Steel is stronger than plywood, screws with pilot holes strengthen construction and are required to pull internal horn pieces and the outer shell together for an air-tight seal.Screws weakens construction; better to use glue blocks, Titebond 3 or similar, though if still wanting screws, then stagger them.

Glue blocks could be a good addition, but increase part count and build time.

OK, just responded to what was posted and a pity I no longer have access to all the various materials destruction testing I was involved in to prove my point and a bunch of others what with you adding in metal, hardware variables and while pilot holes is stronger than self tapping, both proved weaker than glue blocks in the various vibration/destruction testing our shipping crates had to meet.

So what are the guidelines , book, manual to read or videos to watch to get the most strongest panel bonds for high power subwoofer in 2024GM said: while pilot holes is stronger than self tapping, both proved weaker than glue blocks in the various vibration/destruction testing our shipping crates had to meet.

regardless if you spent more time building a PA sub cabinet.

and what is the NASA space Shuttle procedure to bond the wood pieces in order

for them to survive multiple orbital reentry from the Exosphere to the Troposphere

at least 6 times to qualify for the "Sub Cabinet Shuttle Program"

for them to survive multiple orbital reentry from the Exosphere to the Troposphere

at least 6 times to qualify for the "Sub Cabinet Shuttle Program"

Have look on West Systems site for an article on creating a monocoque body using ply and glass sandwich. They host a book from Gougen Bros that has details on engineering the strongest seams and joints, as well as stiffening panels and such. A cab about 15L done with 8mm marine grade ply and done by the book will be good for over 30kw reciprocating motor on the mount points or 'hard point'. The book and articles only explain the construction aspects. The other aspect is to engineer the structure of that box with load lines from the hard pointSo what are the guidelines , book, manual to read or videos to watch to get the most strongest panel bonds for high power subwoofer in 2024

regardless if you spent more time building a PA sub cabinet.

Not quite Shuttle sub territory, but as high-tech as it gets with standard home DIY. It's a shame that I can't find a driver for my Cub Sandwich project as I have ported the systems used in the book to an easier and less messy workflow by making use of further CAD modelling than hull programs allow replacing funky construction steps and areas by including CNC and printers

Ic, but 15L will not make it for a PA subs drivers

300 to 650 liters are more in the range of a PA subs cabinet

300 to 650 liters are more in the range of a PA subs cabinet

The 15L box would be the challenging one, it gets easier as the box gets larger, to an extant to around 2.4m length but then starts getting more difficult again as the size goes up. Due to implications with standard board size, scarfing and tabbing (in the book) of things like panels and frames/stringers. Horns are no problem. They are just like an inverted boat with the tapered shape on the inside. A box to hold an 18" sub will be good with 12mm ply and the process in the book. I can do it with ply down to 8mm, but I am used to working with this method. Ply is awesome when using this process. PVC foam is better in every way except for impact resistance, but Kevlar in the matrix will help with this. I do use foam for smaller, like the 8' rowing boat that I made, and 8mm ply for the 4.35m centre consoleIc, but 15L will not make it for a PA subs drivers

300 to 650 liters are more in the range of a PA subs cabinet

A ply sub design would need to be redone to accommodate the monocoque structurals and this process would add narrow trusses crossing each flat panel, turning it into a hi-hat over the pane. The hi-hat tabs in an alloy extrusion should be visualised here, with the tabs down on the panel and the tabs made up of fillets glassed in as per the book. These fillets also go on the seams and are again tabbed in by the glass. If one can model this well in their mind, then one can use that to design a horn or line where the internal partitions and panels double duty as such structurals

At one time, I serviced inflatables used by agencies in Au while I worked for the distributor. I learned a lot about making of these craft there an am fairly good at it now. While developing a SUP type low to the water powered skiff as the body for my amphibious go-kart, I experimented with using dowels as drop stitch analogues between large expenses of sheet material that are fairly close together. Will port that to the TL for the ZXI sub

Sounds very interesting, is there any literature about it? What about a keystone made of 12mm ply or an skhorn.

I wonder why that process is not widespread among the DIY community.

Is it overly expensive?

Or ten fold complicated over regular woodworking.

I wonder why that process is not widespread among the DIY community.

Is it overly expensive?

Or ten fold complicated over regular woodworking.

The gougen bros book and other material on the west systems website. Speakers may be associated with furniture, hence most haven’t looked for a better solution. But some manufacturers have. It doesn’t have to be glass skins and longitudinal grain wood skins works well to fix MDF and has been used for a long time by speaker manufacturers who try for a higher end cabinets. A skin fixed to a panel needs to stretch for the panel to bend. Engineered right, the skin is not stretching and the panel not bending!

Hello. i have some more noob questions 🙄

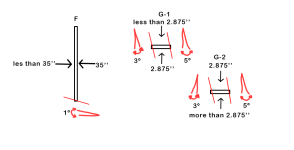

1- I'm confused about the G angles in particular. According to the plans in posts #478 and #487, I'm attaching an image with a question.

2- Does anyone have the plan in metric and for 18mm panels? I see that there are some versions but with errors.

3- Regarding drivers. The 18sw115 costs me €511, the 18sw100 €400, and the B&C 18TBX100 €277. Which one is more worthwhile in terms of performance/€? Is the SW115 worth the extra money or is it just a minor increase in volume? And between the SW100 and the TBX100? The frequency response, as I've read, is similar, but they differ more in final volume, right? Is there any other model to consider?

4- Regarding the choice of 4 ohm or 8 ohm speakers, is it a personal choice or is there a consensus as to which to choose? The disadvantage of 4 ohm is that it has lower quality (higher distortion)? Or are there some other differences?

many thanks.

1- I'm confused about the G angles in particular. According to the plans in posts #478 and #487, I'm attaching an image with a question.

