Cool stuff. The Jamo crossover looks very compromised to save component cost (e.g. first order bandpass on the mids); I'm sure you can do better.

The cabinet panels can be lined with bitumen pads to reduce resonance, and light layers of sheep's wool or similar. Some guidelines Cabinet-damping

The cabinet panels can be lined with bitumen pads to reduce resonance, and light layers of sheep's wool or similar. Some guidelines Cabinet-damping

Yea motokok, the xover parts is asian 335K 100V cheap bulk = 3,3 uF caps, and biggest coil was 0,74 mH.

Hole xover is about 5 usd i belive.

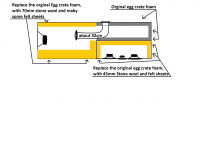

Now i have draw in windows Paint how i think about fillings, and the elips cabinette is really rigid and also have a reinforcement in the middle, so i doubt i has much resonance.

Think it´s more about getting woofer to play clean and suit the woofers behavior.

Regards John

Hole xover is about 5 usd i belive.

Now i have draw in windows Paint how i think about fillings, and the elips cabinette is really rigid and also have a reinforcement in the middle, so i doubt i has much resonance.

Think it´s more about getting woofer to play clean and suit the woofers behavior.

Regards John

Attachments

Hello guy`s

Had to wait a while because they send me wrong woofer´s, but now i have everything and have begain re-build the speakers inside.

Wrote wrong about F3 and F6 before motokok, in WinISD F3 is about 27,34 hz and F6 is 23,7 hz ! ( not F3 49 and F6 42 asi wrote before 🙄)

I have a little problem/eye-opener about the reflex-pipe-solution i had i mine, if i use a 100 mm diameter pipe it´s going to be 44,9 cm long and taking 3,53 liter from the quite "small/slim" box. ( work´s but look´s gigantic inside and end´s about 11,5 cm from the backside of the woofer)

If i use a 70 mm diameter pipe it´s going to be 20 cm long and taking 0,73 liter. ( more easy to execute inside, even if i have to solve the original port-hole in the speaker because its bigger)

And if i use a 48 mm diameter pipe it´s going to be 8,15 cm long and taking 0,15 liter. ( feel´s like a toy, but fantastic if it really work´s but more work with orginal reflex-hole in cabinette)

In WinISD i read 2 m/s in air velocity from rear port with 100 mm diameter pipe, 4,5 m/s with 68 mm pipe and 9 m/s in 48 mm pipe.

Can i belive those numbers ?

And are there some serious disadvantages with 68 mm or 48 mm reflex pipe?

Previously in speakerbuildings I only used 100 mm pipe, but that was in big 100 liter cabinette and up to 300 hz, now the cabinette is slim and more problematic.

The 150uF cap´s are gigantic and with 10mH coils and other stuff, its going to be a fight to get the xover fixed inside the cabinette.

And all new damping-materials inside cabinettet (Rockwool, Filt, cotton-polt)

And a few pic´s on my on-going 🙂

Extra 16mm baffel, will paint it black tomorrow,

Regards John

Had to wait a while because they send me wrong woofer´s, but now i have everything and have begain re-build the speakers inside.

Wrote wrong about F3 and F6 before motokok, in WinISD F3 is about 27,34 hz and F6 is 23,7 hz ! ( not F3 49 and F6 42 asi wrote before 🙄)

I have a little problem/eye-opener about the reflex-pipe-solution i had i mine, if i use a 100 mm diameter pipe it´s going to be 44,9 cm long and taking 3,53 liter from the quite "small/slim" box. ( work´s but look´s gigantic inside and end´s about 11,5 cm from the backside of the woofer)

If i use a 70 mm diameter pipe it´s going to be 20 cm long and taking 0,73 liter. ( more easy to execute inside, even if i have to solve the original port-hole in the speaker because its bigger)

And if i use a 48 mm diameter pipe it´s going to be 8,15 cm long and taking 0,15 liter. ( feel´s like a toy, but fantastic if it really work´s but more work with orginal reflex-hole in cabinette)

In WinISD i read 2 m/s in air velocity from rear port with 100 mm diameter pipe, 4,5 m/s with 68 mm pipe and 9 m/s in 48 mm pipe.

Can i belive those numbers ?

And are there some serious disadvantages with 68 mm or 48 mm reflex pipe?

