You guys are so lucky with your BB prices. Down here it nearly 200USD for 18mm 1200x2400 and about 130 for 12mm.

Ouch that's very high. Although my old supplier was like $81 plus tax.

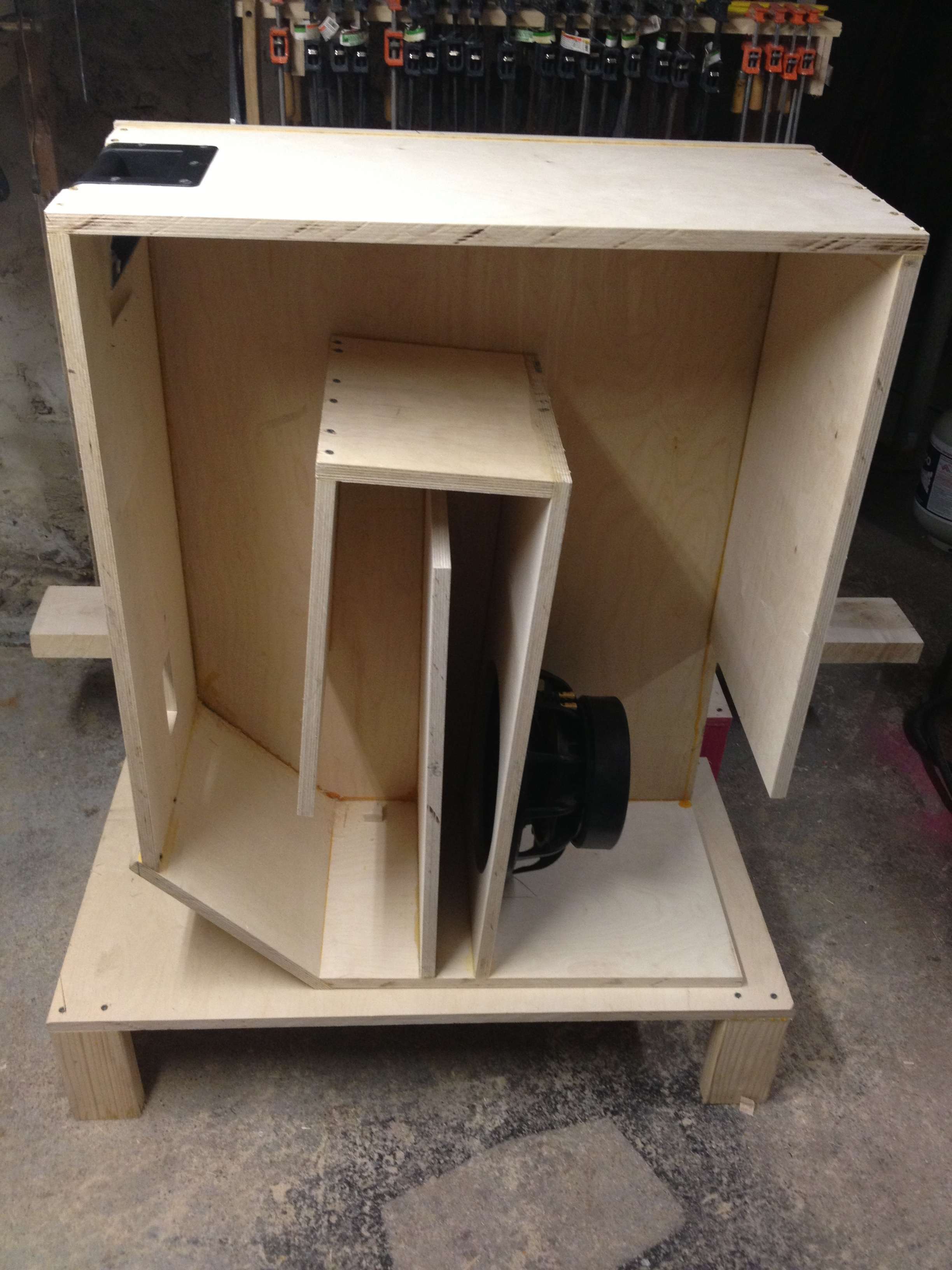

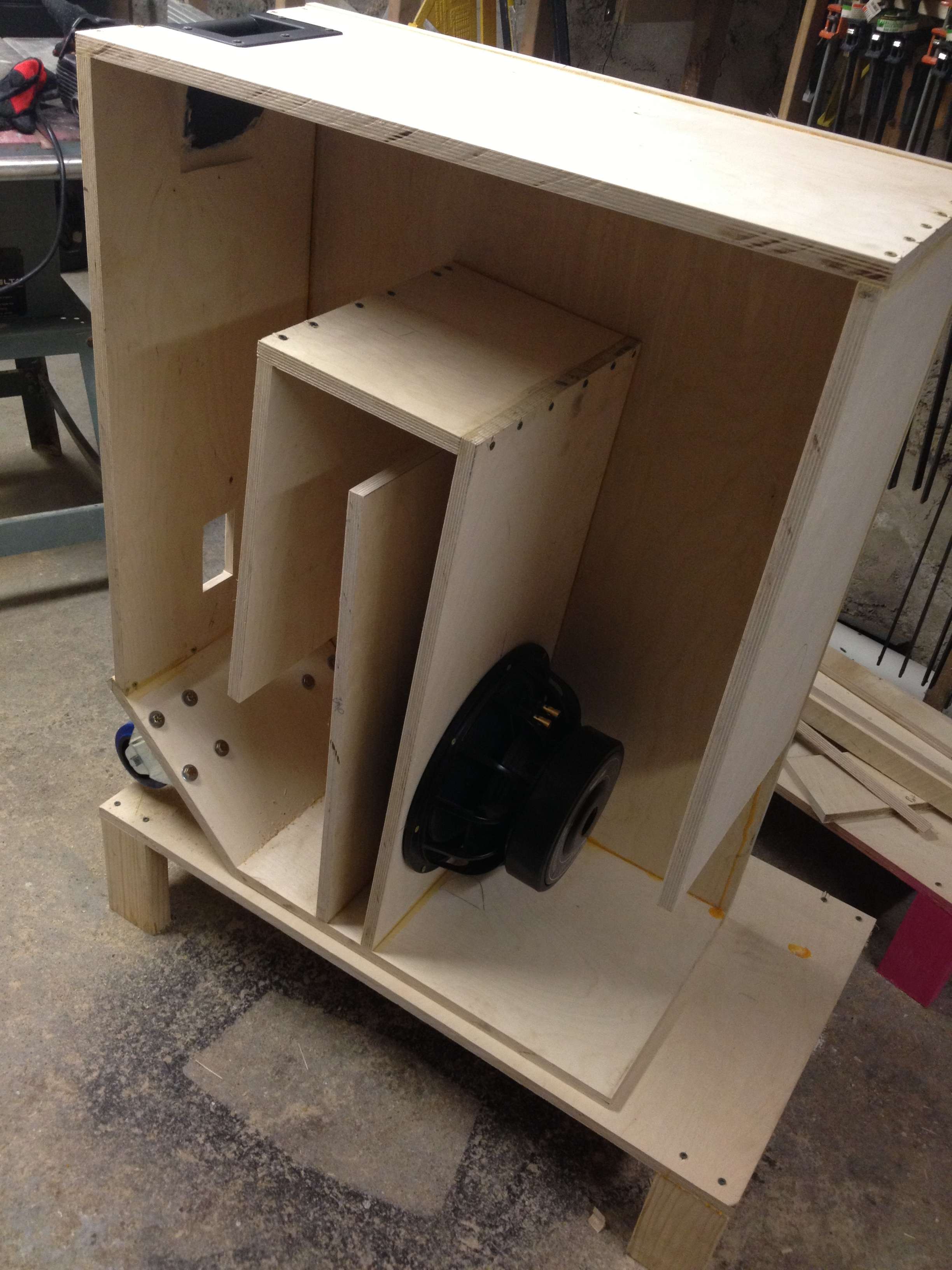

Got the thing almost complete!

