Some guitar speakers have totally straight-sided cones with or without ribs (many of these are seamed, some are pressed pulp), some have slightly curvilinear cones with ribs (most of the 12 inch Celestions are this way), and some have more obviously curvilinear smooth cones (EV, JBL). I originally thought that the classic Celestion guitar speakers had straight-sided cones, but upon closer inspection I realized that there is a slight curve.

My question is this: what types of curves are typically used for the curvilinear cones? Exponential? Bézier curves? Something else? I've found some references to exponential cone profiles, but most just say 'curvilinear'.

My question is this: what types of curves are typically used for the curvilinear cones? Exponential? Bézier curves? Something else? I've found some references to exponential cone profiles, but most just say 'curvilinear'.

Last edited:

I guess no one here knows...

For those that are curious, my intent is to try to make a cone for a 1955 Bell & Howell branded Jensen P12P I acquired some time ago. The original cone was torn and partially separated from the basket. I have no idea whether I'll end up with something usable, but I thought it might be interesting to try 🙂. I do know a little bit about papermaking, so I'm not flying completely blind here. It seems to be difficult to find much detailed information regarding speaker cone manufacturing though... I guess a lot of it is trade secret or at least not widely published.

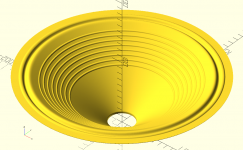

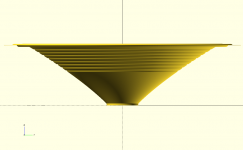

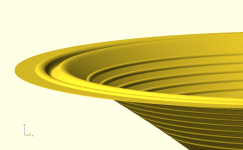

I decided to try a quadratic Bézier curve for the main cone body. The surround is a piecewise cubic Bézier spline. Attached are a few basic renderings (OpenSCAD) of the cone shape (shown with orthographic projection, not perspective).

For those that are curious, my intent is to try to make a cone for a 1955 Bell & Howell branded Jensen P12P I acquired some time ago. The original cone was torn and partially separated from the basket. I have no idea whether I'll end up with something usable, but I thought it might be interesting to try 🙂. I do know a little bit about papermaking, so I'm not flying completely blind here. It seems to be difficult to find much detailed information regarding speaker cone manufacturing though... I guess a lot of it is trade secret or at least not widely published.

I decided to try a quadratic Bézier curve for the main cone body. The surround is a piecewise cubic Bézier spline. Attached are a few basic renderings (OpenSCAD) of the cone shape (shown with orthographic projection, not perspective).

Attachments

Making cones requires specialized and expensive dies and machinery.

Absolute minimum, which is "acceptable", sort of, but only for dull woofers, unusable for Guitar, is a cone shaped fine screen/sieve , which you can turn in a lathe over a hardwood former, in those lathes which do not use a cutting tool but a polished iron ball at the end of an "oar", to push aluminum sheet metal into shape to make pots and pans.

It can turn a flat piece of glorified window screen into a cone shaped sieve.

Then you can pass very liquid cellulose paste suspension through it, water will go through and fiber will stay forming the cone, similar to handmade paper, then let air dry.

There are cones made that way, but they are too thick-heavy-soft-fluffy , have a characteristic "mountainous" back and are absolutely dull sounding.

Like I said, suitable only for woofers.

For Guitar you need way thinner and more rigid ones, let alone much lighter, so standard is to have male/female dies to press the original thick fluffy cone into a thin, strong and flexible one .... which are expensive

To boot, to rise production rate which otherwise would be abysmally slow is to attach overheated steam pipes to them so cone dries quickly, in seconds, and stays very compact and flexible.

Notice there are not too many cone factories worldwide, reason being they require quite an investment.

I have worked in an Argentine speaker cone Factory, basic process was same as this, my friend used an old house type bathtub to hold the paste, not kidding; it looks like "black dirty water", perfect for a Japanese Horror movie 😉

Absolute minimum, which is "acceptable", sort of, but only for dull woofers, unusable for Guitar, is a cone shaped fine screen/sieve , which you can turn in a lathe over a hardwood former, in those lathes which do not use a cutting tool but a polished iron ball at the end of an "oar", to push aluminum sheet metal into shape to make pots and pans.

It can turn a flat piece of glorified window screen into a cone shaped sieve.

Then you can pass very liquid cellulose paste suspension through it, water will go through and fiber will stay forming the cone, similar to handmade paper, then let air dry.

