YepIf you are happy with your creation, that's all that matters. 🙂

Havent made up my mind on round or rectangular., work in progress.Do you prefer round membrane?

What are you working on at the moment?

Have you seen Camerton audio and Contrast audio balsa Bmr drivers?

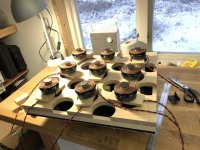

My current project are large bmr’s.

I presented these a few pages back in this thread.

Two variants: a small one with a Sd similar to 15 inch speaker and a larger one with a Sd similar to 4 x 15 inch speakers.

My goal is a fullrange speaker 20 to 20KHz with serious SPL capabillity.

I’m inspired by the appended article…investigation high spl loudspeakers.

No I haven’t seen them, I’ll have look, thanks for the tip!

Attachments

Do you have legit evidence to back up your claims? Or are you just spewing nonsense as usual? 🙂A back grill like that above (#8,761) has no value audio-wise, other than aesthetics, or just somehow to convince the accidental buyer to empty his purse. To me, it looks more like the Japanese war flag. 🙂

Excellent design and execution Eucy! Concerning your half tube construction, I have been entertaining this concept - not to make use of the front panel vibrations, but to take them around the curve and dampen them, by putting absorptive material in the half tube. My thought is that given more distance for the vibration to travel, it will be more effectively damped and not reflected. The attached picture is of .375" EPS, 2 lb density, that I put in an oven (170F IIRC) to bend the curve. The heating/bending really stiffened the piece so much, that I think 1/4" EPS is viable. Thoughts anyone, on this approach?Ahh Burnt - thanks for that Pedrick info - love it - what a loss to mankind !

Viridian - OK - Not sure how deep to go into this - but started with thinking somewhat outside the square.

I wanted to see if I could induce vibrations in a back panel by using a resilient curved mount on either side, so I stated with small trial pieces and was encouraged to go further. The aim was to reinforce the front panel output, to get a bigger panel area from a smaller footprint, to get the vibrations to 'turn the corner' so to speak. Of course, there is also the effect of the back waves energising the rear panel so it's hard to know the extent to which each mode contributes.

However, there was a distinctive audible effect in deeper mids and lows so I persevered. The rest involved tuning out negative effects of reflected waves, tunnel effects, etc etc.

What you see is the result of many, many hours of testing, listening, modifying, and repeated test builds.

Basically, the panels are supported along each edge with a 60mm resilient (springy) half tube, damped side, top, bottom and rear ports and are provided. Is this the right size/separation - I don't know - there's a limit to the amount of experimenting a single person can do, (and that's where this forum could be more useful).

The front and rear panel size is 900x300 mm - 3mm poplar ply - each selectively stiffened with light bracing, and treated with Shellac.

The front panel is driven by a single Dayton Audio DAEX25SHF-4 exciter, (with my 'Eucydome' of course). A DAEX32ep-4 thruster is attached to the lower portion of the rear panel in reverse phase, and has been used in both subwoofer and full range modes. In subwoofer mode it gives a moderate boost in the 50-60Hz range, but that I believe is mainly down to the poor subwoofer output of the Fosi amp unit I'm using.

More work needs to be done in the full range mode to prevent interference. (I'm not a fan of the Thruster really.)

Comparing to a single panel of the same size - chalk and cheese imo - can't say any more.

Still needs bass boost on the amp but I usually listen to it without the rear exciter engaged.

I demonstrate them to friends by rotating them - there's no audible difference between face on, edge on or reversed.

The house I've just moved into has a media room with wall mounted speakers and when listening to a stereo source, the difference in the sound stage is quite marked. With closed eyes, the 3 way stage is quite narrow, esp in the vocals, but opens up a lot when the panels are switched in.

Very happy overall - not sure where to go from here at the moment.. too many conflicting demands but the concept I feel is sound (no pun intended) , free standing, small footprint, DML spacialisation.

I'll mull on it over time.

BTW, the speakers in the rear of the photos are hybrids - western red cedar panels, 1200x400x4mm with mast mounts (3 point mounting), each with a DAEX25SHF-4 exciter and 8" down firing woofers in an MDF box with constrained layer damping.

