Be extremely careful when there is an audio signal connected to the pcb. The output voltage from the upper two transformers is high enough to kill you! So never connect it to an amplifier while measuring. Keep the mains disconnected as well while you're measuring. There is no isolation transformer so the whole thing is live when connected to the mains.

Your last post didn't get translated and my Italian is, how to put it, pretty poor.

Your last post didn't get translated and my Italian is, how to put it, pretty poor.

Ooops 🙂 I didn't notice...

here's what I was saying:

don't you see something strange in the two cards?

in the burned resistor area...

here's what I was saying:

don't you see something strange in the two cards?

in the burned resistor area...

Indeed! Good for you spotting the difference. 👍

The bottom PCB was not assembled correctly. The center tap on the boost transformer was not connected!

Looks like maudio is giving you great advice on the repairs and improvements to your ES300s.

For reference, here are links to the pictures for the ES200RS and ES300 that were used to create the schematics that maudio posted.

https://www.diyaudio.com/community/threads/rusty-transformer-metallaminations.329849/post-5603385

https://www.diyaudio.com/community/...actually-effect-the-sound.312114/post-5181583

The bottom PCB was not assembled correctly. The center tap on the boost transformer was not connected!

Looks like maudio is giving you great advice on the repairs and improvements to your ES300s.

For reference, here are links to the pictures for the ES200RS and ES300 that were used to create the schematics that maudio posted.

https://www.diyaudio.com/community/threads/rusty-transformer-metallaminations.329849/post-5603385

https://www.diyaudio.com/community/...actually-effect-the-sound.312114/post-5181583

Here is a schematic of a later ES200RS model, the later 300RS is identical afaik. I also include a schematic of an older one of an ES300, don't know what version.

If it is only one cap to replace, you can change that without taking off the whole PCB. It's fiddly but dodable, use a small mirror. It's even possible to change all diodes and caps on the HV supply that way but it's a time consuming way to do it.

View attachment 1471792View attachment 1471813

I see, resistor connected to the other terminal of the mirror drive transformer. How strange. Was there even a resistor on that other pcb?

But then again these speakers are from a very early production era in which many modifications were being tested. Could it be the mirror drive transformer on the other pcb is wired differently. Check visually or with your multimeter which pins are used. The resistor should go to the pin that has two wires connected to it.

But then again these speakers are from a very early production era in which many modifications were being tested. Could it be the mirror drive transformer on the other pcb is wired differently. Check visually or with your multimeter which pins are used. The resistor should go to the pin that has two wires connected to it.

no resistance on the two boards. remember...the 3rd transformer was disconnected and the two tracks were disconnected. now you see them connected because I restored them this afternoon.

is the board in smoke that highlights the position of the burned resistance positioned correctly?

is the board in smoke that highlights the position of the burned resistance positioned correctly?

Yes, but measure both bottom transformers. Check resistance between all 4 pins.

With the tracks connected back up, you must install resistors otherwise it can't work properly

With the tracks connected back up, you must install resistors otherwise it can't work properly

here are the measurements performed today on the 3rd transform:

same values for the other one too.

Code:

| |

0.82

| |

0.67same values for the other one too.

ok, the burnt resistor that is not present was connected in the correct position. (at 3 on the board)

what value does this resistor have? 0.8?

why is it burnt?

what value does this resistor have? 0.8?

why is it burnt?

You measured the transformer only horizontally. Measure also vertically. It's only one winding on this one, not two.

The value of the resistor is unknown... It is parts of a crossover network. So it depends on the value of the other components as well: the capacitor(s) and other resistors if present.

Use the other schematics as a reference. In my old es200 it's 5.6 ohms with a 47uf cap. The es200rs schematic posted above uses 27uf and 3.3ohm. with 68uf in series with the resistor.

You'll have to experiment a bit. Order a few resistors, say 3.3, 5.6 and 8.2 ohm. Try how it sounds or measures, and adjust when needed. You may have to change the value of the capacitor as well. There are four in parallel so it's easy to remove one or two to try it out.

The resistor should be rated at least 5, better 10 watt.

Another option is to modify the interface to something like the es200rs schematic. That is a proven concept.

The value of the resistor is unknown... It is parts of a crossover network. So it depends on the value of the other components as well: the capacitor(s) and other resistors if present.

Use the other schematics as a reference. In my old es200 it's 5.6 ohms with a 47uf cap. The es200rs schematic posted above uses 27uf and 3.3ohm. with 68uf in series with the resistor.

You'll have to experiment a bit. Order a few resistors, say 3.3, 5.6 and 8.2 ohm. Try how it sounds or measures, and adjust when needed. You may have to change the value of the capacitor as well. There are four in parallel so it's easy to remove one or two to try it out.