Previously in speakerbuildings I only used 100 mm pipe, but that was in big 100 liter cabinette and up to 300 hz, now the cabinette is slim and more problematic.

The 150uF cap´s are gigantic and with 10mH coils and other stuff, its going to be a fight to get the xover fixed inside the cabinette.

And all new damping-materials inside cabinettet (Rockwool, Filt, cotton-polt)

And a few pic´s on my on-going 🙂

Extra 16mm baffel, will paint it black tomorrow,

Regards John

Attachments

-

IMG_20211026_122551.jpg609.3 KB · Views: 275

IMG_20211026_122551.jpg609.3 KB · Views: 275 -

IMG_20211026_122634.jpg562.2 KB · Views: 260

IMG_20211026_122634.jpg562.2 KB · Views: 260 -

IMG_20211026_150715.jpg370.5 KB · Views: 255

IMG_20211026_150715.jpg370.5 KB · Views: 255 -

IMG_20211026_152923.jpg347.9 KB · Views: 245

IMG_20211026_152923.jpg347.9 KB · Views: 245 -

IMG_20211026_162421.jpg571.4 KB · Views: 229

IMG_20211026_162421.jpg571.4 KB · Views: 229 -

IMG_20211028_165819.jpg241.4 KB · Views: 245

IMG_20211028_165819.jpg241.4 KB · Views: 245 -

IMG_20211026_181428.jpg312.9 KB · Views: 225

IMG_20211026_181428.jpg312.9 KB · Views: 225 -

IMG_20211026_170928.jpg496.9 KB · Views: 228

IMG_20211026_170928.jpg496.9 KB · Views: 228

I think port tuning just has to be experimented with; ditto length and diameter. WinISD should be trustworthy as a starting point, at least.

Wait, did you design the XO already to have bought the components? XO could just be outside in a little box. Allows you to keep tinkering with it, too.

Wait, did you design the XO already to have bought the components? XO could just be outside in a little box. Allows you to keep tinkering with it, too.

Hey motokok

I have bought the most of the xover komponents, but i also have a extra"candy-shop" with komponents from before 🙂

Yea maby i have to have the xover in a box outside, even if i like "clean" stereo/livingroom, because the parts are BIG !.

And the port´s pieces have to be glued together (4 part´s) in the final solution, but maby i can tape the seam in some of the parts when testing.

Hard to get the cabinette airtight if i dont glue the rear port, and if i glue the rear port i can´t reach the 90 degrees (that have to be glued at the same time)

The rear port hole in the cabinette is a little to small to be able to put both rear port and 90 degrees (taped together) into the cabinette. ( i have to use my hand inside for the 90 degrees)

The 40 cm straight 100 mm pipe after the 90 degrees i can glue after.

And i have to unscrew the woofer each time i test ditto length and diameter.

And the Jamo D590 have also a screwed on plate in the bottom ho the speaker stands on, so it´s hard to even try the speaker with woofer witout mount the screwed plate....Makes thing even more hard to be experimented with.

Regards John

I have bought the most of the xover komponents, but i also have a extra"candy-shop" with komponents from before 🙂

Yea maby i have to have the xover in a box outside, even if i like "clean" stereo/livingroom, because the parts are BIG !.

And the port´s pieces have to be glued together (4 part´s) in the final solution, but maby i can tape the seam in some of the parts when testing.

Hard to get the cabinette airtight if i dont glue the rear port, and if i glue the rear port i can´t reach the 90 degrees (that have to be glued at the same time)

The rear port hole in the cabinette is a little to small to be able to put both rear port and 90 degrees (taped together) into the cabinette. ( i have to use my hand inside for the 90 degrees)

The 40 cm straight 100 mm pipe after the 90 degrees i can glue after.

And i have to unscrew the woofer each time i test ditto length and diameter.

And the Jamo D590 have also a screwed on plate in the bottom ho the speaker stands on, so it´s hard to even try the speaker with woofer witout mount the screwed plate....Makes thing even more hard to be experimented with.

Regards John

Last edited:

Have fun! Can you post the datafiles, schematics and sims used for your XO plans? Are you going to replicate the original?

Hi motokok

No i´m building the xover from scratch, and to begain with it look´s like this.

Real advanced to get the SB tweeter in place, because SB Aucustic have build the 26-ADC a little stupid.

