What are the mounting hole and recess dimensions for the Kef coax? I've got my own version of the blade on the drawing board but I haven't bought drivers to put calipers on yet. A shame we can't get data sheets for them from Kef - like the linear Xmax. I do have a pair of R3s so I know they will sound great.

i use an adapter ring so the cutout can be bigger like the original one so the midrange can breath more, not visible in any picture.What are the mounting hole and recess dimensions for the Kef coax? I've got my own version of the blade on the drawing board but I haven't bought drivers to put calipers on yet. A shame we can't get data sheets for them from Kef - like the linear Xmax. I do have a pair of R3s so I know they will sound great.

I saw that on some of the other builds and liked the idea.

I can measure the dimensions for you

Thanks, That ring is a good idea as it gives great flexibility, even to try different drivers - like the Sica 5.5" coax which does have a data sheet.

Erin (erinsaudiocorner.com) has tested both the Q100 and R300 drivers. Much more detailed specifications than any datasheet.

You are correct but I miss the detailed mechanical drawings plus he hasn't done the driver we are planning to use. Erin's R300 driver review was published in 2013 so it must be from the generation prior to the R3.

building is finished, I ll take some worthy photos once weather gets better and I can take some serious measurements, it raining at the moment

they will get some 5axis cnc aluminium feet but I haven't decided on design yet 😛

i made some really basic xo settings with lr2 at 500Hz and lr4 at 2950Hz, adjusted the gain and estimated delay with distance sound takes just so I can hear them a little bit, I know I have to measure them outside to get better/ real measurement results. but even without any eq just with xo they sound very nice especially off axis its insane

is it right to do these steps in order or would it be nice to do something before another step

1. Take them outside for gated measurment

2. measure each way independent

3. eq each way on its own to flat in its estimated frequency spectrum and little bit above. and don't use positiv eq right?

4. time align driver and set gain

5. set crossover

6. measure as a hole + maybe directivity measurements

7. measure inside and calculate room eq with wanted house curve and set this as param eq.

they will get some 5axis cnc aluminium feet but I haven't decided on design yet 😛

i made some really basic xo settings with lr2 at 500Hz and lr4 at 2950Hz, adjusted the gain and estimated delay with distance sound takes just so I can hear them a little bit, I know I have to measure them outside to get better/ real measurement results. but even without any eq just with xo they sound very nice especially off axis its insane

is it right to do these steps in order or would it be nice to do something before another step

1. Take them outside for gated measurment

2. measure each way independent

3. eq each way on its own to flat in its estimated frequency spectrum and little bit above. and don't use positiv eq right?

4. time align driver and set gain

5. set crossover

6. measure as a hole + maybe directivity measurements

7. measure inside and calculate room eq with wanted house curve and set this as param eq.

Attachments

Last edited:

sry i forgot to measure the drive before installing, was just to focus about finally completing the build.What are the mounting hole and recess dimensions for the Kef coax? I've got my own version of the blade on the drawing board but I haven't bought drivers to put calipers on yet. A shame we can't get data sheets for them from Kef - like the linear Xmax. I do have a pair of R3s so I know they will sound great.

here is the adapter dimension if it helps but my measurements weren't completely on point I had to make the 6 holes on the inside a bit bigger

but I have a broken one from key r900 which I think uses the same basket, if u want I can measure its basket

Attachments

thx, its my uncles place he is retired and has a gigantic workshop with really nice machine, sadly not many are useful for speaker because workshop was designed to build windows. but so much space and a big Format circular saw helped a lotBeautiful neat work and wonderfully roomy and organized workshop

building is finished, I ll take some worthy photos once weather gets better and I can take some serious measurements, it raining at the moment

View attachment 1063673

Whoa...

