Interesting read, thank you!

I studied audio parts by their sound and nature of materials. Its interesting that every material has its own sound. The sound of tubes is mostly chemicals, and to some extend construction. That makes it very clear to understand, why the same tubes of different manufacture don't sound the same. Its just because the Valvo company used different chemicals, different processes for a tube compared to the Telefunken company.

I never heard of this fact with transistors, but with electron tubes its obvious. And sometimes two charges of one company sound different.

People who deny this often use sound equipment so bad, that it simply isn't able to let those differences through to the speakers.

I knew of audio systems, where you can swap a transistor pre for a tube pre and still no difference is audible.

Thats the problem with audio in its lower quality and in its high resolution incarnation.

An audio forum isn't that different to any other forum, lets say a car forum. You'll always have people there who drive a basic car and those who drive advanced technology cars like Porsche, which could be used on race tracks, too.

The interesting part of this is, that an older technology brings us higher resolution systems (tubes) vs. newer technology which always claims to be high resolution, but in fact this is just marketing bla bla. The reality is, tubes were always and ever high resolution audio devices when done right. Its possible to audition so much more compared to transistor technology. But its an ancient technology and therefore, marketing never had problems to push the newer technology into markets, claiming that new is better than old.

This is a very unique situation in technology. Lets compare it to cars, who would prefer to drive an older model because its more perfect for driving?

I read about a test of the cathodes ability for having an enormous capability to emit electrons. The test goes this way: run a cathode with lower voltage than stated in the data sheet and look, how long they continue to emit the same, regular amount of electrons at a lower temperature. Only very few cathodes did the trick to go very low in voltage under their rating without having a loss in electrons emittation. This depends mostly on the perfection of producing such cathodes. I know companies that managed to do so and others that failed. This shows, that its very complicated and may have been a strong production secret to construct and produce this kind of electrons. One companys follower failed until today to recreate such cathodes. Their tubes aren't cheap either. We have to accept that either chemicals, production process perfection or simply knowledge has been lost over decades and are not easily becoming available again. Maybe becoming never the same perfection it once had, when it was mass production.

I studied audio parts by their sound and nature of materials. Its interesting that every material has its own sound. The sound of tubes is mostly chemicals, and to some extend construction. That makes it very clear to understand, why the same tubes of different manufacture don't sound the same. Its just because the Valvo company used different chemicals, different processes for a tube compared to the Telefunken company.

I never heard of this fact with transistors, but with electron tubes its obvious. And sometimes two charges of one company sound different.

People who deny this often use sound equipment so bad, that it simply isn't able to let those differences through to the speakers.

I knew of audio systems, where you can swap a transistor pre for a tube pre and still no difference is audible.

Thats the problem with audio in its lower quality and in its high resolution incarnation.

An audio forum isn't that different to any other forum, lets say a car forum. You'll always have people there who drive a basic car and those who drive advanced technology cars like Porsche, which could be used on race tracks, too.

The interesting part of this is, that an older technology brings us higher resolution systems (tubes) vs. newer technology which always claims to be high resolution, but in fact this is just marketing bla bla. The reality is, tubes were always and ever high resolution audio devices when done right. Its possible to audition so much more compared to transistor technology. But its an ancient technology and therefore, marketing never had problems to push the newer technology into markets, claiming that new is better than old.

This is a very unique situation in technology. Lets compare it to cars, who would prefer to drive an older model because its more perfect for driving?

I read about a test of the cathodes ability for having an enormous capability to emit electrons. The test goes this way: run a cathode with lower voltage than stated in the data sheet and look, how long they continue to emit the same, regular amount of electrons at a lower temperature. Only very few cathodes did the trick to go very low in voltage under their rating without having a loss in electrons emittation. This depends mostly on the perfection of producing such cathodes. I know companies that managed to do so and others that failed. This shows, that its very complicated and may have been a strong production secret to construct and produce this kind of electrons. One companys follower failed until today to recreate such cathodes. Their tubes aren't cheap either. We have to accept that either chemicals, production process perfection or simply knowledge has been lost over decades and are not easily becoming available again. Maybe becoming never the same perfection it once had, when it was mass production.

Last edited:

Telefunken, is an interesting company, as far as i know it merged with AEG later on. They were said to have used some of the best materials available, but sometimes they had to take shortcuts as well to be able to compete with the Philips conglomerate. The source of this are a few forum posts i read by Oliver Aarchut who was big on VF14m history, and knew more about tubes than I myself ever will.