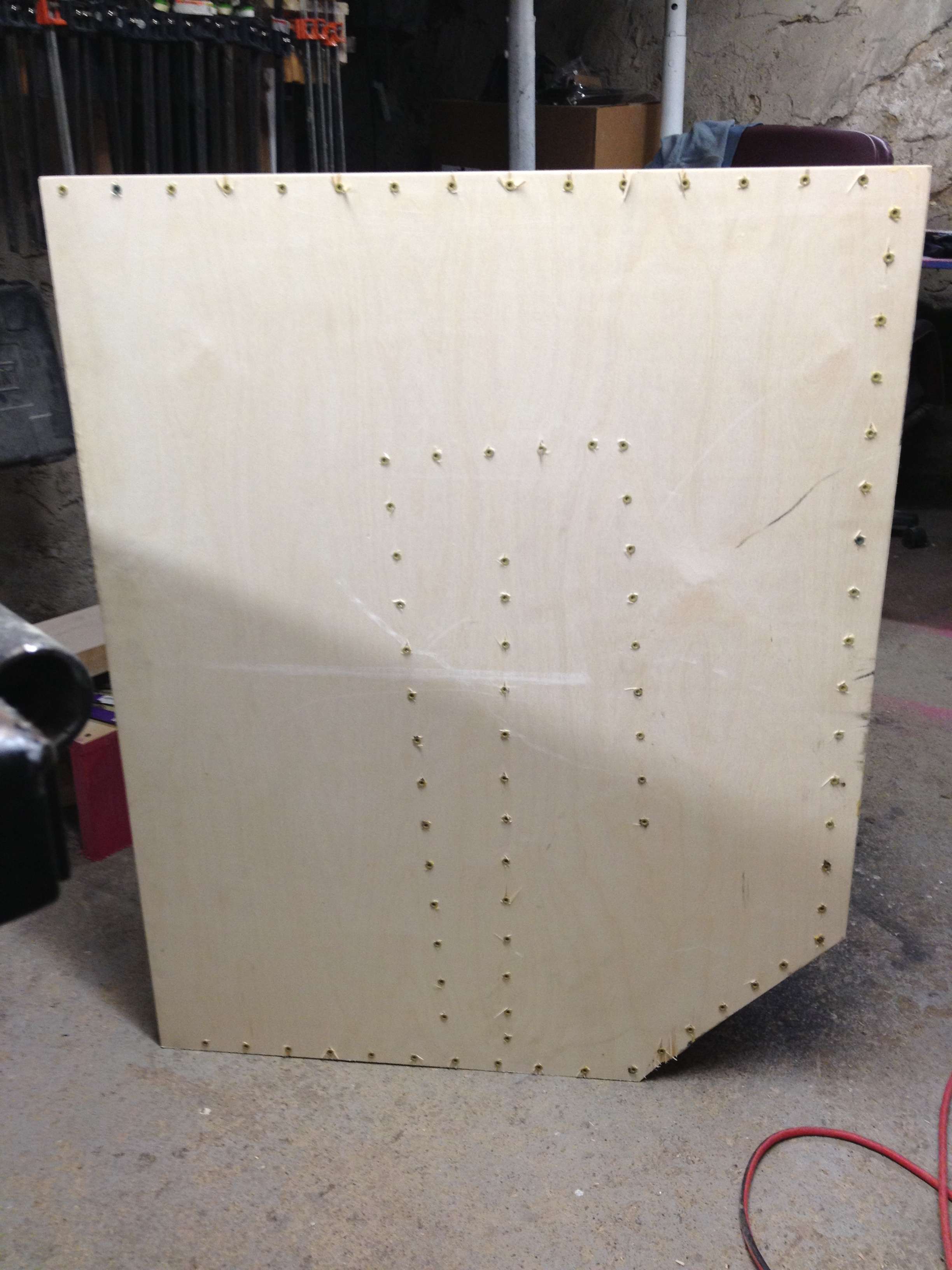

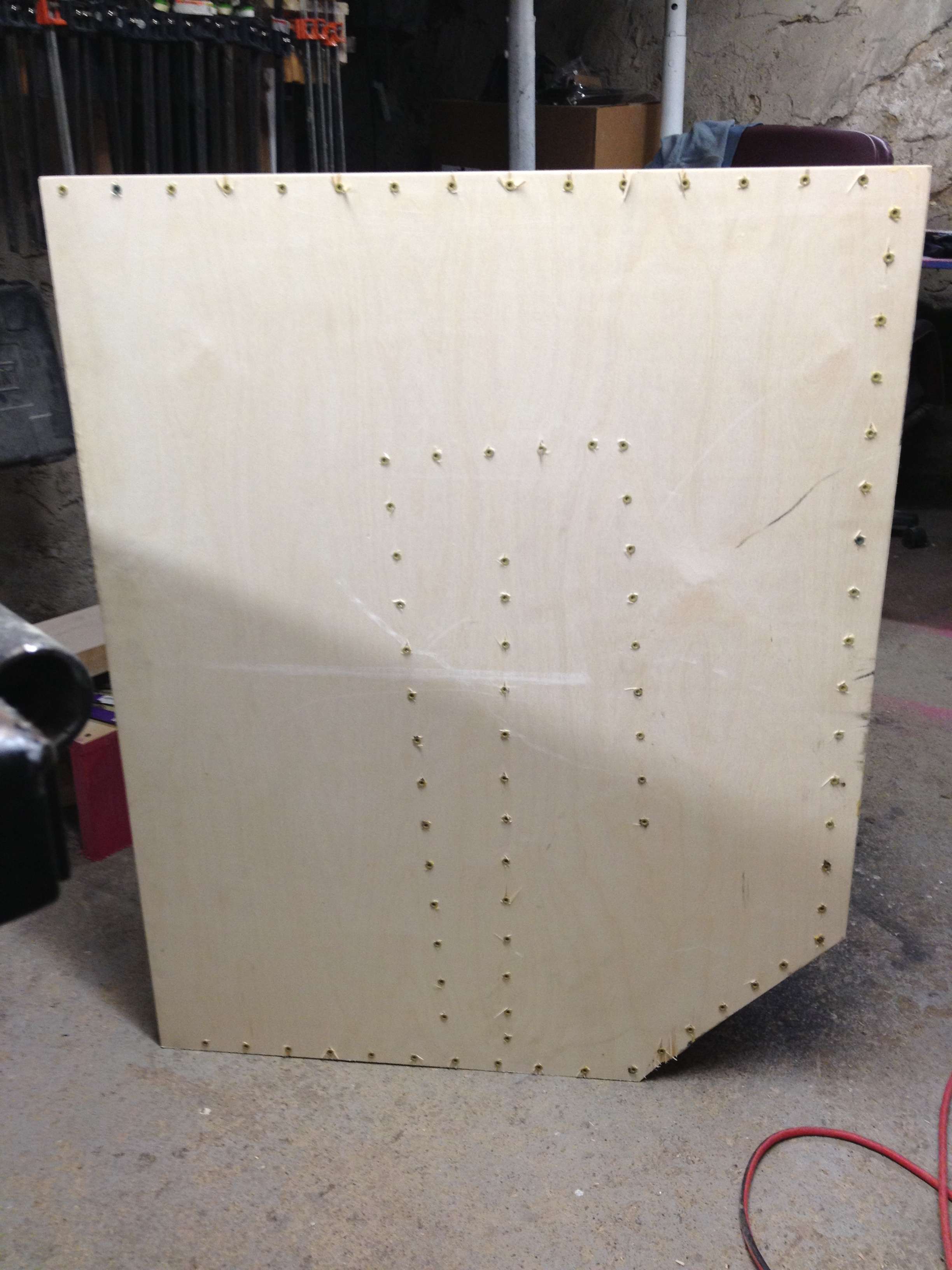