There are cones made that way, but they are too thick-heavy-soft-fluffy , have a characteristic "mountainous" back and are absolutely dull sounding.

Like I said, suitable only for woofers.

For Guitar you need way thinner and more rigid ones, let alone much lighter, so standard is to have male/female dies to press the original thick fluffy cone into a thin, strong and flexible one .... which are expensive

To boot, to rise production rate which otherwise would be abysmally slow is to attach overheated steam pipes to them so cone dries quickly, in seconds, and stays very compact and flexible.

Notice there are not too many cone factories worldwide, reason being they require quite an investment.

I have worked in an Argentine speaker cone Factory, basic process was same as this, my friend used an old house type bathtub to hold the paste, not kidding; it looks like "black dirty water", perfect for a Japanese Horror movie 😉

A LOT of investment in custom clamps, jigs, and molds.not too many cone factories worldwide, reason being they require quite an investment.

Same process in Rusian:

One of the now-dead US factories had a room full of sample cones, coils, caps. A customer who wanted "a little of this and some of that" could have a sample made-up and playing in a few minutes.

No; and the one time I joined a specialty forum to ask, the forum crashed for weeks. So my lips are sealed.I guess no one here knows...

@JMFahey: Thanks for taking the time to type that up. I've spent a lot of time looking for information so I'm well aware of the basic process for commercially made cones. Some previous posts of yours in this forum as well as others about speaker manufacturing (which were very helpful) turned up in my searches. I've seen that video as well as the one PRR posted.

One thing I haven't been able to find all that much information on is precise details of the composition of the pulp slurry. There is some information out there, however. Loudspeaker Components, LLC has some very basic information on the pulps they use. I'm not clear on exactly what they mean when they list 'hemp' though. They could mean hemp hemp (as in industrial hemp aka cannabis sativa) or, possibly more likely, abacá (also known as Manila hemp). I found this patent by John Harrison of Tone Tubby which shows that their "hemp" cones are abacá, not true hemp, and also has some details about pulp additives (binders, sizes, etc.).

I'll likely start out with a pulp that is mostly kraft, but I think I'll probably try adding a small percentage of cotton rag fiber to improve the durability and stiffness of the resulting paper. Different fibers processed in different ways with different average length, etc. will have different properties (stiffness, internal damping, etc). I had hoped I might be able to find some detailed information on the pulps used in guitar cones to give me a good starting point, but it seems (not surprisingly) that the finer points are trade secrets.

I don't think that hot pressing is strictly required. I will be making a rigid form/mold that should allow me to cold press the cone with a decent amount of pressure. Production speed is not a concern for me, of course.

There are obviously lots of variables in play here, so I'm not sure what to expect. If I can't make a cone that sounds good using my minimal tooling, I'll just recone the speaker with a commercially available cone.

One thing I haven't been able to find all that much information on is precise details of the composition of the pulp slurry. There is some information out there, however. Loudspeaker Components, LLC has some very basic information on the pulps they use. I'm not clear on exactly what they mean when they list 'hemp' though. They could mean hemp hemp (as in industrial hemp aka cannabis sativa) or, possibly more likely, abacá (also known as Manila hemp). I found this patent by John Harrison of Tone Tubby which shows that their "hemp" cones are abacá, not true hemp, and also has some details about pulp additives (binders, sizes, etc.).

I'll likely start out with a pulp that is mostly kraft, but I think I'll probably try adding a small percentage of cotton rag fiber to improve the durability and stiffness of the resulting paper. Different fibers processed in different ways with different average length, etc. will have different properties (stiffness, internal damping, etc). I had hoped I might be able to find some detailed information on the pulps used in guitar cones to give me a good starting point, but it seems (not surprisingly) that the finer points are trade secrets.

I don't think that hot pressing is strictly required. I will be making a rigid form/mold that should allow me to cold press the cone with a decent amount of pressure. Production speed is not a concern for me, of course.

There are obviously lots of variables in play here, so I'm not sure what to expect. If I can't make a cone that sounds good using my minimal tooling, I'll just recone the speaker with a commercially available cone.

As you say, probably trade secret. Except: there is "art paper" and a lot of universities have paper studios.composition of the pulp slurry

https://www.google.com/search?q=paper+making+art+university

A key component is a master paper maker, who likely knows FAR more than the students can absorb, and might inform a honest seeker on a narrow process.

There is a typically also a "Director" who oversees funding and politics but is a dilettante at paper-making. You want the guy with pulp in his blood.

(I once worked in the same school as such a paper-shop and saw the paper-maker at meetings, but never got my hands wet.)