The magnet is 70 mm but the bindings + & - is way wider at 83 mm, and if you drill the hole 83mm then its not much left to screw in because the holes on 26-ADC is 88,5 mm.

And in my case i had to manufacture a real thin wood-ring, and then cut out for the bindings.

But mowing forward, and have the extra baffel painted and mounted.

Tomorrow next speaker and make the xover.

Was my files the one you asked for ?,,,frd, zma and XSim´s ?

Regards John

No i´m building the xover from scratch, and to begain with it look´s like this.

Real advanced to get the SB tweeter in place, because SB Aucustic have build the 26-ADC a little stupid.

The magnet is 70 mm but the bindings + & - is way wider at 83 mm, and if you drill the hole 83mm then its not much left to screw in because the holes on 26-ADC is 88,5 mm.

And in my case i had to manufacture a real thin wood-ring, and then cut out for the bindings.

But mowing forward, and have the extra baffel painted and mounted.

Tomorrow next speaker and make the xover.

Was my files the one you asked for ?,,,frd, zma and XSim´s ?

Regards John

Attachments

Yes, thanks, just interested. Hmm, you couldn't you just stick with the 9300? Or compare them when tuned to similar responses?

Hade the same thought sins last week motokok, both on fitting and that 6 Ohm in SS 9300, so i get the total impedance up a little from the 3,1 ohm starting around 10K

The thing is that i bought the SS 9300 to build a center and surroundspeaker in my basement setup for cinema-use (need 1 more), and the SS is 3 times more expensive.

But i have solved the 26ADC fitting-problems, and i think a quite ordenary amp will fix the load now when im at minimum 3 ohm.

And if i don´t like the Sb 26ADC after a little tweaking, i will shift to the SS after a few week´s.

Regards John

The thing is that i bought the SS 9300 to build a center and surroundspeaker in my basement setup for cinema-use (need 1 more), and the SS is 3 times more expensive.

But i have solved the 26ADC fitting-problems, and i think a quite ordenary amp will fix the load now when im at minimum 3 ohm.

And if i don´t like the Sb 26ADC after a little tweaking, i will shift to the SS after a few week´s.

Regards John

Getting my project going, but got my *** kicked time to time.

My extra 16mm baffel can´t even be used so waisted time!

Because the Peerlees 830667 only have a total of 30 mm in basket to breathe, and Jamo´s orginal 15 mm woofer-baffle is maximum.

Sadly i diden´t look real closely at the 830667 basket before, the big magnet makes the angle of the basket a super steep angle.

I also have the "first" xover soldered, and it´s BIG hahaha.

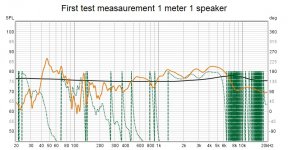

And i have now spend a few hour´s with the program REW and finaly manage to do my first measaurement in my life...and with the "new" xover.

I can´t understand much of this measaurement, but i understand the RED line is SPL and the green is phase.

Why phase look´s like that from 3 K and up ?

The mic was at 1 meter and about in the middle of the MTM. ( 1 speaker )

Regards John

My extra 16mm baffel can´t even be used so waisted time!

Because the Peerlees 830667 only have a total of 30 mm in basket to breathe, and Jamo´s orginal 15 mm woofer-baffle is maximum.

Sadly i diden´t look real closely at the 830667 basket before, the big magnet makes the angle of the basket a super steep angle.

I also have the "first" xover soldered, and it´s BIG hahaha.

And i have now spend a few hour´s with the program REW and finaly manage to do my first measaurement in my life...and with the "new" xover.

I can´t understand much of this measaurement, but i understand the RED line is SPL and the green is phase.

Why phase look´s like that from 3 K and up ?

The mic was at 1 meter and about in the middle of the MTM. ( 1 speaker )

Regards John

Attachments

Last edited:

In your umik 1 manual it must talk about windowing of measurements, and gives examples I think. Above 6K you have the phase swinging between +/- 180 degrees, which you can see earlier as single events at 150, 280, 380 480Hz.

I would expect once you bring the window down to 3-5mS you will see a gentle fall of of the lower frequency info as you trade resolution, and your measurement will become quasi anechoic.

Once windowed at 3-6mS time, you can see that the data from 400Hz to 6KHz wont change and it is letting you see basically what is happening at your 1 metre measuring distance. it looks like the tweeter needs another 2-3dB of attenuation to get it down to your mid level or if you can bring the mid up by the same amount that would do it.