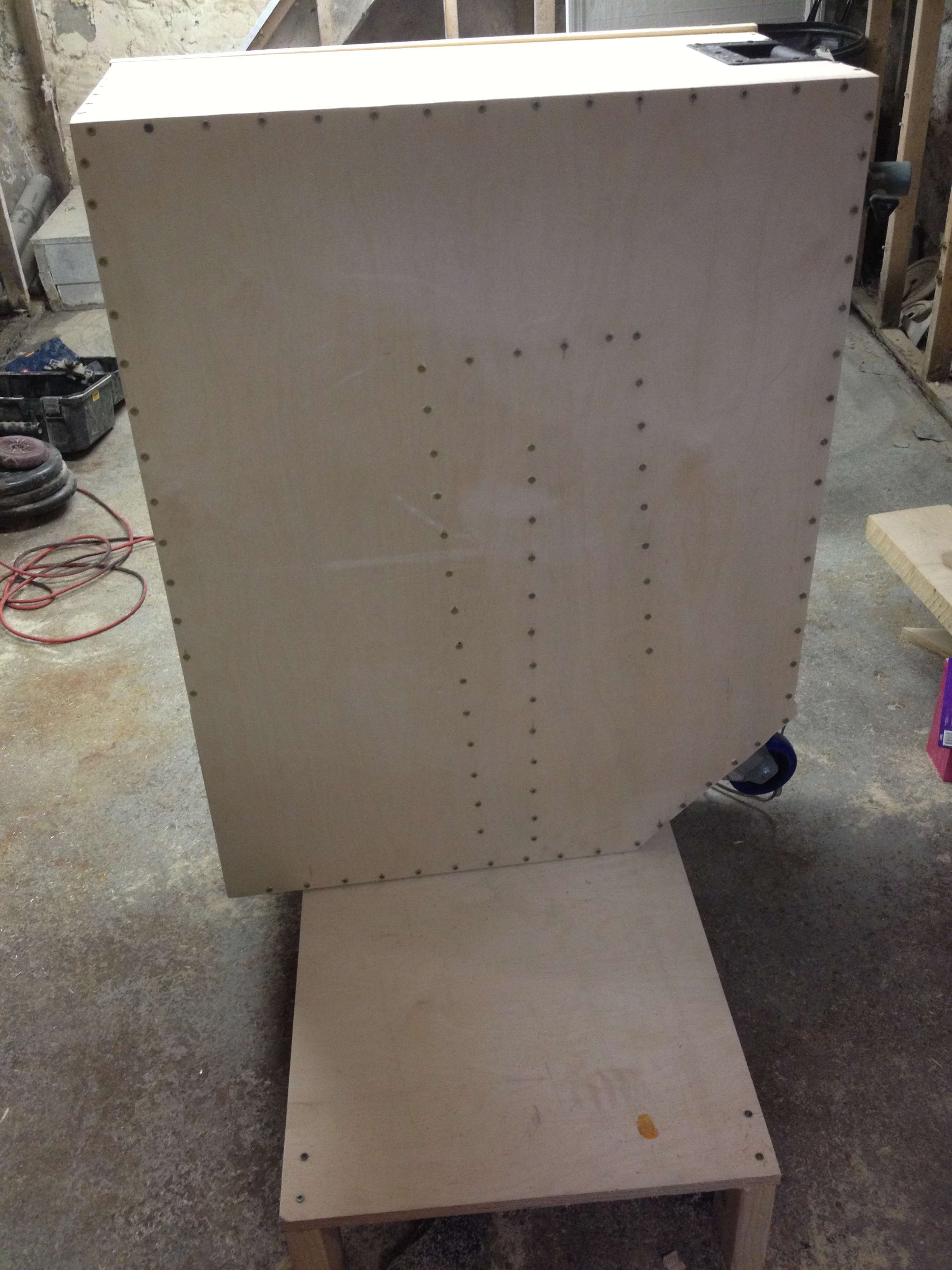

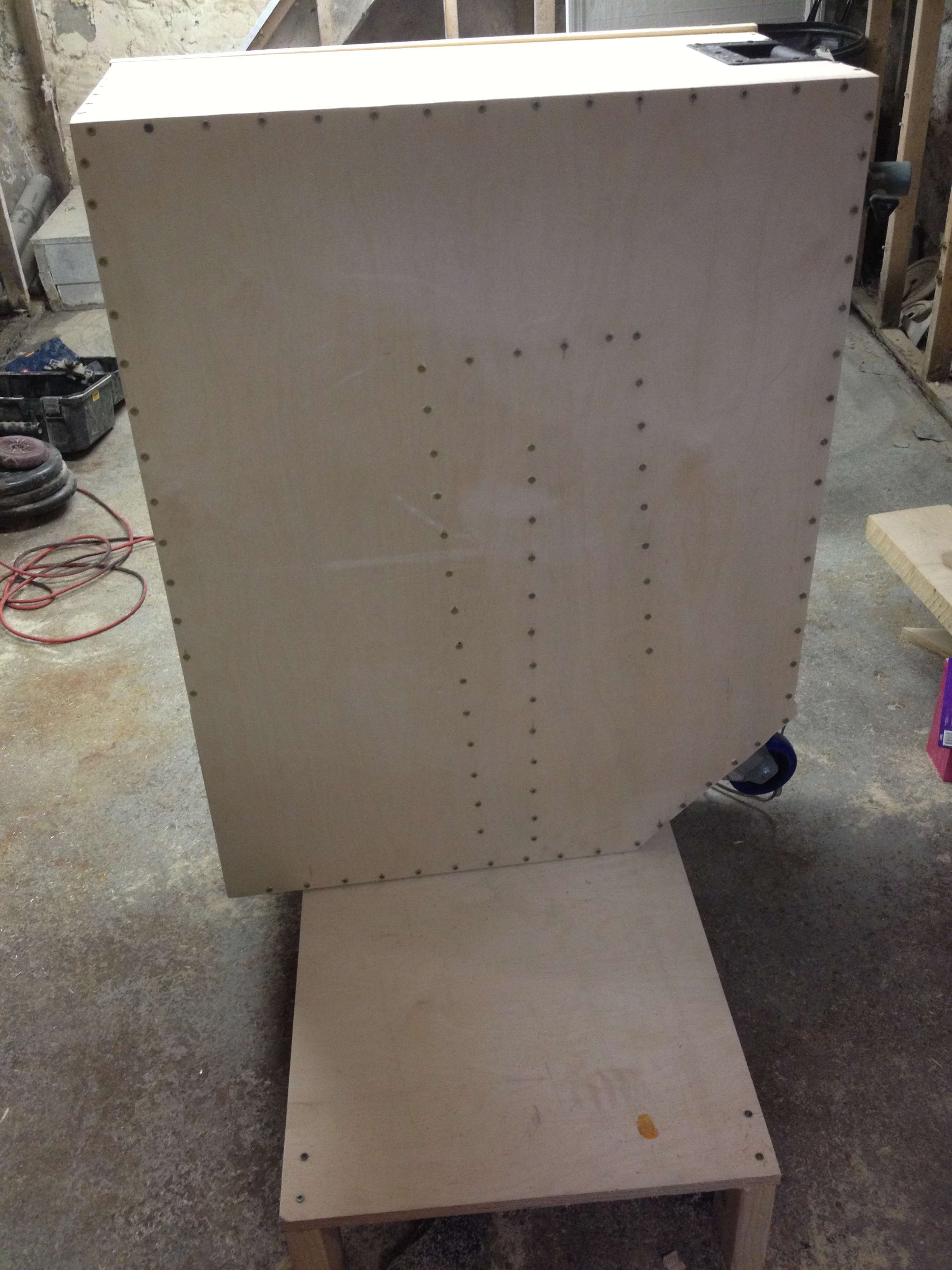

Lots o screws! I'll grind them down after its complete.