Cheers

Eucy

Aint that a fire hazard? How long did you bake it?Excellent design and execution Eucy! Concerning your half tube construction, I have been entertaining this concept - not to make use of the front panel vibrations, but to take them around the curve and dampen them, by putting absorptive material in the half tube. My thought is that given more distance for the vibration to travel, it will be more effectively damped and not reflected. The attached picture is of .375" EPS, 2 lb density, that I put in an oven (170F IIRC) to bend the curve. The heating/bending really stiffened the piece so much, that I think 1/4" EPS is viable. Thoughts anyone, on this approach?

View attachment 1133250

No hazard. Didn't take long - I watched it bend in the oven window. The piece was sitting flat on a board with the edge over hung. It bent down by its own weight. Higher temp than I needed but 170 is as low as I can set it.Aint that a fire hazard? How long did you bake it?

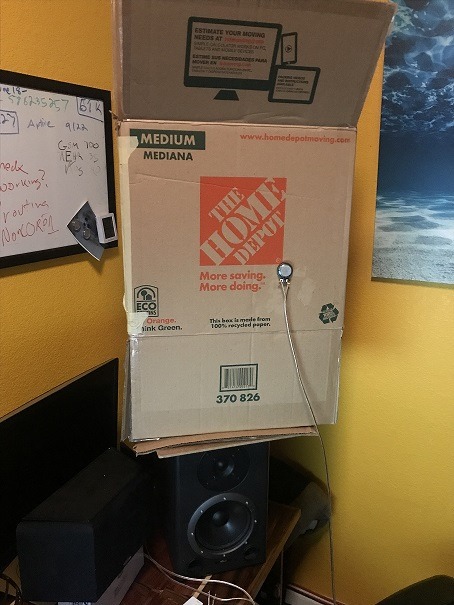

Experimenting with DML after watching the "best speakers" youtube video. I bought a few 6$ DAEX19CT-4 exciters and the little Dayton 15w amp. I pressed the exciters against all kinds of stuff: various wood scraps, hanging ceiling tile, hanging the famous pink insulation thing, and what immediately jumped out was the cardboard box. So far the best config is one section removed so it's a triangle and standing on end. I'd like to go down to a "small" but sounds nowhere as good. So how good, really? I still have some audio gear in storage from bachelor days so grabbed a Roland RSM-90 I haven't heard in 15 years and also an Energy surround unit. I'm sure the floor-standing Energy will win so not dragging it in here.

Going mono, the Roland is infinitely better playing Nile or Tool. For symphonic, classical guitar, Enya; the box easily beats the little Energy, and its a tie with the Roland -- it's a tradeoff of fuller sound on Roland vs. expansive articulate highs on the Home Depot box. That it's even a contest is amazing. I'm building a small woofer (not sub per se) to fill in the DMLs and see how that goes. (as in picture Roland L, DML R actually sounds pretty damn good).

I went with the small exciters for several reasons, cheap and expendable until I'm more confident in my building, but also folks have criticized the DMLs for lacking highs and even put tweeters on their panels. I figured the little guys would have a great chance of making good highs, and if I need a tweeter the project is no longer worth it. However, I also discovered right away that the highs are much better if the exciter faces the listener.

So the question is, does anyone here have experience with the DAEX19CT-4's, and what would be a good upgrade that might give me a fuller sound without sacrificing the the great highs I'm getting now?

.

Going mono, the Roland is infinitely better playing Nile or Tool. For symphonic, classical guitar, Enya; the box easily beats the little Energy, and its a tie with the Roland -- it's a tradeoff of fuller sound on Roland vs. expansive articulate highs on the Home Depot box. That it's even a contest is amazing. I'm building a small woofer (not sub per se) to fill in the DMLs and see how that goes. (as in picture Roland L, DML R actually sounds pretty damn good).

I went with the small exciters for several reasons, cheap and expendable until I'm more confident in my building, but also folks have criticized the DMLs for lacking highs and even put tweeters on their panels. I figured the little guys would have a great chance of making good highs, and if I need a tweeter the project is no longer worth it. However, I also discovered right away that the highs are much better if the exciter faces the listener.

So the question is, does anyone here have experience with the DAEX19CT-4's, and what would be a good upgrade that might give me a fuller sound without sacrificing the the great highs I'm getting now?

.

