Those are for Blanda+Blanda.

For Blanda+gronsaker the estimated numbers are 70, 50, 40, so an XO 70 hz to woofer if you are using the natural rolloff of the sats (ie REL-style woofers), or higher if you have both high pass and low pass. The latter will play louder.

dave

For Blanda+gronsaker the estimated numbers are 70, 50, 40, so an XO 70 hz to woofer if you are using the natural rolloff of the sats (ie REL-style woofers), or higher if you have both high pass and low pass. The latter will play louder.

dave

You'd then suggest to stick on two Blanda from a sound point of view?

I'd prefer the former, but I will start listening to them without woofer.

I'd prefer the former, but I will start listening to them without woofer.

Is there a speaker and speaker cabinet you would suggest for the woofer?

I'm going to buy the A7MS and would add the woofer as well to get free shipping.

I'm going to buy the A7MS and would add the woofer as well to get free shipping.

There is a huge selection of woofers.

What does the particular vendor offer? Your € budget? Your size budget?

dave

What does the particular vendor offer? Your € budget? Your size budget?

dave

Hi Dave, sorry for the late reply.

I don't have experience with woofers as with my previous floorstand I never felt the need to extend more lows.

From your reply I understand you suggest to buy one already done compared to DIY.

At this point I would prefer to buy it used for budget reasons. What could be in the same league of these speakers?

I will then try it with the FHXL and Silbury as well.

I don't have experience with woofers as with my previous floorstand I never felt the need to extend more lows.

From your reply I understand you suggest to buy one already done compared to DIY.

At this point I would prefer to buy it used for budget reasons. What could be in the same league of these speakers?

I will then try it with the FHXL and Silbury as well.

Not quite. As far as bass reproduction is concerned, yes. As far as that the shape of a speaker determines refraction profile and power response, it couldn't be further from the truth.It's the internal volume of the enclosure that counts, not the shape of it. Spherical, cubical, monkey coffin--makes no difference. Just get the internal volume right for the drivers you have using Thiel Small parameters.

You are correct. I was referring only to low frequency parameters, or just woofer design. T/S parameters are not invoked in design of mid and HF sections of a speaker.

Dave, I manufacture industrial prototypes. I can fabricate any shape. Can you share references to those complicated looking shapes and why a sphere is the worst? What is the function of the rod extending from the back of the driver through to the pointy part at the very back of the housing? I started making spheres because everyone here is making them. This is a lot of work to go after better performance, and in my case, just about any shape is a similar amount of work as any other. Please inform me of the ideal shape if such a thing exists.

I began my spherical speakers using acrylic hemispheres as molds. The hemispheres can be purchased in a wide variety of sizes. Some shops like globalplastics can make custom sizes for a little extra. I made fiberglass molds from the acrylic because fiberglass resin attacks the acrylic. The actual fiberglass spheres were made using the fiberglass hemisphere molds.

Having made several fiberglass hemispheres, I cut a hole in one and 3-D printed an insert shaped to fit the flange of the drivers. After gluing the insert into the hole in the hemisphere, I made another mold of that. Each speaker sphere needs a front and a back mold to make the front and back half of the spherical enclosure.

Prep work involves many coats of paste wax in the mold and several coats of sprayed-on polyvinyl alcohol that serves as a release layer. Layup starts with two or more layers of gelcoat painted inside the mold. Gelcoat and polyester fiberglass resin need to be mixed with about one or two percent peroxide hardener before use or they will not harden. Wait for each coat to harden before applying the next. Then I paint the inside with polyester resin (don't use epoxy because it will not dissolve the binder in the chopped strand mat that comes next). I use chopped strand mat for the structural glass in the composite. I tear off little chunks that I glue to the interior of the hemisphere one little chunk at a time using a brush and more polyester resin. This is the easiest technique for complex curves like a sphere because the woven cloth will not flex into a complex curve. Gradually I cover the entire interior with the chopped strand fiberglass. This is random fibers held with a binder until you apply it. Then the resin dissolves the binder and the loose fibers can conform to any shape.

The spheres in the picture were for a cheap set of drivers from a Dayton Audio B652 bookshelf speaker. We want to do whoop tests on the unmodified speaker and one made with two hemispheres. If a spherical enclosure and possible internal reflection mitigating structures work, we plan to make some for nicer drivers. This is my first post on the forum, so any advice from members is welcome please!

