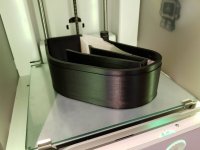

Ok so the long print went fine and all is good.

Except that I completely forgot why I made the original in two parts to begin with... I Can't mount the god damn driver!

Except that I completely forgot why I made the original in two parts to begin with... I Can't mount the god damn driver!

Last edited:

Ok so the long print went fine and all is good.

Except that I completely forgot why I made it in two parts to begin with... I Can't mount the god damn driver!

Epoxy the two halves together?

Hello, very nice project thanks for sharing.

Has a matter i have a pair of FE25 and a big enough 3D printer and thanks to the COVID-19 a bit of time in front of me.

I want to give a shot to it but with some twist to be able for example to include some low end driver in the future, and to have a removable front panel instead of splitting the enclosure in two.

What part of the design can i twist and what should remain the same ? The internal volume, the section, the overall shape ?

Thanks for your help.

Best regards,

Anthony

Has a matter i have a pair of FE25 and a big enough 3D printer and thanks to the COVID-19 a bit of time in front of me.

I want to give a shot to it but with some twist to be able for example to include some low end driver in the future, and to have a removable front panel instead of splitting the enclosure in two.

What part of the design can i twist and what should remain the same ? The internal volume, the section, the overall shape ?

Thanks for your help.

Best regards,

Anthony

Do you plan to 3d print as well? Or the combination?Hello, very nice project thanks for sharing.

Has a matter i have a pair of FE25 and a big enough 3D printer and thanks to the COVID-19 a bit of time in front of me.

I want to give a shot to it but with some twist to be able for example to include some low end driver in the future, and to have a removable front panel instead of splitting the enclosure in two.

What part of the design can i twist and what should remain the same ? The internal volume, the section, the overall shape ?

Thanks for your help.

Best regards,

Anthony

I can make the front removable if you wish. Or give the side mount version a proper solution.

Hello,

I want to 3D print it has well (just waiting for a .8mm nozzle), the wooden side are really nice and i would probably have went that way if i still had my CNC router, unfortunately i moved and it had to go.

Thanks for your proposal, but i have plenty of time to do it considering the actual situation in France, and your step file will be a huge help.

I will share mine once i reach a satisfactory result but i do have a silly idea...

I was looking at cura's setting the other days, especially the infill, i was searching for something open enough so i could fill the inside of the walls with sand to damp the resonances.

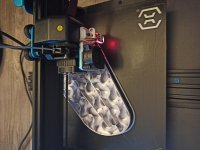

The gyroid made sense in that regard, so i print a couple of test pieces including a cube with very skinny walls. It is not so clean but wow the strength of that thing is unbelievable.

One thing leading to another I'm now thinking to fill the inside of the box with with a gyroid like structure just to see if it will affect the speakers response.

If this work the end goal is some descent small sub to go with it, if not well not a all lot of loses and still a fun project.

I want to 3D print it has well (just waiting for a .8mm nozzle), the wooden side are really nice and i would probably have went that way if i still had my CNC router, unfortunately i moved and it had to go.

Thanks for your proposal, but i have plenty of time to do it considering the actual situation in France, and your step file will be a huge help.

I will share mine once i reach a satisfactory result but i do have a silly idea...

I was looking at cura's setting the other days, especially the infill, i was searching for something open enough so i could fill the inside of the walls with sand to damp the resonances.

The gyroid made sense in that regard, so i print a couple of test pieces including a cube with very skinny walls. It is not so clean but wow the strength of that thing is unbelievable.

One thing leading to another I'm now thinking to fill the inside of the box with with a gyroid like structure just to see if it will affect the speakers response.

An externally hosted image should be here but it was not working when we last tested it.

If this work the end goal is some descent small sub to go with it, if not well not a all lot of loses and still a fun project.

When you 3D print a solid you can choose level of infill porosity. Something like 8% infill density might have similar effect as this wavy matrix stuff (which is very cool). You can basically print custom shaped internal damping instead of using stuffing. Plus, the box will be very rigid and not resonate.

That's the goal, i have tried to do that with the slicer with two 3d models, one for the box and one for the inside, using infill for the inner volume but the result is not so great. So i will just draw the gyroid pattern in cad before hand and slice it.

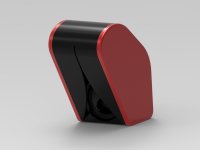

I modified the "sandwich" version to make the driver mountable from the back. The support filamet in the narrow opening is hard to remove without leaving tool marks so i will try to print with PVA as support, which is solvable in water and allows you to make "impossible" geometries. It is a little over kill for this, but since i have it, why not use it?

Attachments

Nice, I think an internal mesh like that will be the way to go forward with 3D printed cabinets. Then your can really take advantage of volume, reinforcement and eliminate internal standing waves!

Last edited by a moderator:

YouTuber Hexibase 3d printed a similar enclosure Here.

Dont suppose you guys saw the latest "worlds smallest transmission line" video from Hexibase?

YouTube

i know it starts some interesting conversations about peoples take on what is a TL. Made me want to build this thing, but didnt have the tectonics used, only the TEBM35's.

The PLA did not stick enough to the PVA, causing wrapping and eventually the head got stuck and misaligned itself...

View attachment 829284

View attachment 829285

thats the problem with the 3d printing enclosures...having an ender 3, it is slower than the one you are using, so doing a Hexibase inspired design was looking at 30hours per side and half was through looked like it got misaligned...real roll of the dice with what you get out of it 🙁

Dont suppose you guys saw the latest "worlds smallest transmission line" video from Hexibase?

Some decided inaccuracies there, and i wonder how he deisgned the TL, it kinda looks out to lunch/ His modeled response is good for such a small driver.

And it is far from the smallest TL, those would be in the ones used for tweeters.

dave

thats the problem with the 3d printing enclosures...having an ender 3, it is slower than the one you are using, so doing a Hexibase inspired design was looking at 30hours per side and half was through looked like it got misaligned...real roll of the dice with what you get out of it 🙁

Try upgrading to the dual gear extrusion, you can get from 9cm³ to 15cm³/min, worth the 20 bucks on aliexpress

- Home

- Loudspeakers

- Full Range

- Desktop TL / BLH with 3Fe25