Further to post #8,765

NXT was mostly a scientific laboratory, rather than a maker of loudspeakers. NXT was to produce prototypes, patents and sell licences mostly. Scientists, engineers are not really good at doing business, and eventually NXT failed as a business enterprise. Verity pulled the plug. Another venture capital took over, but later HiWave Technologies went bust too. While they were existing, they made lot of scientific engineering findings, but what's available for us are only the patents, which show only the basic idea. Lot of information is hidden there, but spaced in many separate patents. Finally, the scientific engineering knowledge that NXT and HiWave accumulated was bought by Tectonic Labs and Google, that is, HiWave was divided into two and sold. Most of the employees went to work in those companies. Some are still there. While we will never get a chance to see those scientific achievements, they must've been great knowledge for these companies to buy them off and employ the HiWave/NXT staff.

I also got caught to this Tech Ingredients nonsense, promoted by some here, and wasted some time. Of course, anything an exciter was stuck on would sing, but that doesn't make it a loudspeaker. I just can't think of hanging polystyrene sheet on threads from the ceiling or a tripod or a stand in the living room. It was much easier to stick it under a tall glass vase out of the way, but that would not have solved the DM matter. Then came in @Sandasnickaren with his project, which inspired. Later, I saw @Veleric's product which helped too. I read the Göbel patent very carefully, taking notes. Then, suddenly decided to read NXT patents, which I had never done before. There's now a chance to make a DM, once and for all. I take notes, and post some here for others to see, or use. If my laptop breaks down or OneDrive goes out of service, they'd be here for future reference. 🙂

For the moment, the panel must be a composite, with two thin skins and a very light, lower density core, and they should be of different materials. The core is considered more or less as air, and is there only to keep those two skins at a certain distance away from each other. It would be better, if the two skins be metallic and has as little as possible thickness, and the core to carry more air and still be stiff. SIPs come to mind here. Separately the skins or the core has very little strength and stiffness, but glued together as a composite become very strong. Next matter is the transducer to be used, buy those commercially available, or make them yourself--NXT gives ideas how to.

3-ply wood panels might be considered as composites, but they are of the same material, and core cannot be considered as air. Or, maybe 3-ply with metallic skins would do, like balsa with metallic skins (@Sandasnickaren project). Maybe, 3-4mm 3-ply linden-balsa-linden with metallic skins. Or, something like Dibond, but with much lighter polypropylene or cellulose core, or EPS core.

And,The story, it appears, begins with attempts by DERA (Defence Evaluation Research Agency) engineers to identify and prevent sympathetic vibration or resonance, in laminates used in the inside of helicopters and aircraft. In an inevitably noisy environment at the best of times, the added rattle from internal cladding was a distinct distraction for air crew. In the course of investigations it was unexpectedly discovered that the laminates in question were acting as wide band, multiple pole radiators. That is, given a range of extraneous vibratory frequencies, they did not simply act as a simple, spring-mass resonator at one frequency or harmonic, but were amplifying a range of frequencies cross their surfaces. This, we are told, was not good and, more to the point, classical physics decreed that the laminates should not have been doing what they were doing!

So, DERA, having patented the basic principle, looked for an appropriate partner with the right background to pursue a technology that showed a lot of promise, but needed a wider expertise in acoustics and loudspeaker technology. They opened negotiations with the Verity Group Plc. (Wharfedale, Mission etc.) and ultimately, the technology was transferred from DERA under a joint collaborative and licensing agreement, forming a new research and IP holding company, NXT New Transducers Ltd.

Even Verity had their doubts, but viewed it as an analytical problem whose solution promised a new era in loudspeaker technology. The story goes that subsequent work by a range of analysts, Neil Harris and Henry Azima in particular, slowly unravelled the way the sound radiation properties were optimised. Over time, Harris and Azima, along with Verity's IPR. advisor, Martin Colloms, have applied for some 23 patents covering the NXT rigid panel and driver technology.

NXT was mostly a scientific laboratory, rather than a maker of loudspeakers. NXT was to produce prototypes, patents and sell licences mostly. Scientists, engineers are not really good at doing business, and eventually NXT failed as a business enterprise. Verity pulled the plug. Another venture capital took over, but later HiWave Technologies went bust too. While they were existing, they made lot of scientific engineering findings, but what's available for us are only the patents, which show only the basic idea. Lot of information is hidden there, but spaced in many separate patents. Finally, the scientific engineering knowledge that NXT and HiWave accumulated was bought by Tectonic Labs and Google, that is, HiWave was divided into two and sold. Most of the employees went to work in those companies. Some are still there. While we will never get a chance to see those scientific achievements, they must've been great knowledge for these companies to buy them off and employ the HiWave/NXT staff.

