hardly of any relevance

yes, in cases of most benign use

had on bench most expensive gadgets, Yore Japanese, with all sorts of problems simply because they didn't use split washers for mounting TO220 on heatsink, screws and rest being proper steel hardware

with time plastic bushing gave slightly up, resulting in lesser thermal contact to heatsink, so plastic bushing gave up even more ....... ending in scorched solder and traces

anyhow - I don't care, everyone is doing it to own liking

I'm usually screaming only when I see major issue with safety regarding mains

yes, in cases of most benign use

had on bench most expensive gadgets, Yore Japanese, with all sorts of problems simply because they didn't use split washers for mounting TO220 on heatsink, screws and rest being proper steel hardware

with time plastic bushing gave slightly up, resulting in lesser thermal contact to heatsink, so plastic bushing gave up even more ....... ending in scorched solder and traces

anyhow - I don't care, everyone is doing it to own liking

I'm usually screaming only when I see major issue with safety regarding mains

Right you are, but this one caught me. It would be a shame to see a perfectly build PSU going south.

Rather than plastic bypass caps, I thought you were going to ask about using only film caps in the power supply. I read about doing this years ago in a Lamm preamp:

https://www.stereophile.com/content/lamm-industries-l21-reference-preamplifier

but can afford neither a Lamm preamp nor DIY all film-cap power supply. Given that people who can afford it — for example, Pass Labs reference preamps — still don’t do it, I figured it was a 1% improvement.

Still, I’ve wondered… has anyone here done the experiment?

https://www.stereophile.com/content/lamm-industries-l21-reference-preamplifier

but can afford neither a Lamm preamp nor DIY all film-cap power supply. Given that people who can afford it — for example, Pass Labs reference preamps — still don’t do it, I figured it was a 1% improvement.

Still, I’ve wondered… has anyone here done the experiment?

Technically not a good idea. You want some loss in your decoupling caps.

If they are lossless, any hf junk coming in on the top pole would go unchanged into the ground rail, which generally is a bad idea.

Lack of any losses is also the reason why some voltage regulators oscillate with a film cap on their output, but not with an elcap.

If you read the datasheets of voltage regulators, very often they give the minimum ESR (equivalent series R) for the final decoupling cap, usually somewhere between 0.1 and 2 or 3 ohms.

Same with the superreg - many builders ended up with a power oscillator by not reading the building guide and putting a super duper $$$ film cap at the output.

Jan

If they are lossless, any hf junk coming in on the top pole would go unchanged into the ground rail, which generally is a bad idea.

Lack of any losses is also the reason why some voltage regulators oscillate with a film cap on their output, but not with an elcap.

If you read the datasheets of voltage regulators, very often they give the minimum ESR (equivalent series R) for the final decoupling cap, usually somewhere between 0.1 and 2 or 3 ohms.

Same with the superreg - many builders ended up with a power oscillator by not reading the building guide and putting a super duper $$$ film cap at the output.

Jan

I had a 40 year old Conrad Johnson Premier Three B tube preamp with only filmcaps for PSU duties.Rather than plastic bypass caps, I thought you were going to ask about using only film caps in the power supply. I read about doing this years ago in a Lamm preamp:

https://www.stereophile.com/content/lamm-industries-l21-reference-preamplifier

but can afford neither a Lamm preamp nor DIY all film-cap power supply. Given that people who can afford it — for example, Pass Labs reference preamps — still don’t do it, I figured it was a 1% improvement.

Still, I’ve wondered… has anyone here done the experiment?

And they dry out becoming yellow and break...They were / are sometimes used to fasten TO220's.

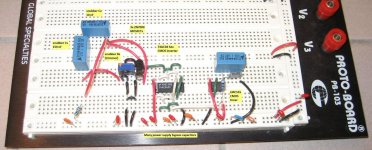

The first prototype Quasimodo was slapped together on a solderless breadboard. Since I had no 1-ampere gate driver ICs at hand, I just used several CMOS logic inverters in parallel. And since I had no power MOSFETs, I just used three junkbox 2N7000s (TO-92 packaged) in parallel.

You, yes you, could do the same on your solderless breadboard. Today.

There is also a stripped-down, lower cost variant here on these Forums. Search thread titles for the word Cheapomodo .

_

You, yes you, could do the same on your solderless breadboard. Today.

There is also a stripped-down, lower cost variant here on these Forums. Search thread titles for the word Cheapomodo .

_

Attachments

I once had a pair of Threshold S/1000's (SA/1 hardware but then in bridged mode to get 500 Watts at 8 Ohms) that had a hum over the speakers.

I cleaned all GND connectors and surfaces with a contactcleaner going to this metalplate and the hum went away. Just simple as that.

As mentioned, the biggest issue with metal plates is corrosion and conductivity, especially on the ground side. As long as this is taken into account into your grounding and earthing scheme, and proper maintenance is done, things should be fine.Pray tell us why this procedure could be audible?

The case serving as ground is a nono for decades. Just clarifying to separate it from earth. Even though we still see it in "authentic" circuits like guitar tube amps.Same here, what about the metal case, serving as ground? What about copper plates?

Brushed brass is a weird choice for a high current amp. It has many times lower conductivity than copper, the brushing lowers the contact surface, and if you do something like use it for ground and allow big return currents to flow across it, you may have noise or hum.Brass looks great also ;-)

They look great though on my Pass Labs amps...Brushed brass is a weird choice for a high current amp. It has many times lower conductivity than copper, the brushing lowers the contact surface, and if you do something like use it for ground and allow big return currents to flow across it, you may have noise or hum.

🙂

I have an ASC motor run and Solen PP caps in my outboard tube amp PS. I can’t speak to any advantages in terms of sound quality, but the caps will undoubtedly outlast me.

If you can find 30000uF film caps, I strongly encourage you to use them.

Now I’ll wait for a certain curmudgeon to enter the thread to deride you for even thinking about recapping it at all. 🍿

If you can find 30000uF film caps, I strongly encourage you to use them.

Now I’ll wait for a certain curmudgeon to enter the thread to deride you for even thinking about recapping it at all. 🍿

Last edited:

Many people don't have an ESR meter.

I guess a simple signal generator and scope are more common.

Here is a simple and easy way to measure ESR with them.

Well worth looking at:

I guess a simple signal generator and scope are more common.

Here is a simple and easy way to measure ESR with them.

Well worth looking at:

Okay that could be the case. Does anodizing something with the conductivity of aluminium?that's hardly brass, rather funny color anodized Al

I have a Peak Electronic ESR70 ESR meter and I will measure the ESR of the 35 year old Mallory’s I took out of my Threshold amplifiers.Many people don't have an ESR meter.

I'm curious, you could compare the values with the datasheet specs. Unfortunetely, the ESR70 upper range is 22.000µF. Don't know about the Mallory's.

That's for capacity but it still will measure ESR. I have a capacity meter also so I can measure if the capacity is still around the 29,000uF specified.I'm curious, you could compare the values with the datasheet specs. Unfortunetely, the ESR70 upper range is 22.000µF. Don't know about the Mallory's.

- Home

- Amplifiers

- Pass Labs

- Film caps in powersupplies