Philips ran the majority of European tube manufacturers, The Netherlands alone had three that i know of: The plant in Eindhoven on the Strijp-S complex and two in Limburg: Sittard & Heerlen.

There were a lot of tubes that were re-stamped Philips tubes, for example POPE is 100% Philips. There was a common joke i was told by some 80 year old, that POPE was commonly reffered to as : "Productie Overschot Philips Eindhoven" Which translates into: Production surplus Philips Eindhoven.

For those interested in tube lore: there is a list of tube codes and markings floating around on the web, If you look closely you realize the Alphabet was exhausted in denoting different places of manufacture.

Most of the machines for tube manufacture where made by the BEM and EBM groups, If you look at the placards on some of the EI machines now residing in the UK with the GBVP, The automated stuff was made by BEM in the Netherlands.

Multilayer cathodes are indeed quite complicated, i suppose they applied the cathode paste in different layers by passing the spray rack through different spray booths wit different compounds.

Marstran.com • View topic - Eye witness info from GEC

Philips ran the majority of European tube manufacturers, The Netherlands alone had three that i know of: The plant in Eindhoven on the Strijp-S complex and two in Limburg: Sittard & Heerlen.

There were a lot of tubes that were re-stamped Philips tubes, for example POPE is 100% Philips. There was a common joke i was told by some 80 year old, that POPE was commonly reffered to as : "Productie Overschot Philips Eindhoven" Which translates into: Production surplus Philips Eindhoven.

For those interested in tube lore: there is a list of tube codes and markings floating around on the web, If you look closely you realize the Alphabet was exhausted in denoting different places of manufacture.

Most of the machines for tube manufacture where made by the BEM and EBM groups, If you look at the placards on some of the EI machines now residing in the UK with the GBVP, The automated stuff was made by BEM in the Netherlands.

Multilayer cathodes are indeed quite complicated, i suppose they applied the cathode paste in different layers by passing the spray rack through different spray booths wit different compounds.

Marstran.com • View topic - Eye witness info from GEC

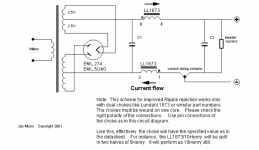

No, high current pulses put much greater stress on the transformer secondary than continuous conduction. The choke needs to have sufficient inductance to ensure continuous conduction. Check ANY textbook.

Well, the second "no"...

Actually, N101N's reasoning means that the power supply transformer will be relieved

Another possibility is that you don`t understand.

They need a minimal current draw.

When a poorly implemented choke supply rings, I'd say do a better job 🙄

A well implemented choke supply works well.

Of course.

Firstly, it is essential to differentiate between "choke input filter", LC, and "capacitor input filter ", CLC. The switching conduction mode is more efficient than the continuous conduction mode. Higher efficiency implies higher conduction losses and lower thermal losses. Reduced conductivity implies reduced electrical stress.

Philips had a long tradition with his light bulb manufacturing, so they decided to go into manufacturing of electron tubes. Its the same way the electron tube was invented, it all started with experimenting with light bulbs.

I read Olivers writings about TAB. Even very interesting read.

Don't know where the german tube producing machinery was originated, but I think they developed it by themself. Russians took many machines to their country from the east germany, so the easteners had to build new ones for their RFT tube manufacturing. They don't had the money to buy foreign machines.

The technology is stone age like, but chemical processes can be very complex.

Today, we see complicated optical/chemical processes with the invention of the integrated circuit. The newest generations of processors, I read only Zeiss made it to produce the masters with their advanced optical machinery. They are into nanometer circuits now.

Once I read about Intel, they copy the process, once successfully established, from one factory to another by 100%. Not one minimal difference, in fact its cloning of a complete factory. Thats how difficult its to manufacture electron chips today.

And exactly that difficult was it some 80 years ago to produce those super- cathodes of electron tubes. We see, many have managed, but only a very few of them managed to produce cathodes with extremely high electron emissions, even when temperature was far below ratings.

I read Olivers writings about TAB. Even very interesting read.

Don't know where the german tube producing machinery was originated, but I think they developed it by themself. Russians took many machines to their country from the east germany, so the easteners had to build new ones for their RFT tube manufacturing. They don't had the money to buy foreign machines.

The technology is stone age like, but chemical processes can be very complex.

Today, we see complicated optical/chemical processes with the invention of the integrated circuit. The newest generations of processors, I read only Zeiss made it to produce the masters with their advanced optical machinery. They are into nanometer circuits now.