The resistor should be rated at least 5, better 10 watt.

Another option is to modify the interface to something like the es200rs schematic. That is a proven concept.

ok, I also measure the 3 vertically. in this post https://www.diyaudio.com/community/...actually-effect-the-sound.312114/post-5181583 you can see two green resistors and on one of the two boards I have one just like those - measured is 0.79. anyway the problem of the resistors is quickly solved, I have several of these 5 and 10W types to do some tests, but the problem is that for the tests it is not so simple if every time you have to resolder the board on the three transformers. there is another thing that is not very clear - the addition of the capacitor in series on the "burned" resistor should be placed before or after?

Indeed! Good for you spotting the difference. 👍

The bottom PCB was not assembled correctly. The center tap on the boost transformer was not connected!

Looks like maudio is giving you great advice on the repairs and improvements to your ES300s.

For reference, here are links to the pictures for the ES200RS and ES300 that were used to create the schematics that maudio posted.

https://www.diyaudio.com/community/threads/rusty-transformer-metallaminations.329849/post-5603385

https://www.diyaudio.com/community/...actually-effect-the-sound.312114/post-5181583

Without the help of - maudio - and all of you, I would now be at sea without a compass.

🙂

Hold on a minute.... We first need to figure out what's going on around your mirror drive transformers. Something strange there. The measurements you posted above indicate that all 4 pins of the transformer are used, that's weird. We also have the resistor going to the wrong pad on one of the PCB which is suspicious, I cannot believe the speakers have been around for 30 years without anyone noticing something is wrong. And since this is a speaker from a very early stage of production, we can not rule out that your mirror drive transformers are different from the later ones and we need to know that.

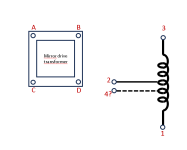

See picture below. The mirror drive will have one winding with a tap somewhere in the middle. It could be possible that yours has even two taps, being from the experimental era... Or that two pins are simply connected together. We need to find out which of the pins A-B-C-D of the transformer correspond with 1-2-3-4 of the coil.

I assume your access to test equipment is limited so we will try to use your LCR meter to find out. The winding will have a very low resisitance, my guess is <1 ohm for the whole winding. But I guess it should be possible to figure it out with the meter on the 20 ohm range. Measuring very low values with your meter will not give high accuracy but it will do.

Start by removing one leg of the big green 0.68ohm resistor from the PCB. If f you already put a new resistor in place of the burned one, remove that as well. This disconnects the transformer from the rest of the circuit, necessary to get a good reading that is not disturbed by other components on the pcb.

Next connect both meter probes together to do a zero reading. It will not show zero but a very low value, this is the resistance of your test leads. Write that down. You have to subtract this value from all following measurements to compensate for the error caused by the test lead resistance.

Now start probing all 4 transformer pins. Between 1 and 3 you will find the highest resistance reading. That tells you what transformer connections go to the ends of the winding. Between those pins and the pins connected to the tap(s), you will find lower readings. The sum of the readings between the end points and the taps should match the reading of the whole winding, at least more or less. If there are two taps, you should be able to determine that too. Two interconnected pins will show zero ohm (after you compensated for the test lead resistance).

See picture below. The mirror drive will have one winding with a tap somewhere in the middle. It could be possible that yours has even two taps, being from the experimental era... Or that two pins are simply connected together. We need to find out which of the pins A-B-C-D of the transformer correspond with 1-2-3-4 of the coil.

I assume your access to test equipment is limited so we will try to use your LCR meter to find out. The winding will have a very low resisitance, my guess is <1 ohm for the whole winding. But I guess it should be possible to figure it out with the meter on the 20 ohm range. Measuring very low values with your meter will not give high accuracy but it will do.

Start by removing one leg of the big green 0.68ohm resistor from the PCB. If f you already put a new resistor in place of the burned one, remove that as well. This disconnects the transformer from the rest of the circuit, necessary to get a good reading that is not disturbed by other components on the pcb.

Next connect both meter probes together to do a zero reading. It will not show zero but a very low value, this is the resistance of your test leads. Write that down. You have to subtract this value from all following measurements to compensate for the error caused by the test lead resistance.