These look like Kef LS70 🙂

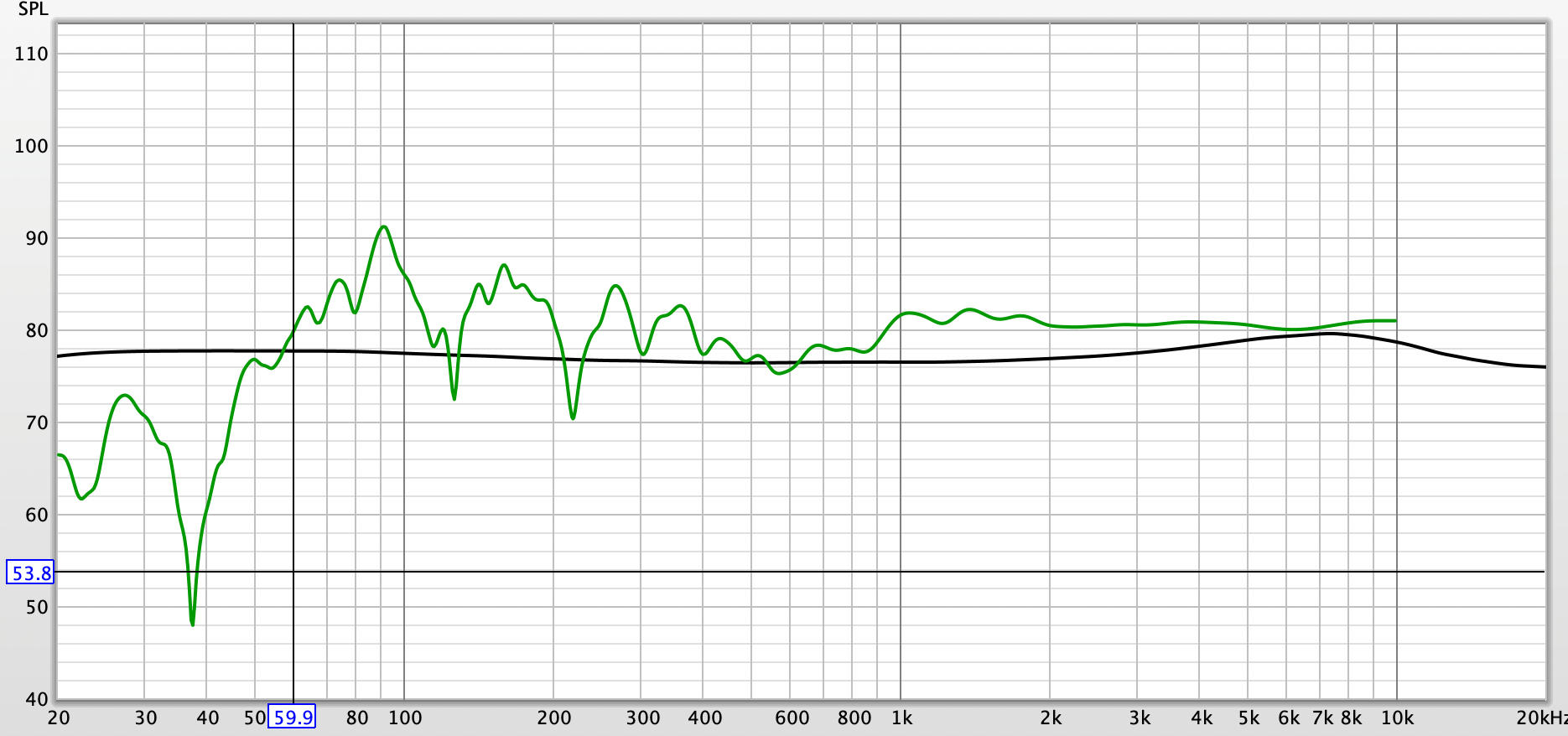

I will get a driver on order shortly so don't worry about the measuring it mechanically. I'm much more interested in the acoustic measurements. What you have shown has an exceptionally clean top end for a coax driver. Is there any smoothing on the graph? Unfortunately, the room is corrupting the lower frequencies. Eagerly awaiting those outdoor measurements ideally a full set of polars; at least enough to estimate how equalizable the response is over an area.

yes they are smoothed, rew var smoothingWhat you have shown has an exceptionally clean top end for a coax driver. Is there any smoothing on the graph?

