As promised here (a long time ago ^^)

I release the STL flat cut version of the 6.5" SB26 version here :

https://www.audiohorn.net/p/tweeter-waveguide.html

With measurement in this implementation, and why I have modified it like this.

Initially it was for a Ikea bol project with SB17 for Aznowicz :

I release the STL flat cut version of the 6.5" SB26 version here :

https://www.audiohorn.net/p/tweeter-waveguide.html

With measurement in this implementation, and why I have modified it like this.

Initially it was for a Ikea bol project with SB17 for Aznowicz :

That's very cool! 3Dprinting is really changing everything.

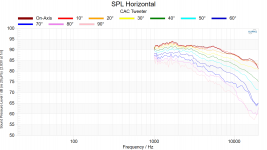

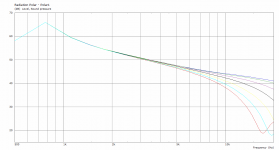

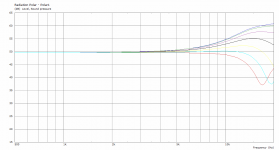

PS: the predicted DI of my waveguide in-box you posted is not what the actual result would be. Here is a Klippel measurement, although I didn't generate the DI from it, you can see it would be quite smooth:

PS: the predicted DI of my waveguide in-box you posted is not what the actual result would be. Here is a Klippel measurement, although I didn't generate the DI from it, you can see it would be quite smooth:

Attachments

I thinks it's a matter of implémentation, as in the version I modify, it's just a implementation modification, the WG is the same (so thanks to you ^^).

The in-box implementation was this, it's not a predicted one, it's a real measurement and use of Vituix CAD :

It's not mine but it's representative of regular implementation of Somasonus that we see on Facebook groups, there is even a little round on the box, not bad.

The in-box implementation was this, it's not a predicted one, it's a real measurement and use of Vituix CAD :

It's not mine but it's representative of regular implementation of Somasonus that we see on Facebook groups, there is even a little round on the box, not bad.

Ah, I see. In my own implementation, I used 1.25" roundovers, which start pretty close to the edge of the waveguide. ABEC modeling showed this had the most promise. The T25B waveguide liked this sort of baffle even better:

You can find the bits (in the US) here: https://www.mlcswoodworking.com/shopsite_sc/store/html/smarthtml/pages/bt_round_over.html#126

You can find the bits (in the US) here: https://www.mlcswoodworking.com/shopsite_sc/store/html/smarthtml/pages/bt_round_over.html#126

oh good ! Do you have a picture ?

It's all a mater of continuous curve, be careful it should be on all part of the WG implementation, hard to explain but if you mentally cut your implementation on this diagonal axis it should be continuous too.

And if you measure it in (all degrees) diagonal axis it will be visible (and reflected by wall, in room).

It's a radiation divergence due to mouth diffraction, it's why my implementation look like this ^^, with a good roundover on a square box it's good to have a rectangle mouth for midrange narrowing/beaming.

But I like the final result of my bullet lol, it's all in one 😆, and for Azno, with Ikea bol, the elliptic mouth form in "bullet" is better anyway

It's all a mater of continuous curve, be careful it should be on all part of the WG implementation, hard to explain but if you mentally cut your implementation on this diagonal axis it should be continuous too.

And if you measure it in (all degrees) diagonal axis it will be visible (and reflected by wall, in room).

It's a radiation divergence due to mouth diffraction, it's why my implementation look like this ^^, with a good roundover on a square box it's good to have a rectangle mouth for midrange narrowing/beaming.

But I like the final result of my bullet lol, it's all in one 😆, and for Azno, with Ikea bol, the elliptic mouth form in "bullet" is better anyway

Which plunge router can take a 1.25" or 1.5" round-over bit? Which one do you use?Ah, I see. In my own implementation, I used 1.25" roundovers,,,

...You can find the bits (in the US) here: https://www.mlcswoodworking.com/shopsite_sc/store/html/smarthtml/pages/bt_round_over.html#126

Ridgid router, nothing special. I do use the fixed base, but I don't think the plunge base is much different. The hole actually measures 3" so I could almost use the 1.5" bit. But I'm too afraid to test that and see what happens.

Ok, here are the 8" waveguides for the T34B. Also included a new 6.5" elliptical mouth with a higher aspect ration (1:.83). Also included a new 6" elliptical waveguide for the T25B (used my new family of speakers). I've decided to revisit the circular mouth on the SB26 family. The first is a 6.5" model, and it looks good, I'll move on to the other sizes when I have time. I've updated my website to include the new designs.

I'm trying to simulate some waveguides with Akabak, following the YT tutorial by Austin. I think my BEM work is OK as the normalized results tend to be very similar to what @Gaga and Brandon have achieved, but the unnormalized results never seem to match so I guess I'm doing something wrong with the LEM part.

