Hello All,

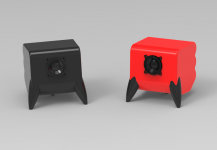

I have some 3Fe25 that i will use as simple PC speakers, Daily radio and Youtube.

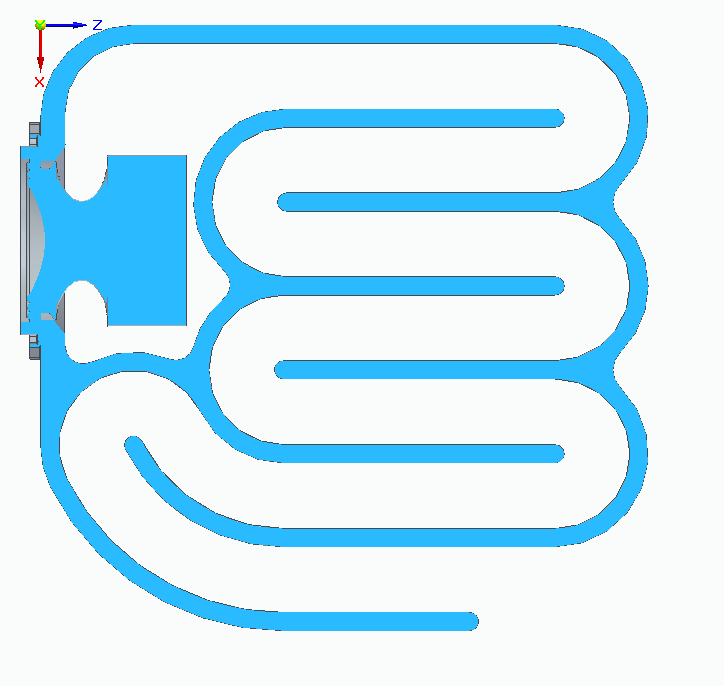

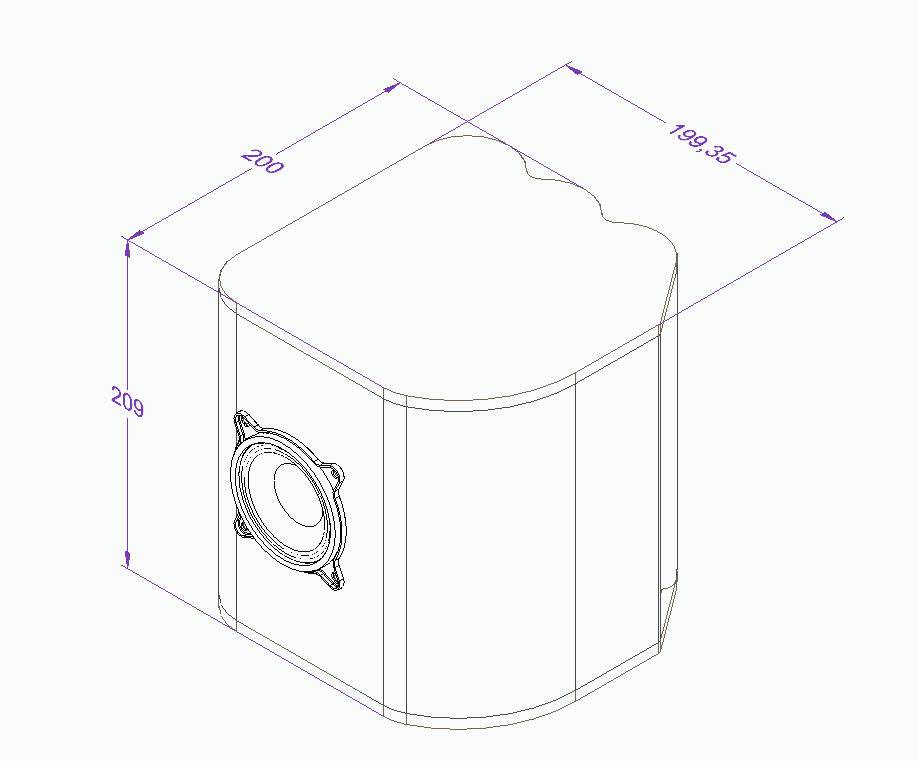

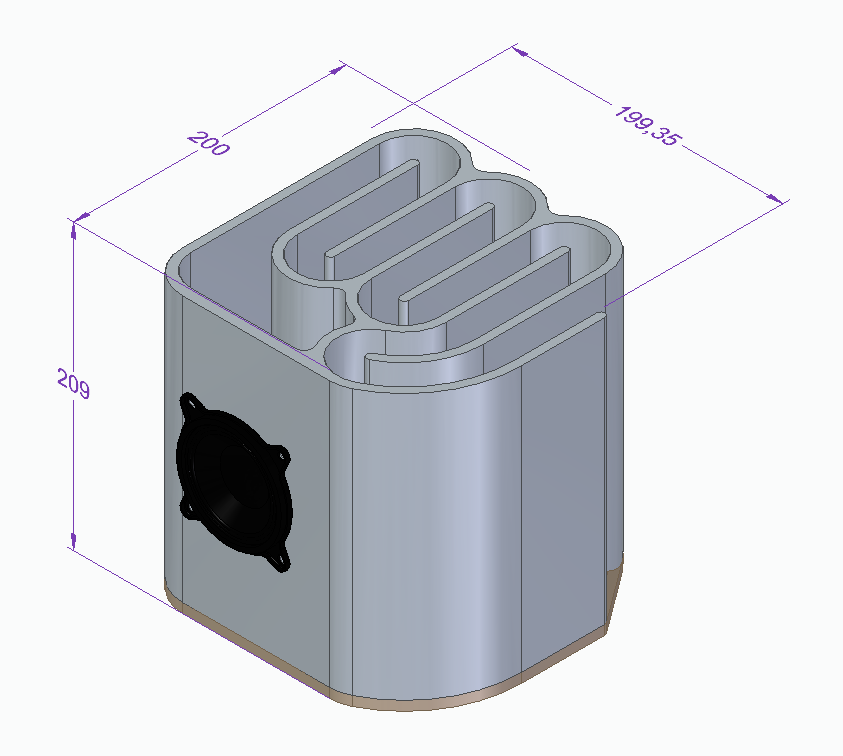

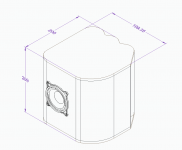

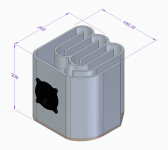

The design will look like this. The horn / tranmission line is a constant Area of 40cm2 for about 100cm.