---------

Ah, there are also 2-week seminars which get you in the studio meeting the paper wizard.

https://www.calstate.edu/SummerArts/Courses/Pages/Papermaking-And-Artist-Books.aspx

Obviously you don't want a tuti-fruity "art" paper but an honestly engineered material.

One of the now-dead US factories had a room full of sample cones, coils, caps. A customer who wanted "a little of this and some of that" could have a sample made-up and playing in a few minutes.

Not sure we are talking about the same Factory, but a guy I corresponded with, ex-Jensen employee, told me they had a room chock full of parts and samples (hey! We are Jensen! who would not send samples?) who picked and assembled anything they wanted, for Lab use.

Now, as commercial prototypes, they could do the same, as long as end product cost between $5/7 in 10000 order batches.

He added they could make incredibly wide range, flat and clean speakers (at least on axis) for OB type baffles, go figure, but of course management would never ever consider such a minuscule market.

EDIT: as far as "secret sauce" paper recipes, you are right.

I "worked" in pressing my own speakers at a friend´s small factory, just because I nagged him until it was easier to let me do something than stand me asking non stop he he, not sure if I am using the right words, but basically, I could "look", but not "ask", so for example I could "see" what was being done, but not "ask" about recipes, temperature, pressure, etc.

Oh well.

Paste was a mixture of short fiber (wood pulp?) and long fiber (cotton?) plus binder, some kind of glue but not sure which one, plus black pigment: lamp black/soot , for the very good reason it´s very black, stable, light and cheap but exact proportions are unknown.

I bet a large pot and a hand mixer can work miracles, you can try many mixes and choose best.

Thanks for the info. Based on my limited knowledge, I'd guess that the short fiber was kraft process wood fiber (used in brown paper bags, cardboard, and a multitude of other things). The long fiber could've been a number of things; cotton, abacá, and/or kapok probably being the most likely. There are quite a lot of sources of long vegetable fibers.

I definitely expect there to be some trial and error 🙂

Information about papermaking in general isn't too hard to come by. For old processes, there are a few books that are now in the public domain that go over just about everything you'd need to know about running a paper mill in the late 19th and early 20th century. Here's one example. For something a little more modern, this youtube channel has lots of useful information (the guy behind it has a PhD in paper science).

I definitely expect there to be some trial and error 🙂

Information about papermaking in general isn't too hard to come by. For old processes, there are a few books that are now in the public domain that go over just about everything you'd need to know about running a paper mill in the late 19th and early 20th century. Here's one example. For something a little more modern, this youtube channel has lots of useful information (the guy behind it has a PhD in paper science).

Thanks for the impressive book you linked to.

Been browsing through it , It shows everything needed for speaker cone making, including the filter-through screen process (they make flat paper but process is same), pressing, and steam force drying.

Which apparently you won´t be able to avoid 🙁

Maybe you can arrange some kind of electrical or hot air die heating which would take , say, a few minutes instead of 30 seconds but otherwise pressed pulp will take forever inside a cold die set.

But hey, you try it and tell us 😉

Been browsing through it , It shows everything needed for speaker cone making, including the filter-through screen process (they make flat paper but process is same), pressing, and steam force drying.

Which apparently you won´t be able to avoid 🙁

Maybe you can arrange some kind of electrical or hot air die heating which would take , say, a few minutes instead of 30 seconds but otherwise pressed pulp will take forever inside a cold die set.

But hey, you try it and tell us 😉

Thanks for the classic book. Of course such books don't tell you how paper "sounds". I've been tapping cones and diaphragms (and woods) for decades; it's also a reference sound for my hearing loss. (My audiologist keeps a potato chip bag on hand, but that stuff is too shrill for any large sound source.)

The sound is both the sheet and the shape.

As for wood: old wood pulp gets brittle, right? Newspapers and books do. Speakers do, it seems, but not nearly as much as an old Tom Swift (Sr) also of the 1920s. Is it the added binder and blacking? Less acid? Or is there a lot of rag? Remember that unlike book paper, the cost of cotton in a speaker is rather trivial.

Fostex has a, excuse the pun, paper on related matters. Note "Biocellulose of sea squirts". Who thought of that??

The sound is both the sheet and the shape.

As for wood: old wood pulp gets brittle, right? Newspapers and books do. Speakers do, it seems, but not nearly as much as an old Tom Swift (Sr) also of the 1920s. Is it the added binder and blacking? Less acid? Or is there a lot of rag? Remember that unlike book paper, the cost of cotton in a speaker is rather trivial.