Glued and screwed the Dayton metal handle In. I'm only using one per cabinet, it'll be easy enough to maneuver with the casters.

Still have a lot of trimming to do, then round over and sanding. And need to get some grade 8 bolts and nuts / washers for the casters. Then let the testing begin!

Got the thing almost complete!

Lots o screws! I'll grind them down after its complete.

Glued and screwed the Dayton metal handle In. I'm only using one per cabinet, it'll be easy enough to maneuver with the casters.

Still have a lot of trimming to do, then round over and sanding. And need to get some grade 8 bolts and nuts / washers for the casters. Then let the testing begin!

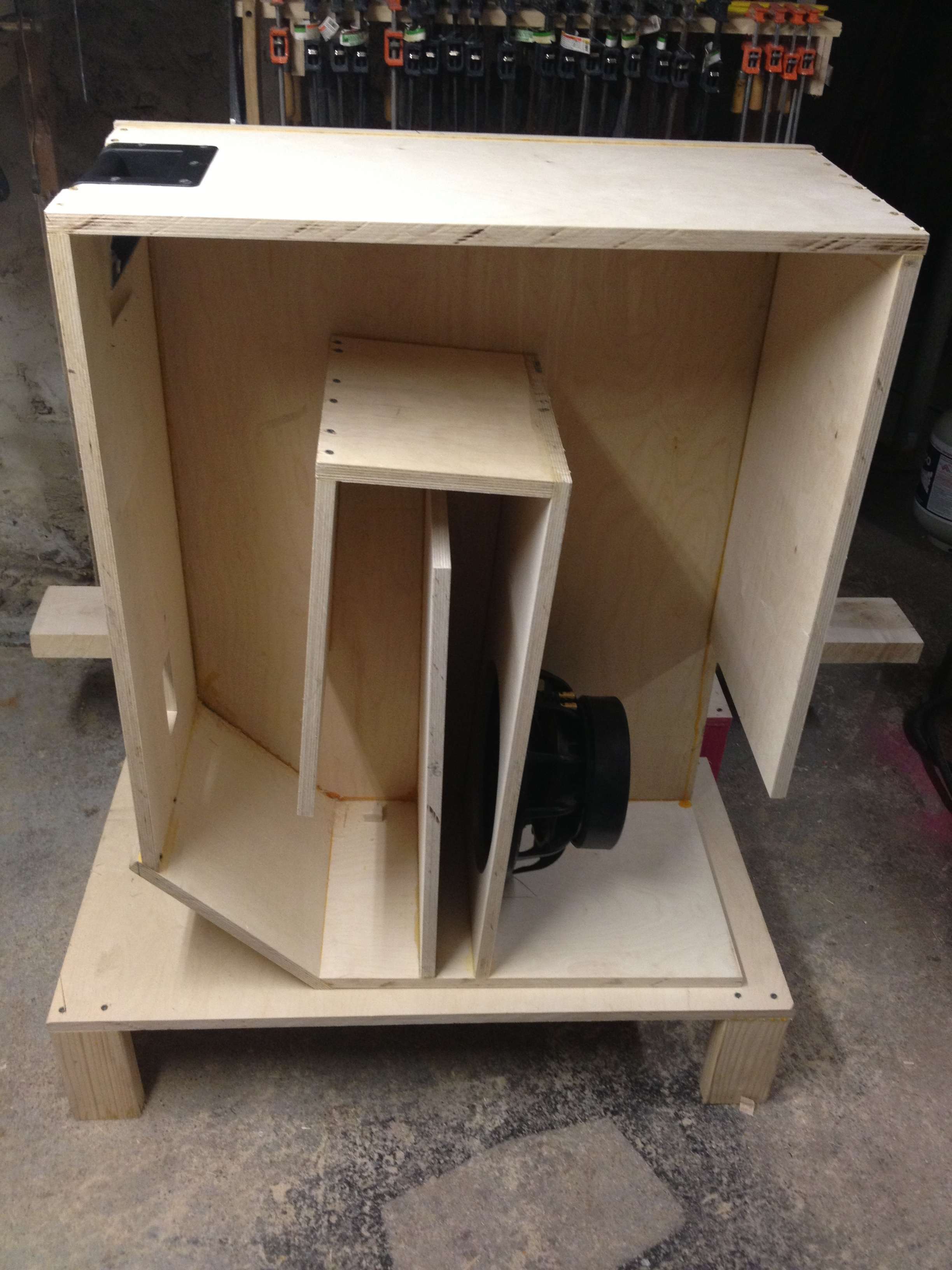

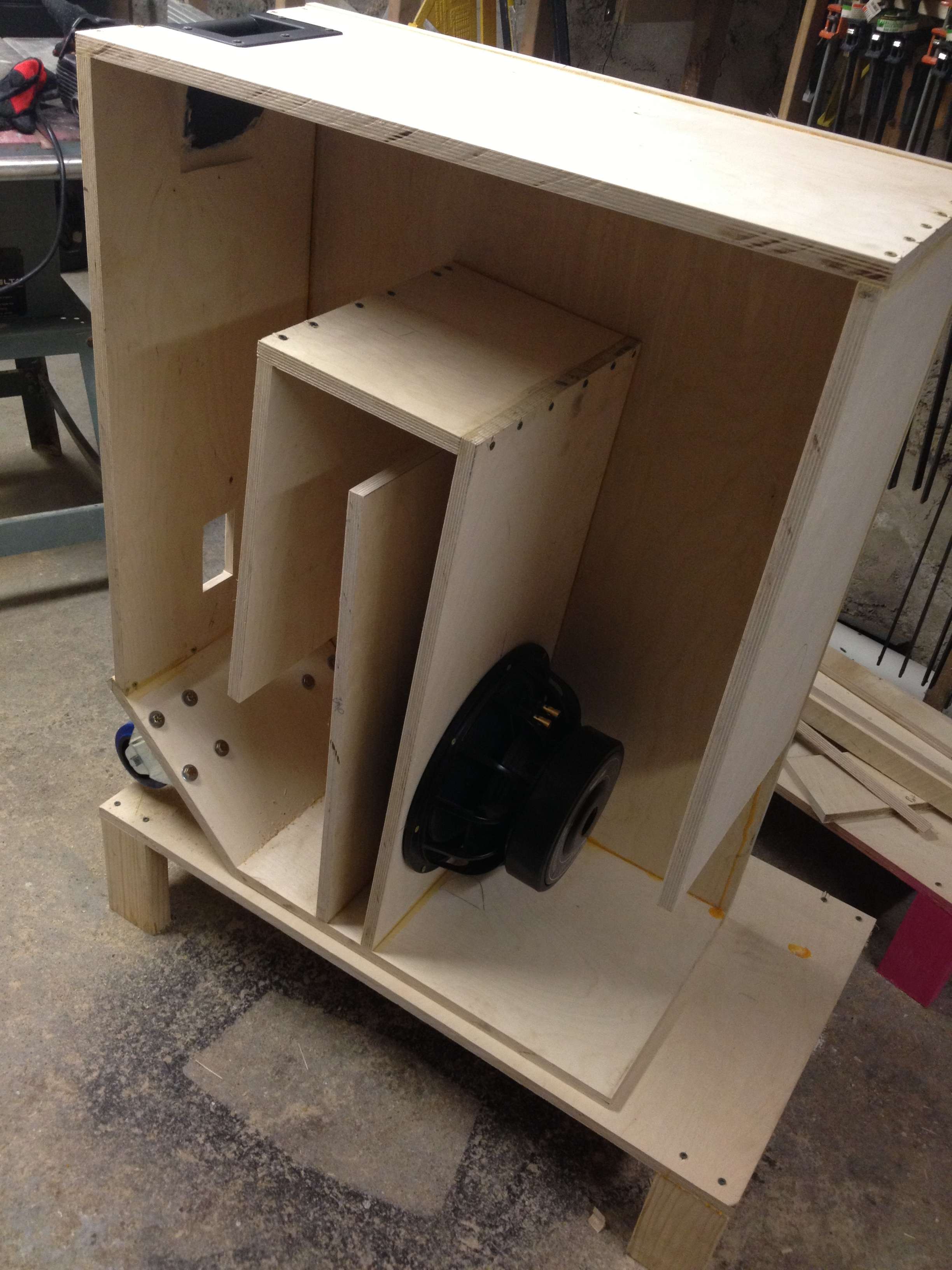

Spent an hour on it today. Almost ready to throw the side panel on!

Grade 8 hardware in the HD casters

Grade 8 hardware in the HD casters

Looks like you decided to not bother with experimentation with the mouth size and shape.Spent an hour on it today. Almost ready to throw the side panel on!

Hope it comes out like your sims!

For now I'm going to test as is.

But if I want I have a method for cutting this front panel leaving an inch and a half on each side, then gluing / bolting flat steel to the back of it. With welded on nuts and holes in the steel, I can then swap front panels and test that way.