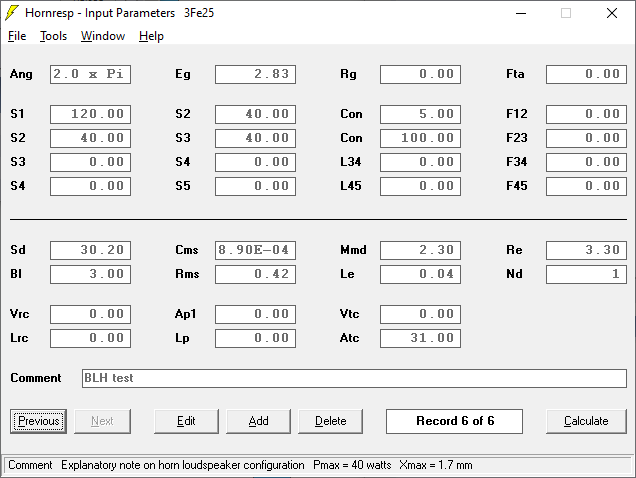

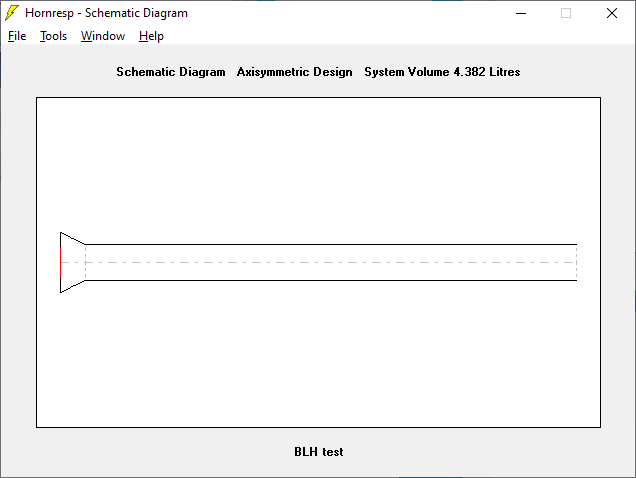

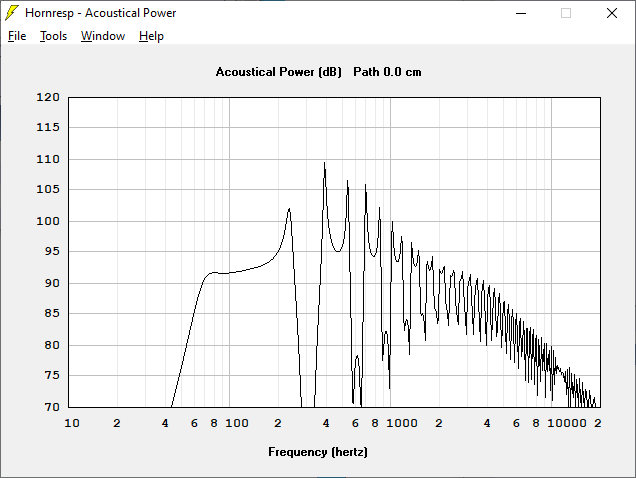

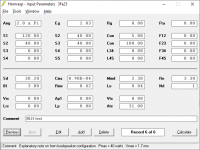

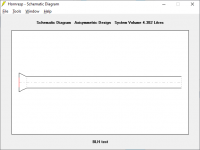

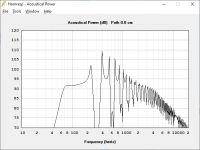

What is the proper way to simulate this? I did some test with Hornsesp but im not sure i do it correctly.