Fostex has a, excuse the pun, paper on related matters. Note "Biocellulose of sea squirts". Who thought of that??

Attachments

I plan to. I still have to make the tooling though, so it may be a little while.But hey, you try it and tell us 😉

Any paper will degrade over time, but some (cotton, for example) tends to degrade much more slowly than others. Newsprint is a bit of a special case since it is mechanically pulped. Mechanical pulping leaves all the lignin from the wood in the paper. The lignin content has been assumed for a long time to be the reason for the fast deterioration of mechanical properties, but this recent (2020) paper says otherwise. In any case, acid is bad for cellulose.old wood pulp gets brittle, right? Newspapers and books do.

Chemical pulping (kraft process, for example) removes most of the lignin. It also avoids damaging the fibers as much, so the average fiber length is greater. As far as I know, no one uses mechanically pulped paper in speaker cones.

Paper with high cotton content tends to last a long time and is used for currency, legal documents, etc. Archival-grade paper is mostly cotton.

A lot of older paper (before 1960 or so) used rosin-alum sizing, which is acidic. This causes the cellulose to break down over time, turning the paper brittle. Modern paper is usually sized with akyl ketene dimer (AKD) or alkenyl succinic anhydride (ASA), which are not acidic. This video has lots of information on sizing.

Thanks for the Fostex white paper. It has some potentially useful information.

SOme older cones I see are clearly a piece of flat paper rolled into a cone, with the resultant seam on a radius of the cone. How does that style figure into this, if at all.

I used to have a huge 18 inch EV speaker with a cone of Styrofoam. The dust dome was molded plastic with a 3-D EV logo molded into it.

I used to have a huge 18 inch EV speaker with a cone of Styrofoam. The dust dome was molded plastic with a 3-D EV logo molded into it.

That's (unsurprisingly) called a seamed cone. They have a particular sound that's a bit different than the molded cones. As far as I know, seamed cones are usually made of calendered paper, which has a higher density and lower internal damping than is achievable with molded cones. A lot of American guitar (and other musical instrument) speakers from the '50s and '60s had seamed cones.

And, I suspect, no wet pulp in the speaker factory. Buy flat paper, cut roll and seam, some waste but no mess.a seamed cone. They have a particular sound that's a bit different

Molded cones, either you are up to your elbows in pulp or you pay someone to mold them elsewhere.

I've finally made a bit of progress on the tooling. I made a cone mold/form/die (not sure what term is more correct...) from MDF and gypsum cement using basically the same process as I used to make these big waveguides a couple years ago. Here's the MDF form with the basecoat running mold:

Here's the plaster basecoat (cut 50/50 with sand):

And the finish coat:

I used a bit of wood filler to fix some small imperfections (note the yellowish discolorations). The surface finish isn't perfect (I guess I'm a little out of practice), but should be perfectly usable 🙂. Next step is to put a finish on the mold to seal it up. After that I'll work on the screen mold that will capture the pulp fibers.

Here's the plaster basecoat (cut 50/50 with sand):

And the finish coat:

I used a bit of wood filler to fix some small imperfections (note the yellowish discolorations). The surface finish isn't perfect (I guess I'm a little out of practice), but should be perfectly usable 🙂. Next step is to put a finish on the mold to seal it up. After that I'll work on the screen mold that will capture the pulp fibers.

Next in my 'making a guitar cone using junk I found around the house' adventure: trying a preliminary test cone to see if the basic process works.

Here's the screen mold (sieve?) I made out of some aluminum window screen and pine scrap I had laying around:

The seemingly random bolts sticking out are to make it sink in water. To the other side of this, I attach a large (11.75 inch diameter) tube I made from aluminum roof flashing (that I, again, had laying around):

This whole assembly is placed into a large bin that is filled with water. I dumped the pulp slurry into the big tube and dispersed it by agitating the mixture with my hand. Next, I slowly lifted screen (and tube) out of the water-filled bin, depositing the cellulose fibers onto the screen. After letting it drain for a bit, I removed the tube, flipped the screen over, and placed it over the solid cone mold pictured in my previous post (looks basically the same now, but painted gloss black and waxed). I pressed on the back of the screen with a towel to transfer the soon-to-be-paper to the mold and remove some of the excess water. Then I removed the screen and (carefully) pressed the cone directly with a cotton cloth and a wallpaper roller (plus a 3D-printed tool for the surround). Final density can be controlled by how hard it is pressed. I dried the cone with the help of a space heater.