Here's the SB26 in an infinite baffle (no wg for simplicity), first with a source directly routed to a radiator linked to the BEM driver and then with a source-resistance-elecdyndriver-radiator model, the elec-dyn driver being grounded, enclosured and filled with SB26 T/S parameters. Comparing the results to those of Gaga here it seems like I should achieve something between my results 😅 Any ideas?

Here's the SB26 in an infinite baffle (no wg for simplicity), first with a source directly routed to a radiator linked to the BEM driver and then with a source-resistance-elecdyndriver-radiator model, the elec-dyn driver being grounded, enclosured and filled with SB26 T/S parameters. Comparing the results to those of Gaga here it seems like I should achieve something between my results 😅 Any ideas?

Attachments

The manual saysI'm trying to simulate some waveguides with Akabak, following the YT tutorial by Austin. I think my BEM work is OK as the normalized results tend to be very similar to what @Gaga and Brandon have achieved, but the unnormalized results never seem to match so I guess I'm doing something wrong with the LEM part.

Here's the SB26 in an infinite baffle (no wg for simplicity), first with a source directly routed to a radiator linked to the BEM driver and then with a source-resistance-elecdyndriver-radiator model, the elec-dyn driver being grounded, enclosured and filled with SB26 T/S parameters. Comparing the results to those of Gaga here it seems like I should achieve something between my results 😅 Any ideas?

LE Diaphragm Parameters

Dome TweeterThe dome-tweeter is usually modeled with the front diaphragm only. The rear of the dome is regarded as part of the speaker and its effects are part of the TS-parameters (see also component Speaker). |

So I would take out the enclosure and just fill in the Elec-Dyn Driver parts.

Simulating with constant acceleration is usually good enough when you are really looking at the directivity of the diaphragm and waveguide.

AKABAK defaults to constant velocity so it needs to be changed to have a falling not rising response.

This what I have been using to simulate Dome tweeters with constant acceleration.

Different amplification for the different parts and weight as Divide by jw.

Thanks! I seem to be unable to assign fixed driving no matter how I try to unreference the feature from any LE stuff. But I removed the enclosure and switched the radiator reference to the lumped Elec-Dyn driver instead of the BEM driver and now things seem in line with Gaga's results, at least for the infinite baffle version. FWIW I'm not trying to simulate only the directivity, but also the frequency response

The difference between them in this scenario is not really that useful for the effort it takes, but have a look at the link below if you really want to get into itFWIW I'm not trying to simulate only the directivity, but also the frequency response

https://www.diyaudio.com/community/...-design-the-easy-way-ath4.338806/post-6809304

As far as I am concerned the important thing to simulate is, does the dome and surround shape work in the waveguide.

Jean, maybe you will find some time to post your results? 🙂I have yet to find were I put those measurements😡 but I did them and found that, effect was very small, the worst was at 0° (max 1 dB from memory above 10 kHz) and was even reduced off axes. At the price of a T34B, I did not hesitate...

Brandon. Is it possible to obtain real 6.5" Waveguide for Bliesma T34B? I've downloaded file "6.5x1.1 83 A T34 v2 stl.zip" but unfortunately it's 7.28" waveguide 🙁

My old Bosch fixed-base handles a 1.375" (35mm) roundover when the plastic base is removed from the metal frame. The bit vendor was adamant about not running it beyond 8000 rpm and chamfering the work piece beforehand to reduce the material removed, both of which were useful tips. Even then watching the edge carbide flying by the base opening a quarter inch away (6.35 mm for y'all what ain't got Freedom Units) was a sobering experience - definitely a time for triple-checking the chuck was tight.Which plunge router can take a 1.25" or 1.5" round-over bit? Which one do you use?

This profile piqued my interest: the initial radius is quite large so the initial standing wave diffuses cleanly and the radius tightens the further you get from the front panel, but it's okay since less energy is going all the way around to the side of the box. In theory, anyway. Of course you avoid laying down a bead at the front edge -- that would be silly.

Plus, tbh, the profile is prettier than a straight roundover.

Last edited:

Ehh, Eltomassito you scared me. I've bought Satori MW16P and Bliesma T34B and was planning to build speakers with 6.5 circular waveguide. I was simulating layout in this post #1101. But I was sure that external width is exactly 6.5". Now you make me aware that my layout will looks like much more ridiculous than I thought and I must abandon my plans 🙁Brandon. Is it possible to obtain real 6.5" Waveguide for Bliesma T34B? I've downloaded file "6.5x1.1 83 A T34 v2 stl.zip" but unfortunately it's 7.28" waveguide 🙁

I'm using a 6" (6.78" with the driver flange) with the T25B and MW16TX, and it integrates really well. I'll do one for the T34B also. Since my goal is matching directivity and acoustic center for the intended woofers (nominal 6.5"), I don't design around the aesthetic aspect. You start giving up too much utility.

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!