I haven't turned down the idea of the keystone yet!

But if I want I have a method for cutting this front panel leaving an inch and a half on each side, then gluing / bolting flat steel to the back of it. With welded on nuts and holes in the steel, I can then swap front panels and test that way.

I haven't turned down the idea of the keystone yet!

^umm have you looked around in this forum? There's tons of Tapped Horns in here that walk all over BFM designs 😉

^umm have you looked around in this forum? There's tons of Tapped Horns in here that walk all over BFM designs 😉

I have just started looking recently. From what I have seen nothing really "walks" all over his designs comparing apples to apples, but they seem to offer flatter freq response and in some cases smaller pack size, but more expensive drivers and more power need to be used.

I'm not saying his designs are end all be all, hence why I am looking at trying some new designs, (I'm in no way a BFM activist that only listens to what is posted on that forum, I am always open to try anything)

Well obviously you can't ignore Hoffman's iron law, but I'd prefer not to build a BFM cab after seeing what's readily available (shared) here...

I'd prefer not to build a BFM cab after seeing what's readily available (shared) here...

And the fact that you pay for the design, and heaven forbid you ask a question that may be answered in the material 🙂 I have received friendlier responses from open forums and would not expect that kind of attitude, especially when I paid for something no matter ow silly the question.

Got some stuff in, just need one more amp for 4 way fully active system.

Almost ready for the last side to go on

Just to make sure the bolts don't vibrate loose...

One side flush trimmed, gotta do the other then start testing! Woohoo!

Almost ready for the last side to go on

Just to make sure the bolts don't vibrate loose...

One side flush trimmed, gotta do the other then start testing! Woohoo!

Last edited:

I dunno I just did screws every 50mm.

I use titebond III yellow wood glue. I don't use PL unless I need to fill gaps, or when gluing dissimilar materials (like the handle)

I find with good construction, no gaps and good mechanical clamping (in this case screws because I don't care about external appearance, and using my pocket hole jig was too time consuming) that the regular wood glue works great and is super easy to clean up, wipe off excess etc.

PL premium? I can't say the same.

I use titebond III yellow wood glue. I don't use PL unless I need to fill gaps, or when gluing dissimilar materials (like the handle)

I find with good construction, no gaps and good mechanical clamping (in this case screws because I don't care about external appearance, and using my pocket hole jig was too time consuming) that the regular wood glue works great and is super easy to clean up, wipe off excess etc.

PL premium? I can't say the same.

i see you have an old qsc mx2000😎

i stil have my 2 qsc ex4000 .

to me the best sounding pa amps up til now.

i stil have my 2 qsc ex4000 .

to me the best sounding pa amps up til now.

mRgSr Hi nice portable pa sub but can this be built with 15 mm BB I have 3 X 4'X8' sitting in my garage? Also the Lab 12's weigh a ton! LOL . . .

Thanks!

Thanks!

Well considering its a 500w rms cabinet, you *may* be able to get away with it. But honestly, with the 18mm and the good casters and the positioning of the handle, it is very very very easy to tilt back and roll around.

I placed the casters as far to the sides as possible, to kind of help with the cabinet wanting to topple over when rolling it around. But even so, a hand just stabilizing it while holding the handle makes it pretty easy.

If you do go with the 15mm, I suggest a lot of bracing. Internal panels are only 13.5" wide, but bracing should be run in the center of all panels if using the thinner wood.

I placed the casters as far to the sides as possible, to kind of help with the cabinet wanting to topple over when rolling it around. But even so, a hand just stabilizing it while holding the handle makes it pretty easy.

If you do go with the 15mm, I suggest a lot of bracing. Internal panels are only 13.5" wide, but bracing should be run in the center of all panels if using the thinner wood.

i see you have an old qsc mx2000😎

i stil have my 2 qsc ex4000 .

to me the best sounding pa amps up til now.

Yah just picked it up for $425. Not the greatest deal, but I was fine with the power per $ ratio, and I really enjoy the QSC mx1500 I have on my home theater amp, so I gave it a go.

This should provide more than enough headroom for a pair of these PAL12 subs.

Finished up the cabinet except for the round overs and coating with duratex. Also need a grill solution

Testing setup. I know there are objects within 25 feet, but this is the farthest away from my house that I could get. My neighbors house and truck is the closest large object. Behind the cabinet is the road, aka no houses for at least 100ft.

Testing setup. I know there are objects within 25 feet, but this is the farthest away from my house that I could get. My neighbors house and truck is the closest large object. Behind the cabinet is the road, aka no houses for at least 100ft.

Last edited:

- Home

- Loudspeakers

- Subwoofers

- $325 Lab 12 based PA tapped horn ~ 35Hz extension