SA2015 4 channel VMOS

... small progress ...

Some vote statistics:

... small progress ...

Some vote statistics:

- votes: 17, average: 4.59 of "5,1,5,5,5,5,5,5,5,4,5,5,5,5,4,5,4"

- votes: 16, average: 4.81 of "5,5,5,5,5,5,5,5,4,5,5,5,5,4,5,4"

Attachments

Last edited:

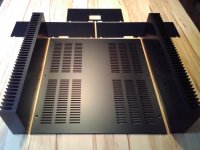

SA2015 4 channel VMOS - case parts

... today got missing parts to finish the amplifier case ...

... today got missing parts to finish the amplifier case ...

- Aluminium heatsink and top panel CNC machining and anodizing:

high quality from schaeffer-ag.de!

- Powder coating of inner iron shield::

high quality from wolfmair.at!

Attachments

... today got missing parts to finish the amplifier case ...

- Aluminium heatsink and top panel CNC machining and anodizing:

high quality from schaeffer-ag.de!

BR, Toni

- Powder coating of inner iron shield::

high quality from wolfmair.at!

Very-very Nice!!!

A wonderful enclosure!

Last edited:

Thx!

Case mount test so far OK. All parts fit.

Unfortunately the heatsinks are not 100% flat. During mounting the error is about 0.5mm in the middle. So we need some force to correct this during mounting.

Next time I need to do a better finish for the heatsinks before anodizing - especially for the saw edges.

Have fun, Toni

Case mount test so far OK. All parts fit.

Unfortunately the heatsinks are not 100% flat. During mounting the error is about 0.5mm in the middle. So we need some force to correct this during mounting.

Next time I need to do a better finish for the heatsinks before anodizing - especially for the saw edges.

Have fun, Toni

Attachments

Looking good! I've often had to put heat sinks in a press with some lumber to get them straight enough to use. I've been glass blasting mine to blend the surfaces but this comes out slightly dull after anodizing.

Thx!

The 0.5mm maybe can be corrected with the mounting brackets (= "bias" the brackets 🙂).

Correcting them in a press is a good tip - thx - I will try this.

BTW: glass blasting hardens the aluminium surface and may influence the anodizing result.

BR, Toni

The 0.5mm maybe can be corrected with the mounting brackets (= "bias" the brackets 🙂).

Correcting them in a press is a good tip - thx - I will try this.

BTW: glass blasting hardens the aluminium surface and may influence the anodizing result.

BR, Toni

Outstanding work, Tony, very professional  !

!

May I ask about the total costs of this enclosure?

Best regards!

!

!May I ask about the total costs of this enclosure?

Best regards!

Thx ... prices ... hmmm ... astronomic ...

but below EUR 1k including anodized feets, cnc machined and anodized heatsinks, inner iron shields, powder coating. Would be a lot cheaper if the top plate wouldn't be cnc machined aluminium but instead lasered iron and powder coated. The 4mm aluminium top plate is the most expensive part but it is worth the money - IMHO looks very professional.

A group buy would bring the costs down a bit but you still need some metal work skills and some special metal work tools.

BTW: for comparison - the toroid (8x35V AC / 850VA) is custom made and costs about ~ 300 EUR

BR, Toni

but below EUR 1k including anodized feets, cnc machined and anodized heatsinks, inner iron shields, powder coating. Would be a lot cheaper if the top plate wouldn't be cnc machined aluminium but instead lasered iron and powder coated. The 4mm aluminium top plate is the most expensive part but it is worth the money - IMHO looks very professional.

A group buy would bring the costs down a bit but you still need some metal work skills and some special metal work tools.

BTW: for comparison - the toroid (8x35V AC / 850VA) is custom made and costs about ~ 300 EUR

BR, Toni

Attachments

Last edited:

Thx!

BTW: glass blasting hardens the aluminium surface and may influence the anodizing result.

BR, Toni

The dye used in anodizing is actually translucent to a point so the shine on the aluminum is actually the shine you see in the finished product. Glass blasting dulls the finish slightly. This is what causes the duller finished product.

IXTH80N20L are hard to get...

Transistors for audio are more and more becoming "unobtanium" ...🙁

Transistors for audio are more and more becoming "unobtanium" ...🙁

... small progress ...

... 32 pieces of TTC5200 need to be soldered...

... 32 pieces of TTA1943 need to be soldered...

... case milling and engraving has begun ...

Can I create an example using the +/- 100 volts?

And can add 2sc5200 as 10 12 pairs.

regards.

Have you looked at the SOA plots for the 1943/5200?

Look at the current capability when Vce=100Volts.

How much does that have to be de-rated when your installation raises Tc above 25degrees C?

Look at the current capability when Vce=100Volts.

How much does that have to be de-rated when your installation raises Tc above 25degrees C?

Can I create an example using the +/- 100 volts?

And can add 2sc5200 as 10 12 pairs.

regards.

If you want to use 2SC5200/2SA1943 the driver stage needs to be redesigned. Driving those power bjt above +-70V isn't a good idea as AndrewT wrote!

If you want high power on 8R speakers you better do bridging using 2xSA2014 modules. you easy could get 880 W@8R. of course 4R speakers can not be used when bridged!

BR, Toni

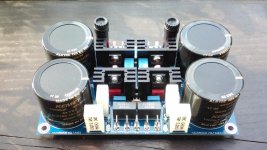

Low profile caps for more room looks as an excellent solution!... small progress ...

... all 4 power supply pcb checked and ready for mounting in the case...

Have fun, Toni

The box in a box just away....

Good job Toni!

Hello everyone

Use a program that designs prints.

Can I share a used program?

I would like to design a printed version without the use of cord.

I like that the circuit has a low THD.

Thank you very much

regards winate

Use a program that designs prints.

Can I share a used program?

I would like to design a printed version without the use of cord.

I like that the circuit has a low THD.

Thank you very much

regards winate

I'm unsure if I understand you ...

Do you want to offer us something or do you need another pcb layout?

BR, Toni

Do you want to offer us something or do you need another pcb layout?

BR, Toni

SA2015 4 channel VMOS

... testing the first amplifier module on the new heatsink ...

+/- 50V regulated power supply, VAS diode and SOA protection in situ, bias 250mA

THD+N 20k@105W@8R: 0.0026% (bw 80k)

THD+N 20k@200W@4R: 0.0068% (bw 80k)

SNR referred to full power:

BR, Toni

... testing the first amplifier module on the new heatsink ...

+/- 50V regulated power supply, VAS diode and SOA protection in situ, bias 250mA

THD+N 20k@105W@8R: 0.0026% (bw 80k)

THD+N 20k@200W@4R: 0.0068% (bw 80k)

SNR referred to full power:

- 121 dB A-w

- 117 dB bw 20k

- 113 dB bw. 80k

- 107 dB wb

- 25 uV A-w

- 39 uV bw. 20k

- 62 uV bw. 80k

- 137 uV wb

BR, Toni

Attachments

Last edited:

- Home

- Amplifiers

- Solid State

- 2stageEF high performance class AB power amp / 200W8R / 400W4R