I also got caught to this Tech Ingredients nonsense, promoted by some here, and wasted some time. Of course, anything an exciter was stuck on would sing, but that doesn't make it a loudspeaker. I just can't think of hanging polystyrene sheet on threads from the ceiling or a tripod or a stand in the living room. It was much easier to stick it under a tall glass vase out of the way, but that would not have solved the DM matter. Then came in @Sandasnickaren with his project, which inspired. Later, I saw @Veleric's product which helped too. I read the Göbel patent very carefully, taking notes. Then, suddenly decided to read NXT patents, which I had never done before. There's now a chance to make a DM, once and for all. I take notes, and post some here for others to see, or use. If my laptop breaks down or OneDrive goes out of service, they'd be here for future reference. 🙂

For the moment, the panel must be a composite, with two thin skins and a very light, lower density core, and they should be of different materials. The core is considered more or less as air, and is there only to keep those two skins at a certain distance away from each other. It would be better, if the two skins be metallic and has as little as possible thickness, and the core to carry more air and still be stiff. SIPs come to mind here. Separately the skins or the core has very little strength and stiffness, but glued together as a composite become very strong. Next matter is the transducer to be used, buy those commercially available, or make them yourself--NXT gives ideas how to.

3-ply wood panels might be considered as composites, but they are of the same material, and core cannot be considered as air. Or, maybe 3-ply with metallic skins would do, like balsa with metallic skins (@Sandasnickaren project). Maybe, 3-4mm 3-ply linden-balsa-linden with metallic skins. Or, something like Dibond, but with much lighter polypropylene or cellulose core, or EPS core.

That's how the polystyrene is formed and extruded. It starts to flow at about 100°C. You've heated it ~77°C, so it bent by its own weight. The top surface has a glassy feel, right? You can actually make it have any form, by placing something under it, as far as you keep the temperature less than 100°C.Excellent design and execution Eucy! Concerning your half tube construction, I have been entertaining this concept - not to make use of the front panel vibrations, but to take them around the curve and dampen them, by putting absorptive material in the half tube. My thought is that given more distance for the vibration to travel, it will be more effectively damped and not reflected. The attached picture is of .375" EPS, 2 lb density, that I put in an oven (170F IIRC) to bend the curve. The heating/bending really stiffened the piece so much, that I think 1/4" EPS is viable. Thoughts anyone, on this approach?

View attachment 1133250

One of the first things I noticed with the EPS panels was the fast dynamic sound.Havent made up my mind on round or rectangular., work in progress.

My current project are large bmr’s.

I presented these a few pages back in this thread.

Two variants: a small one with a Sd similar to 15 inch speaker and a larger one with a Sd similar to 4 x 15 inch speakers.

My goal is a fullrange speaker 20 to 20KHz with serious SPL capabillity.

I’m inspired by the appended article…investigation high spl loudspeakers.

No I haven’t seen them, I’ll have look, thanks for the tip!

you could play a recording of a submachine gun , and it would sound like it was being fired in the room !

No compression or softening of the sound.

My wife's friend put his head around the door, and said he could feel his teeth rattling in his head 😂

On ordinary speakers, this recording sounds soft and boxy, more of a thud , than a bang.

But it was the ease at which it produced the sound, similar to a horn , but without the horn sound.

Steve.

I still have some 'ultra high density' EPS to play with. Thanks to the pea sized bit of Blu Tack stuck on the front of the panel where the exciter sits (on the other side), the sound with the 2mm ceiba ply does seem to have cleaned up a bit. I've got some silicone coaster bumpers somewhere which may be worth trying instead of the Blu Tack. I'm not going to try the EPS until it's warm enough to do the sanding outside though.

Lordtarquin.

I treat EPS differently to ply, you could also try the strip of paper technique for ply, but you really need to see the results in real time while adjusting the position of the paper.

Do you have ways to measure your panels while making the adjustments ?