It will be 3d printed so the goal is to have it within 200x200x200 mm. Wallthickness is 6mm, but 8mm where the driver gets mounted.

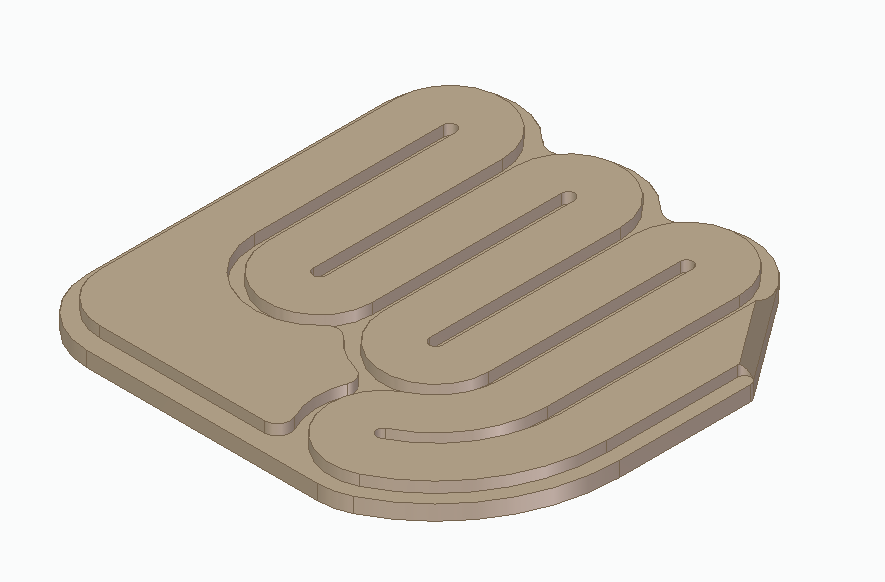

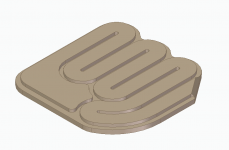

The top and bottom will be 12mm MDF or Plywood with a milled slot to make it air tight when i glue it together with the 3d printed part.

I have some 3Fe25 that i will use as simple PC speakers, Daily radio and Youtube.

The design will look like this. The horn / tranmission line is a constant Area of 40cm2 for about 100cm.

What is the proper way to simulate this? I did some test with Hornsesp but im not sure i do it correctly.

It will be 3d printed so the goal is to have it within 200x200x200 mm. Wallthickness is 6mm, but 8mm where the driver gets mounted.

The top and bottom will be 12mm MDF or Plywood with a milled slot to make it air tight when i glue it together with the 3d printed part.

Attachments

-

Annotation 2019-09-14 173753.png18.6 KB · Views: 935

Annotation 2019-09-14 173753.png18.6 KB · Views: 935 -

Annotation 2019-09-14 174008.png12.9 KB · Views: 912

Annotation 2019-09-14 174008.png12.9 KB · Views: 912 -

Annotation 2019-09-14 174038.png6.8 KB · Views: 909

Annotation 2019-09-14 174038.png6.8 KB · Views: 909 -

Annotation 2019-09-14 174100.png13.3 KB · Views: 913

Annotation 2019-09-14 174100.png13.3 KB · Views: 913 -

Annotation 2019-09-14 174830.png16.9 KB · Views: 921

Annotation 2019-09-14 174830.png16.9 KB · Views: 921 -

Annotation 2019-09-14 175117.png53.9 KB · Views: 914

Annotation 2019-09-14 175117.png53.9 KB · Views: 914 -

Annotation 2019-09-14 175555.png29.8 KB · Views: 910

Annotation 2019-09-14 175555.png29.8 KB · Views: 910

Seems needlessly complex for a desktop speaker, but maybe that's just me?

jeff

You are probably right, but the hands on build time will probably be less than an hour. I have a lot of time on the road with my computer which gives me the time to over do it i suppose.

I will print a template for a hand router so the milling will only take some minutes when all is printed and done.

So far it's just a concept so i'm pretty open for ideas!