Once I read about Intel, they copy the process, once successfully established, from one factory to another by 100%. Not one minimal difference, in fact its cloning of a complete factory. Thats how difficult its to manufacture electron chips today.

And exactly that difficult was it some 80 years ago to produce those super- cathodes of electron tubes. We see, many have managed, but only a very few of them managed to produce cathodes with extremely high electron emissions, even when temperature was far below ratings.

In practice, I found that is better to have a resin potted choke for less audible noise from choke itself. For electrical noise, other members like 50AE mentioned the AC/DC requiriments, for not saturating them; the noise becoming far worse when it saturatesWhat chokes are you all using when implementing a choke input filter? I have attempted a choke input several times and tried a variety of chokes, some modern and many vintage, but have not kept a choke in the first position in the final design. I have a purpose built listening room that is very, very quiet, and choke inputs have always created mechanical buzzing in the choke mostly, but less often in both choke and transformer. This buzzing noticeably increases the noise floor and, more importantly, annoys me. Any suggestions for chokes that will be silent in the input position would be much appreciated,

+1 for andyjevans small 1-2µF input capacitor for helping with noise

In sum, better to have a 100% dedicated choke made for LC input

In practice, I found that is better to have a resin potted choke for less audible noise from choke itself.

Not just resin potted, but also (more important) vacuum impregnated.

Some core materials are extremely fickle when it comes to noise. Not every potting material works. Sometimes you need hard as glass epoxy. Polyurethane potting compound or ceresin won't always cut it. There are two sources of vibration - the core's magnetostriction and the coils. For the coils, where the issue comes more to power transformers, you need vacuum impregnation with thin lacquer, but potting helps too, because even a sturdy winding can excite the whole bobbin to vibrate.

Coil noise gets worse with:

-current draw

-leakage inductance.

When it comes to core, this is where glue helps, especially for C-cores. From experience I know amorphous are worst when it comes to vibration, then nanocrystalline and HiB behaves the most silently.

Coil noise gets worse with:

-current draw

-leakage inductance.

When it comes to core, this is where glue helps, especially for C-cores. From experience I know amorphous are worst when it comes to vibration, then nanocrystalline and HiB behaves the most silently.

I remember the CRT projectors on the ceiling creating a nice noise floor, then we build "hush boxes" to ged rid of the noise.

Exactly the reason why I stayed away from choke input supplies.Some core materials are extremely fickle when it comes to noise. Not every potting material works. Sometimes you need hard as glass epoxy. Polyurethane potting compound or ceresin won't always cut it. There are two sources of vibration - the core's magnetostriction and the coils. For the coils, where the issue comes more to power transformers, you need vacuum impregnation with thin lacquer, but potting helps too, because even a sturdy winding can excite the whole bobbin to vibrate.

Coil noise gets worse with:

-current draw

-leakage inductance.

When it comes to core, this is where glue helps, especially for C-cores. From experience I know amorphous are worst when it comes to vibration, then nanocrystalline and HiB behaves the most silently.

You never know how this performs. And the voltage spikes can be quite heavy.

I haven’t used choke input because it hasn’t worked properly every time I tried it. In some respects the tube regulated power supply in the Loesch Legacy is what is most interesting about that amp. Tube regulated power supplies would seem to give both low DSR, and low ripple without chokes. However, complexity is substantial and energy consumption is high as well. Still worth a try though as I have not yet built or experienced this type of supply

With a regulated power supply you have another amplifier in the signal chain....

SE is class A by definition, so IMO a regulated power supply should not be necessary.

When used to overcome LC input filter supply problems you're on the wrong track.

When power supply transformer and choke are made for the application, LC input supplies work well (at least in my experience...).

SE is class A by definition, so IMO a regulated power supply should not be necessary.

When used to overcome LC input filter supply problems you're on the wrong track.

When power supply transformer and choke are made for the application, LC input supplies work well (at least in my experience...).

Every regulated PSU has its pros and cons that can be discussed to death in a DIY forum.

Of course, a choke isn't needed and it will produce still low ripple currents.

But that has some disadvantages, too. A good, unregulated PSU doesn't have those disadvantages, but its often more expensive and uses massive iron.

Of course, a choke isn't needed and it will produce still low ripple currents.

But that has some disadvantages, too. A good, unregulated PSU doesn't have those disadvantages, but its often more expensive and uses massive iron.

- Home

- Amplifiers

- Tubes / Valves

- 300b with single stage driver, C3M or?