Steve.

I treat EPS differently to ply, you could also try the strip of paper technique for ply, but you really need to see the results in real time while adjusting the position of the paper.

Do you have ways to measure your panels while making the adjustments ?

Steve.

The reason you dont see much NXT products is because they catered mostly to "Pro/live audio" instead of Audiophiles/DIYers. They are two completely different marketing catagories. Most of NXT products werent sold in the common hi fi audio stores but rather Music/Instrument stores hence the lack of popularity in the audio enthusiast community. Occasionally NXT would license there product to other companies like Teac but failed to build anything note worthy.Further to post #8,765

And,

NXT was mostly a scientific laboratory, rather than a maker of loudspeakers. NXT was to produce prototypes, patents and sell licences mostly. Scientists, engineers are not really good at doing business, and eventually NXT failed as a business enterprise. Verity pulled the plug. Another venture capital took over, but later HiWave Technologies went bust too. While they were existing, they made lot of scientific engineering findings, but what's available for us are only the patents, which show only the basic idea. Lot of information is hidden there, but spaced in many separate patents. Finally, the scientific engineering knowledge that NXT and HiWave accumulated was bought by Tectonic Labs and Google, that is, HiWave was divided into two and sold. Most of the employees went to work in those companies. Some are still there. While we will never get a chance to see those scientific achievements, they must've been great knowledge for these companies to buy them off and employ the HiWave/NXT staff.

I also got caught to this Tech Ingredients nonsense, promoted by some here, and wasted some time. Of course, anything an exciter was stuck on would sing, but that doesn't make it a loudspeaker. I just can't think of hanging polystyrene sheet on threads from the ceiling or a tripod or a stand in the living room. It was much easier to stick it under a tall glass vase out of the way, but that would not have solved the DM matter. Then came in @Sandasnickaren with his project, which inspired. Later, I saw @Veleric's product which helped too. I read the Göbel patent very carefully, taking notes. Then, suddenly decided to read NXT patents, which I had never done before. There's now a chance to make a DM, once and for all. I take notes, and post some here for others to see, or use. If my laptop breaks down or OneDrive goes out of service, they'd be here for future reference. 🙂

For the moment, the panel must be a composite, with two thin skins and a very light, lower density core, and they should be of different materials. The core is considered more or less as air, and is there only to keep those two skins at a certain distance away from each other. It would be better, if the two skins be metallic and has as little as possible thickness, and the core to carry more air and still be stiff. SIPs come to mind here. Separately the skins or the core has very little strength and stiffness, but glued together as a composite become very strong. Next matter is the transducer to be used, buy those commercially available, or make them yourself--NXT gives ideas how to.

3-ply wood panels might be considered as composites, but they are of the same material, and core cannot be considered as air. Or, maybe 3-ply with metallic skins would do, like balsa with metallic skins (@Sandasnickaren project). Maybe, 3-4mm 3-ply linden-balsa-linden with metallic skins. Or, something like Dibond, but with much lighter polypropylene or cellulose core, or EPS core.

If my memory serves me correctly I warned yawl about Tech Ingredients. Its not my problem if you dont want to listen to my advice. 🙄

You never read NXT patents before? I find that odd, since you are the patent king?🤣

Hmmm I just recently mentioned skins in my previous post. Anything touching the surface of said panel material becomes the skin and will take on some of the skins sound signature depending on the skin used. For example paper has a warmer/duller sound but it will sound more accurate. While Aluminum will have a brighter more lively sound. Many factors involved its not as simple as one might think. If your core material is already warm sounding to begin with then you wouldnt want to use paper unless you want it to sound really warm, you have to find the RIGHT combination which again boils down to personal preference. Like Goldie locks and the three bears you dont want it too hot or to cold but "JUST RIGHT". 😉

Anyone ever hear a "CERAMIC", type of tweeter or woofer? Ceramic is very clean and articulate sounding but also can sound very dry. The SKIN material that sounds like a ceramic driver is one of my many preffered skins is "PARCHMENT" paper. Here is another tip> One side of the parchment paper does not sound the same as the other side. You have to listen for yourself which side you prefer. Ahhh man giving away to much secrets. 🤣😉

Hi SteveLordtarquin.

I treat EPS differently to ply, you could also try the strip of paper technique for ply, but you really need to see the results in real time while adjusting the position of the paper.