The driver should be offset from the end of the line to cancel the 1st unwanted harmonic. This means less damping needed and more bass.

Look at the Woden Baby Labs which are topologically similar, but have a taper to reduce the needed length.

Woden Design 3" Box Designs, BabyLabs & more

dave

Look at the Woden Baby Labs which are topologically similar, but have a taper to reduce the needed length.

Woden Design 3" Box Designs, BabyLabs & more

dave

YouTuber Hexibase 3d printed a similar enclosure Here.

Yes i saw that, and since i have a printer and the speakers avaliable i started doing my own. Question now is how to optimize them since my Hornresp knowledge is limited.

Now i'm playing around thinking how they would look like on a desk with some legs.

Ideas are welcome! I will share the printer files if anyone is interested

Attachments

Neat. I will do some reading on how to offset the driver in hornresp. I am limited to about 5 liter in horn volume.The driver should be offset from the end of the line to cancel the 1st unwanted harmonic. This means less damping needed and more bass.

Look at the Woden Baby Labs which are topologically similar, but have a taper to reduce the needed length.

Woden Design 3" Box Designs, BabyLabs & more

dave

It is not a horn, it is a TL. Optimal vented volume is about 2.5 litre, you might not have enuff volume for a TL with only 5 litres.

dave

dave

The driver should be offset from the end of the line to cancel the 1st unwanted harmonic. This means less damping needed and more bass.

Which will offset the extra damping required due to all those lovely round corners allowing excessive mids/HF to exit the pipe, comb filtering with the driver's output. 🙁

GM

Now i'm playing around thinking how they would look like on a desk with some legs.

I like your original concept better. You just need to model the line again.

jeff

I could make the insides with irregular pyramids or any other shapes if that would help?Which will offset the extra damping required due to all those lovely round corners allowing excessive mids/HF to exit the pipe, comb filtering with the driver's output. 🙁

GM

All you need do is have sharp corners/u-turns instead of nicely rounded, like Fostex or similar designs. If you want the exterior rounded, then make it a separate shell and fill the gaps with something massive such as sand as it ideally needs to be well damped/heavy.

Also, mouth should terminate on the baffle with the driver.

GM

Also, mouth should terminate on the baffle with the driver.

GM

All you need do is have sharp corners/u-turns instead of nicely rounded, like Fostex or similar designs. If you want the exterior rounded, then make it a separate shell and fill the gaps with something massive such as sand as it ideally needs to be well damped/heavy.

Also, mouth should terminate on the baffle with the driver.

GM

The exterior will just be a result of the interior in this case. The aesthetic can be solved later. The reason for sharp corners as you say, if I understand correctly, is so the high and mid frequencys from the back of the speaker don't bounce straight out the mouth of the horn?

About the mouth of the horn to end on the same baffle as the driver, are you referring to a BLH? How do you add where the mouth is positioned relative to the driver in hornresp?

The reason for sharp corners as you say, if I understand correctly, is so the high and mid frequencys from the back of the speaker don't bounce straight out the mouth of the horn?

A little of thta maybe, but primarily the “square” bends create an expansion in the line which is a low pass filter.

dave

A little of thta maybe, but primarily the “square” bends create an expansion in the line which is a low pass filter.

dave

For a BLH, is that something that is possible to simulate in Hornresp?

Also, is it the same for a TL?

Not really.

Yes, you only want smooth corners when wanting as much HF through as practical, such as a FLH. That said, a reactance annulled BLH performs as a FLH, so in some apps may need to be as smooth as a folded FLH.

GM

Yes, you only want smooth corners when wanting as much HF through as practical, such as a FLH. That said, a reactance annulled BLH performs as a FLH, so in some apps may need to be as smooth as a folded FLH.

GM

For a BLH, is that something that is possible to simulate in Hornresp?

Also, is it the same for a TL?

It can certainly be done in MJK MathCad.

Each bend looks like this when you unfold it:

dave

Attachments

Don't have mine loaded and didn't think to mention it since it's no longer available and most folks won't even try to use AkAbak.

Don't have mine loaded and didn't think to mention it since it's no longer available and most folks won't even try to use AkAbak.GM

oh, blimey, we should trade details 🙂

I'm doing exactly the same as you but for Dayton Audio PS95's

L̶a̶t̶e̶ ̶T̶h̶i̶r̶t̶i̶e̶s̶, Early Fourties, Tools, Electronics, Life – Been reading way too many maker blogs. Here's my contribution

I'm doing exactly the same as you but for Dayton Audio PS95's

L̶a̶t̶e̶ ̶T̶h̶i̶r̶t̶i̶e̶s̶, Early Fourties, Tools, Electronics, Life – Been reading way too many maker blogs. Here's my contribution

- Home

- Loudspeakers

- Full Range

- Desktop TL / BLH with 3Fe25