Well done you are taking measurements, and you are going to learn a lot quickly.

Note, I do not understand why your tweeter level drops so sharply at 6K, or is it simply the peerless woofer and faital pro mid? Or is that due to you cutting out some info at the start of the test tone i.e. where you have chosen to start the window?

I would expect once you bring the window down to 3-5mS you will see a gentle fall of of the lower frequency info as you trade resolution, and your measurement will become quasi anechoic.

Once windowed at 3-6mS time, you can see that the data from 400Hz to 6KHz wont change and it is letting you see basically what is happening at your 1 metre measuring distance. it looks like the tweeter needs another 2-3dB of attenuation to get it down to your mid level or if you can bring the mid up by the same amount that would do it.

Well done you are taking measurements, and you are going to learn a lot quickly.

Note, I do not understand why your tweeter level drops so sharply at 6K, or is it simply the peerless woofer and faital pro mid? Or is that due to you cutting out some info at the start of the test tone i.e. where you have chosen to start the window?

Last edited:

Thank you raymondj 🙂

Hard to learn new advanced things at almost 55 hahaha, but fun.

Dont know if i have some settings wrong in REW, tomorrow i will try and read more and test.

Just for fun i also connected right speaker who has new mid´s and a Scanspeak 93000, but old Jamo woofer and xover.

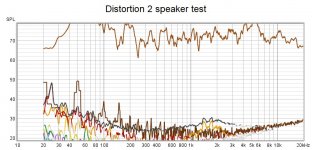

The mesaurement together was like this, and the waterfall like this.

Anyway not the same 6K dipp in tweeter.

With "Var smoothing" on "graph" in REW.

Regards John

Hard to learn new advanced things at almost 55 hahaha, but fun.

Dont know if i have some settings wrong in REW, tomorrow i will try and read more and test.

Just for fun i also connected right speaker who has new mid´s and a Scanspeak 93000, but old Jamo woofer and xover.

The mesaurement together was like this, and the waterfall like this.

Anyway not the same 6K dipp in tweeter.

With "Var smoothing" on "graph" in REW.

Regards John

Attachments

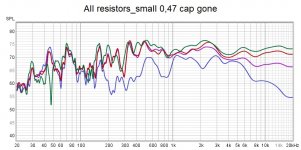

Begain modify the xover to get better response over 6K, the Blue curve is before i begain, the Purple after the resistor before cap on tweeter gone, and Red and Green after also resistor after cap´s gone and also the small 0,47uf cap in serie with resistor.

dB SPL curva at 2dB

Phase at 1 Ohm curve

Regards John

dB SPL curva at 2dB

Phase at 1 Ohm curve

Regards John

Attachments

You seem to be making progress.

Interestingly the response of the other speaker with the new midranges and original bass and crossover doesn't look to bad does it ?

It might be useful to have that as a sensible backstop for reference. Whilst you work on the new solution.

Just out of interest you do not need to load a calibration file for the microphone?

As the response is still rather lumpy it might be interesting to reverse the tweeter phase and see what kind of graph that generates it should give you a basic idea of how the mid and tweeter phase is working for you, or against you .

Alternatively just keep us updated with latest response and circuit diagram that generated that response so others can track the changes you are making and see how you address the ripples in the frequency response. Getting a bump out of the response if it 2 or 3 dBs can be tricky. Some times you can get away with them on other occasions you may hear it all the time, and then will need to notch it out.

If you wanted to look at just the midrange shape I would switch of the amp and disconnect the tweeter and put a 4 Ohm resistor in its place to simulate the load of the tweeter back into the whole network.

Power the amp back on and see what the midrange response look like in isolation.

Try to get the smoothest response you can you can, and maybe reconsider the old crossover values and simplify your new design where possible. You will learn from all of this that for sure. Keep up the good work and stay warm.

If you do find a troublesome bump, move the microphone 30 degrees or so to either the right or the left and re measure, this should show you how the bump changes of axis and demonstrate that you wont have to deal with it if it flattens out nicely.

Interestingly the response of the other speaker with the new midranges and original bass and crossover doesn't look to bad does it ?

It might be useful to have that as a sensible backstop for reference. Whilst you work on the new solution.

Just out of interest you do not need to load a calibration file for the microphone?

As the response is still rather lumpy it might be interesting to reverse the tweeter phase and see what kind of graph that generates it should give you a basic idea of how the mid and tweeter phase is working for you, or against you .

Alternatively just keep us updated with latest response and circuit diagram that generated that response so others can track the changes you are making and see how you address the ripples in the frequency response. Getting a bump out of the response if it 2 or 3 dBs can be tricky. Some times you can get away with them on other occasions you may hear it all the time, and then will need to notch it out.

If you wanted to look at just the midrange shape I would switch of the amp and disconnect the tweeter and put a 4 Ohm resistor in its place to simulate the load of the tweeter back into the whole network.

Power the amp back on and see what the midrange response look like in isolation.

Try to get the smoothest response you can you can, and maybe reconsider the old crossover values and simplify your new design where possible. You will learn from all of this that for sure. Keep up the good work and stay warm.

If you do find a troublesome bump, move the microphone 30 degrees or so to either the right or the left and re measure, this should show you how the bump changes of axis and demonstrate that you wont have to deal with it if it flattens out nicely.

Last edited:

Forgot to tell you that im begain to distrust my own FRD files for the SB 26ADC in XSim, so i made new one´s just to try it out. ( Im ashamed)

And now the impedance went up a little, and also SPL curve!

Think maby spl-trace capture the 60° off-axis curve last time, otherwise i can´t understand it.

Yea raymondj the Scan speak 93000 seems quite "happy" with orginal tweeter-xover, but it is a real good tweeter so wasen´t surprised to see better result ....and the more you measure and the more you understand, the more tests/tweaks you have to do hahaha.

And i have load the calibration file for the microphone 🙂

Understand now why Arine Nudell and Albert Von Schwikert kept to themselves mostly R.I.P my legend´s <3

I have also shift the other woofer to 830667, so now both have SLS woofeers.

BUT....I haven´t done any new damping-materials in the "orginal/Right" Jamo speaker, nor the MTM or woofer-cabinette.

I will also test to reverse the tweeter phase and mesaure, maby you can see more where the "problem" maby lies then.

Smart thing you come up with (disconnect the tweeter and put a 4 Ohm resistor) 🙂 The mid work´s from 150-2750 hz, so it´s a big deal!

Your input rajmondj is soooo appreciated

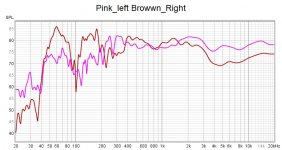

So these mesaurements are Pink the re-done one with new port and rockwool/damping and new xover

Brown all new driver´s but orginal xover, inner-damping and orginal port 14 cm 100 mm pipe. ( no more SS 9300)

Pink/Left speaker stands closer to the left wall in almost a corner, Brown/Right speaker stands 3 M from the corner and have also 1 meter extra seelinghight.

Regards John

And now the impedance went up a little, and also SPL curve!

Think maby spl-trace capture the 60° off-axis curve last time, otherwise i can´t understand it.

Yea raymondj the Scan speak 93000 seems quite "happy" with orginal tweeter-xover, but it is a real good tweeter so wasen´t surprised to see better result ....and the more you measure and the more you understand, the more tests/tweaks you have to do hahaha.

And i have load the calibration file for the microphone 🙂

Understand now why Arine Nudell and Albert Von Schwikert kept to themselves mostly R.I.P my legend´s <3

I have also shift the other woofer to 830667, so now both have SLS woofeers.

BUT....I haven´t done any new damping-materials in the "orginal/Right" Jamo speaker, nor the MTM or woofer-cabinette.

I will also test to reverse the tweeter phase and mesaure, maby you can see more where the "problem" maby lies then.

Smart thing you come up with (disconnect the tweeter and put a 4 Ohm resistor) 🙂 The mid work´s from 150-2750 hz, so it´s a big deal!

Your input rajmondj is soooo appreciated

So these mesaurements are Pink the re-done one with new port and rockwool/damping and new xover

Brown all new driver´s but orginal xover, inner-damping and orginal port 14 cm 100 mm pipe. ( no more SS 9300)

Pink/Left speaker stands closer to the left wall in almost a corner, Brown/Right speaker stands 3 M from the corner and have also 1 meter extra seelinghight.

Regards John

Attachments

Last edited:

- Home

- Loudspeakers

- Multi-Way

- 3 way upgrading Jamo D590 replacements and filter question