I began my spherical speakers using acrylic hemispheres as molds. The hemispheres can be purchased in a wide variety of sizes. Some shops like globalplastics can make custom sizes for a little extra. I made fiberglass molds from the acrylic because fiberglass resin attacks the acrylic. The actual fiberglass spheres were made using the fiberglass hemisphere molds.

Having made several fiberglass hemispheres, I cut a hole in one and 3-D printed an insert shaped to fit the flange of the drivers. After gluing the insert into the hole in the hemisphere, I made another mold of that. Each speaker sphere needs a front and a back mold to make the front and back half of the spherical enclosure.

Prep work involves many coats of paste wax in the mold and several coats of sprayed-on polyvinyl alcohol that serves as a release layer. Layup starts with two or more layers of gelcoat painted inside the mold. Gelcoat and polyester fiberglass resin need to be mixed with about one or two percent peroxide hardener before use or they will not harden. Wait for each coat to harden before applying the next. Then I paint the inside with polyester resin (don't use epoxy because it will not dissolve the binder in the chopped strand mat that comes next). I use chopped strand mat for the structural glass in the composite. I tear off little chunks that I glue to the interior of the hemisphere one little chunk at a time using a brush and more polyester resin. This is the easiest technique for complex curves like a sphere because the woven cloth will not flex into a complex curve. Gradually I cover the entire interior with the chopped strand fiberglass. This is random fibers held with a binder until you apply it. Then the resin dissolves the binder and the loose fibers can conform to any shape.

The spheres in the picture were for a cheap set of drivers from a Dayton Audio B652 bookshelf speaker. We want to do whoop tests on the unmodified speaker and one made with two hemispheres. If a spherical enclosure and possible internal reflection mitigating structures work, we plan to make some for nicer drivers. This is my first post on the forum, so any advice from members is welcome please!

Can you share references to those complicated looking shapes and why a sphere is the worst?

The issue is that the internal dimension is the same, which gives a very strong internal resonance. No reference required, that is just geometry.

On the outside a sphere is very good as long as the driver mounting leaves no discontinuities.

As to the teardrop shape i would reference the work done by B&W and Eclipse.

dave

Last edited:

The volume of a sphere is 4.1888 * r * r *r where r is the radius (i.e. half the inside diameter of the sphere). E.g If the sphere has an internal diameter of 1.0 metre:

r = 0.5m

v = 4.1888 * 0.5 * 0.5 * 0.5 = 0.5236 cubic metres.

Care: You also need to allow for any internal space lost due to battens, drivers etc...

(4/3)*pi*r^3

I have been working with sciencelookes in the fiberglass speakers. Some more pic. One of the advantages of fiberglass is that the strength of the enclosure can be increased to avoid resonances. I will be measuring them and comparing with the ba52, just used as a driver donor to make a/b test. I have several ideas for the Internal resonance that will be testing and posting the results.

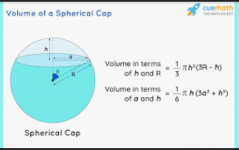

When calculating the volume of a sphere for a speakers cabinet, the formula to use is the one for a truncated sphere.

We can calculate the volume of a section of a sphere using the formula, V = (1/3)πh2(3R - h), where, height h of the spherical section, and radius R of the sphere from which the section was cut.

Below the hemispheres before attaching and the tweeter driver

When calculating the volume of a sphere for a speakers cabinet, the formula to use is the one for a truncated sphere.

We can calculate the volume of a section of a sphere using the formula, V = (1/3)πh2(3R - h), where, height h of the spherical section, and radius R of the sphere from which the section was cut.

Below the hemispheres before attaching and the tweeter driver

Attachments

Thank you so much! I started making fiberglass spheres because everyone is making spheres, but almost any shape could be created using this process. The teardrop shape could be cut from foam on a lathe to make a solid buck that serves as the model for a mold. We could even use a CNC if there is a specific geometry.

There are so many considerations once you move away from rectangular boxes. So we want the front to curve away smoothly on the outside but we do not want a symmetrical sphere inside because it creates resonances at wavelengths that are multiples on the interior radius? Is this why the interior cone shape at the back? To create a continuously decreasing radius that prevents one wavelength from dominating?

Should the inside of the teardrop still be lined with foam or other sound absorbing material? We were planning sort of a radial honeycomb inside the spheres or possibly soft foam fingers with a ball of butyl rubber at the tip of each finger as a way of dampening internal reflections.

Hopefully this forum can be real useful to me. My background is in motion control and some fiberglass work on yachts. I have very limited knowledge of audio, but possess the tools and skills to make pretty much any shape imaginable. I became interested after seeing speaker enclosures taking on all sorts of artsy non-rectangular shapes. Spheres are easy, but when making more than one of something, it can be almost any shape and not create more work unless the shape has a lot of undercuts. Hopefully I can be of some help to forum members by making fiberglass shells or other custom parts.