Here's what I ended up with:

Since this was just a test run, I didn't bother with any dyes or additives (other than a little corn starch, which is a dry strength aid). I made the pulp from a cheap roll of recycled kraft paper (intended for packaging). The final cones will be made out of higher quality fiber.

The mass is 13.5 grams and the thickness is about 0.012-0.013in (0.30-0.33mm). Nearly all of the fibers are captured using this process, so the mass can be tightly controlled. The free air resonance of the cone itself is about 70Hz, which I imagine is reasonably close to what it should be.

I'd call this a fairly successful test, but not completely successful. The main problem I ran into was the presence of some air bubbles between the mold and paper after transferring it from the screen. I got the bubbles pressed out, but there are some inconsistencies on the back of the cone as a result. Hopefully I can figure out how to fix that problem without having to make a new mold with a bunch of holes in it...

Here's the screen mold (sieve?) I made out of some aluminum window screen and pine scrap I had laying around:

The seemingly random bolts sticking out are to make it sink in water. To the other side of this, I attach a large (11.75 inch diameter) tube I made from aluminum roof flashing (that I, again, had laying around):

This whole assembly is placed into a large bin that is filled with water. I dumped the pulp slurry into the big tube and dispersed it by agitating the mixture with my hand. Next, I slowly lifted screen (and tube) out of the water-filled bin, depositing the cellulose fibers onto the screen. After letting it drain for a bit, I removed the tube, flipped the screen over, and placed it over the solid cone mold pictured in my previous post (looks basically the same now, but painted gloss black and waxed). I pressed on the back of the screen with a towel to transfer the soon-to-be-paper to the mold and remove some of the excess water. Then I removed the screen and (carefully) pressed the cone directly with a cotton cloth and a wallpaper roller (plus a 3D-printed tool for the surround). Final density can be controlled by how hard it is pressed. I dried the cone with the help of a space heater.

Here's what I ended up with:

Since this was just a test run, I didn't bother with any dyes or additives (other than a little corn starch, which is a dry strength aid). I made the pulp from a cheap roll of recycled kraft paper (intended for packaging). The final cones will be made out of higher quality fiber.

The mass is 13.5 grams and the thickness is about 0.012-0.013in (0.30-0.33mm). Nearly all of the fibers are captured using this process, so the mass can be tightly controlled. The free air resonance of the cone itself is about 70Hz, which I imagine is reasonably close to what it should be.

I'd call this a fairly successful test, but not completely successful. The main problem I ran into was the presence of some air bubbles between the mold and paper after transferring it from the screen. I got the bubbles pressed out, but there are some inconsistencies on the back of the cone as a result. Hopefully I can figure out how to fix that problem without having to make a new mold with a bunch of holes in it...

IMPRESSIVE.

Congratulations.

It turned out much better than I expected, almost can´t believe you basically made it out of MDF and not turned aluminum or something.

I feared you´d end up with a dull too thick too heavy cone, but 13 grams in perfect.

In fact,the time I "worked" at Buenos Aires cone factory was to make my own (on his machinery of course) because there was no way he would make one weighing less than 18 grams, I succeeded in making 12 and 14 gram ones.

Congratulations again.

In a way, your not using dyes (today) was good because it lets us see more details 🙂

Congratulations.

It turned out much better than I expected, almost can´t believe you basically made it out of MDF and not turned aluminum or something.

I feared you´d end up with a dull too thick too heavy cone, but 13 grams in perfect.

In fact,the time I "worked" at Buenos Aires cone factory was to make my own (on his machinery of course) because there was no way he would make one weighing less than 18 grams, I succeeded in making 12 and 14 gram ones.

Congratulations again.

In a way, your not using dyes (today) was good because it lets us see more details 🙂

13g is light for a 12", good for efficiency.free air resonance of the cone itself is about 70Hz, which I imagine is reasonably close to what it should be.

The voice coil mass should be similar to the cone. That much more mass will drop resonance to around 50Hz, which is classic tuning. "Modern" guitar speakers will be stiffened-up to 80-100Hz for less "subsonic" (<82Hz) wobble and flutter. Car subwoofers are loaded-down to 20Hz (reduced stiffness too, but mostly excess mass). An awful lot of classic Magnavox and Altec come in right around 50Hz. My fav JBL E120 was 60Hz, today's Beyma replacement is 37Hz (lower efficiency).

- Home

- Live Sound

- Instruments and Amps

- Guitar speaker cone profiles

!

!