400 watts or so

Hi,

I think that L34 should to be 32 and not 16 in your Hornresp simulation, distance from the back of the diver cone.

Seems I made a mistake. Could be the reason for the discrepancy between the sim and the measured results....

Okay so the wood measured from 18.2-18.42mm. I think it's safe to just assume 18mm ply. I wrote 18.4mm thickness in the drawing.

All the dims are written in black, just as the red lines are on the drawing in post 108.

The 33.8cm and the 40.7cm are measured along the top edge of panel D.

Just in case you can't read the numbers I wrote down, staring from above the angled caster board (E) the numbers are, going clockwise,

19cm

23.8cm

29cm

40.7cm

33.8cm

Wood thickness is 18.4mm. Lets assume 18mm.

All the dims are written in black, just as the red lines are on the drawing in post 108.

The 33.8cm and the 40.7cm are measured along the top edge of panel D.

Just in case you can't read the numbers I wrote down, staring from above the angled caster board (E) the numbers are, going clockwise,

19cm

23.8cm

29cm

40.7cm

33.8cm

Wood thickness is 18.4mm. Lets assume 18mm.

Last edited:

- Home

- Loudspeakers

- Subwoofers

- $325 Lab 12 based PA tapped horn ~ 35Hz extension