Will definitely be looking up the eclipse speakers to see what specifics they shared.

At this point, any suggestions about what you would do if the sky's the limit, would be appreciated.

I won't need to look through IKEA for wooden salad bowls, I guess is what I'm trying to say.

And the teardrop shape looks even cooler than a sphere, so I'm all for making that unless someone wants to offer a better shape?

There are so many considerations once you move away from rectangular boxes. So we want the front to curve away smoothly on the outside but we do not want a symmetrical sphere inside because it creates resonances at wavelengths that are multiples on the interior radius? Is this why the interior cone shape at the back? To create a continuously decreasing radius that prevents one wavelength from dominating?

Should the inside of the teardrop still be lined with foam or other sound absorbing material? We were planning sort of a radial honeycomb inside the spheres or possibly soft foam fingers with a ball of butyl rubber at the tip of each finger as a way of dampening internal reflections.

Hopefully this forum can be real useful to me. My background is in motion control and some fiberglass work on yachts. I have very limited knowledge of audio, but possess the tools and skills to make pretty much any shape imaginable. I became interested after seeing speaker enclosures taking on all sorts of artsy non-rectangular shapes. Spheres are easy, but when making more than one of something, it can be almost any shape and not create more work unless the shape has a lot of undercuts. Hopefully I can be of some help to forum members by making fiberglass shells or other custom parts.

Will definitely be looking up the eclipse speakers to see what specifics they shared.

At this point, any suggestions about what you would do if the sky's the limit, would be appreciated.

I won't need to look through IKEA for wooden salad bowls, I guess is what I'm trying to say.

And the teardrop shape looks even cooler than a sphere, so I'm all for making that unless someone wants to offer a better shape?

Having made some of these using blanda matt bowls (Ikea) it avoid the fabrication challenges. The bamboo used is very rigid - about 3/8" thick - and not prone to resonate. The biggest thing to remember about a sphere is that it is the strongest geometric shape and in order to resonate it actually has to pulsate in and out rather than individual panels vibrating say along a glued seam in a box enclosure. If you a) damp it well inside (I use a three-part system) and b) put something inside (I mount mine on an internal pole) it breaks up any standing waves anyway.

If you listen to the same drivers in a sphere vs. in a box, the sound is more open and airy, which is the lower diffraction creating a better soundstage.

If you listen to the same drivers in a sphere vs. in a box, the sound is more open and airy, which is the lower diffraction creating a better soundstage.

So we want the front to curve away smoothly on the outside but we do not want a symmetrical sphere inside because it creates resonances at wavelengths that are multiples on the interior radius? Is this why the interior cone shape at the back? To create a continuously decreasing radius that prevents one wavelength from dominating

The first is important, the driver should deform the semi[[sphere on the front as much as possible.

This is probably too flat.

The teardrop shape (and the bits inside) work to decrease and distribute internal resonances. The long shape is a half-wave TL (it could be quarter-wave). It also works to decrease eddy current as the wavefoems pass back past the fatest part of the semi-sphere.

This is what B&W came up with after likely 100s of thousands of £ of research.

And the research would have been in Yen here.

dave

Hmm.. as written, you have h2 instead of h^2 . Do you mean:We can calculate the volume of a section of a sphere using the formula, V = (1/3)πh2(3R - h), where, height h of the spherical section, and radius R of the sphere from which the section was cut.

Or is you're gonna write it "normal" then, it's V = (1/3)(pi)(h^2)*(3r-h)

It's the volume of a spherical cap.

It would be interesting to A-B the same B&W driver in a regular sphere vs. their elaborate tear drop shape to see if you actually hear much difference. Gallo Acoustics or Cabasse might say it's not necessary...?

Red herring? Maybe for a laser beam, but not for sound waves at medium frequencies originating at the edge. Maybe if the sound originated from the center of a sphere, or from the center of a partial sphere there would be those large internal resonances.The issue is that the internal dimension is the same, which gives a very strong internal resonance. No reference required, that is just geometry.

Anyhow, since around the turn of the millennium, Linkwitz has made clear that boxes are intolerable bark-chambers above 200-ish hertz. SL also 'pretty much' discounts diffraction from cabinet edges and shapes his baffles as needed for dispersion.

- Home

- Loudspeakers

- Multi-Way

- How to build a spherical speaker?