Why make them square?I don't think this is a good idea for home audio but am keen on work and discussion in this area. I have a design for a dual 2" driver adapter I am working on: https://www.diyaudio.com/community/...per-scripts-and-m200-fun.385493/#post-7167590 . I have had a hard time making the geometry where the rounded corners transition to square (the simulation linked avoids this by not fully transitioning) but am almost done on another attempt to fix it. I'm not sure yet if my adapter will work at all well!

I'm exactly thinking of home audio.

It would be much cheaper to get two 1" drivers and cross them way lower than a single one instead of buying a corresponding 2"

the practicalities of constructing a large horn means I need to go to flat boards after the initial throat.Why make them square?

I'm exactly thinking of home audio.

It would be much cheaper to get two 1" drivers and cross them way lower than a single one instead of buying a corresponding 2"

I'm not sure this works out, a lot of 1" throat drivers crossover is limited by a rapid rise in harmonic distortion even at low levels below a certain frequency. Also say if we have a 1" driver with a 1.75" diaphragm and a 2" driver with a 3" diaphragm 2*1.75^2 = 6.125, 1*3^2 = 9 so the 2" throat driver still has much more volume displacement without hitting the phase plug assuming that both drivers are constrained by the dome hitting the phase plug. IMO the better approach for better LF output at low cost is to add bandpass mids as per a synergy horn. If you look at this post: https://www.diyaudio.com/community/...per-scripts-and-m200-fun.385493/#post-7009215 you can even see that midrange compresion drivers can be used for this.

As for the 3D printing... something new from Czechia:

(it's still not clear to me how they do the top but it's definitely possible)

(it's still not clear to me how they do the top but it's definitely possible)

Last edited:

Another interesting printer is Vzbot from Simon Vez, now available from Mellow 3D store. Most advanced core xy awd. I proposed him hotrunner extruder in February and he manage it to work. Prusa should be good out of the box but Vzbot is like F1 car.

Started printing yesterday, though I think I'll run out of filament at 90% 🙁Nobody has tried the ST260 BLD?

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-7087469

The simulation promised it to be exceptionally good.

Here's a STEP file: https://at-horns.eu/ext/ST260-BLD-v1-STEP.zip

- I don't promise anything, it can still be a disaster above 12 kHz...

- I don't promise anything, it can still be a disaster above 12 kHz...

I'm getting close to making the concrete horn - this is the top of the outer mold for a mounting flange (3D printed parts).

Last edited:

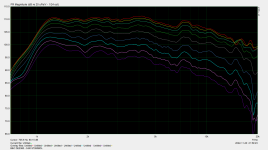

Here are quick measurements of the B&C DE360 - no crossover - at 1M - 0-80 degrees HStarted printing yesterday, though I think I'll run out of filament at 90% 🙁

Attachments

That looks pretty good to me.

This was the KVAR version: https://www.diyaudio.com/community/attachments/b-c-de360-ath-st260-kvar-raw-png.1052174/

- Is it possible that the BLD was measured using a little bit longer time window?

This was the KVAR version: https://www.diyaudio.com/community/attachments/b-c-de360-ath-st260-kvar-raw-png.1052174/

- Is it possible that the BLD was measured using a little bit longer time window?

Last edited:

Hi aragorus, how did you generate this model?I'm gonna give this a simulaton try tomorrow 😀

Reminds me of the huge western electric horns.

my overnight ATH run of an simple round waveguide in an enclosure with LFsrc above and below reached only 59%. The task is using 90+ % of my 16GB of dram and all 12 of my CPU cores. Its likely thrashing its buns off. Is there any chance it will complete?

Oh, just checked and the machine as 32 GB of dram. I'll let it keep going.

Oh, just checked and the machine as 32 GB of dram. I'll let it keep going.

Last edited:

If you went for a detailed simulation (fine mesh, lots of frequencies), this is quite possible.

Here are quick measurements of the B&C DE360 - no crossover - at 1M - 0-80 degrees H

Looks very good to me, could you share Arta pir files of the above, also any distortion measurement made ? According to Xiometry, a pair of Alu CNC's of the BLD step files is about 1200-1300 € with the 10% black friday coupon...

I'm not sure it's worth it. It would be extremely cool though.

- Here's a detail of high frequencies from the simulation (0-90/10 deg), horizontal, vertical:

Throat impedance (linear freq. step):

- Here's a detail of high frequencies from the simulation (0-90/10 deg), horizontal, vertical:

Throat impedance (linear freq. step):

Last edited:

That is incredible. Once you EQ it, it will basically sound the same anywhere in the room.That looks pretty good to me.

This was the KVAR version: https://www.diyaudio.com/community/attachments/b-c-de360-ath-st260-kvar-raw-png.1052174/

- Is it possible that the BLD was measured using a little bit longer time window?

View attachment 1111965

It's possible - I can try to re-bo measurements under the same exact conditions.That looks pretty good to me.

This was the KVAR version: https://www.diyaudio.com/community/attachments/b-c-de360-ath-st260-kvar-raw-png.1052174/

- Is it possible that the BLD was measured using a little bit longer time window?

Which one? the KVAR or the BLD? If I remember correctly, I believe the BLD had better vertical polars than the KVAR. Will repeat the measurements this evening.That is incredible. Once you EQ it, it will basically sound the same anywhere in the room.

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)