2ms gated, hole speaker and no smoothing (ignore the dip in 500hz region crossover is not properly aligned yet)

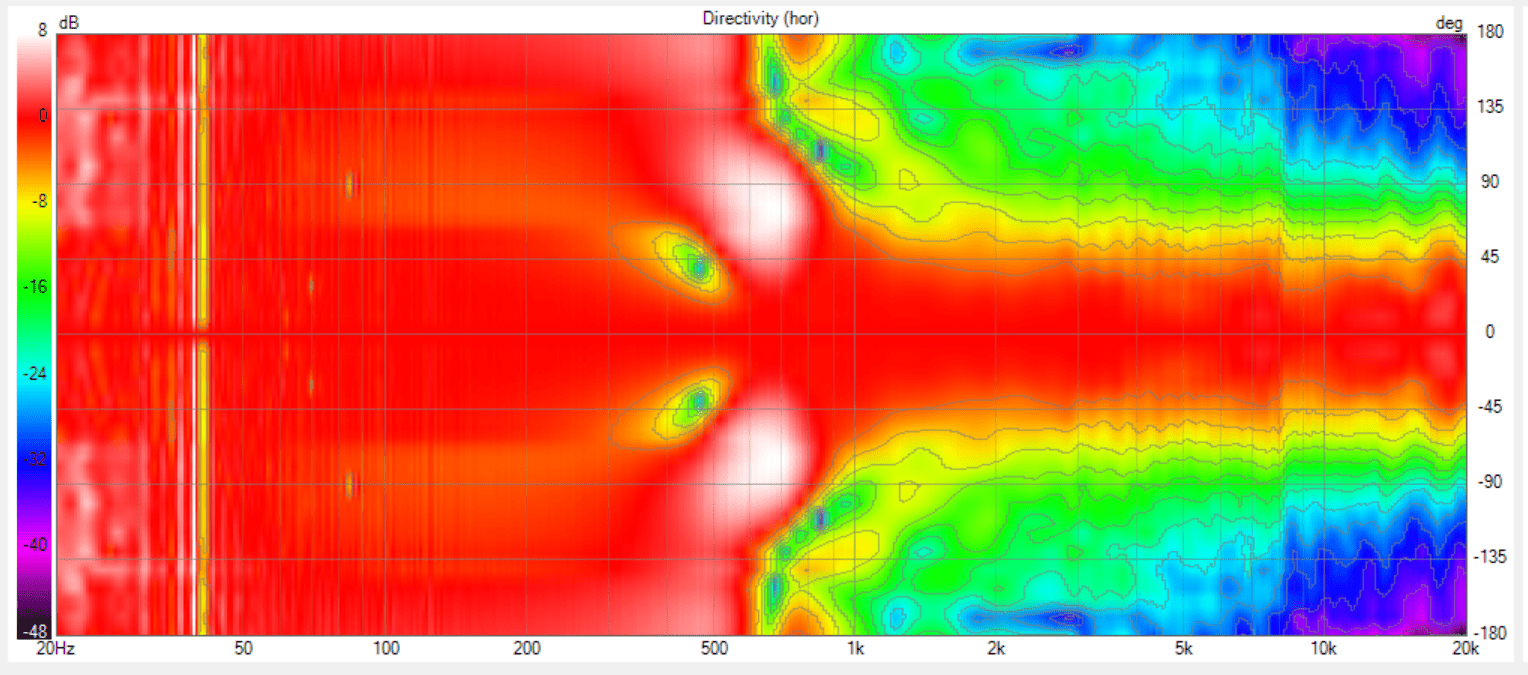

Well i tried my best at measuring but sun was burning insanley so i only did sweeps for tt, ht, mt direct and hole speaker 0-180 degree with 400Hz LR2 and 2900Hz LR4 without any correction, just a bit gain adjust

even outside and raised speaker first reflection was at 3,3ms...but i thinks its bether then nothing. i need a higher rig

gated 3.3 directivity:

server has problems with zips...i ll link measuremnts with cloud

even outside and raised speaker first reflection was at 3,3ms...but i thinks its bether then nothing. i need a higher rig

gated 3.3 directivity:

server has problems with zips...i ll link measuremnts with cloud

Attachments

Last edited:

looking at the files, thanks. you definitely need more height! Build the 2nd speaker and stack them 🙂

Nice garden.

Nice garden.

- Home

- Loudspeakers

- Multi-Way

- 3-way floorstanding with KEF coax (active)