Now start probing all 4 transformer pins. Between 1 and 3 you will find the highest resistance reading. That tells you what transformer connections go to the ends of the winding. Between those pins and the pins connected to the tap(s), you will find lower readings. The sum of the readings between the end points and the taps should match the reading of the whole winding, at least more or less. If there are two taps, you should be able to determine that too. Two interconnected pins will show zero ohm (after you compensated for the test lead resistance).

rereading everything, I focused on the particular topic #topic suggested and I saw how the board is fixed with screws, instead of soldering it directly on the transformer pins. so now I'm considering arranging the fixing in the same way and therefore also the possibility of performing audio tests with different resistance values.

idit - ops 🙂

idit - ops 🙂

the card/cards i removed yesterday are still bare, i have not added anything, nor removed anything. i have only restored the tracks that someone decided to break.

edit:

Maybe you missed a detail on the boards. It's true that you can see on one that the resistor was positioned incorrectly, but when I removed them there was no resistor on the boards, neither the burned one nor the other one - the one that was supposedly connected incorrectly.

edit:

Maybe you missed a detail on the boards. It's true that you can see on one that the resistor was positioned incorrectly, but when I removed them there was no resistor on the boards, neither the burned one nor the other one - the one that was supposedly connected incorrectly.

for the final and decisive measurements, no problem - not today though because I can't. but the boards that I removed yesterday, including the current wire and the plastic box, I took them to the studio to think about the connections better. here are the two boards that you already saw yesterday on the side of the tracks. that's how they looked and I didn't add or remove anything.

I focused on the particular topic #topic

That topic is about my old es200 and yes, they used screws to secure the transformers on that speaker. It's the only Audiostatic that I've ever seen that uses screws here, none of the later ones have it. So I think they abandoned theidea in a very early stage, as being overcomplicated and not needed. The pcb is not very heavy and I've never seen cracked joints around the transformers so I think it is fine without screwing down al transformers.

Maybe you missed a detail on the boards. It's true that you can see on one that the resistor was positioned incorrectly, but when I removed them there was no resistor on the boards

I know. The absence of the resistors and the broken tracks indicate that your speakers were configured to work without the mirror drive system and yes, they work without it. In fact the cheaper Audiostatic models ES50 and ES100 don not have the mirror drive system either. So the mirror drive system is not required but it has a lot of advantages, so it would be nice to get it working again. Since you have the transformers on the PCB, that is the way the speakers were intented to work anyway.

I'll include the owners manual of a 200RS that contains a good explanation of how the mirror drive system works. It extends the low frequency reproduction, raises sensitivity and makes the speaker easier to drive by raising the impedance. All very are desirable things to have. It basically uses the autotransformer to gradually increase the stepup ratio from 1:150 to 1:300 under 300 Hz.

Without mirror drive, these speakers are very difficult to drive and you'll need a very good amplifier that can handle loads down to 2 or even 1.5 ohm. This alone is a good enough reason to restore it.

Getting it to work is not that difficult given the fact that the transformer is already present and the PCB is prepared for it. But we need to find out how your transformers are wired up and for that we need the measurements I asked about. If the PCB's are not mounted on the transformer yet, you can measure the transformers even more easily without the need for removing components from the pcb.

Attachments

To me it looks like one of the PCB's was replaced at some time. There are lots of differences in the screen print. And on the not-burned one, the HV supply section still has a hole present to accomodate a trim potentiometer to adjust the bias, although the potentiometer itself is not installed. The PCB's on my ES200 have this too and the trimpots are even present there. On later models, the potentiometers have disappeared completely.

So my guess is the not-burned one will be older then the other one. Not that it matters, both are perfectly useable.

So my guess is the not-burned one will be older then the other one. Not that it matters, both are perfectly useable.

I took the photos you just saw a little while ago, I have the cards in my hands so on Monday as soon as I go to the warehouse, I will proceed with the measurements you indicated. and then yes, I remember that on the T.3 / mirror there are two wires together, I don't remember which of the points, but yes.

for the fixing in fact I was thinking of using only three points.

and to carry out the tests, I will bring the transformer contacts with an extension of the wires. but this as soon as we can understand this blessed T.3 well 🙂

These cards are a program, you can see that they have done all sorts of things 🙂

for the fixing in fact I was thinking of using only three points.

and to carry out the tests, I will bring the transformer contacts with an extension of the wires. but this as soon as we can understand this blessed T.3 well 🙂

These cards are a program, you can see that they have done all sorts of things 🙂

the measurement of the green resistance is this:

reading - 0,80

dedot - 0,10 (LCR)

Green R = 0,70Ω

reading - 0,80

dedot - 0,10 (LCR)

Green R = 0,70Ω

non vedi qualcosa di strano nelle due schede?

nella zona della resistenza bruciata...

English please:

Don't you see something strange in the two tabs?

in the area of the burned resistance...

- Home

- Loudspeakers

- Planars & Exotics

- Audiostatic ES300