Do you have ways to measure your panels while making the adjustments ?

Steve.

I have REW on PC and a calibrated mic. I'm not sure what I'd need to do to get a full frequency spectrum from say white noise.

When was that?If my memory serves me correctly I warned yawl about Tech Ingredients. Its not my problem if you dont want to listen to my advice.

But, I sort of remember someone else saying practically the same words. 🙂

And, used capital letters to emphasis something.

Last edited:

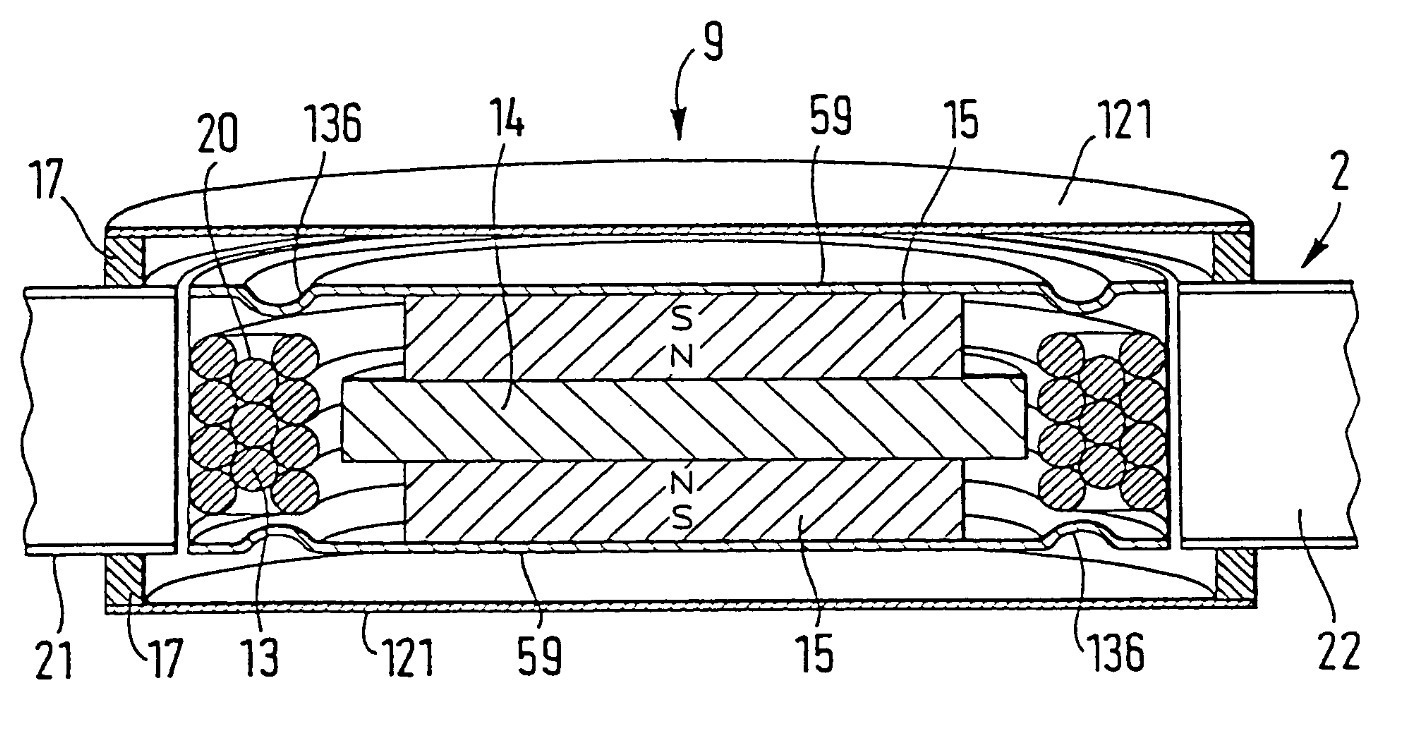

I found this exciter, but there's no description in the patent. I suppose you will be able to understand how its made. Looks like it's supposed work on both skins, placed in a hole in the composite panel. It must be using very thin neodymium magnets, considering the panel should be around 3-5mm thick. It would be nice if someone can give any advice on this. Thanks.

Last edited:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker