I should drop a pair of TC9FD's in and have a listen - except that the drivers are soldered on in this case so it's not a simple swap out the drivers by disconnecting the FASTONs.

I'm not sure i'm on your expertise level on this one, but i'm not sure i understand why a pure sinewave sweeptone can help in regards to transients (and thus the capacity to render lots of information at the same time) analysis....isn't a sinewave the actual opposite of a transient? Moreover, at this level of cone break-up, i would guess all sorts of weird erratic behavior (dampening,resonance,interference,etc) happens and a manufacturer just wants to do«damage control» and make as flat and natural as possible as frequency gets higher....?

A high slew rate transient is composed of a sum of higher frequency sine waves, according to Fourier transform theory. A perfect square wave requires infinite number of frequency components.

I should drop a pair of TC9FD's in and have a listen - except that the drivers are soldered on in this case so it's not a simple swap out the drivers by disconnecting the FASTONs.

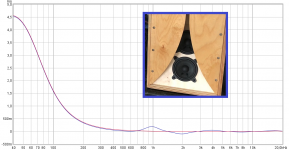

If on subjective front is happy as is maybe let it be 🙂 on objective front will imagine there is more to sensed psycho acoustics than ampltude curves from manufactor datasheets on its own, for example when that driver array sit behind such slit can't imagine first wavefront is a super clean replica of a supposed minimum phase domain, probably some difraction and out of time reflected waves is in that first wavefront as simulated below in blue trace verse the red trace which is a correct minimum phase group delay had driver sat in front. Will guess what we hear is in the charts somewhere but hidden deeply so we have to zoom in and trick with filtered windows plus smoothing and look into other charts than the usual frq response.

Attachments

Last edited:

There's been some recent interest in this speaker using the passive crossover. I have been contacted numerous times by many people about this speaker and this crossover.

To make it easier for folks in the US ordering from PE, here are the equivalent PE part numbers to make this XO using much higher quality and higher watts rated resistors than what I used. BOM is about $25 per speaker in parts. These are Parts Express part #'s.

C1a = 027-354 50uF bipolar electrolytic

paralleled with

C1b = 269-304 6.8uF bipolar electrolytic

C3= 027-216 2.2uF 250v Dayton Precision Audio cap

Put all above in parallel for the tweeter/mid

R1 = 004-5.1 5.1ohm 10W Dayton Precision Audio resistor

(adjust R1 to taste to increase or decrease treble)

R2 = 004-5.1 5.1ohm 10W Dayton Precision Audio resistor

Use same 2.2uF cap for the Zobel (parallel to tweeter/mid with 10R in series):

C2 = 027-216 2.2uF 250v Dayton Precision Audio cap $2.79ea

R3 = 004-10 10ohm 10W Dayton Precision Audio resistor

Use two of these in series for L1 = 269-2128 2mH ferrite core inductor (buyout item so limited stock)

R4 = 004-1 1ohm 10W Dayton Precision Audio resistor

Also a note, this XO has been tested to work well with:

FF85WK

10F/8424

PS95-8

TC9FD

TG9FD (8ohm)

Just adjust R1 (decrease for lower sensitivity drivers - relative to 88dB).

Don't forget to mount fullrange underneath the woofer for proper time alignment.

can R1 be replaced by L-pad to control the volume of full range driver?

i am planning to use the one available below,

DAP Speaker L-Pad Attenuator 100W Mono 3/8" Shaft 8 Ohm

there is no mention of range of resistance it offers to vary. hope its compatible with your xover ckt

DAP Speaker L-Pad Attenuator 100W Mono 3/8" Shaft 8 Ohm

there is no mention of range of resistance it offers to vary. hope its compatible with your xover ckt

i beleive the xover ckt in #810 will be valid of dayton ps-95-8 full range still?

in above ckt, i see R5 and C3 are extra components for RS225-8

in above ckt, i see R5 and C3 are extra components for RS225-8

i am planning to use the one available below,

DAP Speaker L-Pad Attenuator 100W Mono 3/8" Shaft 8 Ohm

there is no mention of range of resistance it offers to vary. hope its compatible with your xover ckt

Hard to say if it will work. You may be better off putting in maybe 2 different values ("Normal" & "Bright") using say nominal ~5ohm for normal and ~2ohm for bright, and use a good quality 10amp SPDT toggle switch to effect changes. This will be much cleaner than a pot wiper, IMO.

i beleive the xover ckt in #810 will be valid of dayton ps-95-8 full range still?

in above ckt, i see R5 and C3 are extra components for RS225-8

Yes, I have tried with PS95-8 and it works well. The R5 and C3 were added later on and significantly reduces the muddiness caused by the 7kHz cone breakup of the woofer. Sounds much better with this simple filter added to RS225. Use two 2.2uF film caps in parallel and put in series with 0.47R 10W resistor and strap that across speaker terminals.

Last edited:

Hi X -

I've started a build of your design, pretty much identical to your latest version and with a pentagonal pyramid dagger. So far the dagger will be of 1/4" ply, the vertices 5" at the bottom, sides extending to nearly touch the back of the cabinet (~11.25"). Will start with TC9FD, which I already have, then optionally upgrade to 10f/8424 later.

Is it your opinion that for the dagger larger is better, within the constraints of the cabinet? Also curious if you simply glue the triangles together, finish the interior with felt and batting, then just glue it to the baffle? What glue or glues have you used? I'm thinking a bit of metal flashing around the base after gluing would provide additional stability, perhaps aluminum tape.

Anyway, I'm pretty excited to get this done and working. Have always wanted a proper 1st-order xover speaker, and I think yours looks so well developed. Thanks for sharing this so freely.

Cam

I've started a build of your design, pretty much identical to your latest version and with a pentagonal pyramid dagger. So far the dagger will be of 1/4" ply, the vertices 5" at the bottom, sides extending to nearly touch the back of the cabinet (~11.25"). Will start with TC9FD, which I already have, then optionally upgrade to 10f/8424 later.

Is it your opinion that for the dagger larger is better, within the constraints of the cabinet? Also curious if you simply glue the triangles together, finish the interior with felt and batting, then just glue it to the baffle? What glue or glues have you used? I'm thinking a bit of metal flashing around the base after gluing would provide additional stability, perhaps aluminum tape.

Anyway, I'm pretty excited to get this done and working. Have always wanted a proper 1st-order xover speaker, and I think yours looks so well developed. Thanks for sharing this so freely.

Cam

My cabinet maker uses Titebond to glue the dagger together and then uses Titebond to glue that to the back of the baffle. Don’t forget to add round overs on back of driver cutout for air flow. I cover the first 3in of the inside of Dagger with felt and stuff polyfill or fiberglass in Dagger progressively looser towards driver. I cover the outside of Dagger with mass loaded butyl rubber car door panel sound absorber sheets. This reduces the bell ringing of the Dagger. Make sure it is airtight from main chamber. You can check by pushing in on woofer and fullrange cone should not move.

Good luck!

Good luck!

Dagger Construction

Thanks! Gluing 5 triangles together to make a neat pyramid assembly looks like a bit of a crafter's challenge. I can see ending up with a pretty wonky dagger without some clever planning and execution, not that it needs to be particularly pretty, but necessarily airtight. I'm thinking Titebond Quick and Thick should make it fairly easy to set the triangles together one-by-one, and hope to end with well-proportioned base. And I'll go with something close to 5" sides, making a base that encompasses a 6.8" circle. Then of course finish it off with felt and stuffing inside, Noico outside.

Also thinking that Velcro is the way to go for mounting the crossover board. I intend to keep it easily removable. Will decrease padding for the TC9FD, which I plan to mount in a round rebate designed for the 10f/8424. I'll do almost anything to avoid routing specifically for that weird squared circle frame - way too finicky to get a really nice recess.

Cam

Thanks! Gluing 5 triangles together to make a neat pyramid assembly looks like a bit of a crafter's challenge. I can see ending up with a pretty wonky dagger without some clever planning and execution, not that it needs to be particularly pretty, but necessarily airtight. I'm thinking Titebond Quick and Thick should make it fairly easy to set the triangles together one-by-one, and hope to end with well-proportioned base. And I'll go with something close to 5" sides, making a base that encompasses a 6.8" circle. Then of course finish it off with felt and stuffing inside, Noico outside.

Also thinking that Velcro is the way to go for mounting the crossover board. I intend to keep it easily removable. Will decrease padding for the TC9FD, which I plan to mount in a round rebate designed for the 10f/8424. I'll do almost anything to avoid routing specifically for that weird squared circle frame - way too finicky to get a really nice recess.

Cam

With really thin material like 1/8in or 3/16in ply I would not bother cutting angles on the Dagger. Just tack with hot melt and use Titebond to secure. The add another bead of Titebond to seal any holes.

hi xrk,

if i want to add a subwoofer to this which one you would suggest?

i am planning on a sealed tarkus bottom box which uses peerless 830668 10" woofer.

if i want to add a subwoofer to this which one you would suggest?

i am planning on a sealed tarkus bottom box which uses peerless 830668 10" woofer.

Just buy a $90 Polk PSW10 with built in plate amp and XO. Unbelievable value and sounds quite nice. It’s vented but you may not notice. If you want to DIY a sealed sub, you will need maybe a larger diameter and more power. I have tested this particular model and it works very well. Use it’s built-in plate amp with XO and adjust to taste - circa below 80Hz, maybe 60Hz even. It brings up the bottom end of a FAST system nicely.

Last edited:

A No-cut Dagger?

X -

Not sure how one might "not cut angles" in ply to make a dagger. Something like soft foamboard could be bent into a cone, I suppose, or a thin, stiff material could be scored and bent into a pyramid. I've got some nice 1/4 ply to cut into 5"x12" equilateral triangles to make a pentagonal pyramid, much like the one you showed in your latest assembly.

Am I missing something?

Cam

X -

Not sure how one might "not cut angles" in ply to make a dagger. Something like soft foamboard could be bent into a cone, I suppose, or a thin, stiff material could be scored and bent into a pyramid. I've got some nice 1/4 ply to cut into 5"x12" equilateral triangles to make a pentagonal pyramid, much like the one you showed in your latest assembly.

Am I missing something?

Cam

I meant the two compound-bevel angles of 36 deg on each tall side to allow the edges to fit together flush. Of course, the outline of each panel is a tall isosceles triangle.

A playground hard rubber athletic marker cone/pylon works well too as mentioned earlier in this thread.

A playground hard rubber athletic marker cone/pylon works well too as mentioned earlier in this thread.

Right! Got it. And yes, isosceles, not equilateral.

I decided to not deal with a bright orange plastic thing in the nice birch-ply box. Esthetics.

I decided to not deal with a bright orange plastic thing in the nice birch-ply box. Esthetics.

It's hidden on inside of cabinet. If it matters, spray paint the orange cone with black paint. 🙂a bright orange plastic thing in the nice birch-ply box

- Home

- Loudspeakers

- Full Range

- 10F/8424 & RS225-8 FAST / WAW Ref Monitor