2- Does anyone have the plan in metric and for 18mm panels? I see that there are some versions but with errors.

3- Regarding drivers. The 18sw115 costs me €511, the 18sw100 €400, and the B&C 18TBX100 €277. Which one is more worthwhile in terms of performance/€? Is the SW115 worth the extra money or is it just a minor increase in volume? And between the SW100 and the TBX100? The frequency response, as I've read, is similar, but they differ more in final volume, right? Is there any other model to consider?

4- Regarding the choice of 4 ohm or 8 ohm speakers, is it a personal choice or is there a consensus as to which to choose? The disadvantage of 4 ohm is that it has lower quality (higher distortion)? Or are there some other differences?

many thanks.

Attachments

i guess those topics have been discussed already in the thread , and all around the DIY forum,

regarding the divers....

is up to what you can afford

set up your money spending goal for your project

and then buy the drivers you can afford.

if you need more SPL... make more cabinets and add more amps

personally i spent dozens of hours simulating almost all kind of 18" and 15" drivers

in popular cabinets here inside HornResp

and concluded this :

what limits you from the the intangible computer sim screen

to the tangible real life of a finished sub cabinet(s) is:

DINERO (money)

regarding the divers....

is up to what you can afford

set up your money spending goal for your project

and then buy the drivers you can afford.

if you need more SPL... make more cabinets and add more amps

personally i spent dozens of hours simulating almost all kind of 18" and 15" drivers

in popular cabinets here inside HornResp

and concluded this :

what limits you from the the intangible computer sim screen

to the tangible real life of a finished sub cabinet(s) is:

DINERO (money)

The interesting midway is B&C 18TBW100-4 and RCF LF18X451.

The difference in output is there, and is usually more feasible than more bins, because of drivers, wood, work, transport, amps ...

4Ohm drivers often have more motor force. So if it doesn't get more expensive on the amp side, 4Ohm is better. Definitely at B&C.

The difference in output is there, and is usually more feasible than more bins, because of drivers, wood, work, transport, amps ...

4Ohm drivers often have more motor force. So if it doesn't get more expensive on the amp side, 4Ohm is better. Definitely at B&C.

NICE bracing!You can buy 3/4” x 3/4” x 6 foot pieces of hardwood at Home Depot for cheap.

Black is the 18TBW100... i miss the W in the chart below... Gezzzz.... too many hits on the PIPE!! lol !!The interesting midway is B&C 18TBW100-4 and RCF LF18X451.

The difference in output is there, and is usually more feasible than more bins, because of drivers, wood, work, transport, amps ...

4Ohm drivers often have more motor force. So if it doesn't get more expensive on the amp side, 4Ohm is better. Definitely at B&C.

The bottom of part "F" is 89 degrees.I'm confused about the G angles in particular. According to the plans in posts #478 and #487, I'm attaching an image with a question.

89 +1 =90 degrees, like a carpenter's square.

The front of "G" is a 5 degree angle, the back of "G" is 3 degrees as shown in post #478.

The bottom of part "F" is 89 degrees.

89 +1 =90 degrees, like a carpenter's square.

The front of "G" is a 5 degree angle, the back of "G" is 3 degrees as shown in post #478

so it's like this?

Not for the right side, 90-3=87 (not 93).so it's like this?

Read up on complementary and supplementary angles, angles that add up to 90 degrees and 180 degrees respectively.

When building, compare any angle cuts you make (use scrap wood..) to a full size drawing to confirm they are correct.

Draw the whole thing out, to scale, on a piece of 1/4” (or 1/8”) plywood. And save the template. Then you can check your angles as they come off the table saw, and for proper fit before assembly. And get the same measurements even years later when you make more.

Hello. i have some more noob questions 🙄

1- I'm confused about the G angles in particular. According to the plans in posts #478 and #487, I'm attaching an image with a question.

2- Does anyone have the plan in metric and for 18mm panels? I see that there are some versions but with errors.

3- Regarding drivers. The 18sw115 costs me €511, the 18sw100 €400, and the B&C 18TBX100 €277. Which one is more worthwhile in terms of performance/€? Is the SW115 worth the extra money or is it just a minor increase in volume? And between the SW100 and the TBX100? The frequency response, as I've read, is similar, but they differ more in final volume, right? Is there any other model to consider?

4- Regarding the choice of 4 ohm or 8 ohm speakers, is it a personal choice or is there a consensus as to which to choose? The disadvantage of 4 ohm is that it has lower quality (higher distortion)? Or are there some other differences?

many thanks.

Cut to all the angles mentioned. It's a little tedious, but it's correct. I would go with what @wg_ski said about making a template first.

With drivers, just bite the bullet and go with 18sw115. I understand that that's a lot of power, but most often they'll still outperform even if underpowered. I'm sending up to 4000W per 8 ohm driver and I tickle my amps with four subs. The B&C 18SW115 is an industry standard for high-end subs, so it'll have the tone you hear from the big manufacturers, but it'll have the depth and response of the tapped horn instead of distortion.

As far as Ohms.. I would say that depends on your goals. I went with 8 Ohm because I have two QSC PLD 4.5 amps that can supply 4000W bridged at 8 Ohms. They weren't able to do that for 4 Ohms with the way QSC does it on those. I'm kinda hating that now though because I'm going to be replacing with a Linea Research 44M20, which excels like most amps at 4 Ohms and 2 Ohms. So now I've got to upgrade the amp And eventually get 4 Ohm drivers for the most volume 🤦♂️. PS- if anyone wants some 18SW115 8 Ohm drivers, I'll have four for sale at some point.

- Home

- Loudspeakers

- Subwoofers

- Keystone Sub Using 18, 15, & 12 Inch Speakers